engine INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 869 of 2395

SEF977Y

Component DescriptionNBEC0191The crankshaft position sensor (POS) is located on the oil pan

facing the gear teeth (cogs) of the signal plate (flywheel). It detects

the crankshaft position signal (1É signal).

The sensor consists of a permanent magnet, core and coil.

When engine is running, the gap between the sensor and the gear

teeth (cogs) will periodically change. Permeability near the sensor

also changes.

Due to the permeability change, the magnetic flux near the core is

changed. Therefore, the voltage signal generated in the coil is

changed.

The ECM receives the voltage signal and detects the crankshaft

position signal (1É signal).

CONSULT-II Reference Value in Data Monitor

Mode

NBEC0492Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

CKPS´RPM (POS)ITachometer: Connect

IRun engine and compare tachometer indication with the CONSULT-II

value.Almost the same speed as the

CONSULT-II value.

DTC P0335 CRANKSHAFT POSITION SENSOR (CKPS) (POS)

Component Description

EC-334

Page 870 of 2395

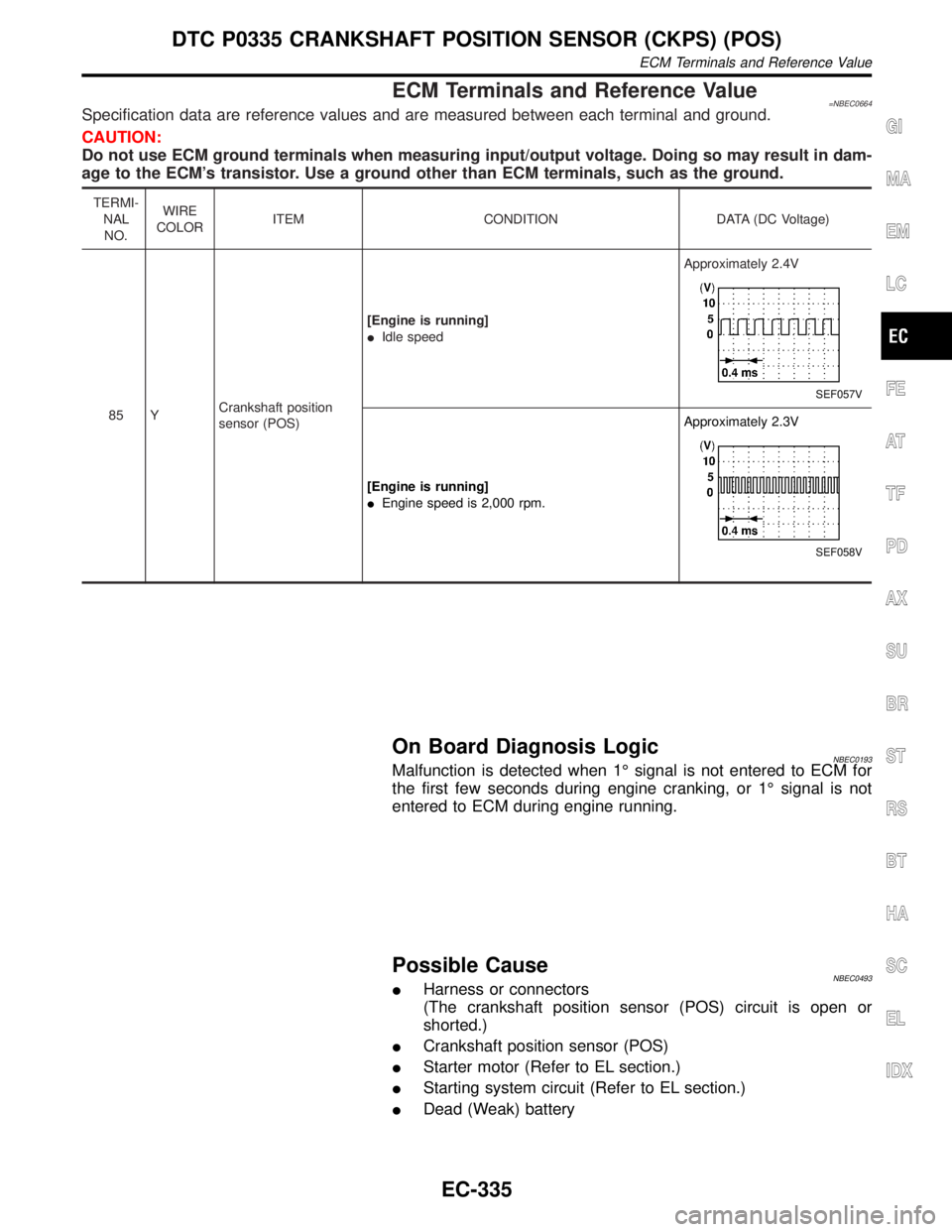

ECM Terminals and Reference Value=NBEC0664Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

85 YCrankshaft position

sensor (POS)[Engine is running]

IIdle speedApproximately 2.4V

SEF057V

[Engine is running]

IEngine speed is 2,000 rpm.Approximately 2.3V

SEF058V

On Board Diagnosis LogicNBEC0193Malfunction is detected when 1É signal is not entered to ECM for

the first few seconds during engine cranking, or 1É signal is not

entered to ECM during engine running.

Possible CauseNBEC0493IHarness or connectors

(The crankshaft position sensor (POS) circuit is open or

shorted.)

ICrankshaft position sensor (POS)

IStarter motor (Refer to EL section.)

IStarting system circuit (Refer to EL section.)

IDead (Weak) battery

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0335 CRANKSHAFT POSITION SENSOR (CKPS) (POS)

ECM Terminals and Reference Value

EC-335

Page 871 of 2395

SEF058Y

DTC Confirmation ProcedureNBEC0194NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that bat-

tery voltage is more than 10.5V.

WITH CONSULT-IINBEC0194S011) Turn ignition switch ªONº and select ªDATA MONITORº mode

with CONSULT-II.

2) Crank engine for at least two seconds.

3) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-338.

WITH GSTNBEC0194S02Follow the procedure ªWith CONSULT-IIº above.

DTC P0335 CRANKSHAFT POSITION SENSOR (CKPS) (POS)

DTC Confirmation Procedure

EC-336

Page 873 of 2395

Diagnostic ProcedureNBEC0196

1 RETIGHTEN GROUND SCREWS

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screws.

SEF959Y

©GO TO 2.

2 CHECK CKPS (POS) POWER SUPPLY CIRCUIT

1. Disconnect harness connectors E132, E135.

SEF978Y

2. Check voltage between harness connector E135 terminal 6 and ground with CONSULT-II or tester.

SEF979Y

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 4.

NG©GO TO 3.

DTC P0335 CRANKSHAFT POSITION SENSOR (CKPS) (POS)

Diagnostic Procedure

EC-338

Page 874 of 2395

3 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E132, E135

IHarness for open or short between ECM and crankshaft position sensor (POS)

IHarness for open or short between ECM relay and crankshaft position sensor (POS)

©Repair open circuit or short to ground or short to power in harness or connectors.

4 CHECK CKPS (POS) GROUND CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between harness connector E135 terminal 1 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

2. Also check harness for short to power.

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E132, E135

IHarness connectors E116, M114

IHarness connectors M32, F23

IHarness for open between crankshaft position sensor (POS) and ground.

©Repair open circuit or short to ground or short to power in harness or connectors.

6 CHECK CKPS (POS) INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 85 and harness connector E135 terminal 5.

Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 8.

NG©GO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E132, E135

IHarness connectors E116, M114

IHarness connectors M32, F23

IHarness for open or short between ECM and crankshaft position sensor (POS)

©Repair open circuit or short to ground or short to power in harness or connectors.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0335 CRANKSHAFT POSITION SENSOR (CKPS) (POS)

Diagnostic Procedure (Cont'd)

EC-339

Page 876 of 2395

10 CHECK CRANKSHAFT POSITION SENSOR (POS)-II

1. Reconnect disconnected harness connectors.

2. Turn ignition switch ªONº.

3. Check voltage between ECM terminal 85 and ground by briefly touching the sensor core with a flat-bladed screwdriv-

ers.

SEF343Z

OK or NG

OK©GO TO 11.

NG©Replace crankshaft position sensor (POS).

11 CHECK CKPS (POS) SHIELD CIRCUIT FOR OPEN AND SHORT

1. Disconnect harness connectors E132, E135.

2. Check harness continuity between harness connector E135 terminal 2 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to power.

OK or NG

OK©GO TO 13.

NG©GO TO 12.

12 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E132, E135

IHarness connectors E116, M114

IHarness connectors M32, F23

IHarness for open between harness connector E135 and engine ground

©Repair open circuit or short to power in harness or connectors.

13 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-140.

©INSPECTION END

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0335 CRANKSHAFT POSITION SENSOR (CKPS) (POS)

Diagnostic Procedure (Cont'd)

EC-341

Page 877 of 2395

SEF252P

Component DescriptionNBEC0197The camshaft position sensor (PHASE) is located on the engine

front cover facing the camshaft sprocket. It detects the cylinder No.

signal.

The sensor consists of a permanent magnet, core and coil.

When engine is running, the gap between the sensor and the

camshaft sprocket will periodically change. Permeability near the

sensor also changes.

Due to the permeability change, the magnetic flux near the core is

changed. Therefore, the voltage signal generated in the coil is

changed.

The ECM receives the voltage signal and detects the cylinder No.

signal.

ECM Terminals and Reference ValueNBEC0665Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

66

76L

LCamshaft position sen-

sor (PHASE)[Engine is running]

IWarm-up condition

IIdle speedApproximately 4.2VH

(AC voltage)

SEF582X

H: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

On Board Diagnosis LogicNBEC0199Malfunction is detected when

(Malfunction A)the cylinder No. signal is not sent to ECM for the

first few seconds during engine cranking,

(Malfunction B)the cylinder No. signal is not sent to ECM during

engine running,

(Malfunction C)the cylinder No. signal is not in the normal pattern

during engine running.

DTC P0340 CAMSHAFT POSITION SENSOR (CMPS) (PHASE)

Component Description

EC-342

Page 878 of 2395

![INFINITI QX4 2001 Factory Service Manual Possible CauseNBEC0494IHarness or connectors

[The camshaft position sensor (PHASE) circuit is open or

shorted.]

ICamshaft position sensor (PHASE)

IStarter motor (Refer to SC section.)

IStarting system INFINITI QX4 2001 Factory Service Manual Possible CauseNBEC0494IHarness or connectors

[The camshaft position sensor (PHASE) circuit is open or

shorted.]

ICamshaft position sensor (PHASE)

IStarter motor (Refer to SC section.)

IStarting system](/img/42/57027/w960_57027-877.png)

Possible CauseNBEC0494IHarness or connectors

[The camshaft position sensor (PHASE) circuit is open or

shorted.]

ICamshaft position sensor (PHASE)

IStarter motor (Refer to SC section.)

IStarting system circuit (Refer to SC section.)

IDead (Weak) battery

DTC Confirmation ProcedureNBEC0200NOTE:

IPerform ªPROCEDURE FOR MALFUNCTION Aº first. If 1st

trip DTC cannot be confirmed, perform ªPROCEDURE

FOR MALFUNCTION B AND Cº.

IIf ªDTC Confirmation Procedureº has been previously

conducted, always turn ignition switch ªOFFº and wait at least

10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that bat-

tery voltage is more than 10.5V at idle.

SEF013Y

PROCEDURE FOR MALFUNCTION ANBEC0200S01With CONSULT-IINBEC0200S01011) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Crank engine for at least 2 seconds.

4) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-345.

With GSTNBEC0200S0102Follow the procedure ªWith CONSULT-IIº above.

SEF058Y

PROCEDURE FOR MALFUNCTION B AND CNBEC0200S02With CONSULT-IINBEC0200S02011) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and run it for at least 2 seconds at idle speed.

4) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-345.

With GSTNBEC0200S0202Follow the procedure ªWith CONSULT-IIº above.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0340 CAMSHAFT POSITION SENSOR (CMPS) (PHASE)

Possible Cause

EC-343

Page 880 of 2395

Diagnostic ProcedureNBEC0202

1 CHECK STARTING SYSTEM

Turn ignition switch to ªSTARTº position.

Does the engine turn over?

Does the starter motor operate?

YesorNo

Ye s©GO TO 2.

No©Check starting system. (Refer to SC-10, ªSTARTING SYSTEMº.)

2 RETIGHTEN GROUND SCREWS

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screws.

SEF959Y

©GO TO 3.

3 CHECK CMPS (PHASE) INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector and CMPS (PHASE) harness connector.

SEF982Y

3. Check harness continuity between CMPS (PHASE) terminal 2 and ECM terminals 66, 76. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 4.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0340 CAMSHAFT POSITION SENSOR (CMPS) (PHASE)

Diagnostic Procedure

EC-345

Page 881 of 2395

4 CHECK CMPS (PHASE) GROUND CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between CMPS (PHASE) terminal 1 and engine ground.

Continuity should exist.

2. Also check harness for short to power.

OK or NG

OK©GO TO 5.

NG©Repair open circuit or short to power in harness or connector.

5 CHECK CAMSHAFT POSITION SENSOR (PHASE)-I

1. Loosen the fixing bolt of the camshaft position sensor (PHASE).

2. Remove the CMPS (PHASE).

3. Visually check the CMPS (PHASE) for chipping.

SEF583P

OK or NG

OK©GO TO 6.

NG©Replace camshaft position sensor (PHASE).

6 CHECK CAMSHAFT POSITION SENSOR (PHASE)-II

Check resistance between CMPS (PHASE) terminals 1 and 2 as shown below.

SEF325X

OK or NG

OK©GO TO 7.

NG©Replace camshaft position sensor (PHASE).

7 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-140.

©INSPECTION END

DTC P0340 CAMSHAFT POSITION SENSOR (CMPS) (PHASE)

Diagnostic Procedure (Cont'd)

EC-346