Idle air INFINITI QX4 2001 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 591 of 2395

32 CHECK HEATED OXYGEN SENSOR 1 (FRONT) (BANK 1)/(BANK 2) SIGNAL

With CONSULT-II

1. Stop engine.

2. Replace heated oxygen sensor 1 (front) (bank 1)/(bank 2).

3. Start engine and warm it up to normal operating temperature.

4. Run engine at approx. 2,000 rpm for approx. 2 minutes under no-load.

5. See ªHO2S1 MNTR (B1)/(B2)º in ªDATA MONITORº mode.

6. Maintaining engine at 2,000 rpm under no-load (engine is warmed up to normal operating temperature.), check that the

monitor fluctuates between ªLEANº and ªRICHº more than 5 times during 10 seconds.

1 time: RICH®LEAN®RICH

2 times: RICH®LEAN®RICH®LEAN®RICH

Without CONSULT-II

1. Stop engine.

2. Replace heated oxygen sensor 1 (front) (bank 1)/(bank 2).

3. Start engine and warm it up to normal operating temperature.

4. Run engine at approx. 2,000 rpm for approx. 2 minutes under no-load.

5. Set voltmeter probe between ECM terminal 63 or 62 and ground.

6. Make sure that voltage fluctuates between 0 - 0.3V and 0.6 - 1.0V more than 5 times during 10 seconds at 2,000 rpm.

1 time: 0 - 0.3V®0.6 - 1.0V®0 - 0.3V

2 times: 0 - 0.3V®0.6 - 1.0V®0 - 0.3V®0.6 - 1.0V®0 - 0.3V

OK or NG

OK©GO TO 3.

NG©GO TO 33.

33 DETECT MALFUNCTIONING PART

Check the following.

IConnect heated oxygen sensor 1 (front) harness connectors to heated oxygen sensor 1 (front).

ICheck fuel pressure regulator. Refer to EC-40.

ICheck mass air flow sensor and its circuit. Refer to EC-150.

ICheck injector and its circuit. Refer to EC-616.

Clean or replace if necessary.

ICheck engine coolant temperature sensor and its circuit. Refer to EC-187.

ICheck ECM function by substituting another known-good ECM.

(ECM may be the cause of a problem, but this is rarely the case.)

©GO TO 3.

BASIC SERVICE PROCEDURE

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment (Cont'd)

EC-56

Page 592 of 2395

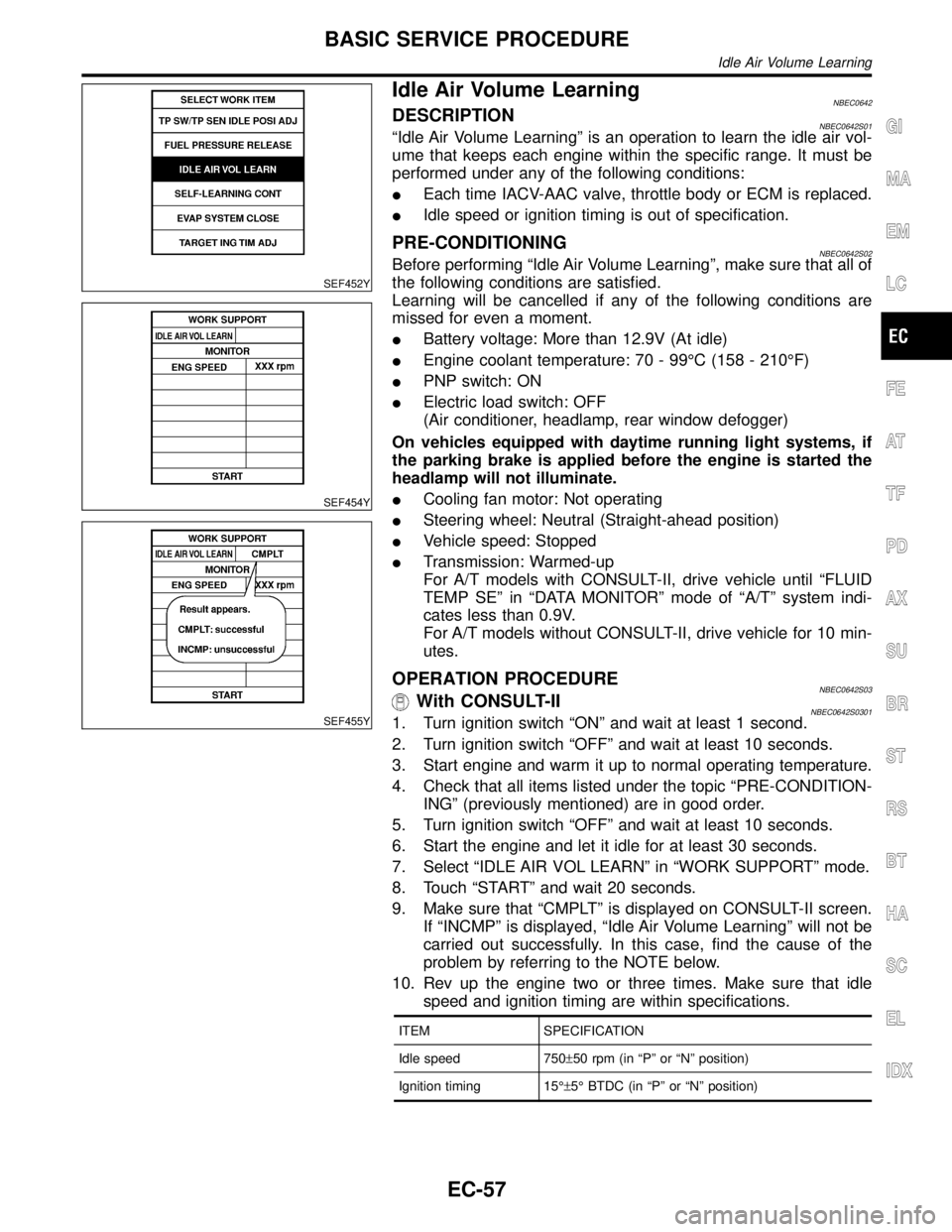

SEF452Y

Idle Air Volume LearningNBEC0642

SEF454Y

SEF455Y

DESCRIPTIONNBEC0642S01ªIdle Air Volume Learningº is an operation to learn the idle air vol-

ume that keeps each engine within the specific range. It must be

performed under any of the following conditions:

IEach time IACV-AAC valve, throttle body or ECM is replaced.

IIdle speed or ignition timing is out of specification.

PRE-CONDITIONINGNBEC0642S02Before performing ªIdle Air Volume Learningº, make sure that all of

the following conditions are satisfied.

Learning will be cancelled if any of the following conditions are

missed for even a moment.

IBattery voltage: More than 12.9V (At idle)

IEngine coolant temperature: 70 - 99ÉC (158 - 210ÉF)

IPNP switch: ON

IElectric load switch: OFF

(Air conditioner, headlamp, rear window defogger)

On vehicles equipped with daytime running light systems, if

the parking brake is applied before the engine is started the

headlamp will not illuminate.

ICooling fan motor: Not operating

ISteering wheel: Neutral (Straight-ahead position)

IVehicle speed: Stopped

ITransmission: Warmed-up

For A/T models with CONSULT-II, drive vehicle until ªFLUID

TEMP SEº in ªDATA MONITORº mode of ªA/Tº system indi-

cates less than 0.9V.

For A/T models without CONSULT-II, drive vehicle for 10 min-

utes.

OPERATION PROCEDURENBEC0642S03With CONSULT-IINBEC0642S03011. Turn ignition switch ªONº and wait at least 1 second.

2. Turn ignition switch ªOFFº and wait at least 10 seconds.

3. Start engine and warm it up to normal operating temperature.

4. Check that all items listed under the topic ªPRE-CONDITION-

INGº (previously mentioned) are in good order.

5. Turn ignition switch ªOFFº and wait at least 10 seconds.

6. Start the engine and let it idle for at least 30 seconds.

7. Select ªIDLE AIR VOL LEARNº in ªWORK SUPPORTº mode.

8. Touch ªSTARTº and wait 20 seconds.

9. Make sure that ªCMPLTº is displayed on CONSULT-II screen.

If ªINCMPº is displayed, ªIdle Air Volume Learningº will not be

carried out successfully. In this case, find the cause of the

problem by referring to the NOTE below.

10. Rev up the engine two or three times. Make sure that idle

speed and ignition timing are within specifications.

ITEM SPECIFICATION

Idle speed 750±50 rpm (in ªPº or ªNº position)

Ignition timing 15ɱ5É BTDC (in ªPº or ªNº position)

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

BASIC SERVICE PROCEDURE

Idle Air Volume Learning

EC-57

Page 593 of 2395

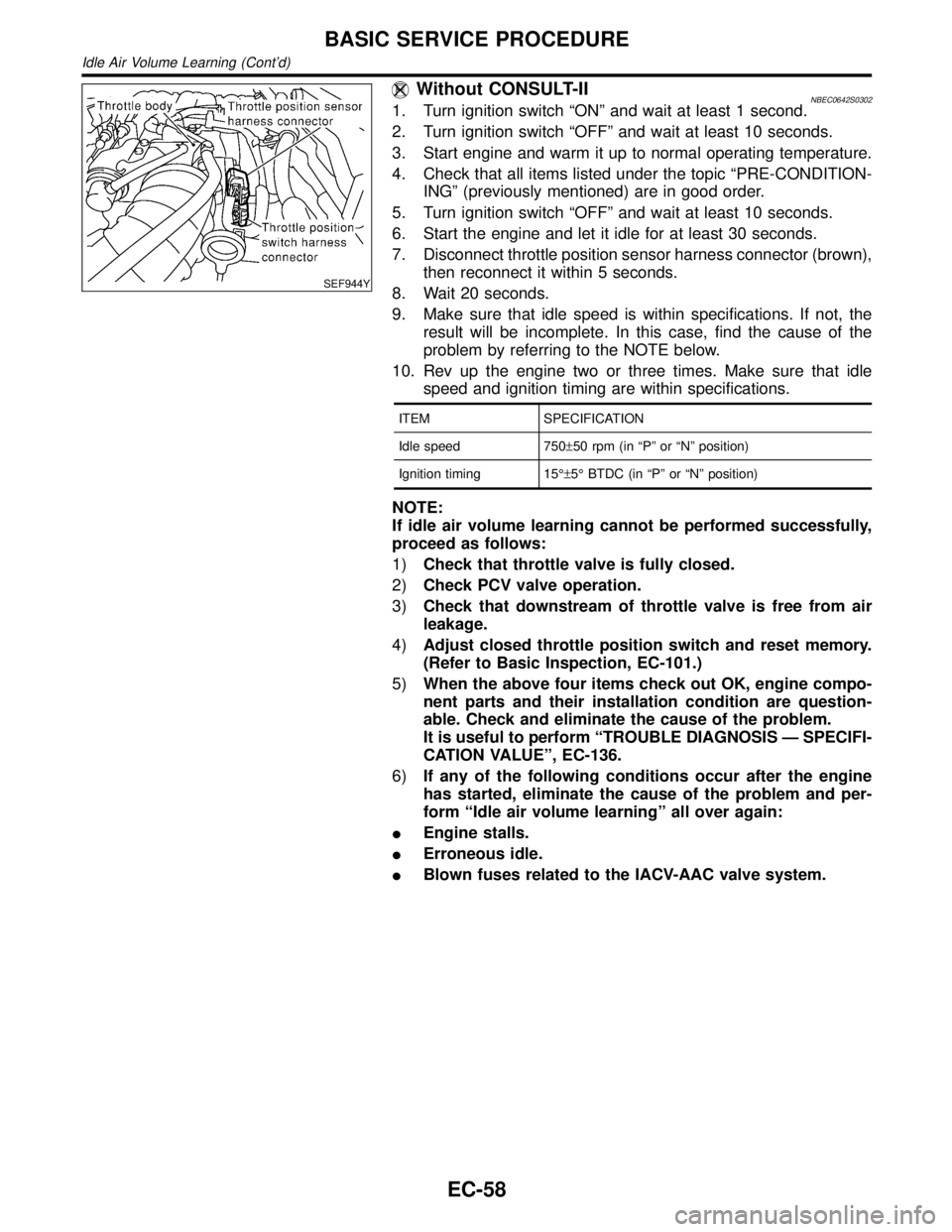

SEF944Y

Without CONSULT-IINBEC0642S03021. Turn ignition switch ªONº and wait at least 1 second.

2. Turn ignition switch ªOFFº and wait at least 10 seconds.

3. Start engine and warm it up to normal operating temperature.

4. Check that all items listed under the topic ªPRE-CONDITION-

INGº (previously mentioned) are in good order.

5. Turn ignition switch ªOFFº and wait at least 10 seconds.

6. Start the engine and let it idle for at least 30 seconds.

7. Disconnect throttle position sensor harness connector (brown),

then reconnect it within 5 seconds.

8. Wait 20 seconds.

9. Make sure that idle speed is within specifications. If not, the

result will be incomplete. In this case, find the cause of the

problem by referring to the NOTE below.

10. Rev up the engine two or three times. Make sure that idle

speed and ignition timing are within specifications.

ITEM SPECIFICATION

Idle speed 750±50 rpm (in ªPº or ªNº position)

Ignition timing 15ɱ5É BTDC (in ªPº or ªNº position)

NOTE:

If idle air volume learning cannot be performed successfully,

proceed as follows:

1)Check that throttle valve is fully closed.

2)Check PCV valve operation.

3)Check that downstream of throttle valve is free from air

leakage.

4)Adjust closed throttle position switch and reset memory.

(Refer to Basic Inspection, EC-101.)

5)When the above four items check out OK, engine compo-

nent parts and their installation condition are question-

able. Check and eliminate the cause of the problem.

It is useful to perform ªTROUBLE DIAGNOSIS Ð SPECIFI-

CATION VALUEº, EC-136.

6)If any of the following conditions occur after the engine

has started, eliminate the cause of the problem and per-

form ªIdle air volume learningº all over again:

IEngine stalls.

IErroneous idle.

IBlown fuses related to the IACV-AAC valve system.

BASIC SERVICE PROCEDURE

Idle Air Volume Learning (Cont'd)

EC-58

Page 602 of 2395

IThe time required for each diagnosis varies with road surface conditions, weather, altitude, individual driv-

ing habits, etc.

Zone A refers to the range where the time required, for the diagnosis under normal conditions*, is the

shortest.

Zone B refers to the range where the diagnosis can still be performed if the diagnosis is not completed

within zone A.

*: Normal conditions refer to the following:

þ Sea level

þ Flat road

þ Ambient air temperature: 20 - 30ÉC (68 - 86ÉF)

þ Diagnosis is performed as quickly as possible under normal conditions.

Under different conditions [For example: ambient air temperature other than 20 - 30ÉC (68 - 86ÉF)], diag-

nosis may also be performed.

Pattern 1:

IThe engine is started at the engine coolant temperature of þ10 to 35ÉC (14 to 95ÉF)

(where the voltage between the ECM terminal 70 and ground is 3.0 - 4.3V).

IThe engine must be operated at idle speed until the engine coolant temperature is greater than 70ÉC

(158ÉF) (where the voltage between the ECM terminal 70 and ground is lower than 1.4V).

IThe engine is started at the fuel tank temperature of warmer than 0ÉC (32ÉF) (where the voltage

between the ECM terminal 92 and ground is less than 4.1V).

Pattern 2:

IWhen steady-state driving is performed again even after it is interrupted, each diagnosis can be conducted.

In this case, the time required for diagnosis may be extended.

Pattern 3:

IThe driving pattern outlined in *2 must be repeated at least 3 times.

Pattern 4:

ITests are performed after the engine has been operated for at least 17 minutes.

IThe accelerator pedal must be held very steady during steady-state driving.

IIf the accelerator pedal is moved, the test must be conducted all over again.

*1: Depress the accelerator pedal until vehicle speed is 90 km/h (56 MPH), then release the accelerator pedal

and keep it released for more than 10 seconds. Depress the accelerator pedal until vehicle speed is 90 km/h

(56 MPH) again.

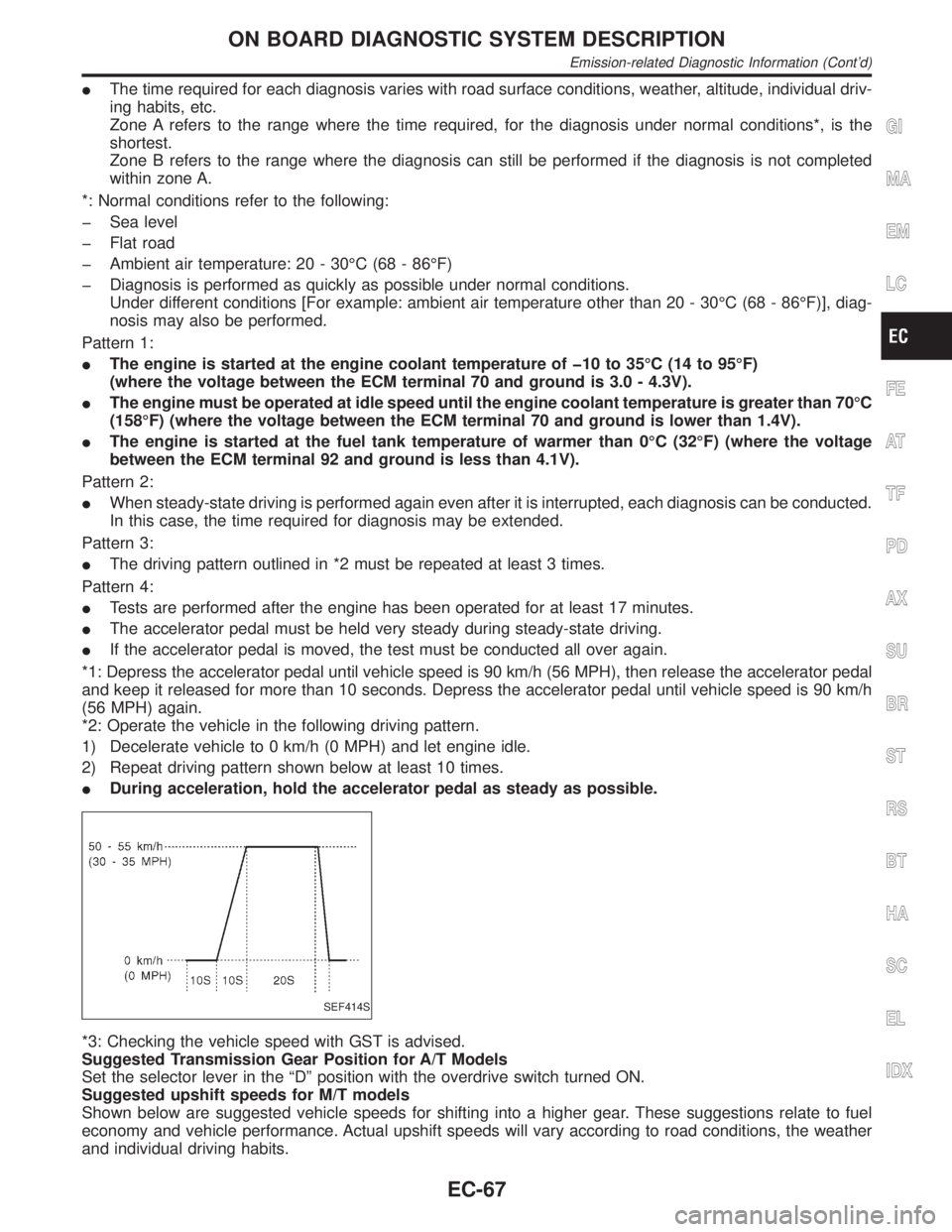

*2: Operate the vehicle in the following driving pattern.

1) Decelerate vehicle to 0 km/h (0 MPH) and let engine idle.

2) Repeat driving pattern shown below at least 10 times.

IDuring acceleration, hold the accelerator pedal as steady as possible.

SEF414S

*3: Checking the vehicle speed with GST is advised.

Suggested Transmission Gear Position for A/T Models

Set the selector lever in the ªDº position with the overdrive switch turned ON.

Suggested upshift speeds for M/T models

Shown below are suggested vehicle speeds for shifting into a higher gear. These suggestions relate to fuel

economy and vehicle performance. Actual upshift speeds will vary according to road conditions, the weather

and individual driving habits.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Emission-related Diagnostic Information (Cont'd)

EC-67

Page 620 of 2395

WORK SUPPORT MODE=NBEC0034S04

WORK ITEM CONDITION USAGE

TP SW/TP SEN IDLE POSI ADJIFOLLOW THE BASIC INSPECTION INSTRUCTION IN

THE SERVICE MANUAL.When adjusting the idle throttle

position

FUEL PRESSURE RELEASEIFUEL PUMP WILL STOP BY TOUCHING ªSTARTº

DURING IDLING.

CRANK A FEW TIMES AFTER ENGINE STALLS.When releasing fuel pressure

from fuel line

IDLE AIR VOL LEARNITHE IDLE AIR VOLUME THAT KEEPS THE ENGINE

WITHIN THE SPECIFIED RANGE IS MEMORIZED IN

ECM.When learning the idle air volume

SELF-LEARNING CONTITHE COEFFICIENT OF SELF-LEARNING CONTROL

MIXTURE RATIO RETURNS TO THE ORIGINAL

COEFFICIENT.When clearing the coefficient of

self-learning control valve

EVAP SYSTEM CLOSE OPEN THE VACUUM CUT VALVE BYPASS VALVE AND

CLOSE THE EVAP CANISTER VENT CONTROL VALVE

IN ORDER TO MAKE EVAP SYSTEM CLOSE UNDER

THE FOLLOWING CONDITIONS.

IIGN SW ªONº

IENGINE NOT RUNNING

IAMBIENT TEMPERATURE IS ABOVE 0ÉC (32ÉF).

INO VACUUM AND NO HIGH PRESSURE IN EVAP

SYSTEM

ITANK FUEL TEMP. IS MORE THAN 0ÉC (32ÉF).

IWITHIN 10 MINUTES AFTER STARTING ªEVAP SYS-

TEM CLOSEº

IWHEN TRYING TO EXECUTE ªEVAP SYSTEM

CLOSEº UNDER THE CONDITION EXCEPT ABOVE,

CONSULT-II WILL DISCONTINUE IT AND DISPLAY

APPROPRIATE INSTRUCTION.

NOTE:

WHEN STARTING ENGINE, CONSULT-II MAY DIS-

PLAY ªBATTERY VOLTAGE IS LOW. CHARGE

BATTERYº, EVEN IN USING CHARGED BATTERY.When detecting EVAP vapor leak

point of EVAP system

TARGET IGNITION TIMING ADJ*IIDLE CONDITIONIWhen adjusting target ignition

timing

After adjustment, confirm target

ignition timing with a timing

light.

IIf once the ªTARGET IDLE

RPM ADJº has been done, the

Idle Air Volume Learning proce-

dure will not be completed.

TARGET IDLE RPM ADJ*IIDLE CONDITION When setting target idle speed

*: This function is not necessary in the usual service procedure.

SELF-DIAGNOSTIC MODENBEC0034S05DTC and 1st Trip DTCNBEC0034S0501Regarding items of ªDTC and 1st trip DTCº, refer to ªTROUBLE

DIAGNOSIS Ð INDEXº (See EC-8.)

Freeze Frame Data and 1st Trip Freeze Frame DataNBEC0034S0502

Freeze frame data

item*1Description

DIAG TROUBLE

CODE

[PXXXX]IThe engine control component part/control system has a trouble code, it is displayed as ªPXXXXº.

(Refer to ªTROUBLE DIAGNOSIS Ð INDEXº, EC-8.)

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT-II (Cont'd)

EC-85

Page 622 of 2395

![INFINITI QX4 2001 Factory Owners Manual DATA MONITOR MODE=NBEC0034S06

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

ENG SPEED [rpm]qqIIndicates the engine speed computed

from the REF signal (120É signal) of the

cran INFINITI QX4 2001 Factory Owners Manual DATA MONITOR MODE=NBEC0034S06

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

ENG SPEED [rpm]qqIIndicates the engine speed computed

from the REF signal (120É signal) of the

cran](/img/42/57027/w960_57027-621.png)

DATA MONITOR MODE=NBEC0034S06

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

ENG SPEED [rpm]qqIIndicates the engine speed computed

from the REF signal (120É signal) of the

crankshaft position sensor (REF).

CKPS´RPM (POS)

[rpm]qIIndicates the engine speed computed

from the POS signal (1É signal) of the

crankshaft position sensor (POS).IAccuracy becomes poor if engine

speed drops below the idle rpm.

IIf the signal is interrupted while the

engine is running, an abnormal value

may be indicated.

POS COUNTqIIndicates the number of signal plate

(Flywheel/Drive Plate) cogs (tooth) dur-

ing one revolution of the engine.

MAS A/F SE-B1 [V]qqIThe signal voltage of the mass air flow

sensor is displayed.IWhen the engine is stopped, a certain

value is indicated.

COOLAN TEMP/S

[ÉC] or [ÉF]qqIThe engine coolant temperature (deter-

mined by the signal voltage of the

engine coolant temperature sensor) is

displayed.IWhen the engine coolant temperature

sensor is open or short-circuited, ECM

enters fail-safe mode. The engine cool-

ant temperature determined by the

ECM is displayed.

HO2S1 (B1) [V]qq

IThe signal voltage of the front heated

oxygen sensor is displayed.

HO2S1 (B2) [V]qq

HO2S2 (B1) [V]qq

IThe signal voltage of the rear heated

oxygen sensor is displayed.

HO2S2 (B2) [V]qq

HO2S1 MNTR (B1)

[RICH/LEAN]qIDisplay of front heated oxygen sensor

signal during air-fuel ratio feedback

control:

RICH ... means the mixture became

ªrichº, and control is being affected

toward a leaner mixture.

LEAN ... means the mixture became

ªleanº, and control is being affected

toward a rich mixture.IAfter turning ON the ignition switch,

ªRICHº is displayed until air-fuel mixture

ratio feedback control begins.

IWhen the air-fuel ratio feedback is

clamped, the value just before the

clamping is displayed continuously. HO2S1 MNTR (B2)

[RICH/LEAN]q

HO2S2 MNTR (B1)

[RICH/LEAN]qIDisplay of rear heated oxygen sensor

signal:

RICH ... means the amount of oxygen

after three way catalyst is relatively

small.

LEAN ... means the amount of oxygen

after three way catalyst is relatively

large.IWhen the engine is stopped, a certain

value is indicated.

HO2S2 MNTR (B2)

[RICH/LEAN]q

VHCL SPEED SE

[km/h] or [mph]qqIThe vehicle speed computed from the

vehicle speed sensor signal is dis-

played.

BATTERY VOLT [V]qqIThe power supply voltage of ECM is

displayed.

THRTL POS SEN [V]qqIThe throttle position sensor signal volt-

age is displayed.

FUEL T/TMP SE

[ÉC] or [ÉF]IThe fuel temperature judged from the

tank fuel temperature sensor signal

voltage is displayed.GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT-II (Cont'd)

EC-87

Page 623 of 2395

![INFINITI QX4 2001 Factory Owners Manual Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

INT/A TEMP SE

[ÉC] or [ÉF]qqIThe intake air temperature determined

by the signal voltage of the intake air

temperature sensor is INFINITI QX4 2001 Factory Owners Manual Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

INT/A TEMP SE

[ÉC] or [ÉF]qqIThe intake air temperature determined

by the signal voltage of the intake air

temperature sensor is](/img/42/57027/w960_57027-622.png)

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

INT/A TEMP SE

[ÉC] or [ÉF]qqIThe intake air temperature determined

by the signal voltage of the intake air

temperature sensor is indicated.

EVAP SYS PRES [V]qIThe signal voltage of EVAP control sys-

tem pressure sensor is displayed.

ABSOL PRES/SE [V]qIThe signal voltage of the absolute pres-

sure sensor is displayed.

FUEL LEVEL SE [V]qIThe signal voltage of the fuel level sen-

sor is displayed.

START SIGNAL

[ON/OFF]qqIIndicates [ON/OFF] condition from the

starter signal.IAfter starting the engine, [OFF] is dis-

played regardless of the starter signal.

CLSD THL POS

[ON/OFF]qqIIndicates idle position [ON/OFF] com-

puted by ECM according to the throttle

position sensor signal.

CLSD THL/P SW

[ON/OFF]qIIndicates mechanical contact [ON/OFF]

condition of the closed throttle position

switch.

AIR COND SIG

[ON/OFF]qqIIndicates [ON/OFF] condition of the air

conditioner switch as determined by the

air conditioner signal.

P/N POSI SW

[ON/OFF]qqIIndicates [ON/OFF] condition from the

park/neutral position (PNP) switch sig-

nal.

PW/ST SIGNAL

[ON/OFF]qqI[ON/OFF] condition of the power steer-

ing oil pressure switch determined by

the power steering oil pressure signal is

indicated.

LOAD SIGNAL

[ON/OFF]qqIIndicates [ON/OFF] condition from the

electrical load signal and/or lighting

switch.

ON ... rear defogger is operating and/or

lighting switch is on.

OFF ... rear defogger is not operating

and lighting switch is not on.

IGNITION SW

[ON/OFF]qIIndicates [ON/OFF] condition from igni-

tion switch.

SWRL CONT S/V

[ON/OFF]qIThe control condition of the swirl con-

trol valve control solenoid valve (deter-

mined by ECM according to the input

signals) is indicated.

ION ... Swirl control valve is closed.

OFF ... Swirl control valve is opened.

INJ PULSE-B1

[msec]q

IIndicates the actual fuel injection pulse

width compensated by ECM according

to the input signals.IWhen the engine is stopped, a certain

computed value is indicated.

INJ PULSE-B2

[msec]

B/FUEL SCHDL

[msec]qIªBase fuel scheduleº indicates the fuel

injection pulse width programmed into

ECM, prior to any learned on board

correction.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT-II (Cont'd)

EC-88

Page 625 of 2395

![INFINITI QX4 2001 Factory Owners Manual Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

INT/V TIM (B1) [ÉCA]

IIndicate [ÉCA] of intake camshaft

advanced angle.

INT/V TIM (B2) [ÉCA]

INT/V SOL (B1) [%]IThe control con INFINITI QX4 2001 Factory Owners Manual Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

INT/V TIM (B1) [ÉCA]

IIndicate [ÉCA] of intake camshaft

advanced angle.

INT/V TIM (B2) [ÉCA]

INT/V SOL (B1) [%]IThe control con](/img/42/57027/w960_57027-624.png)

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

INT/V TIM (B1) [ÉCA]

IIndicate [ÉCA] of intake camshaft

advanced angle.

INT/V TIM (B2) [ÉCA]

INT/V SOL (B1) [%]IThe control condition of the intake

valve timing control solenoid valve is

indicated. INT/V SOL (B2) [%]

TRVL AFTER MIL

[km] or [Mile]IDistance traveled while MIL is activated

VIAS S/V

[ON/OFF]IThe control condition of the VIAS con-

trol solenoid valve (determined by ECM

according to the input signal) is indi-

cated.

IOFF ... VIAS control solenoid valve is

not operating.

ON ... VIAS control solenoid valve is

operating.

SWL CON VC SWIIndicates [ON/OFF] condition from the

swirl control valve control vacuum

check switch.

ON ... Swirl control valve is not opera-

tional.

OFF ... Swirl control valve is opera-

tional.

IDL A/V LEANIDisplay the condition of idle air volume

learning

YET ... Idle air volume learning has not

been performed yet.

CMPLT ... Idle air volume learning has

already been performed successfully.

INCMP ... Idle air volume learning has

not been performed successfully.

Voltage [V]IVoltage measured by the voltage

probe.

Frequency

[msec] or [Hz] or [%]IPulse width, frequency or duty cycle

measured by the pulse probe.IOnly ª#º is displayed if item is unable to

be measured.

IFigures with ª#ºs are temporary ones.

They are the same figures as an actual

piece of data which was just previously

measured.

NOTE:

IAny monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

IRegarding R50 model, ª-B1º indicates right bank and ª-B2º indicates left bank.

IBank 1 (-B1 or BK1) includes No. 1 cylinder.

DATA MONITOR (SPEC) MODENBEC0034S11

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

MAS A/F SE-B1 [V]qqIThe signal voltage of the mass air flow sen-

sor specification is displayed.IWhen the engine is running, specifi-

cation range is indicated.

B/FUEL SCHDL

[msec]IªBase fuel scheduleº indicates the fuel injec-

tion pulse width programmed into ECM,

prior to any learned on board correction.IWhen the engine is running, specifi-

cation range is indicated.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT-II (Cont'd)

EC-90

Page 626 of 2395

![INFINITI QX4 2001 Factory Owners Manual Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

A/F ALPHA-B1 [%]q

IIndicates the mean value of the air-fuel ratio

feedback correction factor per cycle.IWhen the engine is running INFINITI QX4 2001 Factory Owners Manual Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

A/F ALPHA-B1 [%]q

IIndicates the mean value of the air-fuel ratio

feedback correction factor per cycle.IWhen the engine is running](/img/42/57027/w960_57027-625.png)

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

A/F ALPHA-B1 [%]q

IIndicates the mean value of the air-fuel ratio

feedback correction factor per cycle.IWhen the engine is running, specifi-

cation range is indicated.

IThis data also includes the data for

the air-fuel ratio learning control. A/F ALPHA-B2 [%]q

NOTE:

IAny monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

IRegarding R50 model, ªB1º indicates bank 1 and ªB2º indicates bank 2.

ACTIVE TEST MODENBEC0034S07

TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY)

FUEL INJECTIONIEngine: Return to the original

trouble condition

IChange the amount of fuel injec-

tion using CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.IHarness and connector

IFuel injectors

IHeated oxygen sensor

IGNITION TIMINGIEngine: Return to the original

trouble condition

ITiming light: Set

IRetard the ignition timing using

CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.IAdjust initial ignition timing

IACV-AAC/V

OPENINGIEngine: After warming up, idle

the engine.

IChange the IACV-AAC valve

opening percent using CON-

SULT-II.Engine speed changes according

to the opening percent.IHarness and connector

IIACV-AAC valve

POWER BAL-

ANCEIEngine: After warming up, idle

the engine.

IA/C switch ªOFFº

IShift lever ªNº

ICut off each injector signal one

at a time using CONSULT-II.Engine runs rough or dies.IHarness and connector

ICompression

IInjectors

IPower transistor

ISpark plugs

IIgnition coils

ENG COOLANT

TEMPIEngine: Return to the original

trouble condition

IChange the engine coolant tem-

perature using CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.IHarness and connector

IEngine coolant temperature sen-

sor

IFuel injectors

FUEL PUMP

RELAYIIgnition switch: ON

(Engine stopped)

ITurn the fuel pump relay ªONº

and ªOFFº using CONSULT-II

and listen to operating sound.Fuel pump relay makes the operat-

ing sound.IHarness and connector

IFuel pump relay

VIAS SOL VALVEIIgnition switch: ON

ITurn solenoid valve ªONº and

ªOFFº with CONSULT-II and lis-

ten for operating sound.Solenoid valve makes an operating

sound.IHarness and connector

ISolenoid valve

SWIRL CONT

S O L VA LV EIIgnition switch: ON

ITurn solenoid valve ªONº and

ªOFFº with CONSULT-II and lis-

ten for operating sound.Solenoid valve makes an operating

sound.IHarness and connector

ISolenoid valve

PURG VOL

CONT/VIEngine: After warming up, run

engine at 1,500 rpm.

IChange the EVAP canister purge

volume control solenoid valve

opening percent using CON-

SULT-II.Engine speed changes according

to the opening percent.IHarness and connector

ISolenoid valve

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT-II (Cont'd)

EC-91

Page 632 of 2395

MEF036D

IntroductionNBEC0036

SEF233G

SEF234G

The engine has an ECM to control major systems such as fuel

control, ignition control, idle air control system, etc. The ECM

accepts input signals from sensors and instantly drives actuators.

It is essential that both input and output signals are proper and

stable. At the same time, it is important that there are no problems

such as vacuum leaks, fouled spark plugs, or other problems with

the engine.

It is much more difficult to diagnose a problem that occurs intermit-

tently rather than continuously. Most intermittent problems are

caused by poor electric connections or improper wiring. In this

case, careful checking of suspected circuits may help prevent the

replacement of good parts.

A visual check only may not find the cause of the problems. A road

test with CONSULT-II (or GST) or a circuit tester connected should

be performed. Follow the ªWork Flowº on EC-99.

Before undertaking actual checks, take a few minutes to talk with

a customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such problems, espe-

cially intermittent ones. Find out what symptoms are present and

under what conditions they occur. A ªDiagnostic Worksheetº like the

example on next page should be used.

Start your diagnosis by looking for ªconventionalº problems first.

This will help troubleshoot driveability problems on an electronically

controlled engine vehicle.

SEF907L

DIAGNOSTIC WORKSHEETNBEC0036S01There are many operating conditions that lead to the malfunction

of engine components. A good grasp of such conditions can make

trouble-shooting faster and more accurate.

In general, each customer feels differently about a problem. It is

important to fully understand the symptoms or conditions for a

customer complaint.

Utilize a diagnostic worksheet like the one on the next page in order

to organize all the information for troubleshooting.

Some conditions may cause the MIL to come on steady or blink and

DTC to be detected. Examples:

IVehicle ran out of fuel, which caused the engine to misfire.

IFuel filler cap was left off or incorrectly screwed on, allowing

fuel to evaporate into the atmosphere.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð INTRODUCTION

Introduction

EC-97