INFINITI QX4 2001 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 101 of 2395

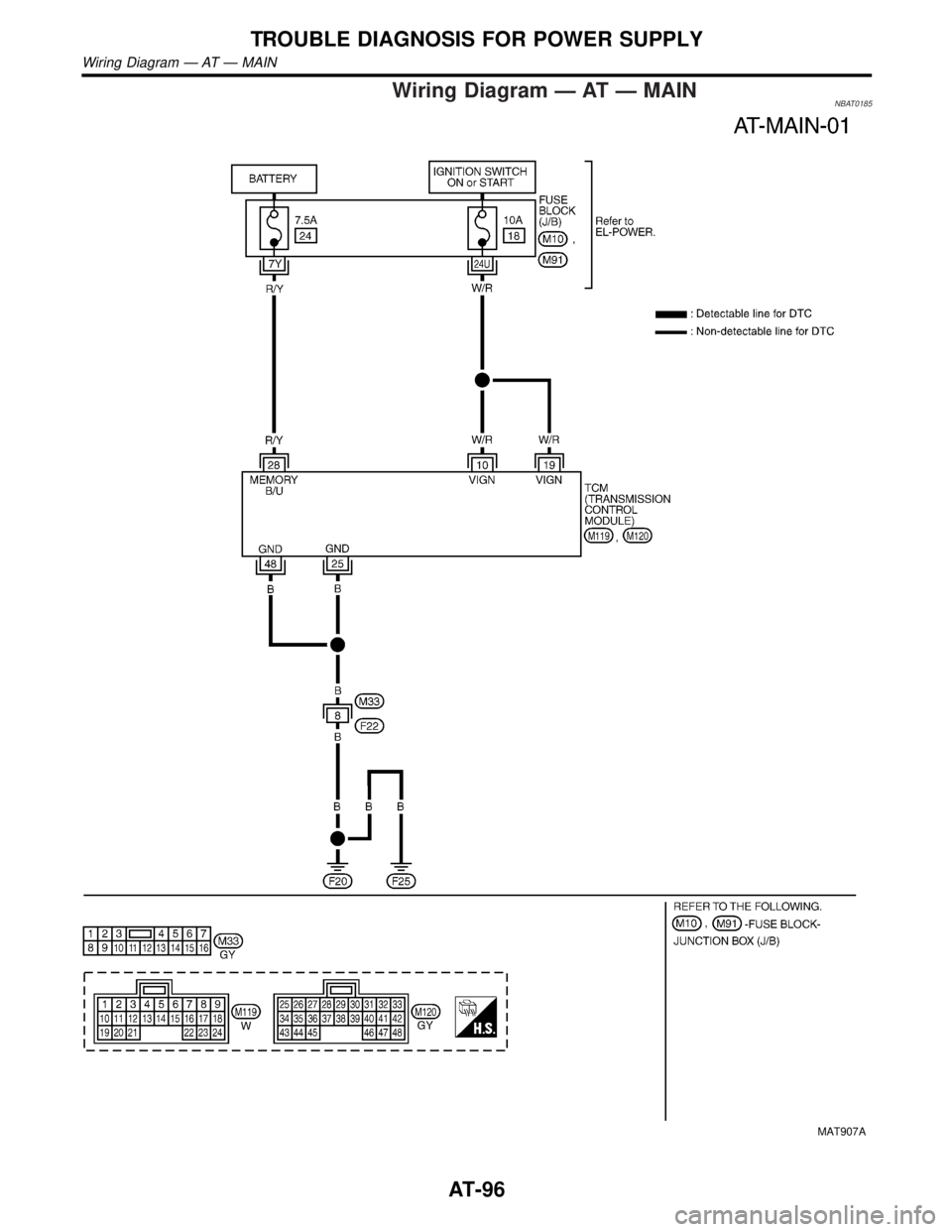

Wiring Diagram Ð AT Ð MAINNBAT0185

MAT907A

TROUBLE DIAGNOSIS FOR POWER SUPPLY

Wiring Diagram Ð AT Ð MAIN

AT-96

Page 102 of 2395

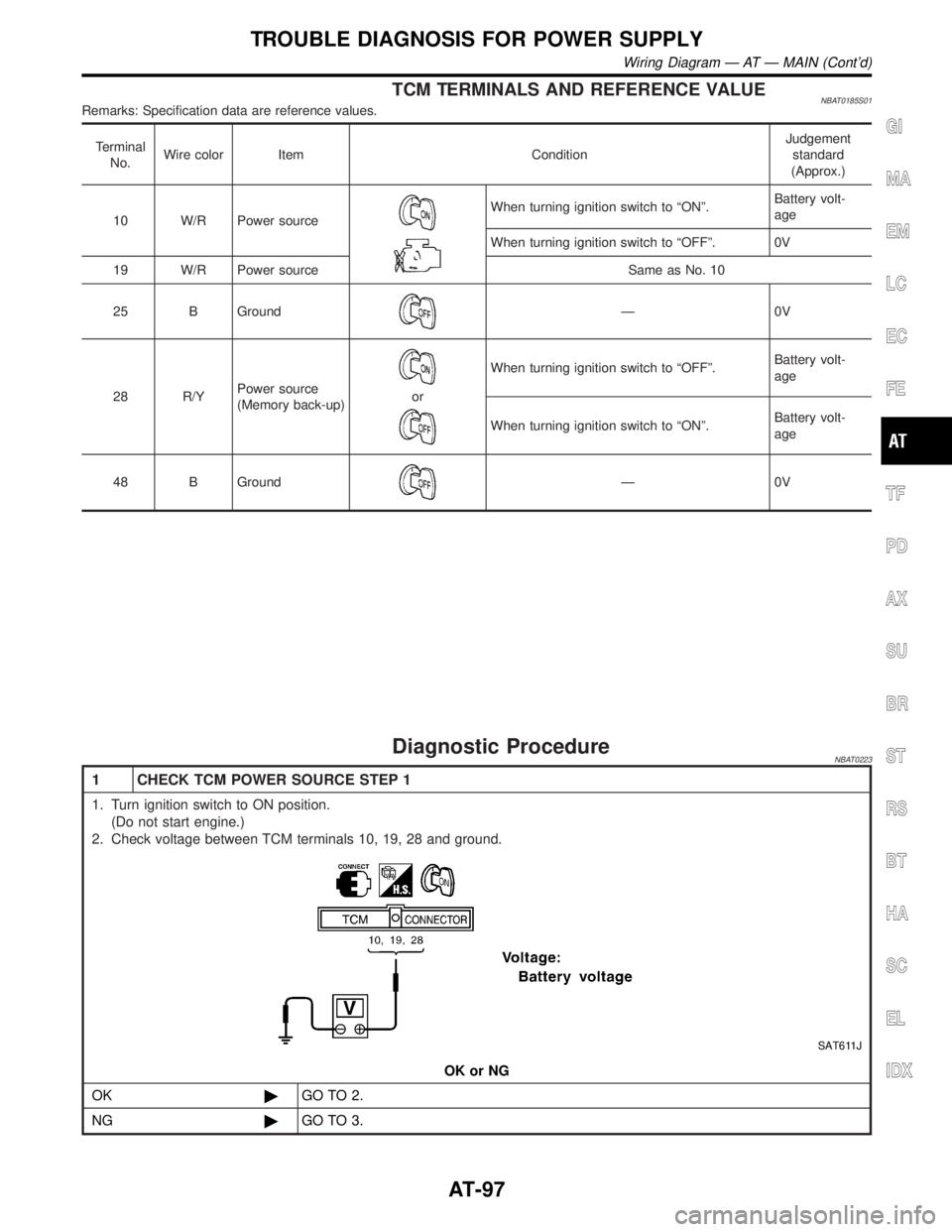

TCM TERMINALS AND REFERENCE VALUENBAT0185S01Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement

standard

(Approx.)

10 W/R Power source

When turning ignition switch to ªONº.Battery volt-

age

When turning ignition switch to ªOFFº. 0V

19 W/R Power source Same as No. 10

25 B Ground

Ð0V

28 R/YPower source

(Memory back-up)

or

When turning ignition switch to ªOFFº.Battery volt-

age

When turning ignition switch to ªONº.Battery volt-

age

48 B Ground

Ð0V

Diagnostic ProcedureNBAT0223

1 CHECK TCM POWER SOURCE STEP 1

1. Turn ignition switch to ON position.

(Do not start engine.)

2. Check voltage between TCM terminals 10, 19, 28 and ground.

SAT611J

OK or NG

OK©GO TO 2.

NG©GO TO 3.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS FOR POWER SUPPLY

Wiring Diagram Ð AT Ð MAIN (Cont'd)

AT-97

Page 103 of 2395

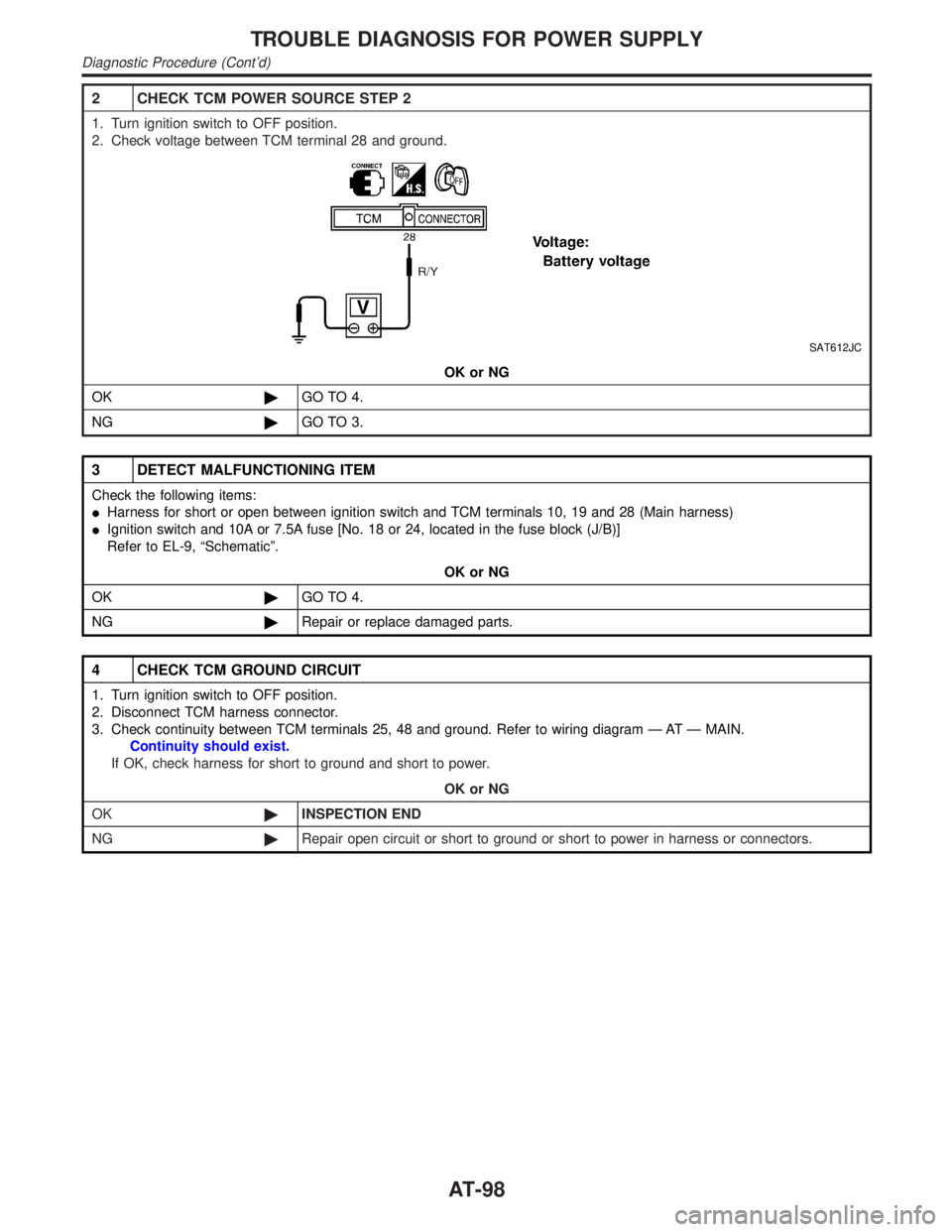

2 CHECK TCM POWER SOURCE STEP 2

1. Turn ignition switch to OFF position.

2. Check voltage between TCM terminal 28 and ground.

SAT612JC

OK or NG

OK©GO TO 4.

NG©GO TO 3.

3 DETECT MALFUNCTIONING ITEM

Check the following items:

IHarness for short or open between ignition switch and TCM terminals 10, 19 and 28 (Main harness)

IIgnition switch and 10A or 7.5A fuse [No. 18 or 24, located in the fuse block (J/B)]

Refer to EL-9, ªSchematicº.

OK or NG

OK©GO TO 4.

NG©Repair or replace damaged parts.

4 CHECK TCM GROUND CIRCUIT

1. Turn ignition switch to OFF position.

2. Disconnect TCM harness connector.

3. Check continuity between TCM terminals 25, 48 and ground. Refer to wiring diagram Ð AT Ð MAIN.

Continuity should exist.

If OK, check harness for short to ground and short to power.

OK or NG

OK©INSPECTION END

NG©Repair open circuit or short to ground or short to power in harness or connectors.

TROUBLE DIAGNOSIS FOR POWER SUPPLY

Diagnostic Procedure (Cont'd)

AT-98

Page 104 of 2395

SAT136K

DescriptionNBAT0028IThe PNP switch assemble includes a transmission range

switch.

IThe transmission range switch detects the selector position

and sends a signal to the TCM.

TCM TERMINALS AND REFERENCE VALUENBAT0028S02Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement

standard

(Approx.)

26 GPNP switch ª1º

position

When setting selector lever to ª1º position.Battery volt-

age

When setting selector lever to other positions. 0V

27 G/WPNP switch ª2º

positionWhen setting selector lever to ª2º position.Battery volt-

age

When setting selector lever to other positions. 0V

34 LPNP switch ªDº

positionWhen setting selector lever to ªDº position.Battery volt-

age

When setting selector lever to other positions. 0V

35 YPNP switch ªRº

positionWhen setting selector lever to ªRº position.Battery volt-

age

When setting selector lever to other positions. 0V

36 PPNP switch ªNº or

ªPº positionWhen setting selector lever to ªNº or ªPº posi-

tion.Battery volt-

age

When setting selector lever to other positions. 0V

ON BOARD DIAGNOSIS LOGICNBAT0028S03

Diagnostic trouble code Malfunction is detected when ... Check item (Possible cause)

: PNP SW/CIRC

TCM does not receive the correct volt-

age signal from the switch based on the

gear position.IHarness or connectors

(The PNP switch circuit is open or

shorted.)

IPNP switch

: P0705

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0705 PARK/NEUTRAL POSITION SWITCH

Description

AT-99

Page 105 of 2395

SAT014K

SAT020K

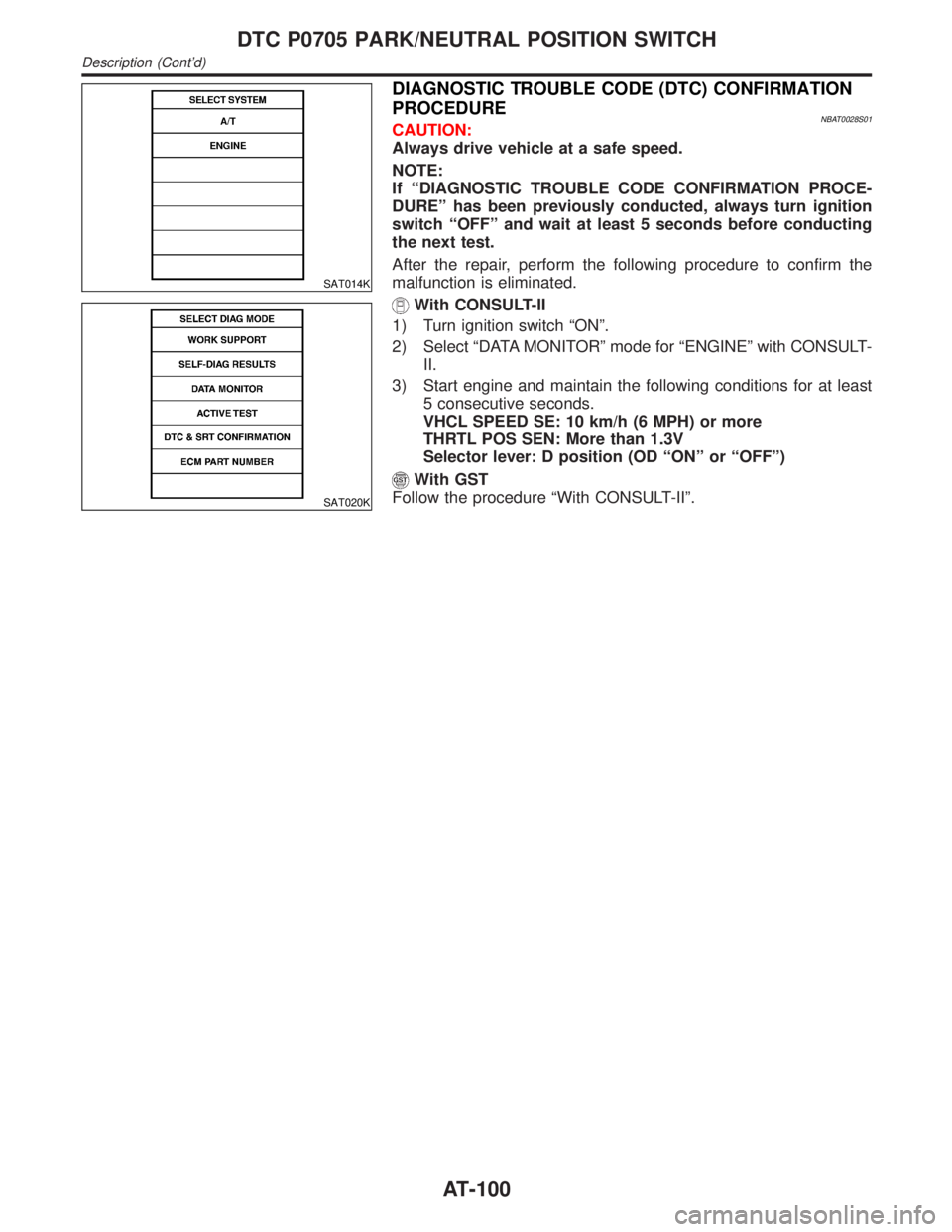

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NBAT0028S01CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode for ªENGINEº with CONSULT-

II.

3) Start engine and maintain the following conditions for at least

5 consecutive seconds.

VHCL SPEED SE: 10 km/h (6 MPH) or more

THRTL POS SEN: More than 1.3V

Selector lever: D position (OD ªONº or ªOFFº)

With GST

Follow the procedure ªWith CONSULT-IIº.

DTC P0705 PARK/NEUTRAL POSITION SWITCH

Description (Cont'd)

AT-100

Page 106 of 2395

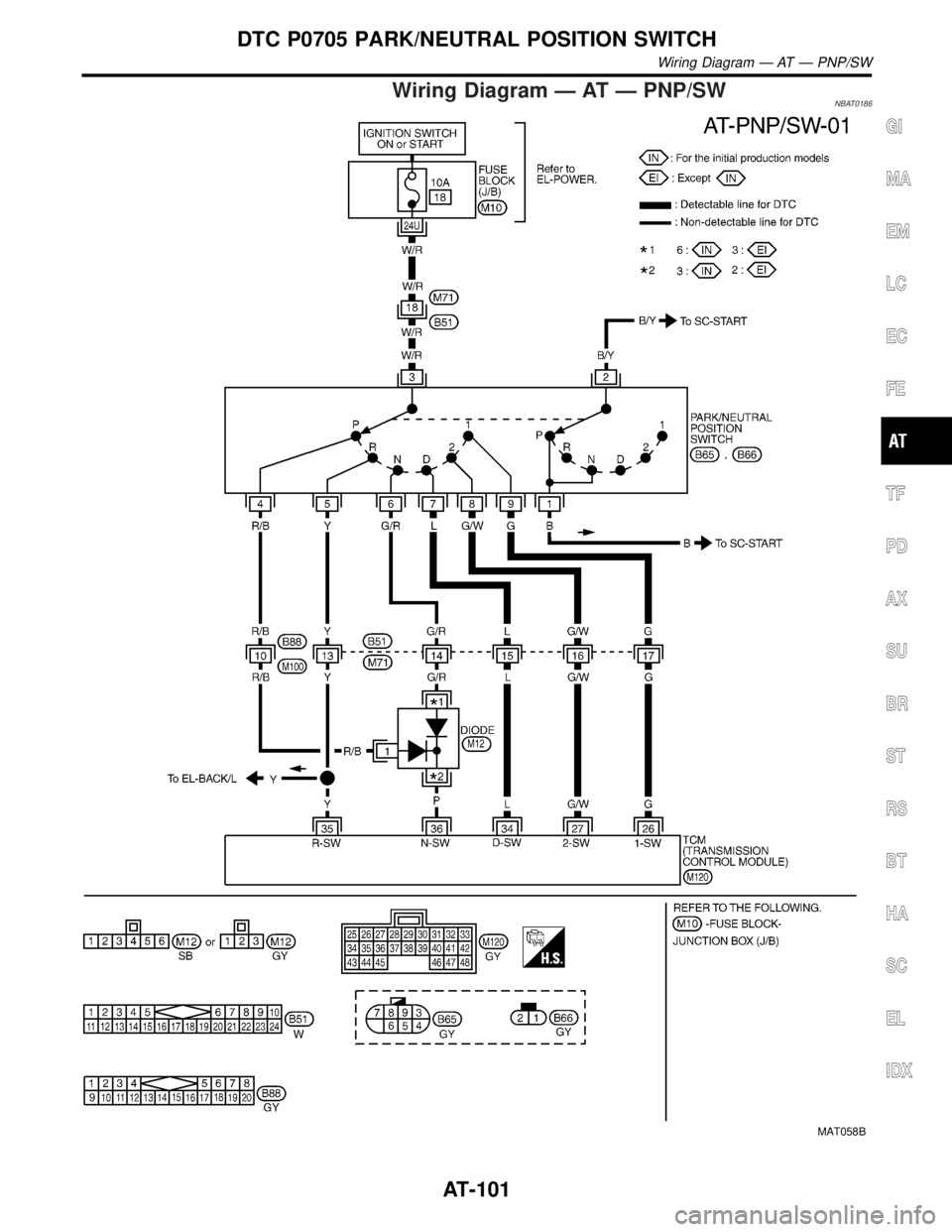

Wiring Diagram Ð AT Ð PNP/SWNBAT0186

MAT058B

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0705 PARK/NEUTRAL POSITION SWITCH

Wiring Diagram Ð AT Ð PNP/SW

AT-101

Page 107 of 2395

Diagnostic ProcedureNBAT0029

1 CHECK PNP SWITCH CIRCUIT (WITH CONSULT-II)

With CONSULT-II

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Select ªTCM INPUT SIGNALSº in ªDATA MONITORº mode for ªA/Tº with CONSULT-II.

3. Read out ªPº, ªRº, ªNº, ªDº, ª2º and ª1º position switches moving selector lever to each position. Check the signal of the

selector lever position is indicated properly.

SAT643J

OK or NG

OK©GO TO 4.

NG©GO TO 3.

2 CHECK PNP SWITCH CIRCUIT (WITHOUT CONSULT-II)

Without CONSULT-II

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between TCM terminals 26, 27, 34, 35, 36 and ground while moving selector lever through each posi-

tion.

MTBL0205

SAT517J

Does battery voltage exist (B) or non-existent (0)?

Ye s©GO TO 4.

No©GO TO 3.

DTC P0705 PARK/NEUTRAL POSITION SWITCH

Diagnostic Procedure

AT-102

Page 108 of 2395

3 DETECT MALFUNCTIONING ITEM

Check the following items:

IPNP switch

Refer to ªComponent Inspectionº, AT-103.

IHarness for short or open between ignition switch and PNP switch (Main harness)

IHarness for short or open between PNP switch and TCM (Main harness)

IDiode (P, N position)

IIgnition switch and 10A fuse [No. 18, located in the fuse block (J/B)]

Refer to EL-9, ªSchematicº.

OK or NG

OK©GO TO 4.

NG©Repair or replace damaged parts.

4 CHECK DTC

Perform Diagnostic Trouble Code (DTC) confirmation procedure, AT-100.

OK or NG

OK©INSPECTION END

NG©GO TO 5.

5 CHECK TCM INSPECTION

1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK©INSPECTION END

NG©Repair or replace damaged parts.

SAT517GB

SAT843BG

Component InspectionNBAT0030PARK/NEUTRAL POSITION SWITCHNBAT0030S021. Check continuity between terminals 1 and 2 and between ter-

minals 3 and 4, 5, 6, 7, 8, 9 while moving manual shaft through

each position.

Lever position Terminal No.

P 1-2 3-4

R 3-5

N 1-2 3-6

D 3-7

2 3-8

1 3-9

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0705 PARK/NEUTRAL POSITION SWITCH

Diagnostic Procedure (Cont'd)

AT-103

Page 109 of 2395

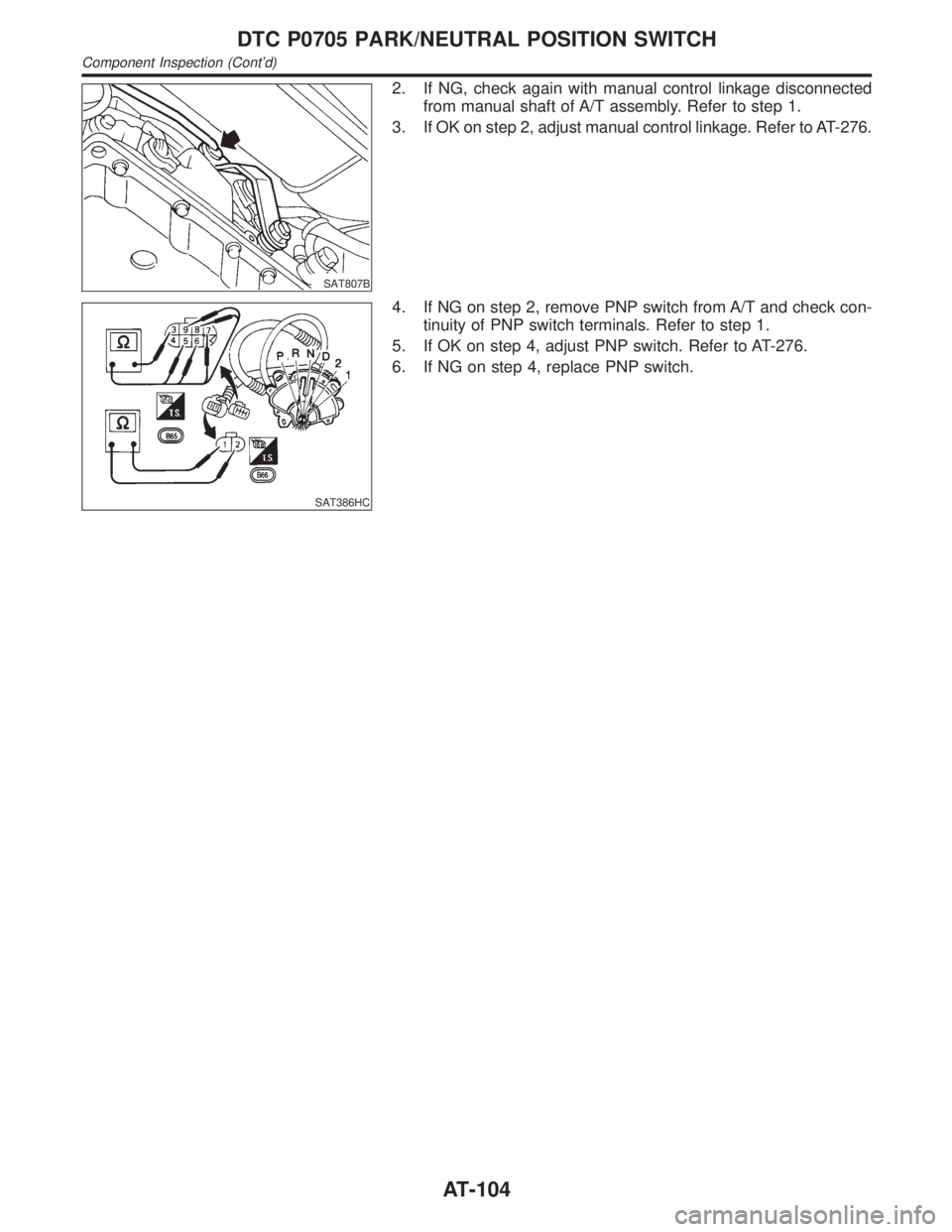

SAT807B

2. If NG, check again with manual control linkage disconnected

from manual shaft of A/T assembly. Refer to step 1.

3. If OK on step 2, adjust manual control linkage. Refer to AT-276.

SAT386HC

4. If NG on step 2, remove PNP switch from A/T and check con-

tinuity of PNP switch terminals. Refer to step 1.

5. If OK on step 4, adjust PNP switch. Refer to AT-276.

6. If NG on step 4, replace PNP switch.

DTC P0705 PARK/NEUTRAL POSITION SWITCH

Component Inspection (Cont'd)

AT-104

Page 110 of 2395

SAT342HA

DescriptionNBAT0031The A/T fluid temperature sensor detects the A/T fluid temperature

and sends a signal to the TCM.

SAT021J

CONSULT-II REFERENCE VALUE IN DATA MONITOR

MODE

NBAT0031S04Remarks: Specification data are reference values.

Monitor item Condition Specification

A/T fluid tempera-

ture sensorCold [20ÉC (68ÉF)]

"

Hot [80ÉC (176ÉF)]Approximately 1.5V

"

Approximately 0.5VApproximately 2.5 kW

"

Approximately 0.3 kW

TCM TERMINALS AND REFERENCE VALUENBAT0031S02Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement

standard

(Approx.)

42 BThrottle position

sensor

(Ground)

Ð0V

47 RA/T fluid tempera-

ture sensorWhen ATF temperature is 20ÉC (68ÉF). 1.5V

When ATF temperature is 80ÉC (176ÉF). 0.5V

ON BOARD DIAGNOSIS LOGICNBAT0031S03

Diagnostic trouble code Malfunction is detected when ... Check item (Possible cause)

: ATF TEMP SEN/CIRC

TCM receives an excessively low or high

voltage from the sensor.IHarness or connectors

(The sensor circuit is open or shorted.)

IA/T fluid temperature sensor

: P0710

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0710 A/T FLUID TEMPERATURE SENSOR CIRCUIT

Description

AT-105