IDX INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 946 of 2395

SEF018S

Component Description=NBEC0622The fuel level sensor is mounted in the fuel level sensor unit. The

sensor detects a fuel level in the fuel tank and transmits a signal

to the ECM.

It consists of two parts, one is mechanical float and the other side

is variable resistor. Fuel level sensor output voltage changes

depending on the movement of the fuel mechanical float.

On Board Diagnostic LogicNBEC0623Driving long distances naturally affect fuel gauge level.

This diagnosis detects the fuel gauge malfunction of the gauge not

moving even after a long distance has been driven.

Malfunction is detected when the output signal of the fuel level

sensor does not change within the specified range even though the

vehicle has been driven a long distance.

Possible CauseNBEC0624IHarness or connectors

(The level sensor circuit is open or shorted.)

IFuel level sensor

Overall Function CheckNBEC0625Use this procedure to check the overall function of the fuel level

sensor function. During this check, a 1st trip DTC might not be

confirmed.

WARNING:

When performing following procedure, be sure to observe the

handling of the fuel. Refer to FE-5, ªFuel Tankº.

TESTING CONDITION:

Before starting overall function check, preparation of draining

fuel and refilling fuel is required.

SEF195Y

WITH CONSULT-IINBEC0625S01NOTE:

Start from step 11, if it is possible to confirm that the fuel

cannot be drained by 30(7-7/8 US gal, 6-5/8 Imp gal) in

advance.

1) Prepare a fuel container and a spare hose.

2) Release fuel pressure from fuel line, refer to ªFuel Pressure

Releaseº, EC-39.

3) Remove the fuel feed hose on the fuel level sensor unit.

4) Connect a spare fuel hose where the fuel feed hose was

removed.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0461 FUEL LEVEL SENSOR FUNCTION

Component Description

EC-411

Page 948 of 2395

SEF018S

Component DescriptionNBEC0626The fuel level sensor is mounted in the fuel level sensor unit. The

sensor detects a fuel level in the fuel tank and transmits a signal

to the ECM.

It consists of two parts, one is mechanical float and the other side

is variable resistor. Fuel level sensor output voltage changes

depending on the movement of the fuel mechanical float.

On Board Diagnostic LogicNBEC0627ECM receives two signals from the fuel level sensor circuit.

One is fuel level sensor power supply circuit, and the other is fuel

level sensor ground circuit.

This diagnosis indicates the former, to detect open or short circuit

malfunction.

Malfunction is detected when an excessively low or high voltage is

sent from the sensor is sent to ECM.

Possible CauseNBEC0628IFuel level sensor circuit

(The fuel level sensor circuit is open or shorted.)

IFuel level sensor

DTC Confirmation ProcedureNBEC0629NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that bat-

tery voltage is more than 11V at ignition switch ªONº.

SEF195Y

WITH CONSULT-IINBEC0629S011) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Wait at least 5 seconds.

4) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-415.

WITH GSTNBEC0629S02Follow the procedure ªWITH CONSULT-IIº above.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0464 FUEL LEVEL SENSOR CIRCUIT

Component Description

EC-413

Page 950 of 2395

Diagnostic Procedure=NBEC0631

1 CHECK FUEL LEVEL SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect fuel level sensor unit harness connector.

3. Turn ignition switch ªONº.

4. Check voltage between fuel level sensor unit terminal 3 and ground, ECM terminal 83 and ground with CONSULT-II or

tester.

SEF374Z

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M2, B1 and M94, F27

IHarness for open or short between combination meter and fuel level sensor unit

©Repair or replace harness or connectors.

3 CHECK FUEL LEVEL SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between fuel level sensor unit terminal 2 and body ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to power.

OK or NG

OK©GO TO 4.

NG©Repair open circuit or short to power in harness or connectors.

4 CHECK FUEL LEVEL SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 59 and fuel level sensor terminal 2. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to power.

OK or NG

OK©GO TO 6.

NG©GO TO 5.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0464 FUEL LEVEL SENSOR CIRCUIT

Diagnostic Procedure

EC-415

Page 952 of 2395

AEC110

Component Description=NBEC0242The vehicle speed sensor is installed in the transaxle. It contains a

pulse generator which provides a vehicle speed signal to the

speedometer. The speedometer then sends a signal to the ECM.

ECM Terminals and Reference ValueNBEC0669Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

86 W/L Vehicle speed sensor[Engine is running]

IJack up front wheels.

IIn 1st gear position

I10 km/h (6 MPH)Approximately 2.5V

SEF583X

[Engine is running]

IJack up front wheels.

IIn 2nd gear position

I30 km/h (19 MPH)Approximately 2.0V

SEF584X

On Board Diagnosis LogicNBEC0244Malfunction is detected when the almost 0 km/h (0 MPH) signal

from vehicle speed sensor is sent to ECM even when vehicle is

being driven.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0500 VEHICLE SPEED SENSOR (VSS)

Component Description

EC-417

Page 954 of 2395

10 km/h (6 MPH) when rotating wheels with suitable gear posi-

tion.

4) If NG, go to ªDiagnostic Procedureº, EC-421.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0500 VEHICLE SPEED SENSOR (VSS)

Overall Function Check (Cont'd)

EC-419

Page 956 of 2395

Diagnostic ProcedureNBEC0248

1 CHECK VEHICLE SPEED SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector and combination meter harness connector.

3. Check harness continuity between ECM terminal 86 and combination meter terminal 13.

Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to power.

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M32, F23

IHarness for open or short between ECM and combination meter

©Repair open circuit or short to ground or short to power in harness or connectors.

3 CHECK SPEEDOMETER FUNCTION

Make sure that speedometer functions properly.

OK or NG

OK©GO TO 5.

NG©GO TO 4.

4 CHECK SPEEDOMETER CIRCUIT FOR OPEN AND SHORT

Check the following.

IHarness connectors M70, B50

IHarness for open or short between combination meter and vehicle speed sensor

IHarness for open or short between vehicle speed sensor and ECM

OK or NG

OK©Check combination meter and vehicle speed sensor. Refer to EL section.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-140.

©INSPECTION END

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0500 VEHICLE SPEED SENSOR (VSS)

Diagnostic Procedure

EC-421

Page 958 of 2395

CONSULT-II Reference Value in Data Monitor

Mode

NBEC0250Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

IACV-AAC/VIEngine: After warming up

IAir conditioner switch: ªOFFº

IShift lever: ªNº

INo-loadIdle 14 - 20 step

2,000 rpm Ð

ECM Terminals and Reference ValueNBEC0670Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

6

7

8

17PU/G

GY

Y

GY/LIACV-AAC valve[Engine is running]

IIdle speed0.1 - 14V

On Board Diagnosis LogicNBEC0252Malfunction is detected when

(Malfunction A)the IACV-AAC valve does not operate properly,

(Malfunction B)the IACV-AAC valve does not operate properly.

Possible CauseNBEC0515MALFUNCTION ANBEC0515S01IHarness or connectors

(The IACV-AAC valve circuit is open.)

IIACV-AAC valve

MALFUNCTION BNBEC0515S02IHarness or connectors

(The IACV-AAC valve circuit is shorted.)

IAir control valve (Power steering)

IIACV-AAC valve

DTC Confirmation ProcedureNBEC0253NOTE:

IIf ªDTC Confirmation Procedureº has been previously

conducted, always turn ignition switch ªOFFº and wait at least

10 seconds before conducting the next test.

IPerform ªPROCEDURE FOR MALFUNCTION Aº first. If 1st

trip DTC cannot be confirmed, perform ªPROCEDURE

FOR MALFUNCTION Bº.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0505 IDLE AIR CONTROL VALVE (IACV) Ð AUXILIARY AIR CONTROL

(AAC) VALVE

CONSULT-II Reference Value in Data Monitor Mode

EC-423

Page 960 of 2395

Wiring DiagramNBEC0254

MEC966C

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0505 IDLE AIR CONTROL VALVE (IACV) Ð AUXILIARY AIR CONTROL

(AAC) VALVE

Wiring Diagram

EC-425

Page 962 of 2395

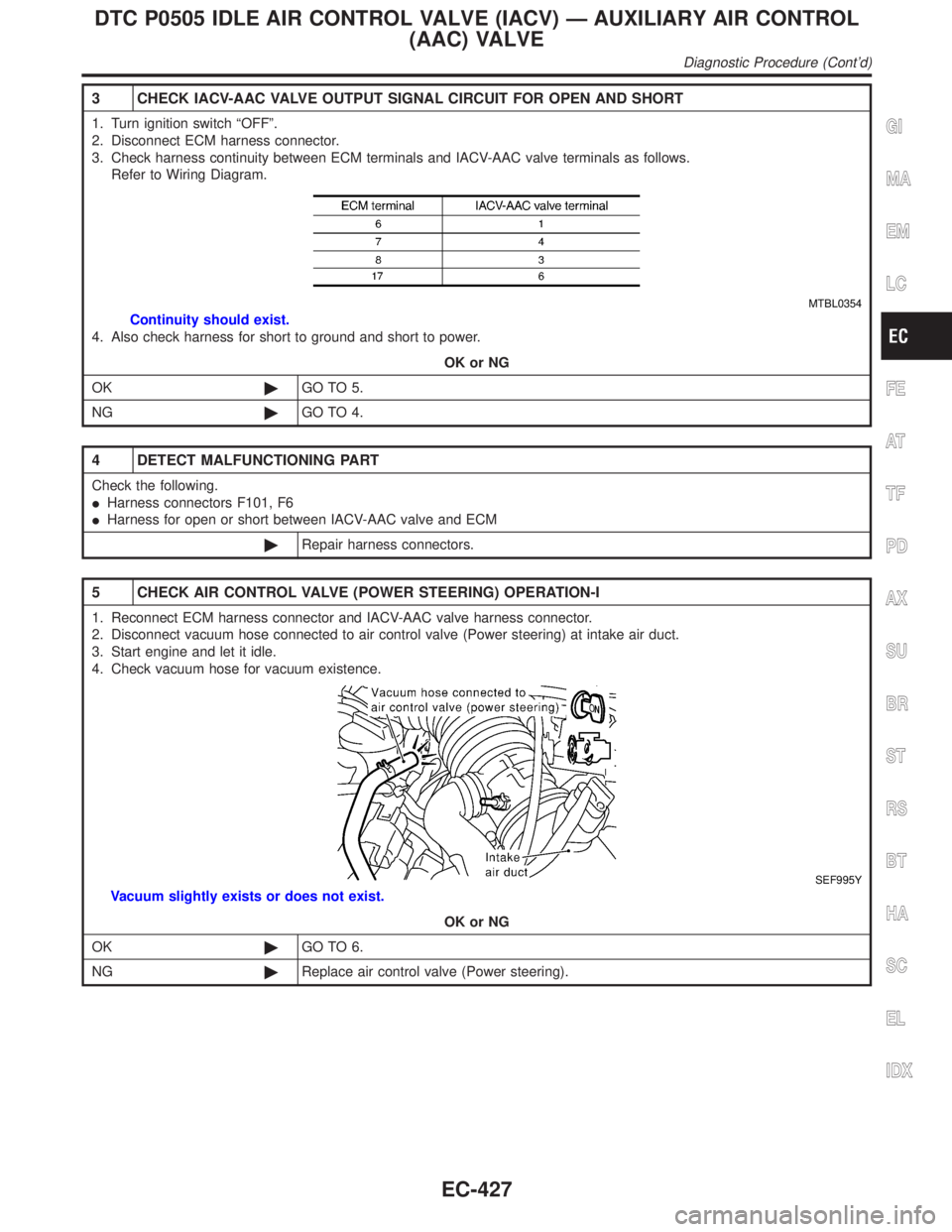

3 CHECK IACV-AAC VALVE OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminals and IACV-AAC valve terminals as follows.

Refer to Wiring Diagram.

MTBL0354

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©GO TO 4.

4 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors F101, F6

IHarness for open or short between IACV-AAC valve and ECM

©Repair harness connectors.

5 CHECK AIR CONTROL VALVE (POWER STEERING) OPERATION-I

1. Reconnect ECM harness connector and IACV-AAC valve harness connector.

2. Disconnect vacuum hose connected to air control valve (Power steering) at intake air duct.

3. Start engine and let it idle.

4. Check vacuum hose for vacuum existence.

SEF995Y

Vacuum slightly exists or does not exist.

OK or NG

OK©GO TO 6.

NG©Replace air control valve (Power steering).

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0505 IDLE AIR CONTROL VALVE (IACV) Ð AUXILIARY AIR CONTROL

(AAC) VALVE

Diagnostic Procedure (Cont'd)

EC-427

Page 964 of 2395

8 CHECK VACUUM HOSES AND TUBES

1. Disconnect vacuum hoses between air control valve (Power steering) and vacuum port, air control valve (Power steer-

ing) and intake air duct.

2. Check the hoses and tubes for crack, clogging, improper connection or disconnection.

SEF109L

OK or NG

OK©GO TO 9.

NG©Repair hoses or tubes.

9 CHECK IACV-AAC VALVE-I

1. Disconnect IACV-AAC valve harness connector.

2. Check resistance between IACV-AAC valve terminal 2 and terminals 1, 3, terminal 5 and terminals 4, 6.

SEF344XA

OK or NG

OK©GO TO 10.

NG©Replace IACV-AAC valve assembly.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0505 IDLE AIR CONTROL VALVE (IACV) Ð AUXILIARY AIR CONTROL

(AAC) VALVE

Diagnostic Procedure (Cont'd)

EC-429