engine INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1745 of 2395

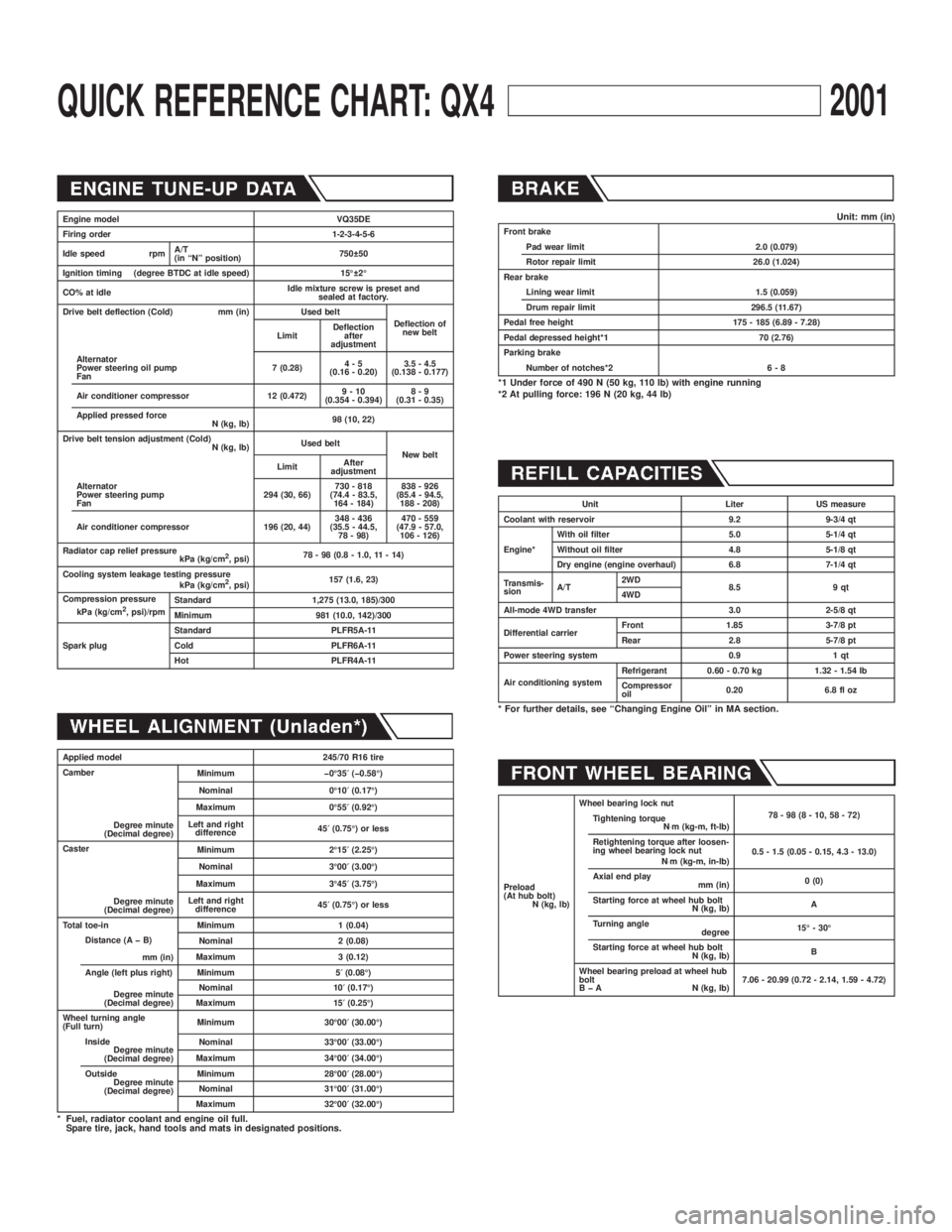

QUICK REFERENCE CHART: QX42001

Engine model VQ35DE

Firing order 1-2-3-4-5-6

Idle speed rpmA/T

(in ªNº position)750 50

Ignition timing (degree BTDC at idle speed) 15É 2É

CO% at idleIdle mixture screw is preset and

sealed at factory.

Drive belt deflection (Cold) mm (in) Used belt

Deflection of

new belt

LimitDeflection

after

adjustment

Alternator

Power steering oil pump

Fan7 (0.28)4-5

(0.16 - 0.20)3.5 - 4.5

(0.138 - 0.177)

Air conditioner compressor 12 (0.472)9-10

(0.354 - 0.394)8-9

(0.31 - 0.35)

Applied pressed force

N (kg, lb)98 (10, 22)

Drive belt tension adjustment (Cold)

N (kg, lb)Used belt

New belt

LimitAfter

adjustment

Alternator

Power steering pump

Fan294 (30, 66)730 - 818

(74.4 - 83.5,

164 - 184)838 - 926

(85.4 - 94.5,

188 - 208)

Air conditioner compressor 196 (20, 44)348 - 436

(35.5 - 44.5,

78 - 98)470 - 559

(47.9 - 57.0,

106 - 126)

Radiator cap relief pressure

kPa (kg/cm

2, psi)78 - 98 (0.8 - 1.0, 11 - 14)

Cooling system leakage testing pressure

kPa (kg/cm

2, psi)157 (1.6, 23)

Compression pressure

kPa (kg/cm

2, psi)/rpmStandard 1,275 (13.0, 185)/300

Minimum 981 (10.0, 142)/300

Spark plugStandard PLFR5A-11

Cold PLFR6A-11

Hot PLFR4A-11

Applied model 245/70 R16 tire

Camber

Degree minute

(Decimal degree)Minimum þ0É35¢(þ0.58É)

Nominal 0É10¢(0.17É)

Maximum 0É55¢(0.92É)

Left and right

difference45¢(0.75É) or less

Caster

Degree minute

(Decimal degree)Minimum 2É15¢(2.25É)

Nominal 3É00¢(3.00É)

Maximum 3É45¢(3.75É)

Left and right

difference45¢(0.75É) or less

Total toe-in Minimum 1 (0.04)

Distance (A þ B)

mm (in)Nominal 2 (0.08)

Maximum 3 (0.12)

Angle (left plus right)

Degree minute

(Decimal degree)Minimum 5¢(0.08É)

Nominal 10¢(0.17É)

Maximum 15¢(0.25É)

Wheel turning angle

(Full turn)Minimum 30É00¢(30.00É)

Inside

Degree minute

(Decimal degree)Nominal 33É00¢(33.00É)

Maximum 34É00¢(34.00É)

Outside

Degree minute

(Decimal degree)Minimum 28É00¢(28.00É)

Nominal 31É00¢(31.00É)

Maximum 32É00¢(32.00É)

* Fuel, radiator coolant and engine oil full.

Spare tire, jack, hand tools and mats in designated positions.

Unit: mm (in)Front brake

Pad wear limit 2.0 (0.079)

Rotor repair limit 26.0 (1.024)

Rear brake

Lining wear limit 1.5 (0.059)

Drum repair limit 296.5 (11.67)

Pedal free height 175 - 185 (6.89 - 7.28)

Pedal depressed height*1 70 (2.76)

Parking brake

Number of notches*2 6 - 8

*1 Under force of 490 N (50 kg, 110 lb) with engine running

*2 At pulling force: 196 N (20 kg, 44 lb)

Unit Liter US measure

Coolant with reservoir 9.2 9-3/4 qt

Engine*With oil filter 5.0 5-1/4 qt

Without oil filter 4.8 5-1/8 qt

Dry engine (engine overhaul) 6.8 7-1/4 qt

Transmis-

sionA/T2WD

8.5 9 qt

4WD

All-mode 4WD transfer 3.0 2-5/8 qt

Differential carrierFront 1.85 3-7/8 pt

Rear 2.8 5-7/8 pt

Power steering system 0.9 1 qt

Air conditioning systemRefrigerant 0.60 - 0.70 kg 1.32 - 1.54 lb

Compressor

oil0.20 6.8 fl oz

* For further details, see ªChanging Engine Oilº in MA section.

Preload

(At hub bolt)

N (kg, lb)Wheel bearing lock nut

78-98(8-10,58-72)

Tightening torque

N×m (kg-m, ft-lb)

Retightening torque after loosen-

ing wheel bearing lock nut

N×m (kg-m, in-lb)0.5 - 1.5 (0.05 - 0.15, 4.3 - 13.0)

Axial end play

mm (in)0 (0)

Starting force at wheel hub bolt

N (kg, lb)A

Turning angle

degree15É - 30É

Starting force at wheel hub bolt

N (kg, lb)B

Wheel bearing preload at wheel hub

bolt

B þ A N (kg, lb)7.06 - 20.99 (0.72 - 2.14, 1.59 - 4.72)

Page 1746 of 2395

GENERAL INFORMATION

SECTION

GI

CONTENTS

PRECAUTIONS...............................................................3

Precautions ..................................................................3

PRECAUTIONS FOR SUPPLEMENTAL

RESTRAINT SYSTEM (SRS)²AIR BAG²AND

²SEAT BELT PRE-TENSIONER²

.................................3

PRECAUTIONS FOR IVIS (INFINITI VEHICLE

IMMOBILIZER SYSTEM - NATS)

.................................3

PRECAUTIONS FOR INFINITI COMMUNICATOR

(IVCS)

.......................................................................4

GENERAL PRECAUTIONS.........................................5

PRECAUTIONS FOR MULTIPORT FUEL

INJECTION SYSTEM OR ENGINE CONTROL

SYSTEM

...................................................................6

PRECAUTIONS FOR THREE WAY CATALYST...........6

PRECAUTIONS FOR HOSES.....................................7

PRECAUTIONS FOR ENGINE OILS...........................8

PRECAUTIONS FOR FUEL........................................8

PRECAUTIONS FOR AIR CONDITIONING..................8

HOW TO USE THIS MANUAL........................................9

HOW TO READ WIRING DIAGRAMS.......................... 11

Sample/Wiring Diagram - EXAMPL - ........................ 11

OPTIONAL SPLICE..................................................12

Description .................................................................13

CONNECTOR SYMBOLS.........................................15

HARNESS INDICATION...........................................16

COMPONENT INDICATION......................................16

SWITCH POSITIONS...............................................16

DETECTABLE LINES AND NON-DETECTABLE

LINES

.....................................................................17

MULTIPLE SWITCH.................................................18

REFERENCE AREA.................................................19

HOW TO CHECK TERMINAL.......................................21

Connector and Terminal Pin Kit.................................21

How to Probe Connectors .........................................21

PROBING FROM HARNESS SIDE............................21

PROBING FROM TERMINAL SIDE...........................21

How to Check Enlarged Contact Spring of

Terminal .....................................................................22

Waterproof Connector Inspection ..............................23

RUBBER SEAL INSPECTION...................................23

WIRE SEAL INSPECTION........................................23Terminal Lock Inspection ...........................................23

HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT...............................24

Work Flow ..................................................................24

Incident Simulation Tests ...........................................25

INTRODUCTION......................................................25

VEHICLE VIBRATION..............................................25

HEAT SENSITIVE....................................................26

FREEZING..............................................................26

WATER INTRUSION................................................27

ELECTRICAL LOAD.................................................27

COLD OR HOT START UP.......................................27

Circuit Inspection .......................................................27

INTRODUCTION......................................................27

TESTING FOR²OPENS²IN THE CIRCUIT................28

TESTING FOR²SHORTS²IN THE CIRCUIT..............29

GROUND INSPECTION...........................................30

VOLTAGE DROP TESTS..........................................30

CONTROL UNIT CIRCUIT TEST...............................32

HOW TO FOLLOW TROUBLE DIAGNOSIS................34

How to Follow Test Groups in Trouble Diagnosis .....35

Key to Symbols Signifying Measurements or

Procedures.................................................................36

CONSULT-II CHECKING SYSTEM...............................38

Function and System Application ..............................38

Nickel Metal Hydride Battery Replacement...............39

Checking Equipment..................................................39

CONSULT-II Data Link Connector (DLC) Circuit ......40

INSPECTION PROCEDURE.....................................40

IDENTIFICATION INFORMATION................................41

Model Variation ..........................................................41

PREFIX AND SUFFIX DESIGNATIONS.....................41

Identification Number .................................................41

VEHICLE IDENTIFICATION NUMBER

ARRANGEMENT

.....................................................42

IDENTIFICATION PLATE..........................................42

ENGINE SERIAL NUMBER.......................................43

AUTOMATIC TRANSMISSION NUMBER...................43

TRANSFER SERIAL NUMBER..................................43

Dimensions ................................................................43

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

Page 1748 of 2395

PrecautionsNBGI0001Observe the following precautions to ensure safe and proper

servicing. These precautions are not described in each indi-

vidual section.

SGI646

PRECAUTIONS FOR SUPPLEMENTAL RESTRAINT

SYSTEM (SRS) ªAIR BAGº AND ªSEAT BELT

PRE-TENSIONERº

NBGI0001S01The Supplemental Restraint System such as ªAIR BAGº and ªSEAT

BELT PRE-TENSIONERº used along with a seat belt, helps to

reduce the risk or severity of injury to the driver and front passen-

ger for certain types of collision. The SRS system composition

which is available to INFINITI QX4 is as follows:

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag

module (located in the center of the steering wheel), front pas-

senger air bag module (located on the instrument panel on

passenger side), seat belt pre-tensioners, a diagnosis sensor

unit, warning lamp, wiring harness and spiral cable.

IFor a side collision

The Supplemental Restraint System consists of side air bag

module (located in the outer side of front seat), satellite sensor,

diagnosis sensor unit (one of components of air bags for a

frontal collision), wiring harness, warning lamp (one of compo-

nents of air bags for a frontal collision).

Information necessary to service the system safely is included in

theRS sectionof this Service Manual.

WARNING:

ITo avoid rendering the SRS inoperative, which could

increase the risk of personal injury or death in the event

of a collision which would result in air bag inflation, all

maintenance must be performed by an authorized INFINITI

dealer.

IImproper maintenance, including incorrect removal and

installation of the SRS, can lead to personal injury caused

by unintentional activation of the system. For removal of

Spiral Cable and Air Bag Module, see the RS section.

IDo not use electrical test equipment on any circuit related

to the SRS unless instructed to in this Service Manual.

Spiral cable and wiring harnesses covered with yellow

insulation tape either just before the harness connectors

or for the complete harness are related to the SRS.

PRECAUTIONS FOR IVIS (INFINITI VEHICLE

IMMOBILIZER SYSTEM Ð NATS)

NBGI0001S08IVIS (NATS) will immobilize the engine if someone tries to start it

without the registered key of IVIS (NATS).

Both of the originally supplied ignition key IDs have been IVIS

(NATS) registered.

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PRECAUTIONS

Precautions

GI-3

Page 1749 of 2395

The security indicator is located on the instrument panel. The indi-

cator blinks when the ignition switch is in OFF or ACC position.

Therefore, IVIS (NATS) warns outsiders that the vehicle is

equipped with the anti-theft system.

IWhen IVIS (NATS) detects trouble, the security indicator lamp

lights up while ignition switch is in ON position.

This lighting up indicates that the anti-theft is not functioning,

so prompt service is required.

IWhen servicing IVIS (NATS) (trouble diagnoses, system initial-

ization and additional registration of other IVIS (NATS) ignition

key IDs), CONSULT-II hardware and CONSULT-II IVIS (NATS)

software is necessary.

Regarding the procedures of IVIS (NATS) initialization and

IVIS (NATS) ignition key ID registration, refer to CONSULT-II

operation manual, IVIS/NVIS.

Therefore, CONSULT-II IVIS (NATS) software (program card

and operation manual) must be kept strictly confidential to

maintain the integrity of the anti-theft function.

IWhen servicing IVIS (NATS) (trouble diagnoses, system initial-

ization and additional registration of other IVIS (NATS) ignition

key IDs), it may be necessary to re-register original key iden-

tification. Therefore, be sure to receive all keys from vehicle

owner.

A maximum of five key IDs can be registered into IVIS (NATS).

IWhen failing to start the engine first time using the key of IVIS

(NATS) (for example, when interference is caused by another

IVIS (NATS) key, an automated full road device or automated

payment device on the key ring), restart as follows.

a) Leave the ignition switch in ON position for approximately 5

seconds.

b) Turn ignition switch to OFF or LOCK position and wait approxi-

mately 5 seconds.

c) Repeat step 1 and 2.

d) Restart the engine while holding the device (which may have

caused the interference) separate from the registered NATS

key. If the no start condition re-occurs, NISSAN recommends

placing the registered IVIS (NATS) key on a separate key ring

to avoid interference from other devices.

PRECAUTIONS FOR INFINITI COMMUNICATOR (IVCS)NBGI0001S09The purpose of INFINITI Communicator is to increase security for

the vehicle owner by providing a convenient way to contact the

most appropriate emergency assistance provider during an emer-

gency.

Improper operation of the system may result in a police response.

The theft warning system also activates INFINITI Communicator.

For details, refer to INFINITI Communicator (IVCS) in the EL sec-

tion.

PRECAUTIONS

Precautions (Cont'd)

GI-4

Page 1750 of 2395

SGI285

GENERAL PRECAUTIONSNBGI0001S02IDo not operate the engine for an extended period of time

without proper exhaust ventilation.

Keep the work area well ventilated and free of any inflammable

materials. Special care should be taken when handling any

inflammable or poisonous materials, such as gasoline, refrig-

erant gas, etc. When working in a pit or other enclosed area,

be sure to properly ventilate the area before working with haz-

ardous materials.

Do not smoke while working on the vehicle.

SGI231

IBefore jacking up the vehicle, apply wheel chocks or other tire

blocks to the wheels to prevent the vehicle from moving. After

jacking up the vehicle, support the vehicle weight with safety

stands at the points designated for proper lifting before work-

ing on the vehicle.

These operations should be done on a level surface.

IWhen removing a heavy component such as the engine or

transaxle/transmission, be careful not to lose your balance and

drop it. Also, do not allow it to strike adjacent parts, especially

the brake tubes and master cylinder.

SEF289H

IBefore starting repairs which do not require battery power:

Turn off ignition switch.

Disconnect the negative battery terminal.

SGI233

ITo prevent serious burns:

Avoid contact with hot metal parts.

Do not remove the radiator cap when the engine is hot.

SGI234

IBefore servicing the vehicle:

Protect fenders, upholstery and carpeting with appropriate cov-

ers.

Take caution that keys, buckles or buttons do not scratch paint.

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PRECAUTIONS

Precautions (Cont'd)

GI-5

Page 1751 of 2395

IClean all disassembled parts in the designated liquid or solvent

prior to inspection or assembly.

IReplace oil seals, gaskets, packings, O-rings, locking washers,

cotter pins, self-locking nuts, etc. with new ones.

IReplace inner and outer races of tapered roller bearings and

needle bearings as a set.

IArrange the disassembled parts in accordance with their

assembled locations and sequence.

IDo not touch the terminals of electrical components which use

microcomputers (such as ECMs).

Static electricity may damage internal electronic components.

IAfter disconnecting vacuum or air hoses, attach a tag to indi-

cate the proper connection.

IUse only the fluids and lubricants specified in this manual.

IUse approved bonding agent, sealants or their equivalents

when required.

IUse tools and recommended special tools where specified for

safe and efficient service repairs.

IWhen repairing the fuel, oil, water, vacuum or exhaust

systems, check all affected lines for leaks.

IDispose of drained oil or the solvent used for cleaning parts in

an appropriate manner.

WARNING:

To prevent ECM from storing the diagnostic trouble codes, do

not carelessly disconnect the harness connectors which are

related to the engine control system and TCM (Transmission

Control Module) system. The connectors should be discon-

nected only when working according to the WORK FLOW of

TROUBLE DIAGNOSES in EC and AT sections.

SGI787

PRECAUTIONS FOR MULTIPORT FUEL INJECTION

SYSTEM OR ENGINE CONTROL SYSTEM

NBGI0001S03IBefore connecting or disconnecting any harness connector for

the multiport fuel injection system or ECM (Engine Control

Module):

Turn ignition switch to OFF position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

IBefore disconnecting pressurized fuel line from fuel pump to

injectors, be sure to release fuel pressure.

IBe careful not to jar components such as ECM and mass air

flow sensor.

PRECAUTIONS FOR THREE WAY CATALYSTNBGI0001S04If a large amount of unburned fuel flows into the catalyst, the cata-

lyst temperature will be excessively high. To prevent this, follow the

instructions below:

IUse unleaded gasoline only. Leaded gasoline will seriously

damage the three way catalyst.

IWhen checking for ignition spark or measuring engine

compression, make tests quickly and only when necessary.

IDo not run engine when the fuel tank level is low, otherwise the

engine may misfire causing damage to the catalyst.

PRECAUTIONS

Precautions (Cont'd)

GI-6

Page 1753 of 2395

PRECAUTIONS FOR ENGINE OILSNBGI0001S05Prolonged and repeated contact with used engine oil may cause

skin cancer. Try to avoid direct skin contact with used oil.

If skin contact is made, wash thoroughly with soap or hand cleaner

as soon as possible.

Health Protection PrecautionsNBGI0001S0501IAvoid prolonged and repeated contact with oils, particularly

used engine oils.

IWear protective clothing, including impervious gloves where

practicable.

IDo not put oily rags in pockets.

IAvoid contaminating clothes, particularly underpants, with oil.

IHeavily soiled clothing and oil-impregnated footwear should

not be worn. Overalls must be cleaned regularly.

IFirst Aid treatment should be obtained immediately for open

cuts and wounds.

IUse barrier creams, applying them before each work period, to

help the removal of oil from the skin.

IWash with soap and water to ensure all oil is removed (skin

cleansers and nail brushes will help). Preparations containing

lanolin replace the natural skin oils which have been removed.

IDo not use gasoline, kerosine, diesel fuel, gas oil, thinners or

solvents for cleaning skin.

IIf skin disorders develop, obtain medical advice without delay.

IWhere practicable, degrease components prior to handling.

IWhere there is a risk of eye contact, eye protection should be

worn, for example, chemical goggles or face shields; in addi-

tion an eye wash facility should be provided.

Environmental Protection PrecautionsNBGI0001S0502Burning used engine oil in small space heaters or boilers can be

recommended only for units of approved design. The heating sys-

tem must meet the requirements of HM Inspectorate of Pollution for

small burners of less than 0.4 MW. If in doubt check with the

appropriate local authority and/or manufacturer of the approved

appliance.

Dispose of used oil and used oil filters through authorized waste

disposal contractors to licensed waste disposal sites, or to the

waste oil reclamation trade. If in doubt, contact the local authority

for advice on disposal facilities.

It is illegal to pour used oil on to the ground, down sewers or drains,

or into water courses.

The regulations concerning pollution vary between regions.

PRECAUTIONS FOR FUELNBGI0001S06Use unleaded gasoline with an octane rating of at least 87 AKI

(Anti-Knock Index) number (research octane number 91).

CAUTION:

Do not use leaded gasoline. Using leaded gasoline will dam-

age the three way catalyst.

Using a fuel other than that specified could adversely affect

the emission control devices and systems, and could also

affect the warranty coverage validity.

PRECAUTIONS FOR AIR CONDITIONINGNBGI0001S07Use an approved refrigerant recovery unit any time the air condi-

tioning system must be discharged. Refer to HA-144, ªHFC-134a

(R-134a) Service Procedureº for specific instructions.

PRECAUTIONS

Precautions (Cont'd)

GI-8

Page 1755 of 2395

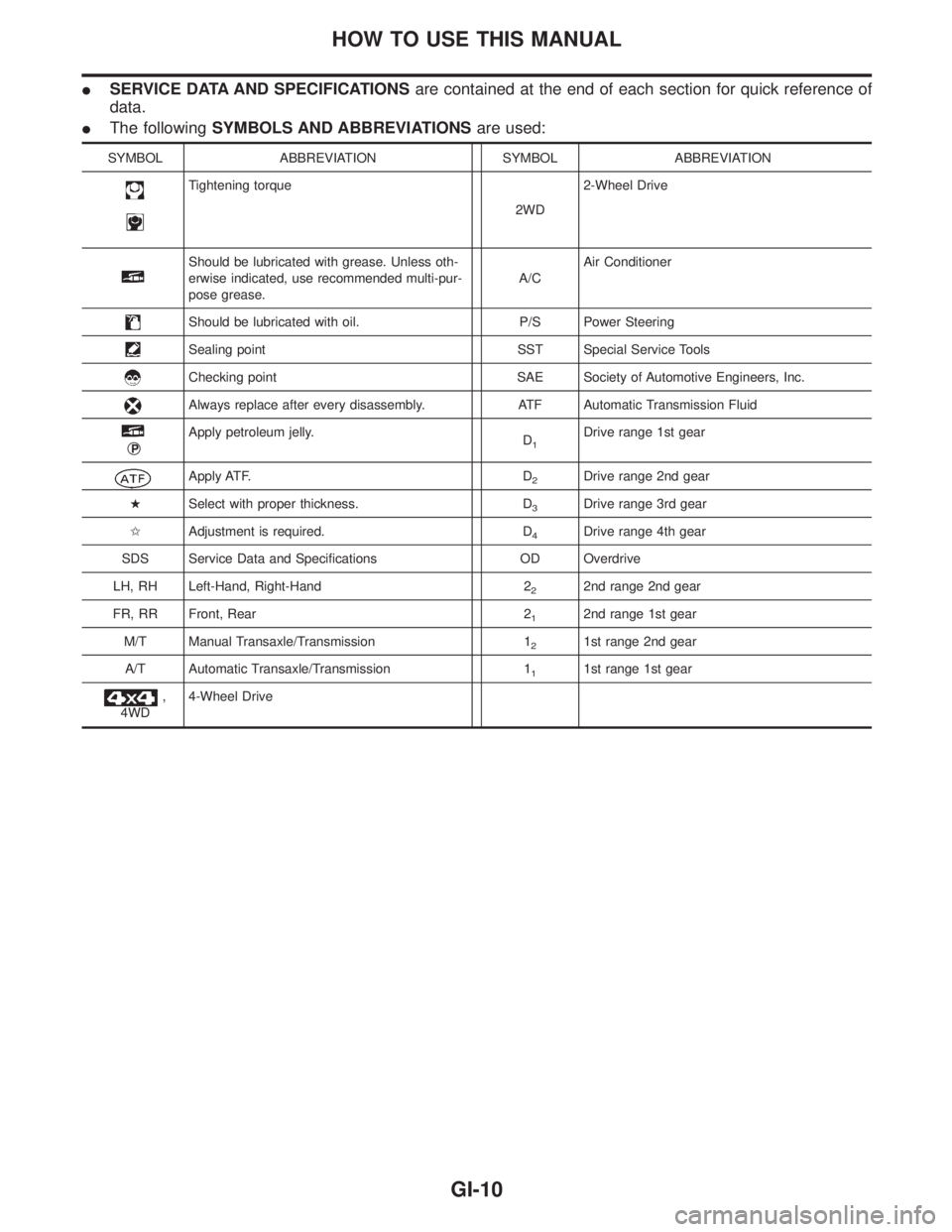

ISERVICE DATA AND SPECIFICATIONSare contained at the end of each section for quick reference of

data.

IThe followingSYMBOLS AND ABBREVIATIONSare used:

SYMBOL ABBREVIATION SYMBOL ABBREVIATION

Tightening torque

2WD2-Wheel Drive

Should be lubricated with grease. Unless oth-

erwise indicated, use recommended multi-pur-

pose grease.A/CAir Conditioner

Should be lubricated with oil. P/S Power Steering

Sealing point SST Special Service Tools

Checking point SAE Society of Automotive Engineers, Inc.

Always replace after every disassembly. ATF Automatic Transmission Fluid

qP

Apply petroleum jelly.

D1Drive range 1st gear

Apply ATF. D2Drive range 2nd gear

HSelect with proper thickness. D

3Drive range 3rd gear

IAdjustment is required. D

4Drive range 4th gear

SDS Service Data and Specifications OD Overdrive

LH, RH Left-Hand, Right-Hand 2

22nd range 2nd gear

FR, RR Front, Rear 2

12nd range 1st gear

M/T Manual Transaxle/Transmission 1

21st range 2nd gear

A/T Automatic Transaxle/Transmission 1

11st range 1st gear

,

4WD4-Wheel Drive

HOW TO USE THIS MANUAL

GI-10

Page 1762 of 2395

SGI862-A

DETECTABLE LINES AND NON-DETECTABLE LINESNBGI0003S0203In some wiring diagrams, two kinds of lines, representing wires,

with different weight are used.

IA line with regular weight (wider line) represents a ªdetectable

line for DTC (Diagnostic Trouble Code)º. A ªdetectable line for

DTCº is a circuit in which ECM (Engine Control Module) can

detect its malfunctions with the on board diagnostic system.

IA line with less weight (thinner line) represents a ªnon-detect-

able line for DTCº. A ªnon-detectable line for DTCº is a circuit

in which ECM cannot detect its malfunctions with the on board

diagnostic system.

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

HOW TO READ WIRING DIAGRAMS

Description (Cont'd)

GI-17

Page 1769 of 2395

NBGI0004

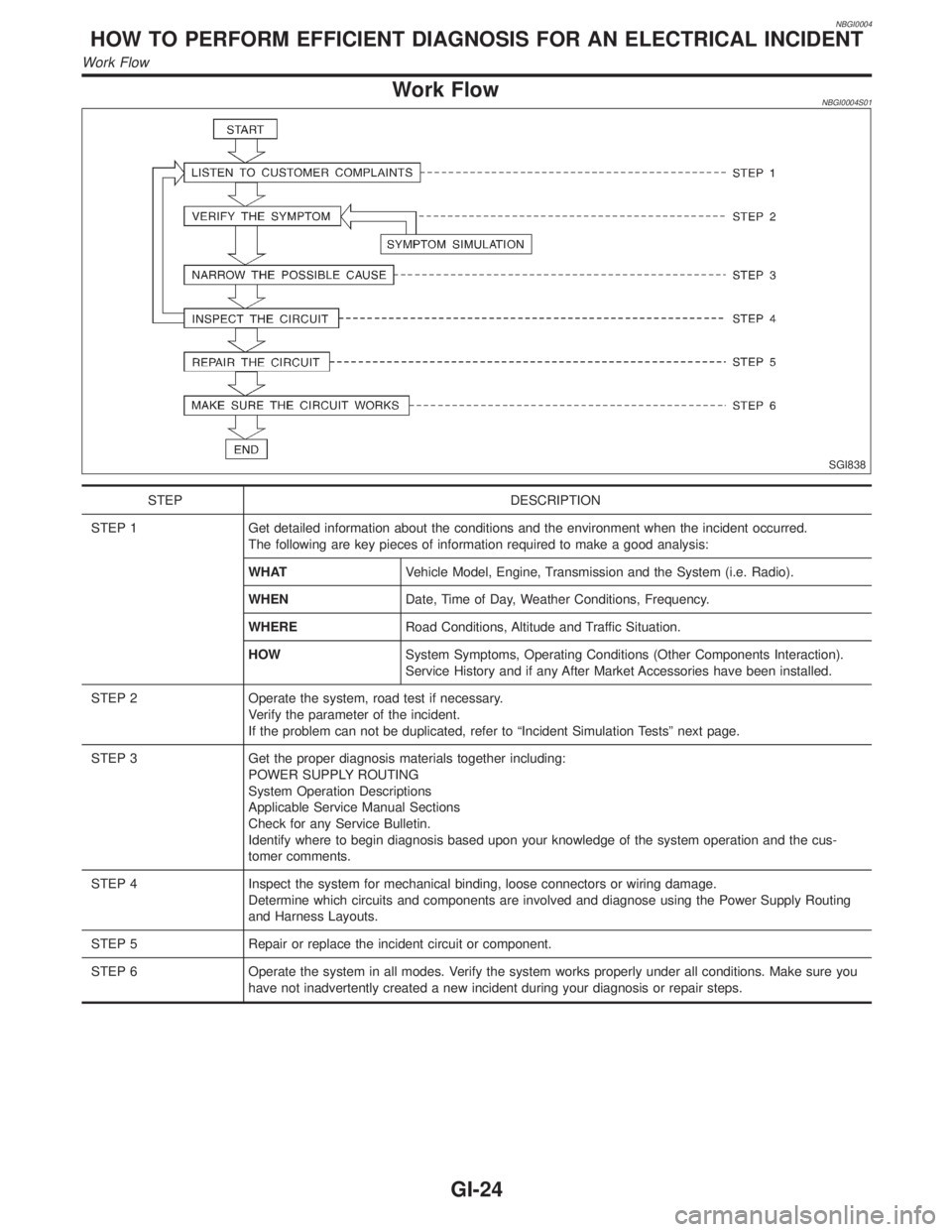

Work FlowNBGI0004S01

SGI838

STEP DESCRIPTION

STEP 1 Get detailed information about the conditions and the environment when the incident occurred.

The following are key pieces of information required to make a good analysis:

WHATVehicle Model, Engine, Transmission and the System (i.e. Radio).

WHENDate, Time of Day, Weather Conditions, Frequency.

WHERERoad Conditions, Altitude and Traffic Situation.

HOWSystem Symptoms, Operating Conditions (Other Components Interaction).

Service History and if any After Market Accessories have been installed.

STEP 2 Operate the system, road test if necessary.

Verify the parameter of the incident.

If the problem can not be duplicated, refer to ªIncident Simulation Testsº next page.

STEP 3 Get the proper diagnosis materials together including:

POWER SUPPLY ROUTING

System Operation Descriptions

Applicable Service Manual Sections

Check for any Service Bulletin.

Identify where to begin diagnosis based upon your knowledge of the system operation and the cus-

tomer comments.

STEP 4 Inspect the system for mechanical binding, loose connectors or wiring damage.

Determine which circuits and components are involved and diagnose using the Power Supply Routing

and Harness Layouts.

STEP 5 Repair or replace the incident circuit or component.

STEP 6 Operate the system in all modes. Verify the system works properly under all conditions. Make sure you

have not inadvertently created a new incident during your diagnosis or repair steps.

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT

Work Flow

GI-24