Engine control INFINITI QX4 2001 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 265 of 2395

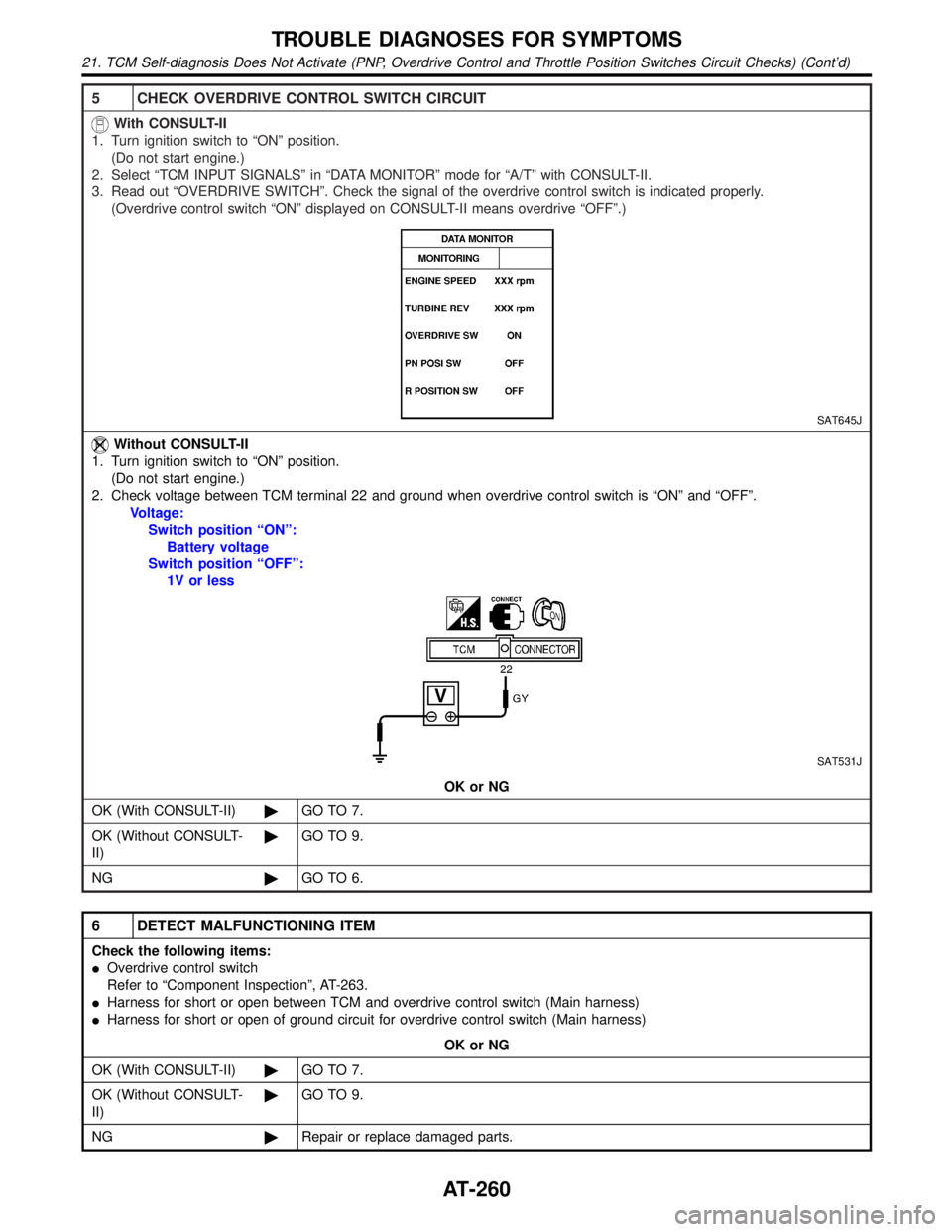

5 CHECK OVERDRIVE CONTROL SWITCH CIRCUIT

With CONSULT-II

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Select ªTCM INPUT SIGNALSº in ªDATA MONITORº mode for ªA/Tº with CONSULT-II.

3. Read out ªOVERDRIVE SWITCHº. Check the signal of the overdrive control switch is indicated properly.

(Overdrive control switch ªONº displayed on CONSULT-II means overdrive ªOFFº.)

SAT645J

Without CONSULT-II

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between TCM terminal 22 and ground when overdrive control switch is ªONº and ªOFFº.

Voltage:

Switch position ªONº:

Battery voltage

Switch position ªOFFº:

1V or less

SAT531J

OK or NG

OK (With CONSULT-II)©GO TO 7.

OK (Without CONSULT-

II)©GO TO 9.

NG©GO TO 6.

6 DETECT MALFUNCTIONING ITEM

Check the following items:

IOverdrive control switch

Refer to ªComponent Inspectionº, AT-263.

IHarness for short or open between TCM and overdrive control switch (Main harness)

IHarness for short or open of ground circuit for overdrive control switch (Main harness)

OK or NG

OK (With CONSULT-II)©GO TO 7.

OK (Without CONSULT-

II)©GO TO 9.

NG©Repair or replace damaged parts.

TROUBLE DIAGNOSES FOR SYMPTOMS

21. TCM Self-diagnosis Does Not Activate (PNP, Overdrive Control and Throttle Position Switches Circuit Checks) (Cont'd)

AT-260

Page 266 of 2395

7 CHECK THROTTLE POSITION SWITCH CIRCUIT (With CONSULT-II)

With CONSULT-II

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Select ªTCM INPUT SIGNALSº in ªDATA MONITORº mode for ªA/Tº with CONSULT-II.

3. Apply vacuum to the throttle opener, then check the following. Refer to steps 1 and 2 of ªPreparationº, ªTCM SELF-

DIAGNOSTIC PROCEDURE (No Tools)º, AT-46.

4. Read out ªCLOSED THL/SWº and ªW/O THRL/P-SWº depressing and releasing accelerator pedal.

Check the signal of throttle position switch is indicated properly.

MTBL0011

SAT646J

OK or NG

OK©GO TO 10.

NG©GO TO 8.

8 DETECT MALFUNCTIONING ITEM

Check the following items:

IThrottle position switch

Refer to ªComponent Inspectionº, AT-264.

IHarness for short or open between ignition switch and throttle position switch (Main harness)

IHarness for short or open between throttle position switch and TCM (Main harness)

OK or NG

OK©GO TO 10.

NG©Repair or replace damaged parts.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSES FOR SYMPTOMS

21. TCM Self-diagnosis Does Not Activate (PNP, Overdrive Control and Throttle Position Switches Circuit Checks) (Cont'd)

AT-261

Page 267 of 2395

9 CHECK THROTTLE POSITION SWITCH CIRCUIT (Without CONSULT-II)

Without CONSULT-II

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between TCM terminals 16, 17 and ground while depressing, and releasing accelerator pedal slowly.

(after warming up engine)

[Refer to ªPreparationº, ªTCM SELF-DIAGNOSTIC PROCEDURE (No Tools)º, AT-46.]

MTBL0519

SAT526J

OK or NG

OK©GO TO 10.

NG©GO TO 8.

10 CHECK DTC

Perform Diagnostic procedure, AT-258.

OK or NG

OK©INSPECTION END

NG©GO TO 11.

11 CHECK TCM INSPECTION

1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK©INSPECTION END

NG©Repair or replace damaged parts.

TROUBLE DIAGNOSES FOR SYMPTOMS

21. TCM Self-diagnosis Does Not Activate (PNP, Overdrive Control and Throttle Position Switches Circuit Checks) (Cont'd)

AT-262

Page 280 of 2395

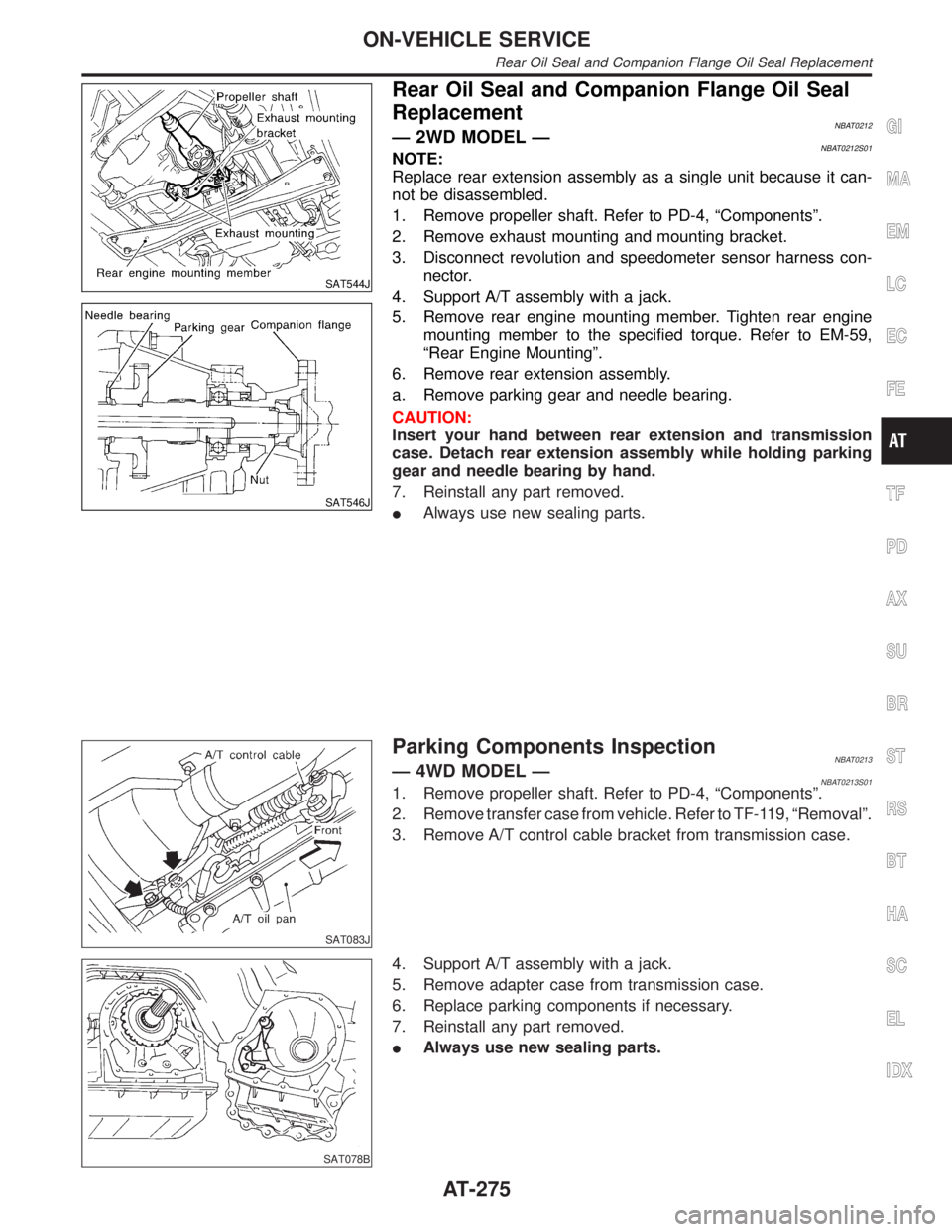

SAT544J

SAT546J

Rear Oil Seal and Companion Flange Oil Seal

Replacement

NBAT0212Ð 2WD MODEL ÐNBAT0212S01NOTE:

Replace rear extension assembly as a single unit because it can-

not be disassembled.

1. Remove propeller shaft. Refer to PD-4, ªComponentsº.

2. Remove exhaust mounting and mounting bracket.

3. Disconnect revolution and speedometer sensor harness con-

nector.

4. Support A/T assembly with a jack.

5. Remove rear engine mounting member. Tighten rear engine

mounting member to the specified torque. Refer to EM-59,

ªRear Engine Mountingº.

6. Remove rear extension assembly.

a. Remove parking gear and needle bearing.

CAUTION:

Insert your hand between rear extension and transmission

case. Detach rear extension assembly while holding parking

gear and needle bearing by hand.

7. Reinstall any part removed.

IAlways use new sealing parts.

SAT083J

Parking Components InspectionNBAT0213Ð 4WD MODEL ÐNBAT0213S011. Remove propeller shaft. Refer to PD-4, ªComponentsº.

2. Remove transfer case from vehicle. Refer to TF-119, ªRemovalº.

3. Remove A/T control cable bracket from transmission case.

SAT078B

4. Support A/T assembly with a jack.

5. Remove adapter case from transmission case.

6. Replace parking components if necessary.

7. Reinstall any part removed.

IAlways use new sealing parts.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON-VEHICLE SERVICE

Rear Oil Seal and Companion Flange Oil Seal Replacement

AT-275

Page 281 of 2395

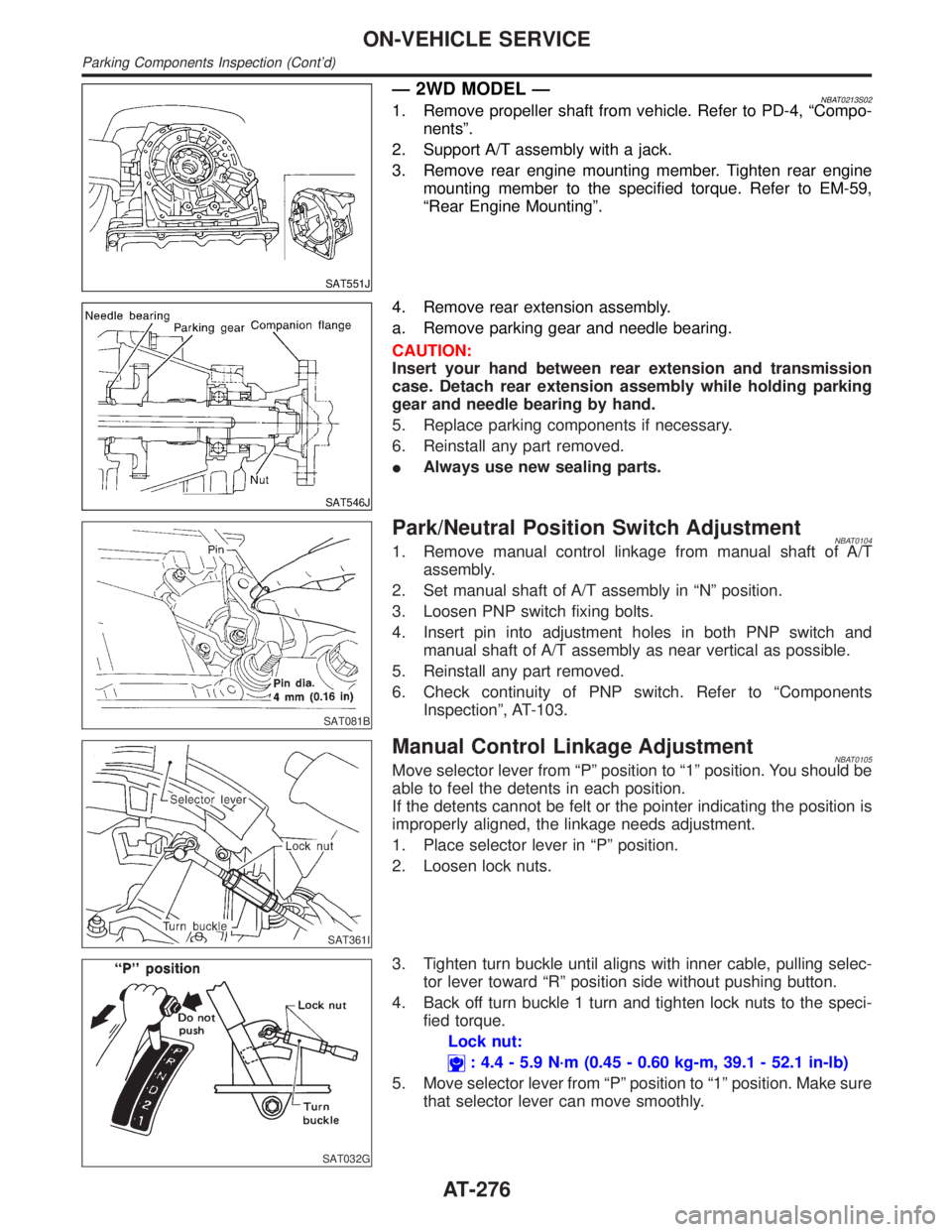

SAT551J

Ð 2WD MODEL ÐNBAT0213S021. Remove propeller shaft from vehicle. Refer to PD-4, ªCompo-

nentsº.

2. Support A/T assembly with a jack.

3. Remove rear engine mounting member. Tighten rear engine

mounting member to the specified torque. Refer to EM-59,

ªRear Engine Mountingº.

SAT546J

4. Remove rear extension assembly.

a. Remove parking gear and needle bearing.

CAUTION:

Insert your hand between rear extension and transmission

case. Detach rear extension assembly while holding parking

gear and needle bearing by hand.

5. Replace parking components if necessary.

6. Reinstall any part removed.

IAlways use new sealing parts.

SAT081B

Park/Neutral Position Switch AdjustmentNBAT01041. Remove manual control linkage from manual shaft of A/T

assembly.

2. Set manual shaft of A/T assembly in ªNº position.

3. Loosen PNP switch fixing bolts.

4. Insert pin into adjustment holes in both PNP switch and

manual shaft of A/T assembly as near vertical as possible.

5. Reinstall any part removed.

6. Check continuity of PNP switch. Refer to ªComponents

Inspectionº, AT-103.

SAT361I

Manual Control Linkage AdjustmentNBAT0105Move selector lever from ªPº position to ª1º position. You should be

able to feel the detents in each position.

If the detents cannot be felt or the pointer indicating the position is

improperly aligned, the linkage needs adjustment.

1. Place selector lever in ªPº position.

2. Loosen lock nuts.

SAT032G

3. Tighten turn buckle until aligns with inner cable, pulling selec-

tor lever toward ªRº position side without pushing button.

4. Back off turn buckle 1 turn and tighten lock nuts to the speci-

fied torque.

Lock nut:

: 4.4 - 5.9 N´m (0.45 - 0.60 kg-m, 39.1 - 52.1 in-lb)

5. Move selector lever from ªPº position to ª1º position. Make sure

that selector lever can move smoothly.

ON-VEHICLE SERVICE

Parking Components Inspection (Cont'd)

AT-276

Page 282 of 2395

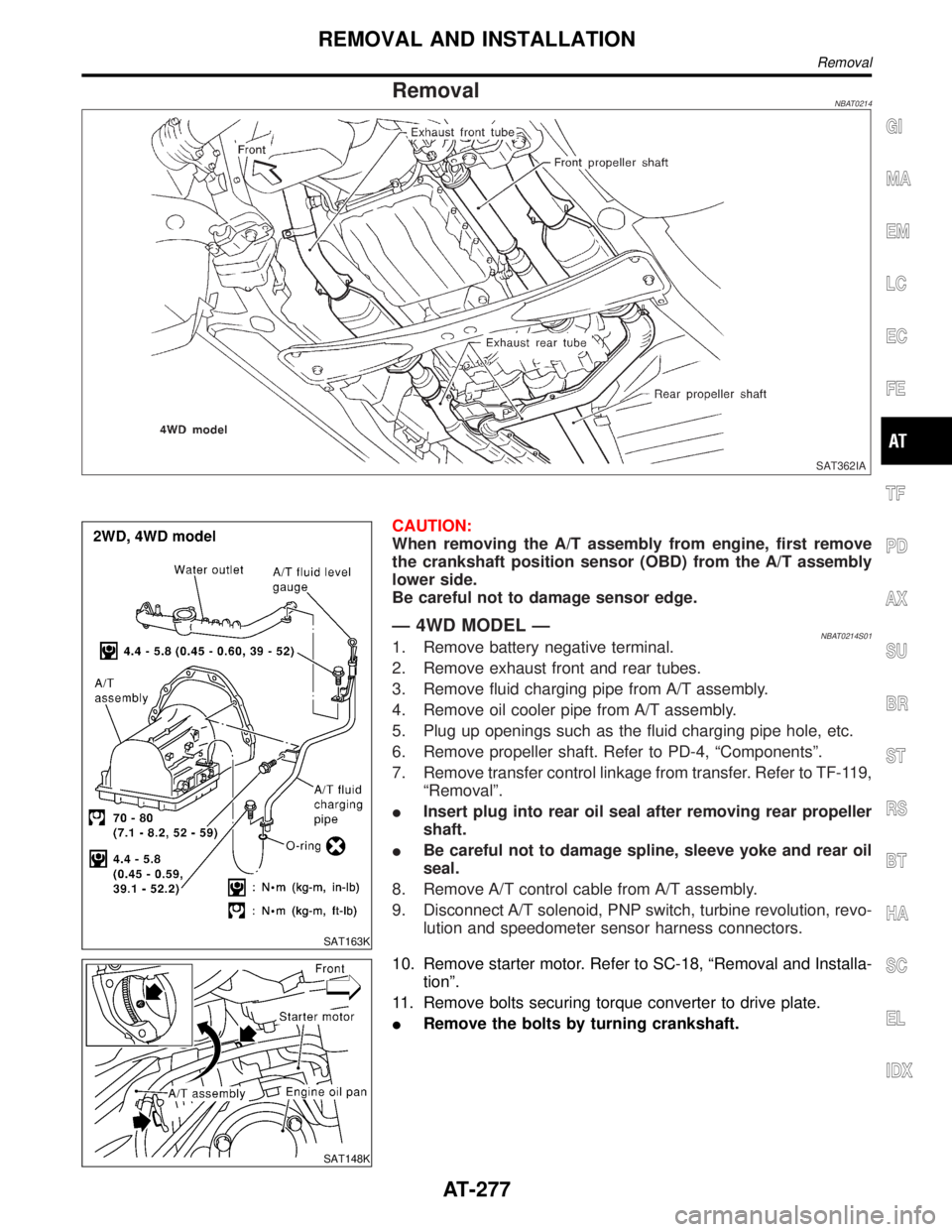

RemovalNBAT0214

SAT362IA

SAT163K

CAUTION:

When removing the A/T assembly from engine, first remove

the crankshaft position sensor (OBD) from the A/T assembly

lower side.

Be careful not to damage sensor edge.

Ð 4WD MODEL ÐNBAT0214S011. Remove battery negative terminal.

2. Remove exhaust front and rear tubes.

3. Remove fluid charging pipe from A/T assembly.

4. Remove oil cooler pipe from A/T assembly.

5. Plug up openings such as the fluid charging pipe hole, etc.

6. Remove propeller shaft. Refer to PD-4, ªComponentsº.

7. Remove transfer control linkage from transfer. Refer to TF-119,

ªRemovalº.

IInsert plug into rear oil seal after removing rear propeller

shaft.

IBe careful not to damage spline, sleeve yoke and rear oil

seal.

8. Remove A/T control cable from A/T assembly.

9. Disconnect A/T solenoid, PNP switch, turbine revolution, revo-

lution and speedometer sensor harness connectors.

SAT148K

10. Remove starter motor. Refer to SC-18, ªRemoval and Installa-

tionº.

11. Remove bolts securing torque converter to drive plate.

IRemove the bolts by turning crankshaft.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REMOVAL AND INSTALLATION

Removal

AT-277

Page 283 of 2395

SAT801C

12. Support A/T and transfer assembly with a jack.

13. Remove rear engine mounting member from body and A/T

assembly. Tighten rear engine mounting member to the speci-

fied torque. Refer to EM-59, ªRear Engine Mountingº.

14. Remove bolts securing A/T assembly to engine.

ISecure torque converter to prevent it from dropping.

ISecure A/T assembly to a jack.

15. Lower A/T assembly with transfer.

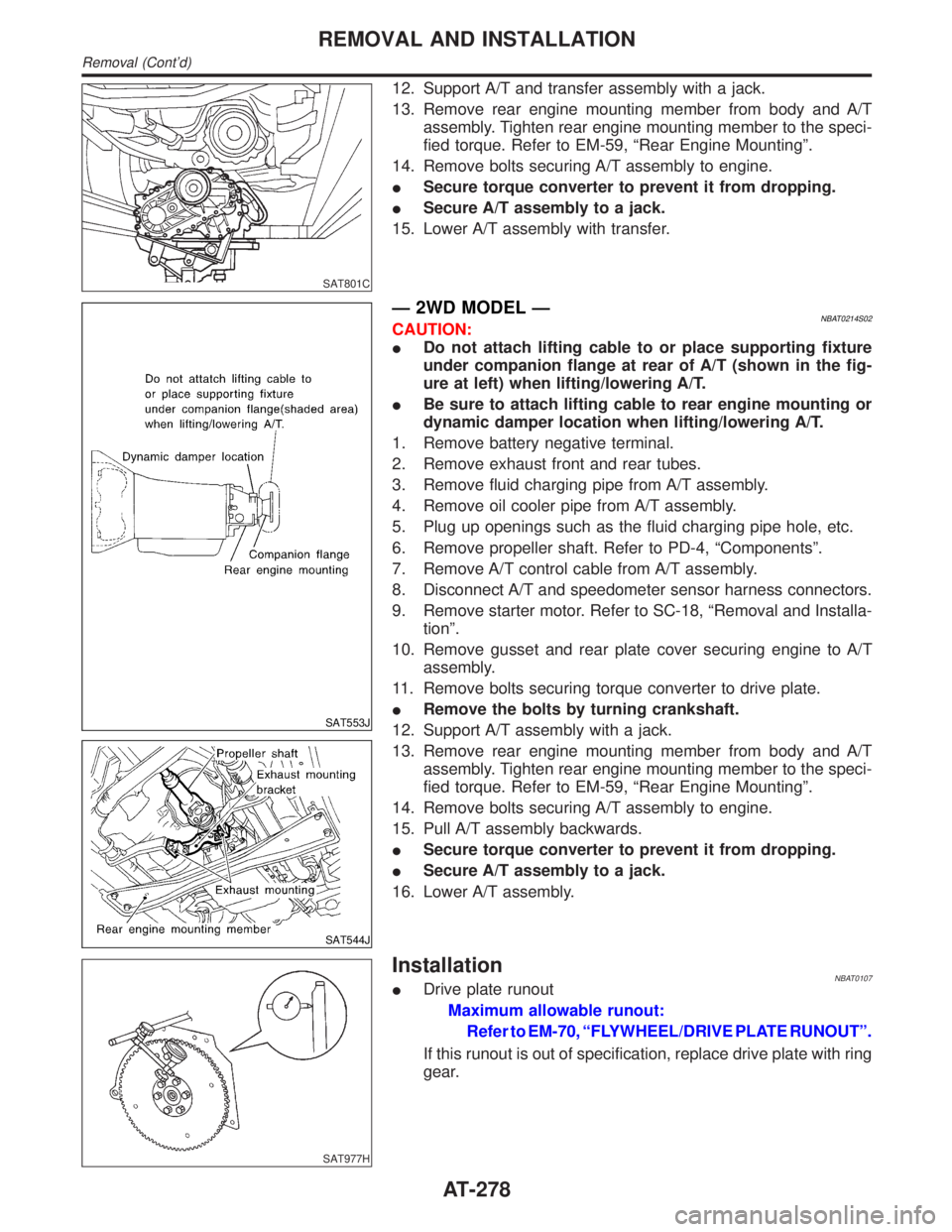

SAT553J

SAT544J

Ð 2WD MODEL ÐNBAT0214S02CAUTION:

IDo not attach lifting cable to or place supporting fixture

under companion flange at rear of A/T (shown in the fig-

ure at left) when lifting/lowering A/T.

IBe sure to attach lifting cable to rear engine mounting or

dynamic damper location when lifting/lowering A/T.

1. Remove battery negative terminal.

2. Remove exhaust front and rear tubes.

3. Remove fluid charging pipe from A/T assembly.

4. Remove oil cooler pipe from A/T assembly.

5. Plug up openings such as the fluid charging pipe hole, etc.

6. Remove propeller shaft. Refer to PD-4, ªComponentsº.

7. Remove A/T control cable from A/T assembly.

8. Disconnect A/T and speedometer sensor harness connectors.

9. Remove starter motor. Refer to SC-18, ªRemoval and Installa-

tionº.

10. Remove gusset and rear plate cover securing engine to A/T

assembly.

11. Remove bolts securing torque converter to drive plate.

IRemove the bolts by turning crankshaft.

12. Support A/T assembly with a jack.

13. Remove rear engine mounting member from body and A/T

assembly. Tighten rear engine mounting member to the speci-

fied torque. Refer to EM-59, ªRear Engine Mountingº.

14. Remove bolts securing A/T assembly to engine.

15. Pull A/T assembly backwards.

ISecure torque converter to prevent it from dropping.

ISecure A/T assembly to a jack.

16. Lower A/T assembly.

SAT977H

InstallationNBAT0107IDrive plate runout

Maximum allowable runout:

Refer to EM-70, ªFLYWHEEL/DRIVE PLATE RUNOUTº.

If this runout is out of specification, replace drive plate with ring

gear.

REMOVAL AND INSTALLATION

Removal (Cont'd)

AT-278

Page 361 of 2395

General SpecificationsNBAT0160

Applied modelVQ35DE engine

2WD 4WD

Automatic transmission model RE4R01A

Transmission model code number 4EX16 4EX17

Stall torque ratio2.0:1

Transmission gear ratio1st 2.785

2nd 1.545

Top 1.000

OD 0.694

Reverse 2.272

Recommended fluidNissan Matic ªDº (Continental U.S. and Alaska) or Genuine Nissan Automatic Trans-

mission Fluid (Canada)*1

Fluid capacity8.5(9 US qt, 7-1/2 Imp qt)

*1: Refer to MA-11, ªFluids and Lubricantsº.

Shift ScheduleNBAT0178VEHICLE SPEED WHEN SHIFTING GEARS THROTTLE POSITIONNBAT0178S01

Throttle positionVehicle speed km/h (MPH)

D

1,D2D2,D3D3,D4D4,D3D3,D2D2,D112,11

Full throttle55-59

(34 - 37)105 - 113

(65 - 70)174 - 184

(108 - 114)170 - 180

(106 - 112)102 - 110

(63 - 68)43-47

(27 - 29)43-47

(27 - 29)

Half throttle37-41

(23 - 25)71-79

(44 - 49)129 - 139

(80 - 86)81-91

(50 - 57)33-41

(21 - 25)12-16

(7 - 10)43-47

(27 - 29)

VEHICLE SPEED WHEN PERFORMING AND RELEASING LOCK-UPNBAT0178S02

Throttle positionOverdrive control switch [Shift posi-

tion]Vehicle speed km/h (MPH)

Lock-up ªONº Lock-up ªOFFº

Full throttleON [D

4] 174 - 184 (108 - 114) 170 - 180 (106 - 112)

OFF [D

3] 104 - 114 (65 - 71) 101 - 111 (63 - 69)

Half throttleON [D

4] 151 - 161 (94 - 100) 106 - 116 (66 - 72)

OFF [D

3] 85-95(53-59) 82-92(51-57)

Stall RevolutionNBAT0163

Stall revolution rpm2,440 - 2,640

Line PressureNBAT0164

Engine speed

rpmLine pressure kPa (kg/cm2, psi)

D, 2 and 1 positions R position

Idle 422 - 461 (4.3 - 4.7, 61 - 67) 667 - 706 (6.8 - 7.2, 97 - 102)

Stall 1,020 - 1,098 (10.4 - 11.2, 148 - 159) 1,422 - 1,500 (14.5 - 15.3, 206 - 218)

SERVICE DATA AND SPECIFICATIONS (SDS)

General Specifications

AT-356

Page 420 of 2395

SBR042D

AdjustmentNBBR00471. Adjust clearance between shoe and drum as follows:

a. Release parking brake lever and loosen adjusting nut.

b. Depress brake pedal fully at least 10 times with engine run-

ning.

2. Pull control lever4-5notches. Then adjust control lever by

turning adjusting nut.

SBR073D

3. Pull control lever with specified amount of force. Check lever

stroke and ensure smooth operation.

Number of notches:6-8

4. Bend warning lamp switchplate to ensure:

IWarning lamp comes on when lever is lifted ªAº notches.

IWarning lamp goes out when lever is fully released.

Number of ªAº notches: 1 or less

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

ST

RS

BT

HA

SC

EL

IDX

PARKING BRAKE CONTROL

Adjustment

BR-31

Page 421 of 2395

PurposeNBBR0087The Anti-Lock Brake System (ABS) consists of electronic and hydraulic components. It allows for control of

braking force so locking of the wheels can be avoided.

1) Improves proper tracking performance through steering wheel operation.

2) Eases obstacle avoidance through steering wheel operation.

3) Improves vehicle stability.

OperationNBBR0088IWhen the vehicle speed is less than 10 km/h (6 MPH) this system does not work.

IThe Anti-Lock Brake System (ABS) has a self-test function. The system turns on the ABS warning lamp

for 1 second each time the ignition switch is turned ªONº. After the engine is started, the ABS warning lamp

turns off. The system performs a test the first time the vehicle reaches 6 km/h (4 MPH). A mechanical noise

may be heard as the ABS performs this self-test. This is a normal part of the self-test feature. If a mal-

function is found during this check, the ABS warning lamp will stay on.

IWhile driving, a mechanical noise may be heard during ABS operation. This is a normal condition.

ABS Hydraulic CircuitNBBR0089

SBR859D

1. Inlet solenoid valve

2. Outlet solenoid valve

3. Reservoir4. Pump

5. Motor

6. Inlet valve7. Outlet valve

8. Bypass check valve

9. Damper

DESCRIPTIONABS

Purpose

BR-32