INFINITI QX4 2001 Factory Repair Manual

Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 61 of 2395

4. 4-3. Cruise testAT-67

AT-71

Part-1

l8. Vehicle Cannot Be Started From D

1, AT-233.

l9. A/T Does Not Shift: D

1,D2Or Does Not Kickdown: D4,D2, AT-236.

l10. A/T Does Not Shift: D

2,D3, AT-239.

l11. A/T Does Not Shift: D

3,D4, AT-242.

l12. A/T Does Not Perform Lock-up, AT-245.

l13. A/T Does Not Hold Lock-up Condition, AT-247.

l14. Lock-up Is Not Released, AT-249.

l15. Engine Speed Does Not Return To Idle (Light Braking D

4,D3), AT-250.

Part-2AT-75

l16. Vehicle Does Not Start From D

1, AT-252.

l9. A/T Does Not Shift: D

1,D2Or Does Not Kickdown: D4,D2, AT-236.

l10. A/T Does Not Shift: D

2,D3, AT-239.

l11. A/T Does Not Shift: D

3,D4, AT-242.

Part-3AT-77

l17. A/T Does Not Shift: D

4,D3When Overdrive Control Switch ªONº,ªOFFº, AT-253

l15. Engine Speed Does Not Return To Idle (Engine Brake In D

3), AT-250.

l18. A/T Does Not Shift: D

3,22, When Selector Lever ªDº,ª2º Position, AT-254.

l15. Engine Speed Does Not Return To Idle (Engine Brake In 2

2), AT-250.

l19. A/T Does Not Shift: 2

2,11, When Selector Lever ª2º,ª1º Position, AT-255.

l20. Vehicle Does Not Decelerate By Engine Brake, AT-256.

lSELF-DIAGNOSTIC PROCEDURE Ð Mark detected items.

lDTC P0705 PNP switch, AT-99.

lDTC P0710 A/T fluid temperature sensor, AT-105.

lDTC P0720 Vehicle speed sensor´A/T (Revolution sensor), AT-111.

lDTC P0725 Engine speed signal, AT-116.

lDTC P0740 Torque converter clutch solenoid valve, AT-148.

lDTC P0745 Line pressure solenoid valve, AT-162.

lDTC P0750 Shift solenoid valve A, AT-168.

lDTC P0755 Shift solenoid valve B, AT-172.

lDTC P1705 Throttle position sensor, AT-176.

lDTC P1760 Overrun clutch solenoid valve, AT-185.

lDTC BATT/FLUID TEMP SEN (A/T fluid temperature sensor and TCM power source), AT-190.

lDTC Vehicle speed sensor´MTR, AT-197.

lDTC Turbine revolution sensor, AT-202.

lDTC A/T communication line, AT-207.

lDTC Control unit (RAM), control unit (ROM), AT-211.

lDTC Control unit (EEP ROM), AT-213.

lPNP, overdrive control and throttle position switches, AT-257.

lBattery

lOthers

5.lFor self-diagnosis NG items, inspect each component. Repair or replace the damaged parts. AT-38

6.lPerform all ROAD TEST and re-mark required procedures. AT-63

7.lPerform DTC CONFIRMATION PROCEDURE for following MIL indicating items and check out NG items.

Refer to EC-60, ªEmission-related Diagnostic Informationº.EC-60

lDTC (P0731, 1103) A/T 1st gear function, AT-120.

lDTC (P0732, 1104) A/T 2nd gear function, AT-126.

lDTC (P0733, 1105) A/T 3rd gear function, AT-132.

lDTC (P0734, 1106) A/T 4th gear function, AT-138.

lDTC (P0744, 1107) A/T TCC S/V function (lock-up), AT-153.

8.lPerform the Diagnostic Procedures for all remaining items marked NG. Repair or replace the damaged

parts.

Refer to the Symptom Chart when you perform the procedures. (The chart also shows some other possible

symptoms and the component inspection orders.)AT-92

AT-97

9.lErase DTC from TCM and ECM memories. AT-35

TROUBLE DIAGNOSIS Ð INTRODUCTION

Introduction (Cont'd)

AT-56

Page 62 of 2395

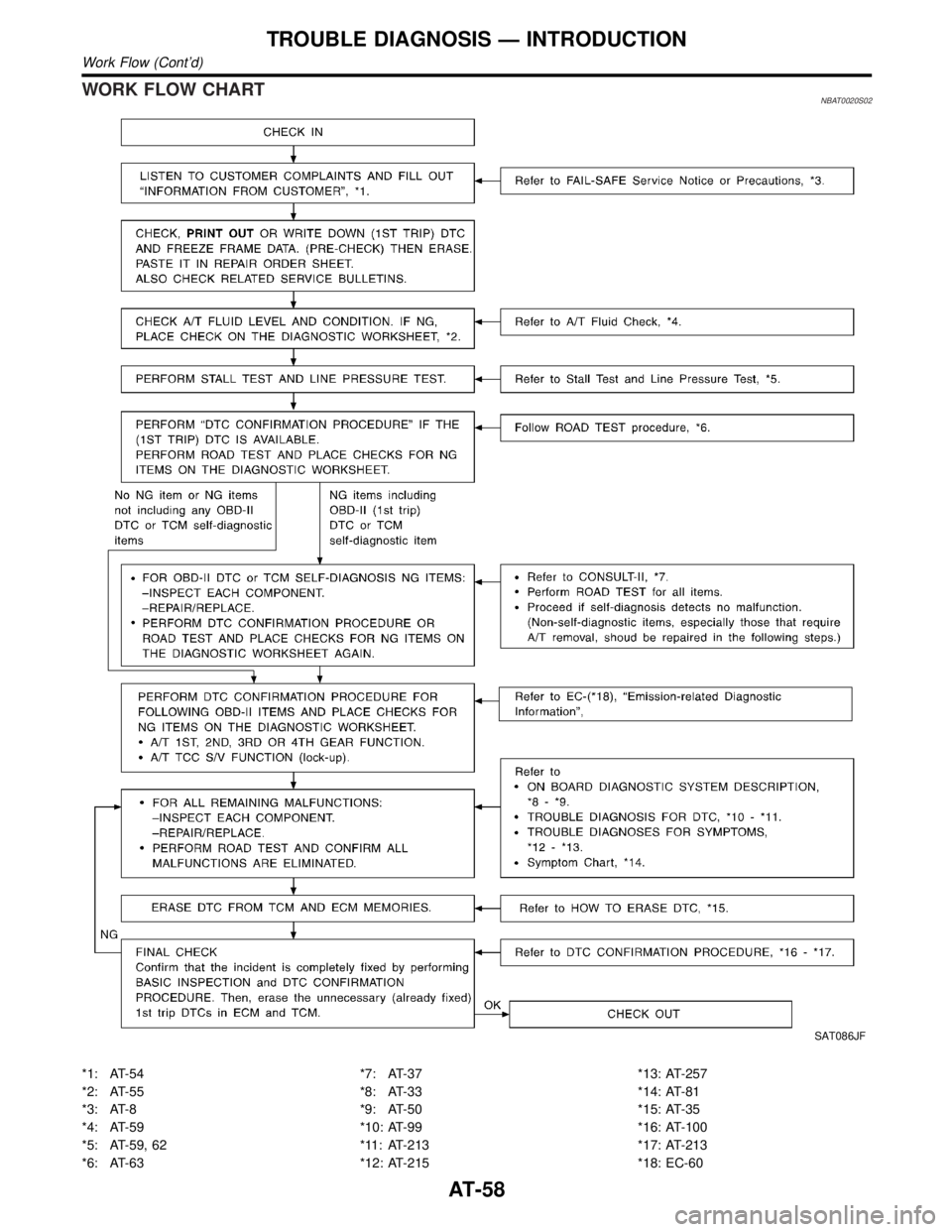

Work FlowNBAT0020HOW TO PERFORM TROUBLE DIAGNOSES FOR QUICK AND ACCURATE REPAIRNBAT0020S01A good understanding of the malfunction conditions can make troubleshooting faster and more accurate.

In general, each customer feels differently about a problem. It is important to fully understand the symptoms

or conditions for a customer complaint.

Make good use of the two sheets provided, ªINFORMATION FROM CUSTOMERº (AT-54) and ªDIAGNOS-

TIC WORKSHEETº (AT-55), to perform the best troubleshooting possible.GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð INTRODUCTION

Work Flow

AT-57

Page 63 of 2395

WORK FLOW CHARTNBAT0020S02

SAT086JF

*1: AT-54

*2: AT-55

*3: AT-8

*4: AT-59

*5: AT-59, 62

*6: AT-63*7: AT-37

*8: AT-33

*9: AT-50

*10: AT-99

*11: AT-213

*12: AT-215*13: AT-257

*14: AT-81

*15: AT-35

*16: AT-100

*17: AT-213

*18: EC-60

TROUBLE DIAGNOSIS Ð INTRODUCTION

Work Flow (Cont'd)

AT-58

Page 64 of 2395

A/T Fluid CheckNBAT0021FLUID LEAKAGE CHECKNBAT0021S011. Clean area suspected of leaking. Ð for example, mating sur-

face of converter housing and transmission case.

2. Start engine, apply foot brake, place selector lever in ªDº posi-

tion and wait a few minutes.

3. Stop engine.

4. Check for fresh leakage.

SAT638A

FLUID CONDITION CHECKNBAT0021S02

Fluid color Suspected problem

Dark or black with burned odor Wear of frictional material

Milky pinkWater contamination Ð Road water

entering through filler tube or breather

Varnished fluid, light to dark brown

and tackyOxidation Ð Over or under filling, Ð

Overheating

FLUID LEVEL CHECKNBAT0021S03Refer to MA-21, ªChecking A/T Fluidº.

SAT647B

Stall TestNBAT0022STALL TEST PROCEDURENBAT0022S011. Check A/T fluid and engine oil levels. If necessary, add fluid

and oil.

2. Drive vehicle for approx. 10 minutes or until fluid and oil reach

operating temperature.

ATF operating temperature:

50 - 80ÉC (122 - 176ÉF)

SAT513G

3. Set parking brake and block wheels.

4. Install a tachometer where it can be seen by driver during test.

IIt is good practice to put a mark on point of specified

engine rpm on indicator.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

A/T Fluid Check

AT-59

Page 65 of 2395

SAT514G

5. Start engine, apply foot brake, and place selector lever in ªDº

position.

6. Accelerate to wide open throttle gradually while applying foot

brake.

7. Quickly note the engine stall revolution and immediately

release throttle.

IDuring test, never hold throttle wide open for more than 5

seconds.

Stall revolution:

Refer to SDS, AT-356.

SAT771B

8. Move selector lever to ªNº position.

9. Cool off ATF.

IRun engine at idle for at least one minute.

10. Repeat steps 5 through 9 with selector lever in ª2º, ª1º and ªRº

positions.

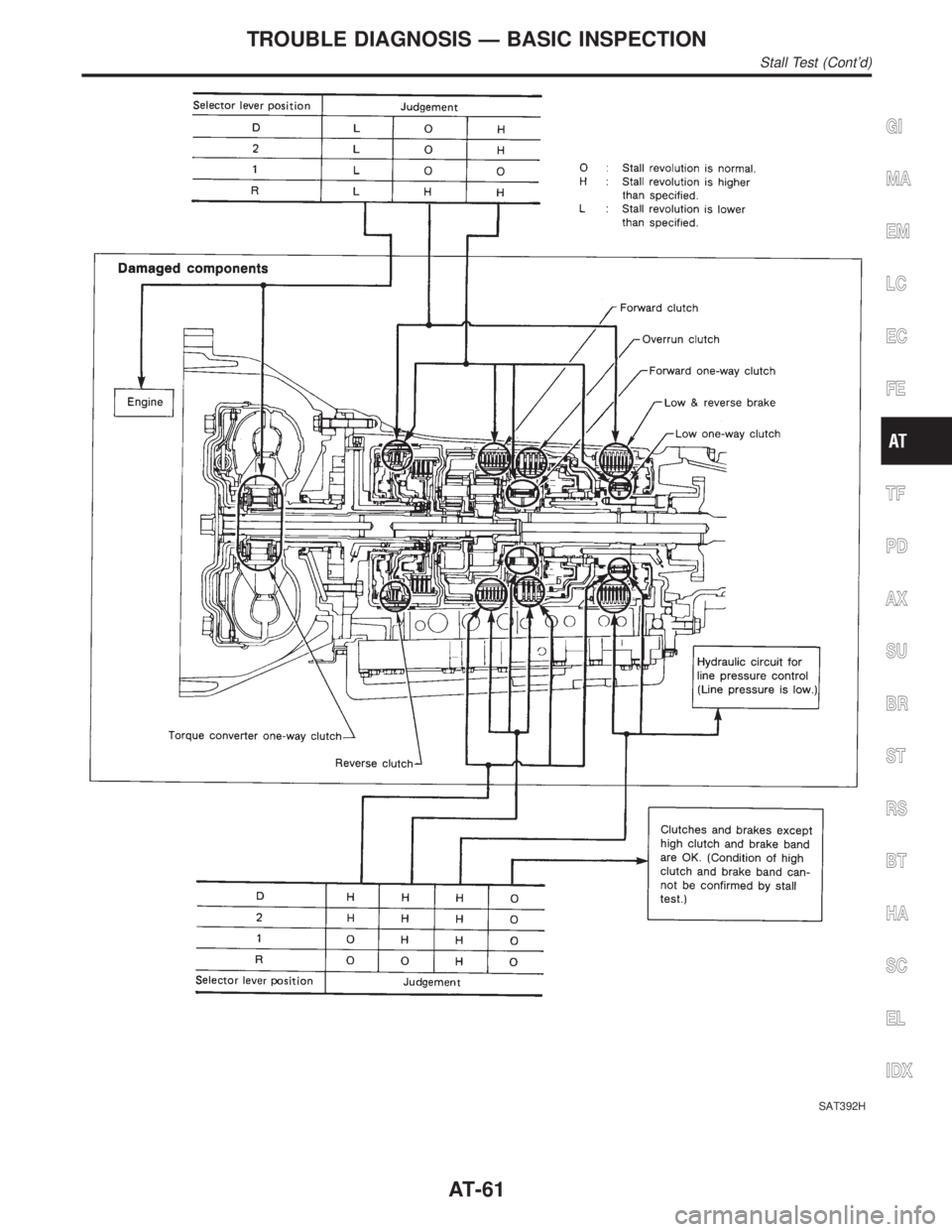

JUDGEMENT OF STALL TESTNBAT0022S02The test result and possible damaged components relating to each

result are shown in the illustration. In order to pinpoint the possible

damaged components, refer to ªWork Flowº, AT-57.

NOTE:

Stall revolution is too high in ªDº or ª2º position:

ISlippage occurs in 1st gear but not in 2nd and 3rd gears. .....

Low one-way clutch slippage

ISlippage occurs at the following gears:

1st through 3rd gears in ªDº position and engine brake func-

tions.

1st and 2nd gears in ª2º position and engine brake functions

with accelerator pedal released (fully closed throttle). ..... For-

ward clutch or forward one-way clutch slippage

Stall revolution is too high in ªRº position:

IEngine brake does not function in ª1º position. ..... Low &

reverse brake slippage

IEngine brake functions in ª1º position. ..... Reverse clutch slip-

page

Stall revolution within specifications:

IVehicle does not achieve speed of more than 80 km/h (50

MPH). ..... One-way clutch seizure in torque converter housing

CAUTION:

Be careful since automatic fluid temperature increases abnor-

mally.

ISlippage occurs in 3rd and 4th gears in ªDº position. ..... High

clutch slippage

ISlippage occurs in 2nd and 4th gear in ªDº position. ..... Brake

band slippage

Stall revolution less than specifications:

IPoor acceleration during starts. ..... One-way clutch seizure in

torque converter

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Stall Test (Cont'd)

AT-60

Page 66 of 2395

SAT392H

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Stall Test (Cont'd)

AT-61

Page 67 of 2395

SAT209GA

Line Pressure TestNBAT0023ILocation of line pressure test ports.

IAlways replace line pressure plugs as they are self-seal-

ing bolts.

SAT647B

LINE PRESSURE TEST PROCEDURENBAT0023S011. Check A/T fluid and engine oil levels. If necessary, add fluid

and oil.

2. Drive vehicle for approx. 10 minutes or until fluid and oil reach

operating temperature.

ATF operating temperature:

50 - 80ÉC (122 - 176ÉF)

SAT518GB

SAT519GB

3. Install pressure gauge to corresponding line pressure port.

SAT513G

4. Set parking brake and block wheels.

IContinue to depress brake pedal fully while line pressure

test is being performed at stall speed.

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Line Pressure Test

AT-62

Page 68 of 2395

SAT493G

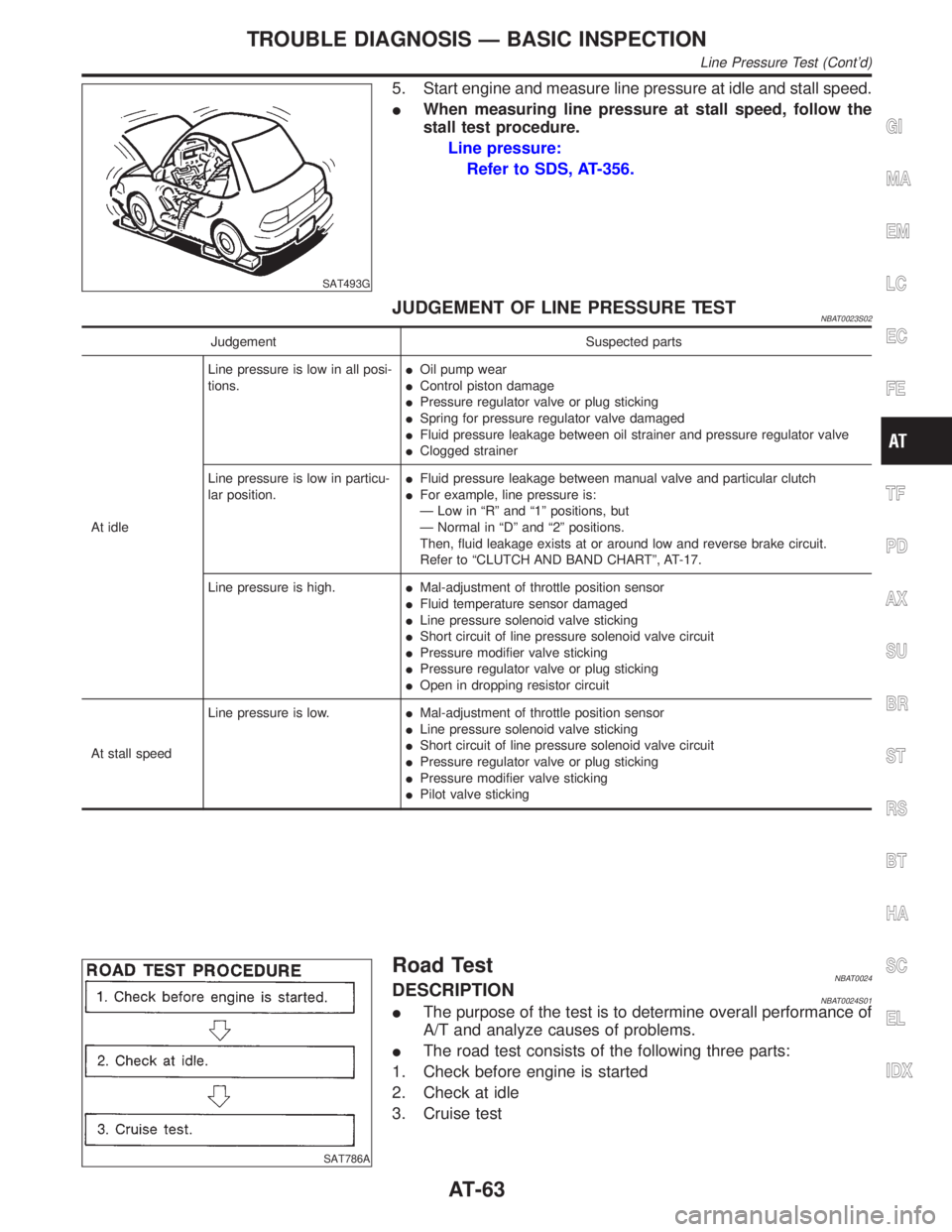

5. Start engine and measure line pressure at idle and stall speed.

IWhen measuring line pressure at stall speed, follow the

stall test procedure.

Line pressure:

Refer to SDS, AT-356.

JUDGEMENT OF LINE PRESSURE TESTNBAT0023S02

Judgement Suspected parts

At idleLine pressure is low in all posi-

tions.IOil pump wear

IControl piston damage

IPressure regulator valve or plug sticking

ISpring for pressure regulator valve damaged

IFluid pressure leakage between oil strainer and pressure regulator valve

IClogged strainer

Line pressure is low in particu-

lar position.IFluid pressure leakage between manual valve and particular clutch

IFor example, line pressure is:

Ð Low in ªRº and ª1º positions, but

Ð Normal in ªDº and ª2º positions.

Then, fluid leakage exists at or around low and reverse brake circuit.

Refer to ªCLUTCH AND BAND CHARTº, AT-17.

Line pressure is high.IMal-adjustment of throttle position sensor

IFluid temperature sensor damaged

ILine pressure solenoid valve sticking

IShort circuit of line pressure solenoid valve circuit

IPressure modifier valve sticking

IPressure regulator valve or plug sticking

IOpen in dropping resistor circuit

At stall speedLine pressure is low.IMal-adjustment of throttle position sensor

ILine pressure solenoid valve sticking

IShort circuit of line pressure solenoid valve circuit

IPressure regulator valve or plug sticking

IPressure modifier valve sticking

IPilot valve sticking

SAT786A

Road TestNBAT0024DESCRIPTIONNBAT0024S01IThe purpose of the test is to determine overall performance of

A/T and analyze causes of problems.

IThe road test consists of the following three parts:

1. Check before engine is started

2. Check at idle

3. Cruise test

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Line Pressure Test (Cont'd)

AT-63

Page 69 of 2395

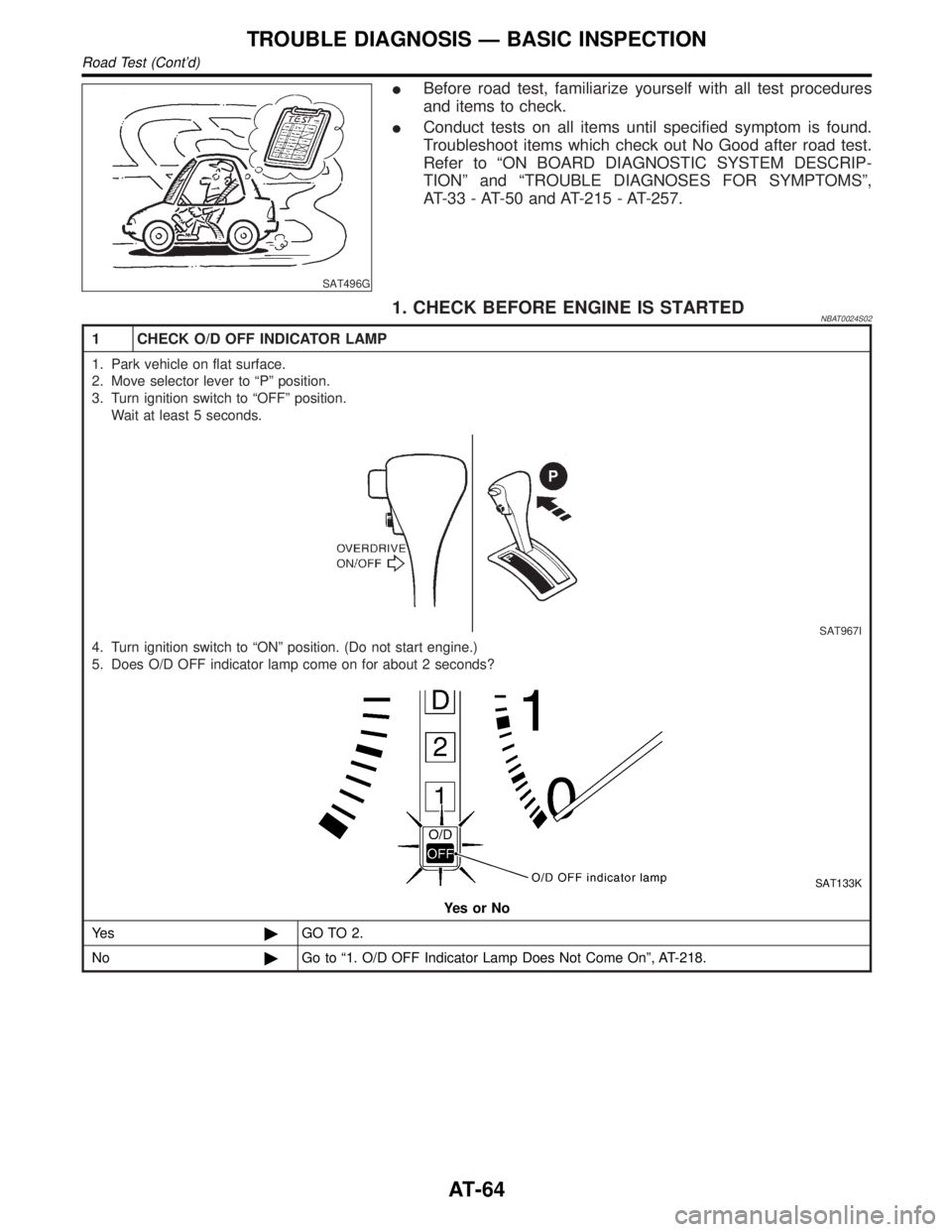

SAT496G

IBefore road test, familiarize yourself with all test procedures

and items to check.

IConduct tests on all items until specified symptom is found.

Troubleshoot items which check out No Good after road test.

Refer to ªON BOARD DIAGNOSTIC SYSTEM DESCRIP-

TIONº and ªTROUBLE DIAGNOSES FOR SYMPTOMSº,

AT-33 - AT-50 and AT-215 - AT-257.

1. CHECK BEFORE ENGINE IS STARTEDNBAT0024S02

1 CHECK O/D OFF INDICATOR LAMP

1. Park vehicle on flat surface.

2. Move selector lever to ªPº position.

3. Turn ignition switch to ªOFFº position.

Wait at least 5 seconds.

SAT967I

4. Turn ignition switch to ªONº position. (Do not start engine.)

5. Does O/D OFF indicator lamp come on for about 2 seconds?

SAT133K

YesorNo

Ye s©GO TO 2.

No©Go to ª1. O/D OFF Indicator Lamp Does Not Come Onº, AT-218.

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Road Test (Cont'd)

AT-64

Page 70 of 2395

2 CHECK O/D OFF INDICATOR LAMP

Does O/D OFF indicator lamp flicker for about 8 seconds?

SAT133K

YesorNo

Ye s©Perform self-diagnosis. Refer to TCM SELF-DIAGNOSIS PROCEDURE (No Tools),

AT-46.

No©GO TO 3.

3 CHECK NG ITEM

1. Turn ignition switch to ªOFFº position.

2. Perform self-diagnosis and note NG items.

Refer to TCM SELF-DIAGNOSIS PROCEDURE (No Tools), AT-46.

©Go to ª2. Check at idleº, AT-66.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Road Test (Cont'd)

AT-65