Idle air INFINITI QX4 2001 Factory Owner's Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 637 of 2395

3 CHECK THROTTLE OPENER FIXING BOLTS

Check throttle opener fixing bolts for loosening.

OK or NG

OK©1. Repair or replace throttle body assembly.

2. GO TO 2.

NG©1. Retighten the fixing bolts.

2. GO TO 2.

4 CHECK THROTTLE OPENER OPERATION-II

1. Start engine and let it idle.

2. Confirm that throttle opener rod moves backward and there is a clearance between throttle drum and throttle opener

rod.

SEF951Y

OK or NG

OK©GO TO 7.

NG©GO TO 5.

5 CHECK VACUUM SOURCE FOR THROTTLE OPENER

1. Disconnect vacuum hose connected to throttle opener.

2. Check vacuum existance with engine running.

SEF952Y

OK or NG

OK©1. Repair or replace throttle body assembly.

2. GO TO 4.

NG©GO TO 6.

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Basic Inspection (Cont'd)

EC-102

Page 647 of 2395

19 CHECK (1ST TRIP) DTC

1. Turn ignition switch ªOFFº.

2. Release vacuum from throttle opener.

3. Remove vacuum pump and vacuum hose from throttle opener.

4. Reinstall original vacuum hose to throttle opener securely.

5. Start engine and warm it up to normal operating temperature.

6. Rev (2,000 to 3,000 rpm) two or three times.

7. Make sure no (1st trip) DTC is displayed with CONSULT-II or GST.

OK or NG

OK©GO TO 21.

NG©GO TO 20.

20 REPAIR MALFUNCTION

Repair or replace components as necessary according to corresponding ªDiagnostic Procedureº.

©GO TO 19.

21 CHECK TARGET IDLE SPEED

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Select ªENG SPEEDº in ªDATA MONITORº mode with CONSULT-II.

3. Check idle speed.

750±50 rpm (in ªPº or ªNº position)

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed.

750±50 rpm (in ªPº or ªNº position)

OK or NG

OK©GO TO 30.

NG©GO TO 22.

22 PERFORM IDLE AIR VOLUME LEARNING

Refer to ªIdle Air Volume Learningº, EC-57.

Which is the result CMPLT or INCMP?

CMPLT or INCMP

CMPLT©GO TO 23.

INCMP©1. Follow the construction of ªIdle Air Volume Leaningº.

2. GO TO 22.

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Basic Inspection (Cont'd)

EC-112

Page 648 of 2395

23 CHECK TARGET IDLE SPEED AGAIN

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Select ªENG SPEEDº in ªDATA MONITORº mode with CONSULT-II.

3. Check idle speed.

750±50 rpm (in ªPº or ªNº position)

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed.

750±50 rpm (in ªPº or ªNº position)

OK or NG

OK©GO TO 28.

NG©GO TO 24.

24 REPLACE IACV-AAC VALVE

Replace IACV-AAC valve.

©GO TO 25.

25 PERFORM IDLE AIR VOLUME LEARNING

Refer to ªIdle Air Volume Learningº, EC-57.

Which is the result CMPLT or INCMP?

CMPLT or INCMP

CMPLT©GO TO 26.

INCMP©1. Follow the construction of ªIdle Air Volume Learningº.

2. GO TO 22.

26 CHECK TARGET IDLE SPEED AGAIN

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Select ªENG SPEEDº in ªDATA MONITORº mode with CONSULT-II.

3. Check idle speed.

750±50 rpm (in ªPº or ªNº position)

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed.

750±50 rpm (in ªPº or ªNº position)

OK or NG

OK©GO TO 28.

NG©GO TO 27.

27 CHECK ECM FUNCTION

1. Substitute another known-good ECM to check ECM function. (ECM may be the cause of a problem, but this is rarely

the case.)

2. Perform initialization of IVIS (NATS) system and registration of IVIS (NATS) ignition key IDs. Refer to ªIVIS (INFINITI

VEHICLE IMMOBILIZER SYSTEM Ð NATS)º, EC-74.

©GO TO 22.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Basic Inspection (Cont'd)

EC-113

Page 649 of 2395

28 CHECK IGNITION TIMING

1. Start engine and warm it up to normal operating temperature.

2. Check ignition timing at idle using a timing light.

SEF572X

Ignition timing:

15ɱ5É BTDC (in ªPº or ªNº position)

OK or NG

OK©GO TO 36.

NG©GO TO 29.

29 CHECK TIMING CHAIN INSTALLATION

Check timing chain installation. Refer to EM-29, ªInstallationº.

OK or NG

OK©GO TO 27.

NG©1. Repair the timing chain installation.

2. GO TO 22.

30 CHECK IGNITION TIMING

1. Start engine and let it idle.

2. Check ignition timing at idle using a timing light.

SEF572X

Ignition timing:

15ɱ5É BTDC (in ªPº or ªNº position)

OK or NG

OK©GO TO 36.

NG©GO TO 31.

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Basic Inspection (Cont'd)

EC-114

Page 650 of 2395

31 PERFORM IDLE AIR VOLUME LEARNING

Refer to ªIdle Air Volume Learningº, EC-57.

Which is the result CMPLT or INCMP?

CMPLT or INCMP

CMPLT©GO TO 32.

INCMP©1. Follow the construction of ªIdle Air volume Learningº.

2. GO TO 31.

32 CHECK TARGET IDLE SPEED AGAIN

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Select ªENG SPEEDº in ªDATA MONITORº mode with CONSULT-II.

3. Check idle speed.

750±50 rpm (in ªPº or ªNº position)

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed.

750±50 rpm (in ªPº or ªNº position)

OK or NG

OK©GO TO 34.

NG©GO TO 33.

33 CHECK ECM FUNCTION

1. Substitute another known-good ECM to check ECM function.

(ECM may be the cause of a problem, but this is rarely the case.)

2. Perform initialization of NVIS (NATS) system and registration of NVIS (NATS) ignition key IDs. Refer to ªNVIS (NISSAN

VEHICLE IMMOBILIZER SYSTEM Ð NATS)º, EC-74.

©GO TO 31.

34 CHECK IGNITION TIMING AGAIN

Check ignition timing again. Refer to Test No. 30.

OK or NG

OK©GO TO 36.

NG©GO TO 35.

35 CHECK TIMING CHAIN INSTALLATION

Check timing chain installation. Refer to EM-29, ªInstallationº.

OK or NG

OK©GO TO 33.

NG©1. Repair the timing chain installation.

2. GO TO 31.

36 ERASE UNNECESSARY DTC

After this inspection, unnecessary DTC No. might be displayed.

Erase the stored memory in ECM and TCM (Transmission control module).

Refer to ªHow to Erase Emission-Related Diagnostic Informationº, EC-72 and AT-35, ªHOW TO ERASE DTCº.

©INSPECTION END

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Basic Inspection (Cont'd)

EC-115

Page 653 of 2395

Symptom Matrix ChartNBEC0041SYSTEM Ð BASIC ENGINE CONTROL SYSTEMNBEC0041S01

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel pump circuit11232 2 2 3 2EC-625

Fuel pressure regulator system3344444 4 4 4EC-40

Injector circuit11232 2 2 2EC-616

Evaporative emission system

3344444 4 4 4EC-32

Air Positive crankcase ventilation sys-

tem1 EC-38

Incorrect idle speed adjustment 1 1 1 1 1 EC-101

IACV-AAC valve circuit1123322 2 2 2 2EC-422

Ignition Incorrect ignition timing adjustment33111 1 1 1EC-101

Ignition circuit 1 1 2 2 2 2 2 2 EC-499

Main power supply and ground circuit

22333 3 32

3EC-142

Air conditioner circuit 3 3 2 HA section

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Symptom Matrix Chart

EC-118

Page 654 of 2395

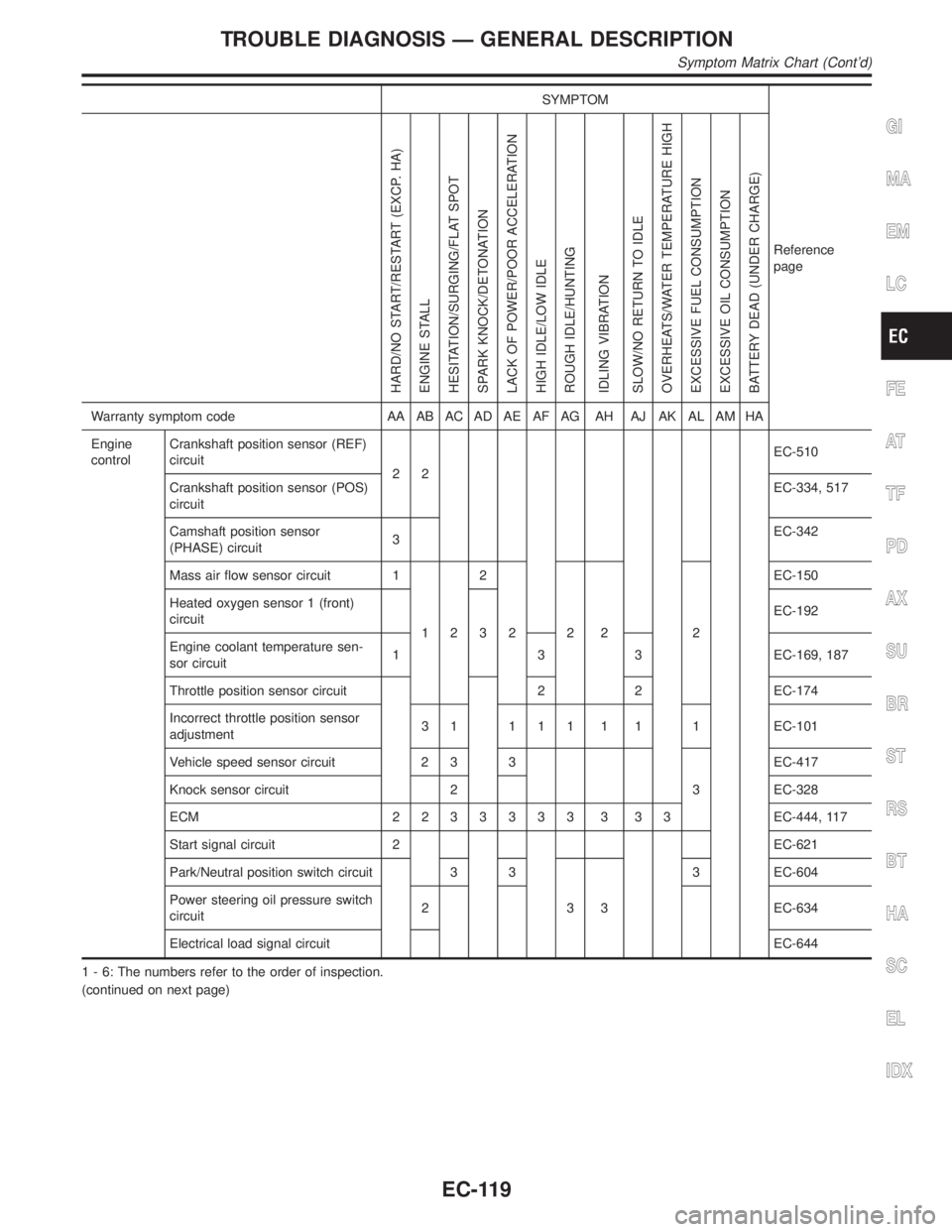

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Engine

controlCrankshaft position sensor (REF)

circuit

22EC-510

Crankshaft position sensor (POS)

circuitEC-334, 517

Camshaft position sensor

(PHASE) circuit3EC-342

Mass air flow sensor circuit 1

122

222 2EC-150

Heated oxygen sensor 1 (front)

circuit

3EC-192

Engine coolant temperature sen-

sor circuit1 3 3 EC-169, 187

Throttle position sensor circuit 2 2 EC-174

Incorrect throttle position sensor

adjustment3 1 1 1 1 1 1 1 EC-101

Vehicle speed sensor circuit 2 3 3

3EC-417

Knock sensor circuit 2 EC-328

ECM 2233333 3 33EC-444, 117

Start signal circuit 2 EC-621

Park/Neutral position switch circuit 3 3

333 EC-604

Power steering oil pressure switch

circuit2 EC-634

Electrical load signal circuitEC-644

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Symptom Matrix Chart (Cont'd)

EC-119

Page 655 of 2395

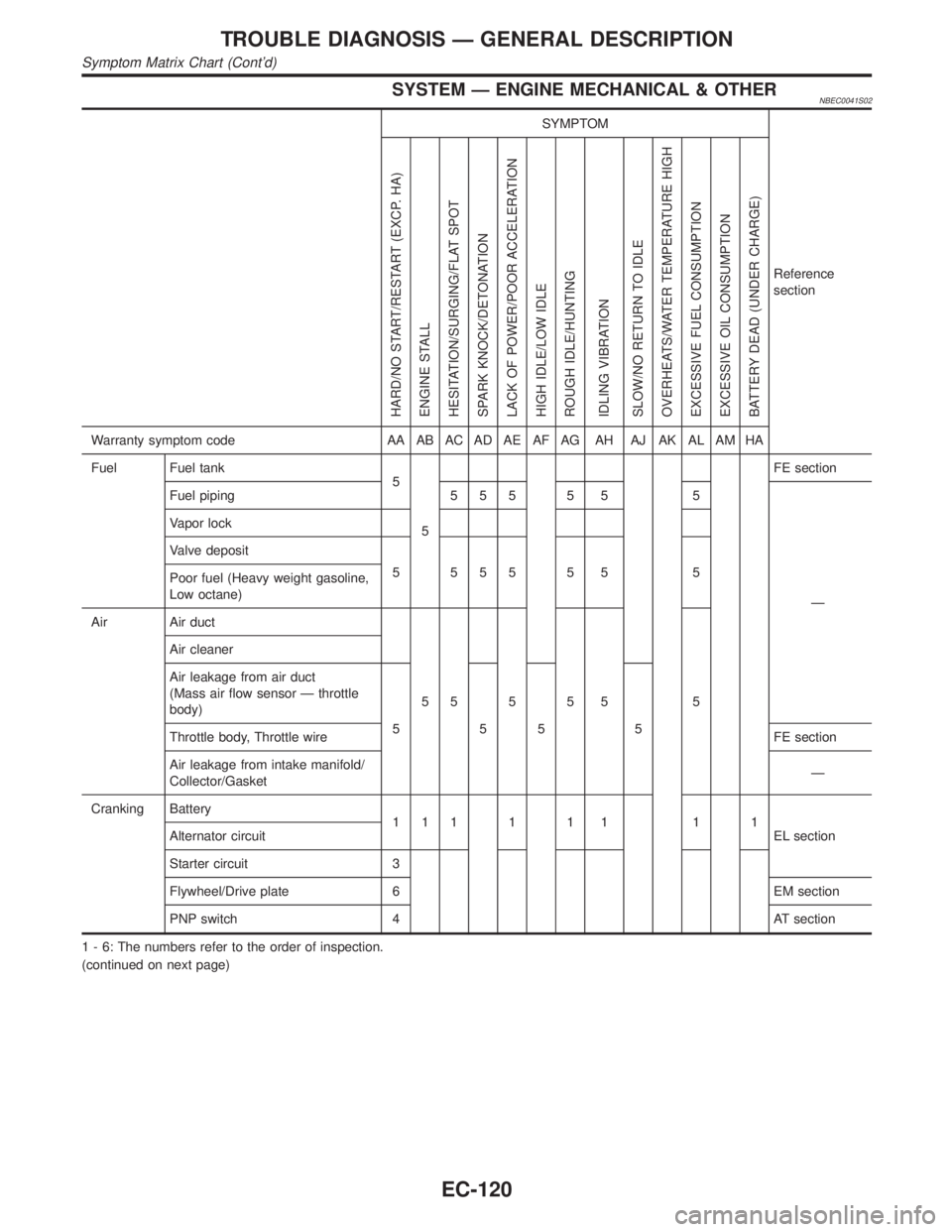

SYSTEM Ð ENGINE MECHANICAL & OTHERNBEC0041S02

SYMPTOM

Reference

section

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel tank

5

5FE section

Fuel piping 5 5 5 5 5 5

Ð Vapor lock

Valve deposit

5 555 5 5 5

Poor fuel (Heavy weight gasoline,

Low octane)

Air Air duct

55555 5 Air cleaner

Air leakage from air duct

(Mass air flow sensor Ð throttle

body)

555 5

Throttle body, Throttle wireFE section

Air leakage from intake manifold/

Collector/GasketÐ

Cranking Battery

111111 11

EL section Alternator circuit

Starter circuit 3

Flywheel/Drive plate 6 EM section

PNP switch 4 AT section

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Symptom Matrix Chart (Cont'd)

EC-120

Page 657 of 2395

SYMPTOM

Reference

section

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

IVIS (INFINITI Vehicle Immobilizer System Ð

NATS)11EC-74 or EL

section

1 - 6: The numbers refer to the order of inspection.

CONSULT-II Reference Value in Data Monitor

Mode

NBEC0042Remarks:

ISpecification data are reference values.

ISpecification data are output/input values which are detected or supplied by the ECM at the connector.

* Specification data may not be directly related to their components signals/values/operations.

i.e. Adjust ignition timing with a timing light before monitoring IGN TIMING, because the monitor may show the specification data in

spite of the ignition timing not being adjusted to the specification data. This IGN TIMING monitors the data calculated by the ECM

according to the signals input from the camshaft position sensor and other ignition timing related sensors.

IIf the real-time diagnosis results are NG and the on board diagnostic system results are OK when diagnosing the mass air flow sensor,

first check to see if the fuel pump control circuit is normal.

MONITOR ITEM CONDITION SPECIFICATION

ENG SPEED

CKPS´RPM (POS)ITachometer: Connect

IRun engine and compare tachometer indication with the CONSULT-II

value.Almost the same speed as

the CONSULT-II value.

POS COUNTIEngine: Running 179 - 181

MAS A/F SE-B1IEngine: After warming up

IAir conditioner switch: ªOFFº

IShift lever: ªNº

INo-loadIdle 1.2 - 1.8V

2,500 rpm 1.6 - 2.2V

COOLAN TEMP/SIEngine: After warming up More than 70ÉC (158ÉF)

HO2S1 (B1)

HO2S1 (B2)

IEngine: After warming upMaintaining engine speed at 2,000

rpm0 - 0.3V+,Approx. 0.6 -

1.0V

HO2S1 MNTR (B1)

HO2S1 MNTR (B2)LEAN+,RICH

Changes more than 5 times

during 10 seconds.

HO2S2 (B1)

HO2S2 (B2)

IEngine: After warming upMaintaining engine speed at 2,000

rpm0 - 0.3V+,Approx. 0.6 -

1.0V

HO2S2 MNTR (B1)

HO2S2 MNTR (B2)LEAN+,RICH

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Symptom Matrix Chart (Cont'd)

EC-122

Page 658 of 2395

MONITOR ITEM CONDITION SPECIFICATION

VHCL SPEED SEITurn drive wheels and compare speedometer indication with the CON-

SULT-II valueAlmost the same speed as

the CONSULT-II value

BATTERY VOLTIIgnition switch: ON (Engine stopped) 11 - 14V

THRTL POS SENIEngine: After warming up, idle

the engineThrottle valve: fully closed 0.15 - 0.85V

IEngine: After warming up

IIgnition switch: ON

(Engine stopped)Throttle valve: fully opened 3.5 - 4.7V

START SIGNALIIgnition switch: ON,START,ON OFF,ON,OFF

CLSD THL POS

CLSD THL/P SWIEngine: After warming up, idle

the engineThrottle valve: Idle position ON

Throttle valve: Slightly open OFF

AIR COND SIGIEngine: After warming up, idle

the engineAir conditioner switch: ªOFFº OFF

Air conditioner switch: ªONº

(Compressor operates.)ON

P/N POSI SWIIgnition switch: ONShift lever: ªPº or ªNº ON

Except above OFF

PW/ST SIGNALIEngine: After warming up, idle

the engineSteering wheel in neutral position

(forward direction)OFF

The steering wheel is turned ON

IGNITION SWIIgnition switch: ON,OFF,ON ON,OFF,ON

INJ PULSE-B2

INJ PULSE-B1IEngine: After warming up

IAir conditioner switch: ªOFFº

IShift lever: ªNº

INo-loadIdle 2.4 - 3.2 msec

2,000 rpm 1.9 - 2.8 msec

B/FUEL SCHDLIEngine: After warming up

IAir conditioner switch: ªOFFº

IShift lever: ªNº

INo-loadIdle 2.0 - 3.2 msec

2,000 rpm 1.4 - 2.6 msec

IGN TIMINGIEngine: After warming up

IAir conditioner switch: ªOFFº

IShift lever: ªNº

INo-loadIdle 15ɱ5É BTDC

2,000 rpm More than 25É BTDC

IACV-AAC/VIEngine: After warming up

IAir conditioner switch: ªOFFº

IShift lever: ªNº

INo-loadIdle 2 - 10 step

2,000 rpm Ð

PURG VOL C/VIEngine: After warming up

IAir conditioner switch: ªOFFº

IShift lever: ªNº

INo-loadIdle 0 %

2,000 rpm Ð

A/F ALPHA-B2

A/F ALPHA-B1IEngine: After warming upMaintaining engine speed at 2,000

rpm54 - 155%

EVAP SYS PRESIIgnition switch: ON Approx. 3.4V

AIR COND RLYIAir conditioner switch: OFF,ON OFF,ON

FUEL PUMP RLYIIgnition switch is turned to ON (Operates for 5 seconds)

IEngine running and crankingON

Except as shown above OFF

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

CONSULT-II Reference Value in Data Monitor Mode (Cont'd)

EC-123