steering INFINITI QX4 2001 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1666 of 2395

CAUTION:

IAfter removing timing chain, do not turn crankshaft and

camshaft separately, or valves will strike piston heads.

IWhen installing camshafts, chain tensioners, oil seals, or

other sliding parts, lubricate contacting surfaces with new

engine oil.

IApply new engine oil to bolt threads and seat surfaces

when installing camshaft sprockets and crankshaft pulley.

IBefore disconnecting fuel hose, release fuel pressure.

Refer to EC-39, ªFuel Pressure Releaseº.

IBe careful not to damage sensor edges.

IDo not spill engine coolant on drive belts.

RemovalNBEM00121. Release fuel pressure.

Refer to EC-39, ªFuel Pressure Releaseº.

2. Remove battery.

3. Remove radiator.

Refer to LC-19, ªREMOVAL AND INSTALLATIONº.

4. Drain engine oil.

5. Remove drive belts and idler pulley with brackets.

6. Remove cooling fan with bracket.

7. Remove engine cover.

8. Remove air duct with air cleaner case, collector, blow-by hose,

vacuum hoses, fuel hoses, water hoses, wires, harnesses,

connectors and so on.

9. Remove the air compressor, and tie it down using rope or the

like to keep it from interfering.

10. Remove the power steering oil pump and reservoir tank. Tie

them down using rope or the like to keep them from interfer-

ing.

11. Remove alternator.

12. Remove the following.

IVacuum gallery

IWater bypass pipe

IBrackets

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TIMING CHAIN

Components (Cont'd)

EM-23

Page 1702 of 2395

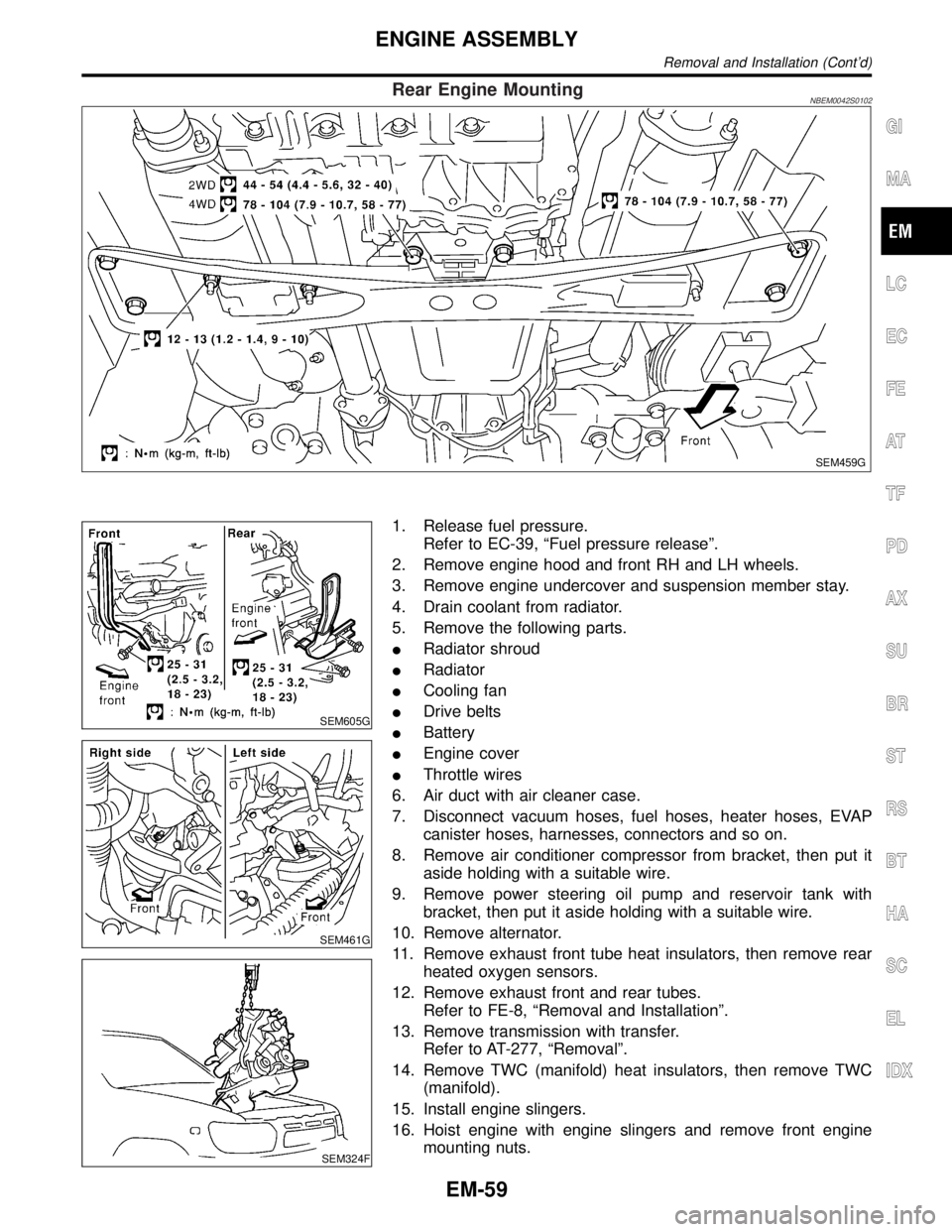

Rear Engine MountingNBEM0042S0102

SEM459G

SEM605G

SEM461G

SEM324F

1. Release fuel pressure.

Refer to EC-39, ªFuel pressure releaseº.

2. Remove engine hood and front RH and LH wheels.

3. Remove engine undercover and suspension member stay.

4. Drain coolant from radiator.

5. Remove the following parts.

IRadiator shroud

IRadiator

ICooling fan

IDrive belts

IBattery

IEngine cover

IThrottle wires

6. Air duct with air cleaner case.

7. Disconnect vacuum hoses, fuel hoses, heater hoses, EVAP

canister hoses, harnesses, connectors and so on.

8. Remove air conditioner compressor from bracket, then put it

aside holding with a suitable wire.

9. Remove power steering oil pump and reservoir tank with

bracket, then put it aside holding with a suitable wire.

10. Remove alternator.

11. Remove exhaust front tube heat insulators, then remove rear

heated oxygen sensors.

12. Remove exhaust front and rear tubes.

Refer to FE-8, ªRemoval and Installationº.

13. Remove transmission with transfer.

Refer to AT-277, ªRemovalº.

14. Remove TWC (manifold) heat insulators, then remove TWC

(manifold).

15. Install engine slingers.

16. Hoist engine with engine slingers and remove front engine

mounting nuts.

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE ASSEMBLY

Removal and Installation (Cont'd)

EM-59

Page 1745 of 2395

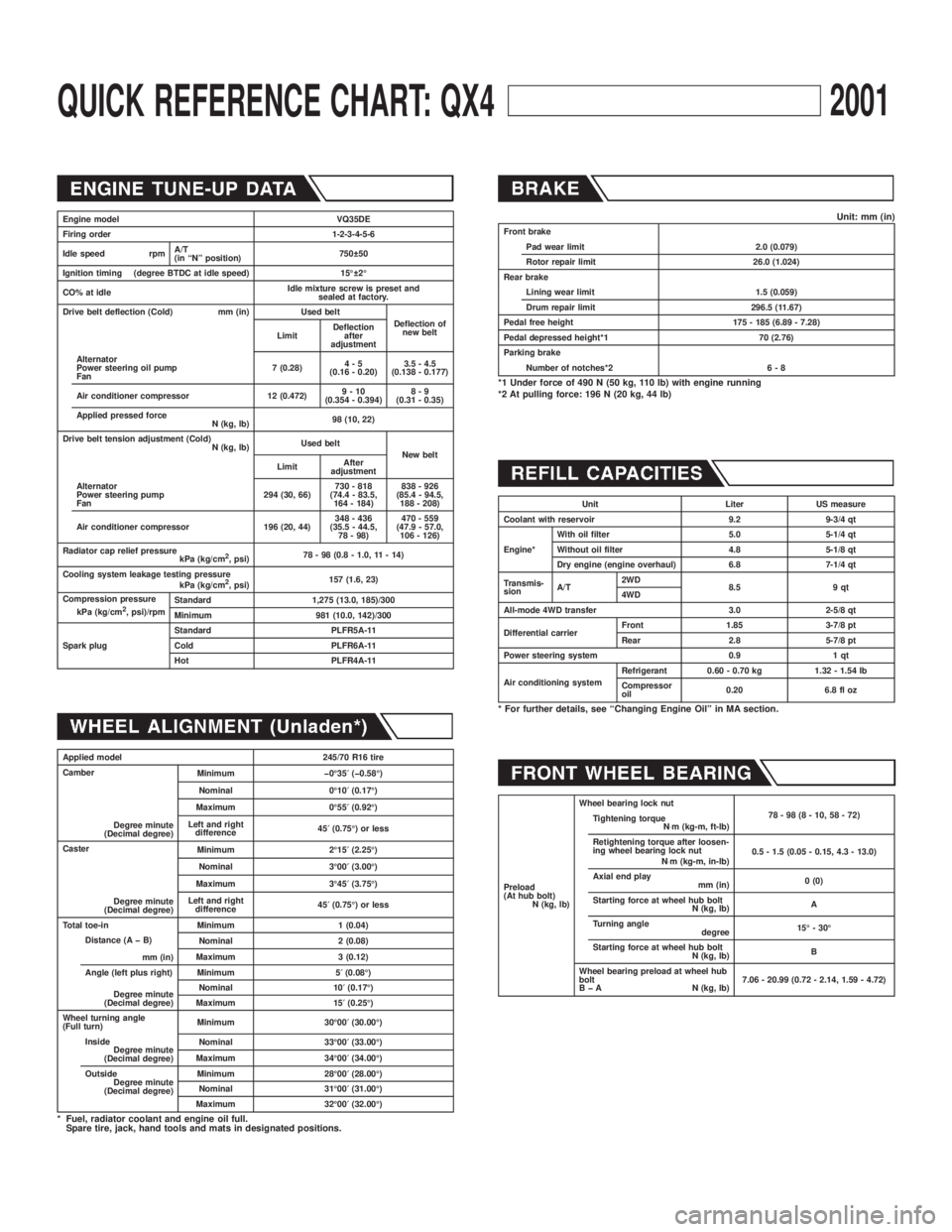

QUICK REFERENCE CHART: QX42001

Engine model VQ35DE

Firing order 1-2-3-4-5-6

Idle speed rpmA/T

(in ªNº position)750 50

Ignition timing (degree BTDC at idle speed) 15É 2É

CO% at idleIdle mixture screw is preset and

sealed at factory.

Drive belt deflection (Cold) mm (in) Used belt

Deflection of

new belt

LimitDeflection

after

adjustment

Alternator

Power steering oil pump

Fan7 (0.28)4-5

(0.16 - 0.20)3.5 - 4.5

(0.138 - 0.177)

Air conditioner compressor 12 (0.472)9-10

(0.354 - 0.394)8-9

(0.31 - 0.35)

Applied pressed force

N (kg, lb)98 (10, 22)

Drive belt tension adjustment (Cold)

N (kg, lb)Used belt

New belt

LimitAfter

adjustment

Alternator

Power steering pump

Fan294 (30, 66)730 - 818

(74.4 - 83.5,

164 - 184)838 - 926

(85.4 - 94.5,

188 - 208)

Air conditioner compressor 196 (20, 44)348 - 436

(35.5 - 44.5,

78 - 98)470 - 559

(47.9 - 57.0,

106 - 126)

Radiator cap relief pressure

kPa (kg/cm

2, psi)78 - 98 (0.8 - 1.0, 11 - 14)

Cooling system leakage testing pressure

kPa (kg/cm

2, psi)157 (1.6, 23)

Compression pressure

kPa (kg/cm

2, psi)/rpmStandard 1,275 (13.0, 185)/300

Minimum 981 (10.0, 142)/300

Spark plugStandard PLFR5A-11

Cold PLFR6A-11

Hot PLFR4A-11

Applied model 245/70 R16 tire

Camber

Degree minute

(Decimal degree)Minimum þ0É35¢(þ0.58É)

Nominal 0É10¢(0.17É)

Maximum 0É55¢(0.92É)

Left and right

difference45¢(0.75É) or less

Caster

Degree minute

(Decimal degree)Minimum 2É15¢(2.25É)

Nominal 3É00¢(3.00É)

Maximum 3É45¢(3.75É)

Left and right

difference45¢(0.75É) or less

Total toe-in Minimum 1 (0.04)

Distance (A þ B)

mm (in)Nominal 2 (0.08)

Maximum 3 (0.12)

Angle (left plus right)

Degree minute

(Decimal degree)Minimum 5¢(0.08É)

Nominal 10¢(0.17É)

Maximum 15¢(0.25É)

Wheel turning angle

(Full turn)Minimum 30É00¢(30.00É)

Inside

Degree minute

(Decimal degree)Nominal 33É00¢(33.00É)

Maximum 34É00¢(34.00É)

Outside

Degree minute

(Decimal degree)Minimum 28É00¢(28.00É)

Nominal 31É00¢(31.00É)

Maximum 32É00¢(32.00É)

* Fuel, radiator coolant and engine oil full.

Spare tire, jack, hand tools and mats in designated positions.

Unit: mm (in)Front brake

Pad wear limit 2.0 (0.079)

Rotor repair limit 26.0 (1.024)

Rear brake

Lining wear limit 1.5 (0.059)

Drum repair limit 296.5 (11.67)

Pedal free height 175 - 185 (6.89 - 7.28)

Pedal depressed height*1 70 (2.76)

Parking brake

Number of notches*2 6 - 8

*1 Under force of 490 N (50 kg, 110 lb) with engine running

*2 At pulling force: 196 N (20 kg, 44 lb)

Unit Liter US measure

Coolant with reservoir 9.2 9-3/4 qt

Engine*With oil filter 5.0 5-1/4 qt

Without oil filter 4.8 5-1/8 qt

Dry engine (engine overhaul) 6.8 7-1/4 qt

Transmis-

sionA/T2WD

8.5 9 qt

4WD

All-mode 4WD transfer 3.0 2-5/8 qt

Differential carrierFront 1.85 3-7/8 pt

Rear 2.8 5-7/8 pt

Power steering system 0.9 1 qt

Air conditioning systemRefrigerant 0.60 - 0.70 kg 1.32 - 1.54 lb

Compressor

oil0.20 6.8 fl oz

* For further details, see ªChanging Engine Oilº in MA section.

Preload

(At hub bolt)

N (kg, lb)Wheel bearing lock nut

78-98(8-10,58-72)

Tightening torque

N×m (kg-m, ft-lb)

Retightening torque after loosen-

ing wheel bearing lock nut

N×m (kg-m, in-lb)0.5 - 1.5 (0.05 - 0.15, 4.3 - 13.0)

Axial end play

mm (in)0 (0)

Starting force at wheel hub bolt

N (kg, lb)A

Turning angle

degree15É - 30É

Starting force at wheel hub bolt

N (kg, lb)B

Wheel bearing preload at wheel hub

bolt

B þ A N (kg, lb)7.06 - 20.99 (0.72 - 2.14, 1.59 - 4.72)

Page 1748 of 2395

PrecautionsNBGI0001Observe the following precautions to ensure safe and proper

servicing. These precautions are not described in each indi-

vidual section.

SGI646

PRECAUTIONS FOR SUPPLEMENTAL RESTRAINT

SYSTEM (SRS) ªAIR BAGº AND ªSEAT BELT

PRE-TENSIONERº

NBGI0001S01The Supplemental Restraint System such as ªAIR BAGº and ªSEAT

BELT PRE-TENSIONERº used along with a seat belt, helps to

reduce the risk or severity of injury to the driver and front passen-

ger for certain types of collision. The SRS system composition

which is available to INFINITI QX4 is as follows:

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag

module (located in the center of the steering wheel), front pas-

senger air bag module (located on the instrument panel on

passenger side), seat belt pre-tensioners, a diagnosis sensor

unit, warning lamp, wiring harness and spiral cable.

IFor a side collision

The Supplemental Restraint System consists of side air bag

module (located in the outer side of front seat), satellite sensor,

diagnosis sensor unit (one of components of air bags for a

frontal collision), wiring harness, warning lamp (one of compo-

nents of air bags for a frontal collision).

Information necessary to service the system safely is included in

theRS sectionof this Service Manual.

WARNING:

ITo avoid rendering the SRS inoperative, which could

increase the risk of personal injury or death in the event

of a collision which would result in air bag inflation, all

maintenance must be performed by an authorized INFINITI

dealer.

IImproper maintenance, including incorrect removal and

installation of the SRS, can lead to personal injury caused

by unintentional activation of the system. For removal of

Spiral Cable and Air Bag Module, see the RS section.

IDo not use electrical test equipment on any circuit related

to the SRS unless instructed to in this Service Manual.

Spiral cable and wiring harnesses covered with yellow

insulation tape either just before the harness connectors

or for the complete harness are related to the SRS.

PRECAUTIONS FOR IVIS (INFINITI VEHICLE

IMMOBILIZER SYSTEM Ð NATS)

NBGI0001S08IVIS (NATS) will immobilize the engine if someone tries to start it

without the registered key of IVIS (NATS).

Both of the originally supplied ignition key IDs have been IVIS

(NATS) registered.

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PRECAUTIONS

Precautions

GI-3

Page 1755 of 2395

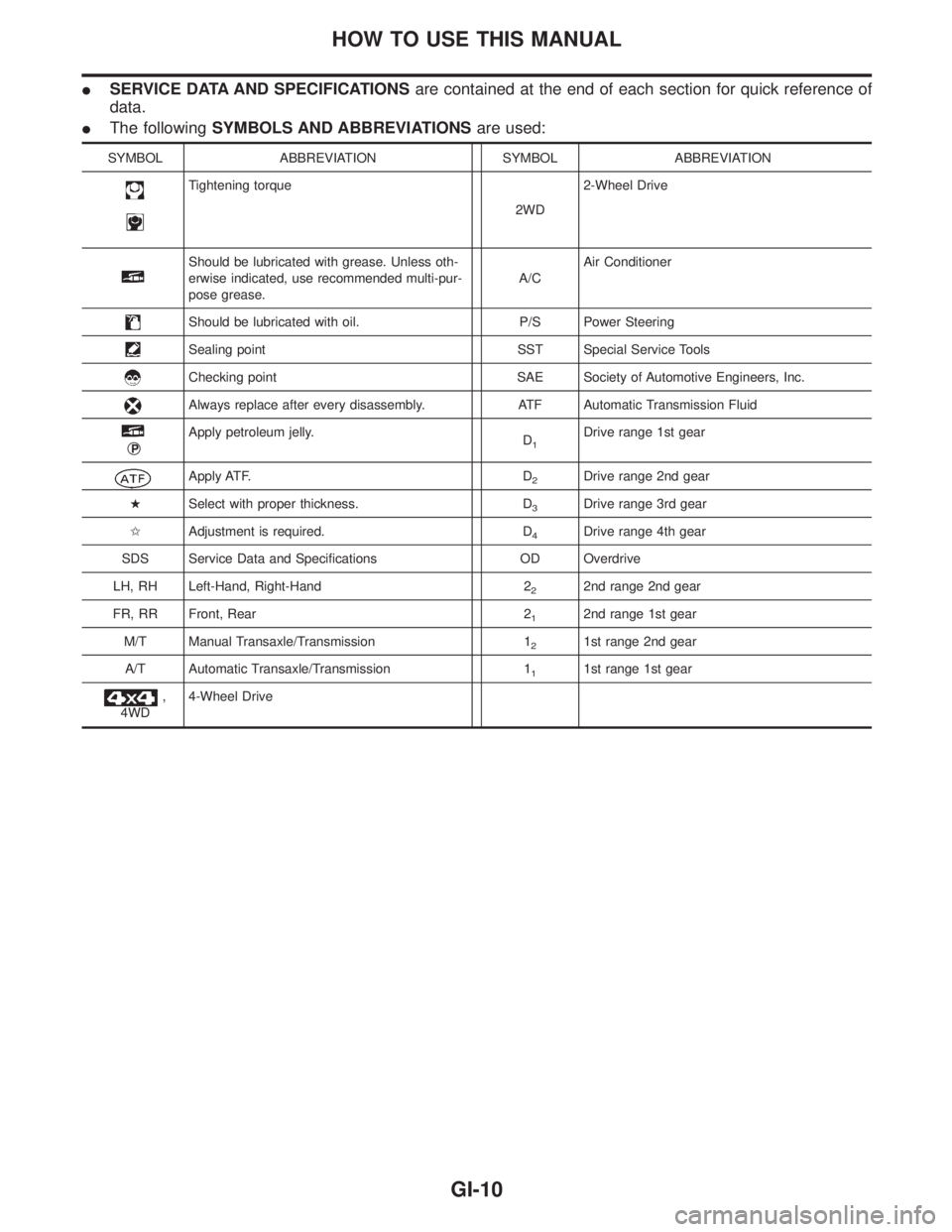

ISERVICE DATA AND SPECIFICATIONSare contained at the end of each section for quick reference of

data.

IThe followingSYMBOLS AND ABBREVIATIONSare used:

SYMBOL ABBREVIATION SYMBOL ABBREVIATION

Tightening torque

2WD2-Wheel Drive

Should be lubricated with grease. Unless oth-

erwise indicated, use recommended multi-pur-

pose grease.A/CAir Conditioner

Should be lubricated with oil. P/S Power Steering

Sealing point SST Special Service Tools

Checking point SAE Society of Automotive Engineers, Inc.

Always replace after every disassembly. ATF Automatic Transmission Fluid

qP

Apply petroleum jelly.

D1Drive range 1st gear

Apply ATF. D2Drive range 2nd gear

HSelect with proper thickness. D

3Drive range 3rd gear

IAdjustment is required. D

4Drive range 4th gear

SDS Service Data and Specifications OD Overdrive

LH, RH Left-Hand, Right-Hand 2

22nd range 2nd gear

FR, RR Front, Rear 2

12nd range 1st gear

M/T Manual Transaxle/Transmission 1

21st range 2nd gear

A/T Automatic Transaxle/Transmission 1

11st range 1st gear

,

4WD4-Wheel Drive

HOW TO USE THIS MANUAL

GI-10

Page 1792 of 2395

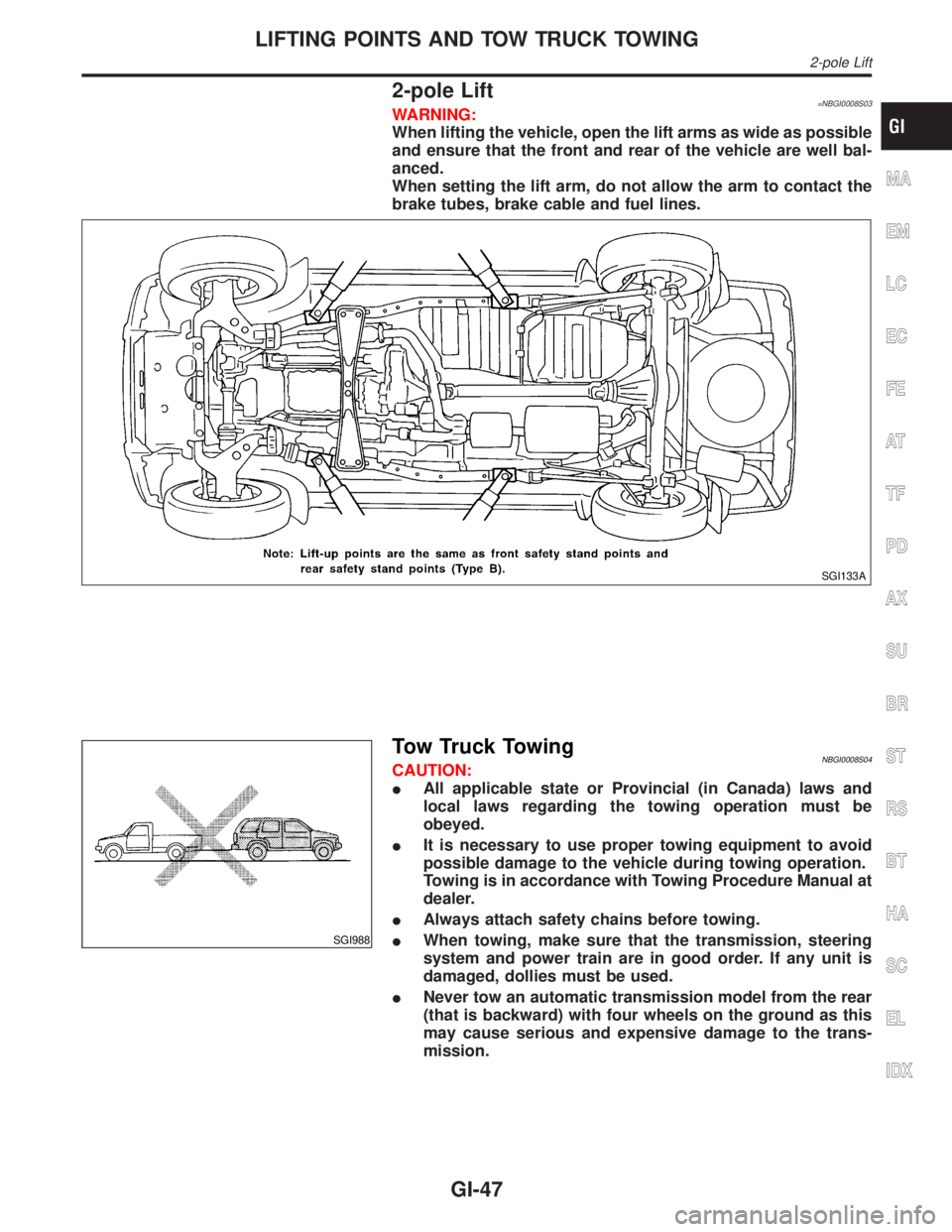

2-pole Lift=NBGI0008S03WARNING:

When lifting the vehicle, open the lift arms as wide as possible

and ensure that the front and rear of the vehicle are well bal-

anced.

When setting the lift arm, do not allow the arm to contact the

brake tubes, brake cable and fuel lines.

SGI133A

SGI988

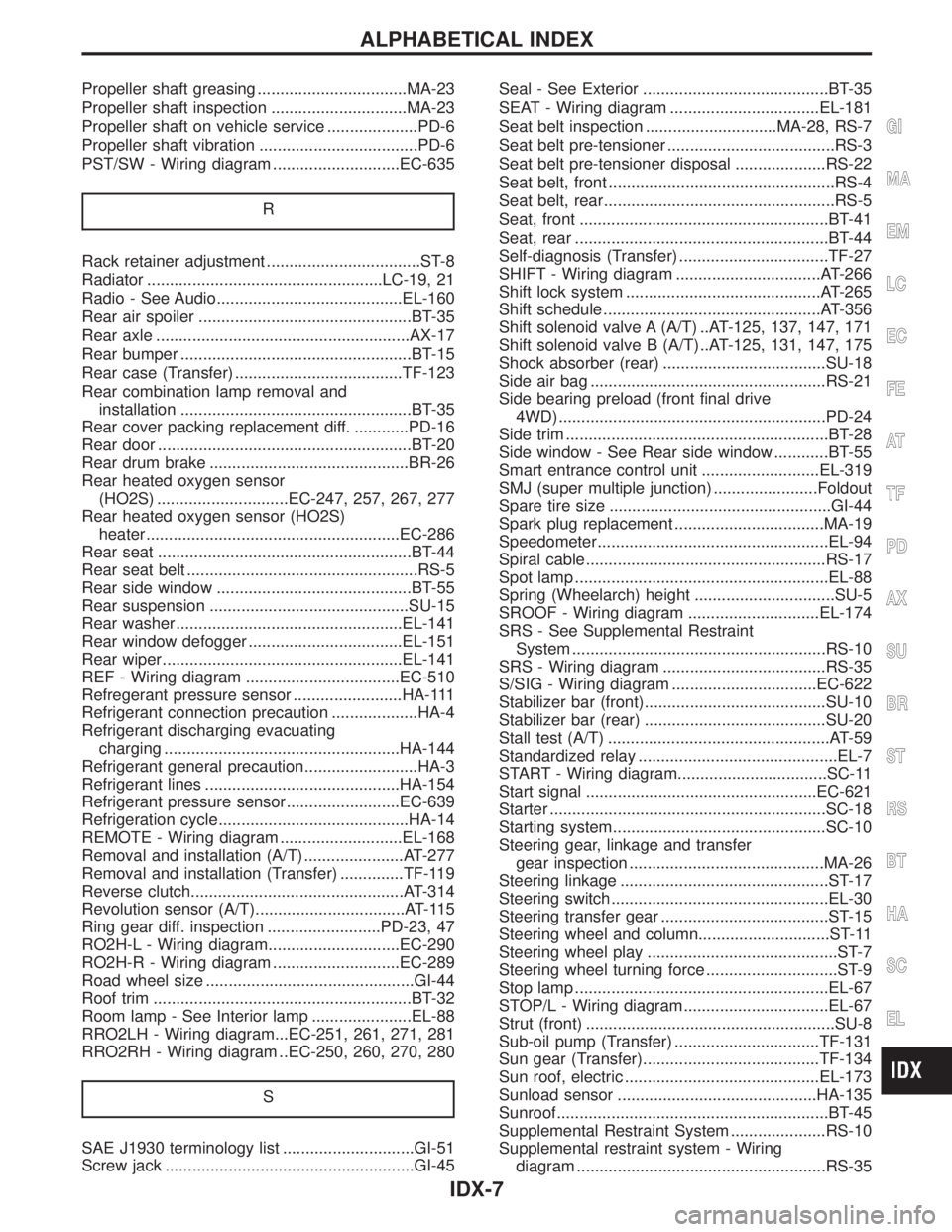

Tow Truck TowingNBGI0008S04CAUTION:

IAll applicable state or Provincial (in Canada) laws and

local laws regarding the towing operation must be

obeyed.

IIt is necessary to use proper towing equipment to avoid

possible damage to the vehicle during towing operation.

Towing is in accordance with Towing Procedure Manual at

dealer.

IAlways attach safety chains before towing.

IWhen towing, make sure that the transmission, steering

system and power train are in good order. If any unit is

damaged, dollies must be used.

INever tow an automatic transmission model from the rear

(that is backward) with four wheels on the ground as this

may cause serious and expensive damage to the trans-

mission.

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

LIFTING POINTS AND TOW TRUCK TOWING

2-pole Lift

GI-47

Page 1793 of 2395

SGI989

2WD MODELSNBGI0008S0402INFINITI recommends that vehicle be towed with the driving (rear)

wheels off the ground as illustrated.

CAUTION:

IWhen towing manual or automatic transmission models

with the front wheels on the ground: Turn the ignition key

to the OFF position and secure the steering wheel in a

straightahead position with a rope or similar device. Never

place the ignition key in the LOCK position. This will result

in damage to the steering lock mechanism.

IWhen towing manual transmission models with the rear

wheels on the ground or four wheels on the ground (if you

do not use towing dollies): Always release the parking

brake and move the transmission shift lever to the N (neu-

tral) position.

Observe the following restricted towing speeds and distances.

Manual transmission models:

ISpeed: Below 95 km/h (60 MPH)

IDistance: Less than 800 km (500 miles)

If the speed or distance must necessarily be greater, remove the

propeller shaft beforehand to prevent damage to the transmission.

SGI950

4WD MODELSNBGI0008S0403INFINITI recommends that a dolly or a flat bed truck be used as

illustrated when towing all-mode 4WD models.

LIFTING POINTS AND TOW TRUCK TOWING

Tow Truck Towing (Cont'd)

GI-48

Page 1965 of 2395

LSV (Load sensing valve) ..............................BR-12

Lubricant (R134a) A/C..................................HA-146

Lubricants .......................................................MA-11

Lubrication circuit (engine) ...............................LC-3

Lubrication-locks, hinges and hood

latches ........................................................MA-27

Luggage room lamp ........................................EL-88

M

MAFS - Wiring diagram................................EC-154

Magnet clutch .......................................HA-104, 150

MAIN - Wiring diagram.................................EC-142

Main oil pump (Transfer)...............................TF-131

Mainshaft (Transfer) ......................................TF-125

Maintenance (engine) ....................................MA-13

MAJOR OVERHALL......................................AT-281

Major overhaul (Transfer) .............................TF-120

Malfunction indicator lamp (MIL) ....................EC-74

Mass air flow sensor (MAFS) .......................EC-150

Master cylinder (brake) ..................................BR-16

Meter ...............................................................EL-94

METER - Wiring diagram................................EL-99

MIL & Data link connectors circuit ...............EC-648

MIL/DL - Wiring diagram ..............................EC-648

MIRROR - Wiring diagram............................EL-177

Mirror defogger .............................................EL-151

Mirror, door......................................................BT-56

Mirror, out side ................................................BT-56

Misfire ...........................................................EC-320

Mode door control linkage adjustment ...........HA-81

Mode door motor ............................................HA-75

Model variation ................................................GI-41

Molding - See Exterior ....................................BT-35

MULTI - Wiring diagram ................................EL-274

Multi-remote control system..........................EL-270

Multiplex communication ..............................HA-142

Multiport fuel injection (MFI) system ..............EC-28

Multiport fuel injection precautions ....................GI-6

N

NATS (Nissan anti-theft system)...................EL-328

NATS (Nissan anti-theft system)

precautions ....................................................GI-3

NATS - Wiring diagram .................................EL-330

NAVI - wiring diagram ...................................EL-394

Navigation System ........................................EL-385

Neutral-4LO switch ........................................TF-112

NVH troubleshooting (AX) ..........................AX-3, 18

NVH troubleshooting (BR)................................BR-6

NVH troubleshooting (PD)................................PD-3

NVH troubleshooting (ST).................................ST-6

NVH troubleshooting (SU) .........................SU-3, 15O

Oil change (capacity) .....................................MA-11

Oil filter (Transfer) .........................................TF-118

Oil pan (engine) .............................................EM-15

Oil pressure (engine) ........................................LC-4

Oil pump (A/T) ...............................................AT-297

Oil pump (engine) .............................................LC-5

Oil pump regulator valve (engine) ....................LC-6

Oil seal replacement (engine)........................EM-35

Oil seal replacement (front final drive

4WD) ...........................................................PD-15

Oil seal replacement (front of final

drive) ...........................................................PD-40

On board diagnostic system ..........................EC-59

Out side mirror ................................................BT-56

Overdrive control switch ................................AT-263

Overrun clutch ...............................................AT-320

Overrun clutch solenoid valve .......................AT-189

P

P/ANT - Wiring diagram ................................EL-170

Park/Neutral position switch .........................EC-604

Park/neutral position switch (A/T) .........AT-103, 263

Parking brake control .....................................BR-30

Parking lamp ...................................................EL-61

PCV (positive crankcase ventilation) .............EC-38

PGC/V - Wiring diagram ......................EC-370, 544

PHASE - Wiring diagram .............................EC-342

Pinion bearing preload diff. ............................PD-25

Pinion gear height diff. .............................PD-25, 53

Piston assembly .............................................EM-71

Piston pin inspection ......................................EM-63

Piston ring inspection.....................................EM-64

Piston to bore clearance ................................EM-66

Planetary carrier (Transfer) ...........................TF-134

PNP/SW - Wiring diagram ...........................EC-607

POS - Wiring diagram ..................................EC-517

POWER - Wiring diagram...............................EL-10

Power antenna ..............................................EL-169

Power door lock ............................................EL-254

Power door mirror .........................................EL-177

Power seat ....................................................EL-181

Power steering fluid level .....................MA-27, ST-8

Power steering gear........................................ST-17

Power steering hydraulic pressure .................ST-10

Power steering oil pressure switch ..............EC-634

Power steering oil pump .................................ST-27

Power steering system bleeding.......................ST-9

Power supply routing ........................................EL-9

Power transistor & ignition coil.....................EC-499

Power window ...............................................EL-241

PRE/SE - Wiring diagram ............................EC-384

Precations for Leak detection dye ...................HA-3

Precautions (General) .......................................GI-5

Pressure test (A/T) ..........................................AT-62

Propeller shaft ..................................................PD-3

ALPHABETICAL INDEX

IDX-6

Page 1966 of 2395

Propeller shaft greasing .................................MA-23

Propeller shaft inspection ..............................MA-23

Propeller shaft on vehicle service ....................PD-6

Propeller shaft vibration ...................................PD-6

PST/SW - Wiring diagram ............................EC-635

R

Rack retainer adjustment ..................................ST-8

Radiator ....................................................LC-19, 21

Radio - See Audio.........................................EL-160

Rear air spoiler ...............................................BT-35

Rear axle ........................................................AX-17

Rear bumper ...................................................BT-15

Rear case (Transfer) .....................................TF-123

Rear combination lamp removal and

installation ...................................................BT-35

Rear cover packing replacement diff. ............PD-16

Rear door ........................................................BT-20

Rear drum brake ............................................BR-26

Rear heated oxygen sensor

(HO2S) .............................EC-247, 257, 267, 277

Rear heated oxygen sensor (HO2S)

heater ........................................................EC-286

Rear seat ........................................................BT-44

Rear seat belt ...................................................RS-5

Rear side window ...........................................BT-55

Rear suspension ............................................SU-15

Rear washer..................................................EL-141

Rear window defogger ..................................EL-151

Rear wiper.....................................................EL-141

REF - Wiring diagram ..................................EC-510

Refregerant pressure sensor ........................HA-111

Refrigerant connection precaution ...................HA-4

Refrigerant discharging evacuating

charging ....................................................HA-144

Refrigerant general precaution.........................HA-3

Refrigerant lines ...........................................HA-154

Refrigerant pressure sensor.........................EC-639

Refrigeration cycle..........................................HA-14

REMOTE - Wiring diagram ...........................EL-168

Removal and installation (A/T) ......................AT-277

Removal and installation (Transfer) ..............TF-119

Reverse clutch...............................................AT-314

Revolution sensor (A/T).................................AT-115

Ring gear diff. inspection .........................PD-23, 47

RO2H-L - Wiring diagram.............................EC-290

RO2H-R - Wiring diagram ............................EC-289

Road wheel size ..............................................GI-44

Roof trim .........................................................BT-32

Room lamp - See Interior lamp ......................EL-88

RRO2LH - Wiring diagram...EC-251, 261, 271, 281

RRO2RH - Wiring diagram ..EC-250, 260, 270, 280

S

SAE J1930 terminology list .............................GI-51

Screw jack .......................................................GI-45Seal - See Exterior .........................................BT-35

SEAT - Wiring diagram .................................EL-181

Seat belt inspection .............................MA-28, RS-7

Seat belt pre-tensioner .....................................RS-3

Seat belt pre-tensioner disposal ....................RS-22

Seat belt, front ..................................................RS-4

Seat belt, rear...................................................RS-5

Seat, front .......................................................BT-41

Seat, rear ........................................................BT-44

Self-diagnosis (Transfer) .................................TF-27

SHIFT - Wiring diagram ................................AT-266

Shift lock system ...........................................AT-265

Shift schedule ................................................AT-356

Shift solenoid valve A (A/T) ..AT-125, 137, 147, 171

Shift solenoid valve B (A/T) ..AT-125, 131, 147, 175

Shock absorber (rear) ....................................SU-18

Side air bag ....................................................RS-21

Side bearing preload (front final drive

4WD) ...........................................................PD-24

Side trim ..........................................................BT-28

Side window - See Rear side window ............BT-55

Smart entrance control unit ..........................EL-319

SMJ (super multiple junction) .......................Foldout

Spare tire size .................................................GI-44

Spark plug replacement .................................MA-19

Speedometer...................................................EL-94

Spiral cable.....................................................RS-17

Spot lamp ........................................................EL-88

Spring (Wheelarch) height ...............................SU-5

SROOF - Wiring diagram .............................EL-174

SRS - See Supplemental Restraint

System ........................................................RS-10

SRS - Wiring diagram ....................................RS-35

S/SIG - Wiring diagram ................................EC-622

Stabilizer bar (front)........................................SU-10

Stabilizer bar (rear) ........................................SU-20

Stall test (A/T) .................................................AT-59

Standardized relay ............................................EL-7

START - Wiring diagram.................................SC-11

Start signal ...................................................EC-621

Starter .............................................................SC-18

Starting system...............................................SC-10

Steering gear, linkage and transfer

gear inspection ...........................................MA-26

Steering linkage ..............................................ST-17

Steering switch................................................EL-30

Steering transfer gear .....................................ST-15

Steering wheel and column.............................ST-11

Steering wheel play ..........................................ST-7

Steering wheel turning force .............................ST-9

Stop lamp ........................................................EL-67

STOP/L - Wiring diagram................................EL-67

Strut (front) .......................................................SU-8

Sub-oil pump (Transfer) ................................TF-131

Sun gear (Transfer).......................................TF-134

Sun roof, electric ...........................................EL-173

Sunload sensor ............................................HA-135

Sunroof............................................................BT-45

Supplemental Restraint System .....................RS-10

Supplemental restraint system - Wiring

diagram .......................................................RS-35

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

ALPHABETICAL INDEX

IDX-7

Page 1996 of 2395

MAINTENANCE

SECTION

MA

CONTENTS

PRECAUTIONS...............................................................2

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...............2

PREPARATION...............................................................3

Special Service Tool ....................................................3

Commercial Service Tool .............................................3

GENERAL MAINTENANCE............................................4

PERIODIC MAINTENANCE............................................6

Schedule 1 ...................................................................7

EMISSION CONTROL SYSTEM MAINTENANCE.........7

CHASSIS AND BODY MAINTENANCE........................8

Schedule 2 ...................................................................9

EMISSION CONTROL SYSTEM MAINTENANCE.........9

CHASSIS AND BODY MAINTENANCE......................10

RECOMMENDED FLUIDS AND LUBRICANTS........... 11

Fluids and Lubricants ................................................ 11

SAE Viscosity Number ..............................................12

GASOLINE ENGINE OIL..........................................12

GEAR OIL...............................................................12

Anti-freeze Coolant Mixture Ratio .............................12

ENGINE MAINTENANCE..............................................13

Checking Drive Belts .................................................13

Changing Engine Coolant..........................................14

-DRAINING ENGINE COOLANT-..............................14

-REFILLING ENGINE COOLANT-..............................15

-FLUSHING COOLING SYSTEM-..............................16

Checking Fuel Lines ..................................................16

Changing Fuel Filter ..................................................16

WITH CONSULT-II..............................................16

WITHOUT CONSULT-II.......................................17

Changing Air Cleaner Filter .......................................17

VISCOUS PAPER TYPE...........................................17

Changing Engine Oil..................................................18

Changing Oil Filter .....................................................18

Changing Spark Plugs ...............................................19

Checking EVAP Vapor Lines .....................................20

CHASSIS AND BODY MAINTENANCE.......................21

Checking Exhaust System.........................................21

Checking A/T Fluid ....................................................21

Changing A/T Fluid ....................................................21Checking All-mode 4WD Transfer Fluid ....................22

Changing All-mode 4WD Transfer Fluid ....................22

Checking Propeller Shaft ...........................................23

Greasing Propeller Shaft ...........................................23

Checking Differential Gear Oil ...................................23

Changing Differential Gear Oil ..................................24

LIMITED-SLIP DIFFERENTIAL GEAR........................24

Balancing Wheels ......................................................24

Tire Rotation ..............................................................24

Checking Brake Fluid Level and Leaks.....................25

Checking Brake Lines and Cables ............................25

Checking Disc Brake .................................................25

ROTOR...................................................................25

CALIPER.................................................................25

PAD........................................................................25

Checking Drum Brake ...............................................26

WHEEL CYLINDER..................................................26

DRUM.....................................................................26

LINING....................................................................26

TEMPORARY METHOD FOR CHECKING LINING

WEAR

.....................................................................26

Checking Steering Gear, Linkage and Transfer

Gear ...........................................................................26

STEERING GEAR....................................................26

STEERING LINKAGE...............................................26

STEERING TRANSFER GEAR..................................26

Checking Power Steering Fluid and Lines ................27

CHECKING FLUID LEVEL........................................27

CHECKING LINES...................................................27

Lubricating Locks, Hinges and Hood Latches...........27

Checking Seat Belts, Buckles, Retractors,

Anchors and Adjusters...............................................28

SERVICE DATA AND SPECIFICATIONS (SDS).........29

Engine Maintenance ..................................................29

DRIVE BELT DEFLECTION......................................29

DRIVE BELT TENSION............................................29

SPARK PLUG TYPE................................................29

Chassis and Body Maintenance ................................29

WHEEL BALANCE...................................................29

GI

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX