Battery INFINITI QX4 2001 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 570 of 2395

SEF462UA

SEF598U

Without CONSULT-IINBEC0019S08021) Attach the EVAP service port adapter securely to the EVAP

service port.

2) Also attach the pressure pump with pressure gauge to the

EVAP service port adapter.

3) Apply battery voltage to between the terminals of both EVAP

canister vent control valve and vacuum cut valve bypass valve

to make a closed EVAP system.

4) To locate the leak, deliver positive pressure to the EVAP sys-

tem until pressure gauge points reach 1.38 to 2.76 kPa (0.014

to 0.028 kg/cm

2, 0.2 to 0.4 psi).

5) Remove EVAP service port adapter and hose with pressure

pump.

6) Locate the leak using a leak detector. Refer to ªEVAPORATIVE

EMISSION LINE DRAWINGº, EC-36.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE AND EMISSION BASIC CONTROL SYSTEM DESCRIPTION

Evaporative Emission System (Cont'd)

EC-35

Page 578 of 2395

SEF943Y

SEF572X

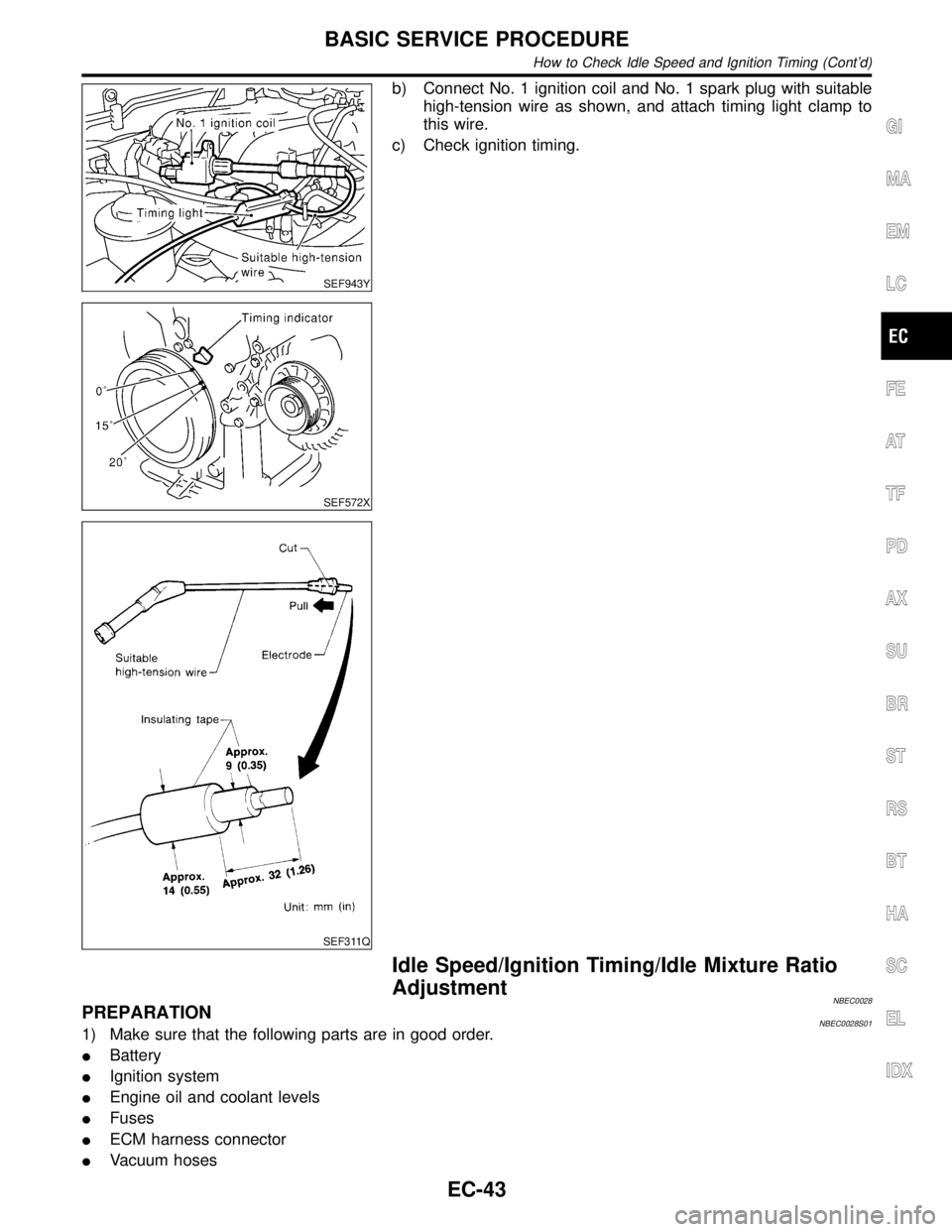

b) Connect No. 1 ignition coil and No. 1 spark plug with suitable

high-tension wire as shown, and attach timing light clamp to

this wire.

c) Check ignition timing.

SEF311Q

Idle Speed/Ignition Timing/Idle Mixture Ratio

Adjustment

NBEC0028PREPARATIONNBEC0028S011) Make sure that the following parts are in good order.

IBattery

IIgnition system

IEngine oil and coolant levels

IFuses

IECM harness connector

IVacuum hoses

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

BASIC SERVICE PROCEDURE

How to Check Idle Speed and Ignition Timing (Cont'd)

EC-43

Page 588 of 2395

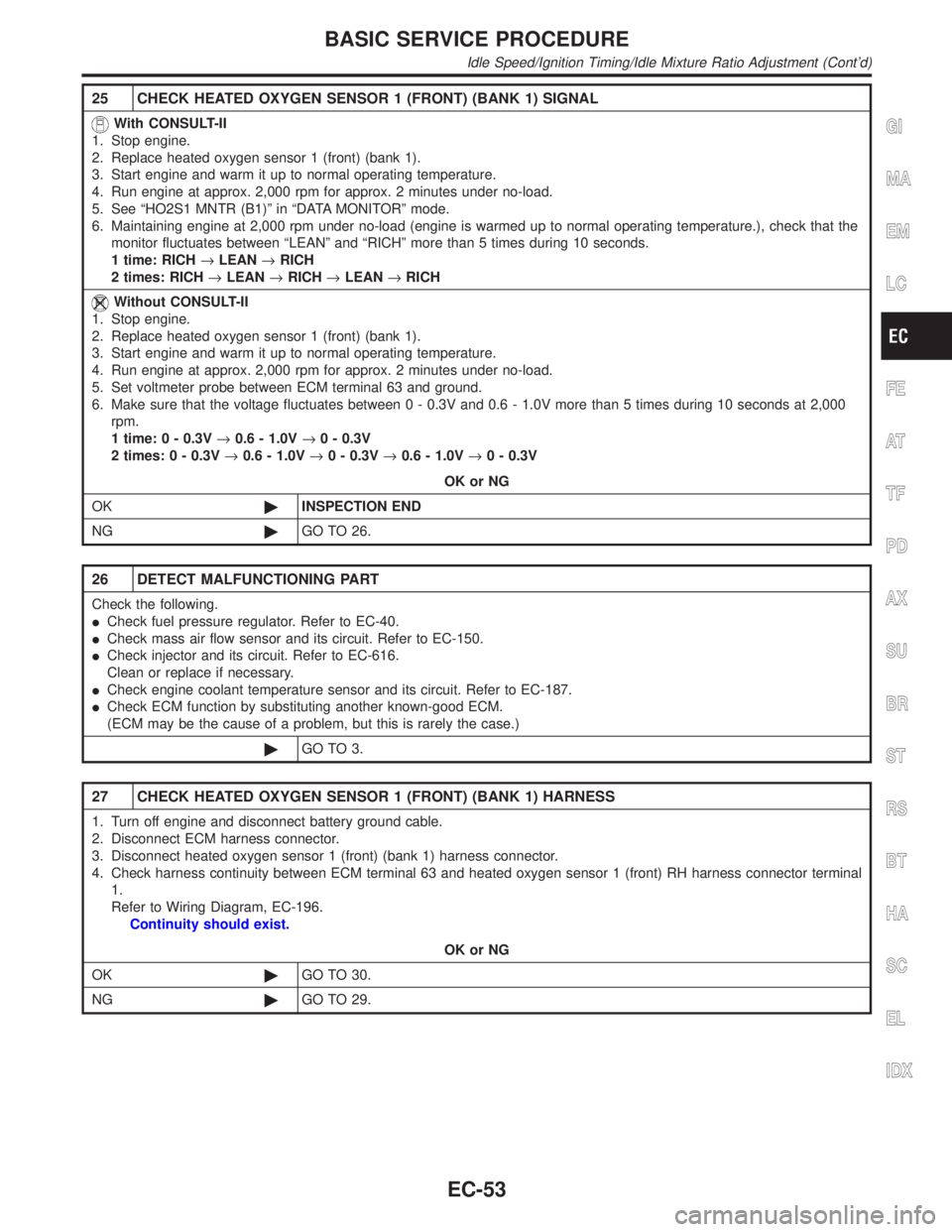

25 CHECK HEATED OXYGEN SENSOR 1 (FRONT) (BANK 1) SIGNAL

With CONSULT-II

1. Stop engine.

2. Replace heated oxygen sensor 1 (front) (bank 1).

3. Start engine and warm it up to normal operating temperature.

4. Run engine at approx. 2,000 rpm for approx. 2 minutes under no-load.

5. See ªHO2S1 MNTR (B1)º in ªDATA MONITORº mode.

6. Maintaining engine at 2,000 rpm under no-load (engine is warmed up to normal operating temperature.), check that the

monitor fluctuates between ªLEANº and ªRICHº more than 5 times during 10 seconds.

1 time: RICH®LEAN®RICH

2 times: RICH®LEAN®RICH®LEAN®RICH

Without CONSULT-II

1. Stop engine.

2. Replace heated oxygen sensor 1 (front) (bank 1).

3. Start engine and warm it up to normal operating temperature.

4. Run engine at approx. 2,000 rpm for approx. 2 minutes under no-load.

5. Set voltmeter probe between ECM terminal 63 and ground.

6. Make sure that the voltage fluctuates between 0 - 0.3V and 0.6 - 1.0V more than 5 times during 10 seconds at 2,000

rpm.

1 time: 0 - 0.3V®0.6 - 1.0V®0 - 0.3V

2 times: 0 - 0.3V®0.6 - 1.0V®0 - 0.3V®0.6 - 1.0V®0 - 0.3V

OK or NG

OK©INSPECTION END

NG©GO TO 26.

26 DETECT MALFUNCTIONING PART

Check the following.

ICheck fuel pressure regulator. Refer to EC-40.

ICheck mass air flow sensor and its circuit. Refer to EC-150.

ICheck injector and its circuit. Refer to EC-616.

Clean or replace if necessary.

ICheck engine coolant temperature sensor and its circuit. Refer to EC-187.

ICheck ECM function by substituting another known-good ECM.

(ECM may be the cause of a problem, but this is rarely the case.)

©GO TO 3.

27 CHECK HEATED OXYGEN SENSOR 1 (FRONT) (BANK 1) HARNESS

1. Turn off engine and disconnect battery ground cable.

2. Disconnect ECM harness connector.

3. Disconnect heated oxygen sensor 1 (front) (bank 1) harness connector.

4. Check harness continuity between ECM terminal 63 and heated oxygen sensor 1 (front) RH harness connector terminal

1.

Refer to Wiring Diagram, EC-196.

Continuity should exist.

OK or NG

OK©GO TO 30.

NG©GO TO 29.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

BASIC SERVICE PROCEDURE

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment (Cont'd)

EC-53

Page 589 of 2395

28 CHECK HEATED OXYGEN SENSOR 1 (FRONT) (BANK 2) HARNESS

1. Turn off engine and disconnect battery ground cable.

2. Disconnect ECM harness connector.

3. Disconnect heated oxygen sensor 1 (front) (bank 2) harness connector.

4. Check harness continuity between ECM terminal 62 and front heated oxygen sensor LH harness connector terminal 1.

Refer to Wiring Diagram, EC-197.

Continuity should exist.

OK or NG

OK©GO TO 30.

NG©GO TO 29.

29 REPAIR OR REPLACE

Repair or replace harness between ECM and heated oxygen sensor 1 (front).

©GO TO 3.

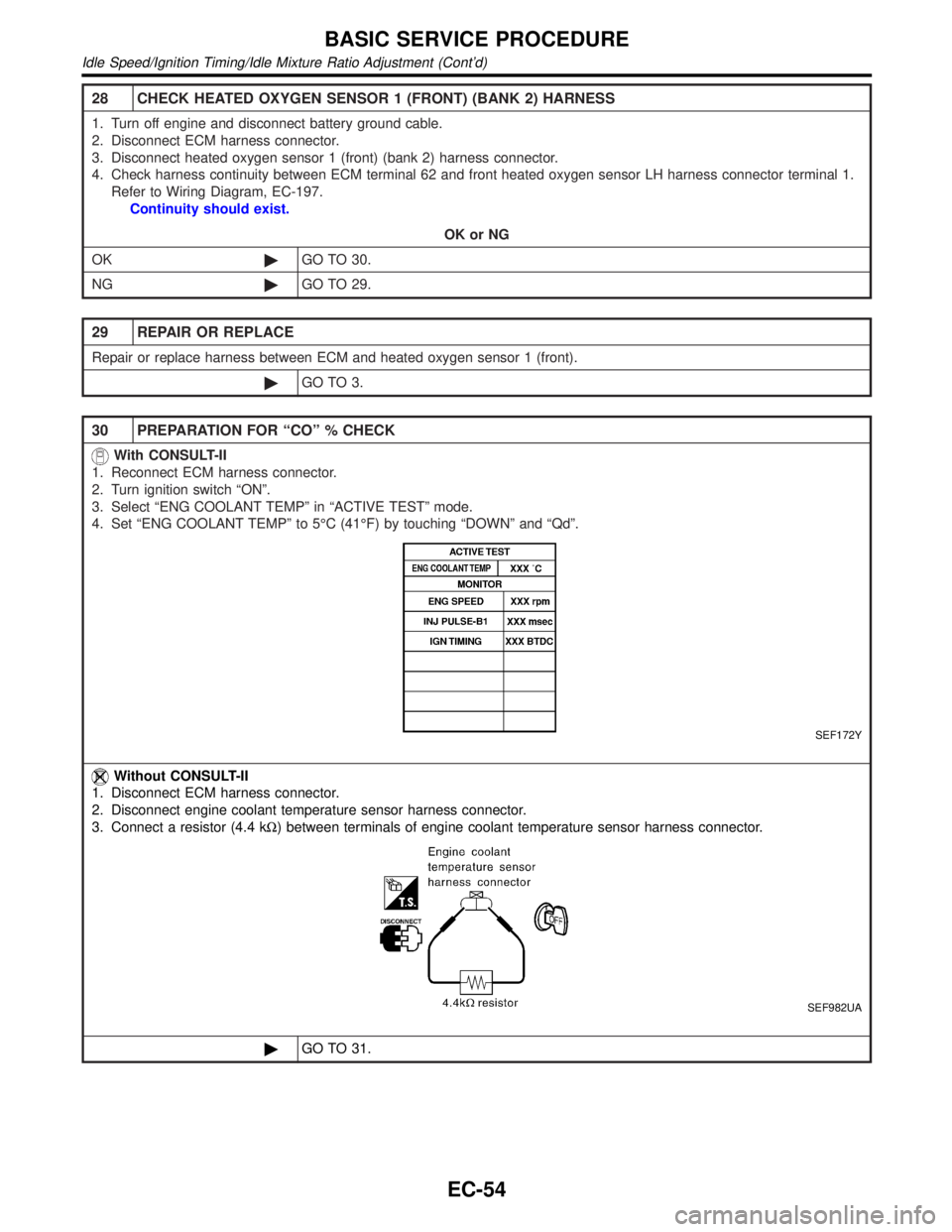

30 PREPARATION FOR ªCOº % CHECK

With CONSULT-II

1. Reconnect ECM harness connector.

2. Turn ignition switch ªONº.

3. Select ªENG COOLANT TEMPº in ªACTIVE TESTº mode.

4. Set ªENG COOLANT TEMPº to 5ÉC (41ÉF) by touching ªDOWNº and ªQdº.

SEF172Y

Without CONSULT-II

1. Disconnect ECM harness connector.

2. Disconnect engine coolant temperature sensor harness connector.

3. Connect a resistor (4.4 kW) between terminals of engine coolant temperature sensor harness connector.

SEF982UA

©GO TO 31.

BASIC SERVICE PROCEDURE

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment (Cont'd)

EC-54

Page 592 of 2395

SEF452Y

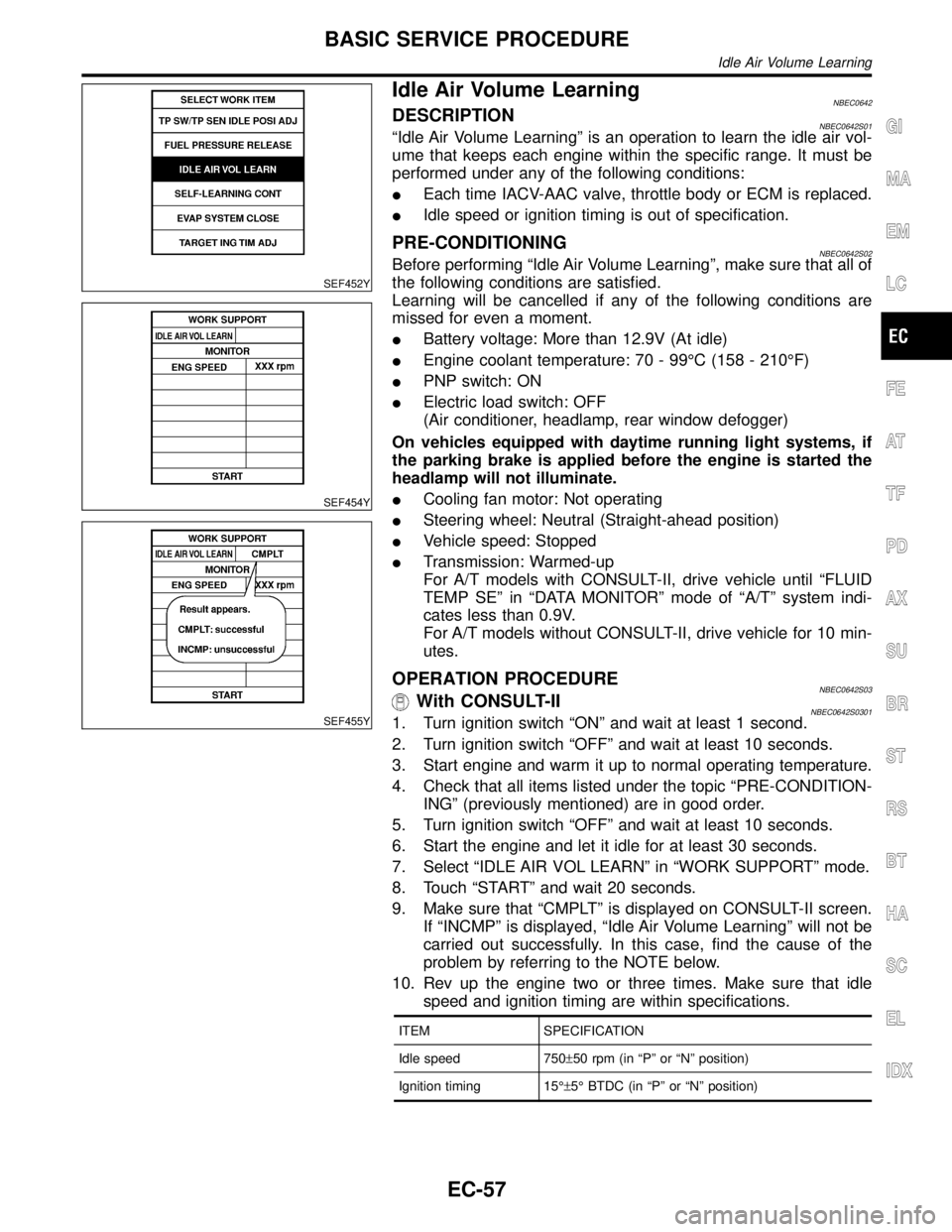

Idle Air Volume LearningNBEC0642

SEF454Y

SEF455Y

DESCRIPTIONNBEC0642S01ªIdle Air Volume Learningº is an operation to learn the idle air vol-

ume that keeps each engine within the specific range. It must be

performed under any of the following conditions:

IEach time IACV-AAC valve, throttle body or ECM is replaced.

IIdle speed or ignition timing is out of specification.

PRE-CONDITIONINGNBEC0642S02Before performing ªIdle Air Volume Learningº, make sure that all of

the following conditions are satisfied.

Learning will be cancelled if any of the following conditions are

missed for even a moment.

IBattery voltage: More than 12.9V (At idle)

IEngine coolant temperature: 70 - 99ÉC (158 - 210ÉF)

IPNP switch: ON

IElectric load switch: OFF

(Air conditioner, headlamp, rear window defogger)

On vehicles equipped with daytime running light systems, if

the parking brake is applied before the engine is started the

headlamp will not illuminate.

ICooling fan motor: Not operating

ISteering wheel: Neutral (Straight-ahead position)

IVehicle speed: Stopped

ITransmission: Warmed-up

For A/T models with CONSULT-II, drive vehicle until ªFLUID

TEMP SEº in ªDATA MONITORº mode of ªA/Tº system indi-

cates less than 0.9V.

For A/T models without CONSULT-II, drive vehicle for 10 min-

utes.

OPERATION PROCEDURENBEC0642S03With CONSULT-IINBEC0642S03011. Turn ignition switch ªONº and wait at least 1 second.

2. Turn ignition switch ªOFFº and wait at least 10 seconds.

3. Start engine and warm it up to normal operating temperature.

4. Check that all items listed under the topic ªPRE-CONDITION-

INGº (previously mentioned) are in good order.

5. Turn ignition switch ªOFFº and wait at least 10 seconds.

6. Start the engine and let it idle for at least 30 seconds.

7. Select ªIDLE AIR VOL LEARNº in ªWORK SUPPORTº mode.

8. Touch ªSTARTº and wait 20 seconds.

9. Make sure that ªCMPLTº is displayed on CONSULT-II screen.

If ªINCMPº is displayed, ªIdle Air Volume Learningº will not be

carried out successfully. In this case, find the cause of the

problem by referring to the NOTE below.

10. Rev up the engine two or three times. Make sure that idle

speed and ignition timing are within specifications.

ITEM SPECIFICATION

Idle speed 750±50 rpm (in ªPº or ªNº position)

Ignition timing 15ɱ5É BTDC (in ªPº or ªNº position)

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

BASIC SERVICE PROCEDURE

Idle Air Volume Learning

EC-57

Page 608 of 2395

SEF823YA

The emission related diagnostic information in the ECM can be erased by selecting ªERASEº in the ªSELF-

DIAG RESULTSº mode with CONSULT-II.

How to Erase DTC (With GST)NBEC0031S0602NOTE:

If the DTC is not for A/T related items (see EC-8), skip step 2.

1. If the ignition switch stays ªONº after repair work, be sure to turn ignition switch ªOFFº once. Wait at least

10 seconds and then turn it ªONº (engine stopped) again.

2. Perform ªSELF-DIAGNOSTIC PROCEDURE (Without CONSULT-II)º in AT section titled ªTROUBLE

DIAGNOSISº, ªSelf-diagnosisº. (The engine warm-up step can be skipped when performing the diagnosis

only to erase the DTC.)

3. Select Mode 4 with GST (Generic Scan Tool).

The emission related diagnostic information in the ECM can be erased by selecting Mode 4 with GST.

IIf the battery is disconnected, the emission-related diagnostic information will be lost after approx.

24 hours.

IThe following data are cleared when the ECM memory is erased.

1) Diagnostic trouble codes

2) 1st trip diagnostic trouble codes

3) Freeze frame data

4) 1st trip freeze frame data

5) System readiness test (SRT) codes

6) Test values

7) Others

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Emission-related Diagnostic Information (Cont'd)

EC-73

Page 617 of 2395

ENGINE CONTROL COMPONENT PARTS/CONTROL

SYSTEMS APPLICATION

NBEC0034S02

ItemDIAGNOSTIC TEST MODE

WORK

SUP-

PORTSELF-DIAGNOSTIC

RESULTS

D ATA

MONI-

TORD ATA

MONI-

TOR

(SPEC)ACTIVE

TESTDTC & SRT

CONFIRMATION

DTC*1FREEZE

FRAME

DATA*2SRT

STATUSDTC

WORK

SUP-

PORT

ENGINE CONTROL COMPONENT PARTS

INPUT

Crankshaft position sensor

(POS)XXXX

Crankshaft position sensor (REF) X X X

Mass air flow sensor X X X

Engine coolant temperature sen-

sorXXXXX

Heated oxygen sensor 1 (front) X X X X X

Heated oxygen sensor 2 (rear) X X X X X

Vehicle speed sensorXXXX

Throttle position sensor X X X

Fuel tank temperature sensor X X X X

EVAP control system pressure

sensorXXX

Absolute pressure sensor X X X

Intake air temperature sensor X X X

Knock sensor X

Ignition switch (start signal) X X

Closed throttle position switch X X X

Closed throttle position switch

(throttle position sensor signal)XX

Air conditioner switch X X

Park/neutral position (PNP)

switchXXX

Power steering oil pressure

switchXX

Battery voltage X X

Ambient air temperature switch X X

Load signal X X

Swirl control valve control

vacuum check switchXXX

Fuel level sensor X X X

Intake valve timing control posi-

tion sensorXXX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT-II (Cont'd)

EC-82

Page 620 of 2395

WORK SUPPORT MODE=NBEC0034S04

WORK ITEM CONDITION USAGE

TP SW/TP SEN IDLE POSI ADJIFOLLOW THE BASIC INSPECTION INSTRUCTION IN

THE SERVICE MANUAL.When adjusting the idle throttle

position

FUEL PRESSURE RELEASEIFUEL PUMP WILL STOP BY TOUCHING ªSTARTº

DURING IDLING.

CRANK A FEW TIMES AFTER ENGINE STALLS.When releasing fuel pressure

from fuel line

IDLE AIR VOL LEARNITHE IDLE AIR VOLUME THAT KEEPS THE ENGINE

WITHIN THE SPECIFIED RANGE IS MEMORIZED IN

ECM.When learning the idle air volume

SELF-LEARNING CONTITHE COEFFICIENT OF SELF-LEARNING CONTROL

MIXTURE RATIO RETURNS TO THE ORIGINAL

COEFFICIENT.When clearing the coefficient of

self-learning control valve

EVAP SYSTEM CLOSE OPEN THE VACUUM CUT VALVE BYPASS VALVE AND

CLOSE THE EVAP CANISTER VENT CONTROL VALVE

IN ORDER TO MAKE EVAP SYSTEM CLOSE UNDER

THE FOLLOWING CONDITIONS.

IIGN SW ªONº

IENGINE NOT RUNNING

IAMBIENT TEMPERATURE IS ABOVE 0ÉC (32ÉF).

INO VACUUM AND NO HIGH PRESSURE IN EVAP

SYSTEM

ITANK FUEL TEMP. IS MORE THAN 0ÉC (32ÉF).

IWITHIN 10 MINUTES AFTER STARTING ªEVAP SYS-

TEM CLOSEº

IWHEN TRYING TO EXECUTE ªEVAP SYSTEM

CLOSEº UNDER THE CONDITION EXCEPT ABOVE,

CONSULT-II WILL DISCONTINUE IT AND DISPLAY

APPROPRIATE INSTRUCTION.

NOTE:

WHEN STARTING ENGINE, CONSULT-II MAY DIS-

PLAY ªBATTERY VOLTAGE IS LOW. CHARGE

BATTERYº, EVEN IN USING CHARGED BATTERY.When detecting EVAP vapor leak

point of EVAP system

TARGET IGNITION TIMING ADJ*IIDLE CONDITIONIWhen adjusting target ignition

timing

After adjustment, confirm target

ignition timing with a timing

light.

IIf once the ªTARGET IDLE

RPM ADJº has been done, the

Idle Air Volume Learning proce-

dure will not be completed.

TARGET IDLE RPM ADJ*IIDLE CONDITION When setting target idle speed

*: This function is not necessary in the usual service procedure.

SELF-DIAGNOSTIC MODENBEC0034S05DTC and 1st Trip DTCNBEC0034S0501Regarding items of ªDTC and 1st trip DTCº, refer to ªTROUBLE

DIAGNOSIS Ð INDEXº (See EC-8.)

Freeze Frame Data and 1st Trip Freeze Frame DataNBEC0034S0502

Freeze frame data

item*1Description

DIAG TROUBLE

CODE

[PXXXX]IThe engine control component part/control system has a trouble code, it is displayed as ªPXXXXº.

(Refer to ªTROUBLE DIAGNOSIS Ð INDEXº, EC-8.)

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT-II (Cont'd)

EC-85

Page 622 of 2395

![INFINITI QX4 2001 Factory Repair Manual DATA MONITOR MODE=NBEC0034S06

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

ENG SPEED [rpm]qqIIndicates the engine speed computed

from the REF signal (120É signal) of the

cran INFINITI QX4 2001 Factory Repair Manual DATA MONITOR MODE=NBEC0034S06

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

ENG SPEED [rpm]qqIIndicates the engine speed computed

from the REF signal (120É signal) of the

cran](/img/42/57027/w960_57027-621.png)

DATA MONITOR MODE=NBEC0034S06

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

ENG SPEED [rpm]qqIIndicates the engine speed computed

from the REF signal (120É signal) of the

crankshaft position sensor (REF).

CKPS´RPM (POS)

[rpm]qIIndicates the engine speed computed

from the POS signal (1É signal) of the

crankshaft position sensor (POS).IAccuracy becomes poor if engine

speed drops below the idle rpm.

IIf the signal is interrupted while the

engine is running, an abnormal value

may be indicated.

POS COUNTqIIndicates the number of signal plate

(Flywheel/Drive Plate) cogs (tooth) dur-

ing one revolution of the engine.

MAS A/F SE-B1 [V]qqIThe signal voltage of the mass air flow

sensor is displayed.IWhen the engine is stopped, a certain

value is indicated.

COOLAN TEMP/S

[ÉC] or [ÉF]qqIThe engine coolant temperature (deter-

mined by the signal voltage of the

engine coolant temperature sensor) is

displayed.IWhen the engine coolant temperature

sensor is open or short-circuited, ECM

enters fail-safe mode. The engine cool-

ant temperature determined by the

ECM is displayed.

HO2S1 (B1) [V]qq

IThe signal voltage of the front heated

oxygen sensor is displayed.

HO2S1 (B2) [V]qq

HO2S2 (B1) [V]qq

IThe signal voltage of the rear heated

oxygen sensor is displayed.

HO2S2 (B2) [V]qq

HO2S1 MNTR (B1)

[RICH/LEAN]qIDisplay of front heated oxygen sensor

signal during air-fuel ratio feedback

control:

RICH ... means the mixture became

ªrichº, and control is being affected

toward a leaner mixture.

LEAN ... means the mixture became

ªleanº, and control is being affected

toward a rich mixture.IAfter turning ON the ignition switch,

ªRICHº is displayed until air-fuel mixture

ratio feedback control begins.

IWhen the air-fuel ratio feedback is

clamped, the value just before the

clamping is displayed continuously. HO2S1 MNTR (B2)

[RICH/LEAN]q

HO2S2 MNTR (B1)

[RICH/LEAN]qIDisplay of rear heated oxygen sensor

signal:

RICH ... means the amount of oxygen

after three way catalyst is relatively

small.

LEAN ... means the amount of oxygen

after three way catalyst is relatively

large.IWhen the engine is stopped, a certain

value is indicated.

HO2S2 MNTR (B2)

[RICH/LEAN]q

VHCL SPEED SE

[km/h] or [mph]qqIThe vehicle speed computed from the

vehicle speed sensor signal is dis-

played.

BATTERY VOLT [V]qqIThe power supply voltage of ECM is

displayed.

THRTL POS SEN [V]qqIThe throttle position sensor signal volt-

age is displayed.

FUEL T/TMP SE

[ÉC] or [ÉF]IThe fuel temperature judged from the

tank fuel temperature sensor signal

voltage is displayed.GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT-II (Cont'd)

EC-87

Page 631 of 2395

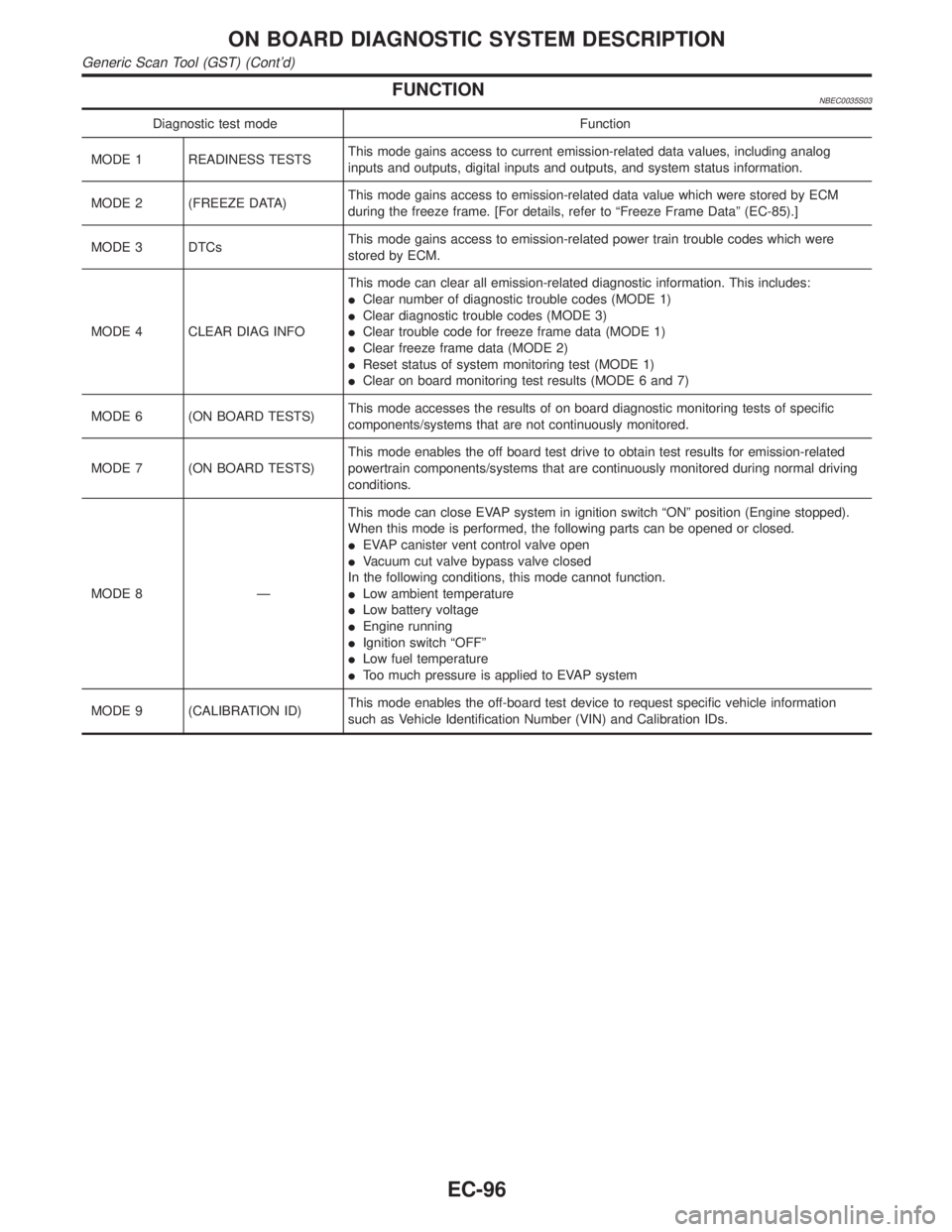

FUNCTIONNBEC0035S03

Diagnostic test mode Function

MODE 1 READINESS TESTSThis mode gains access to current emission-related data values, including analog

inputs and outputs, digital inputs and outputs, and system status information.

MODE 2 (FREEZE DATA)This mode gains access to emission-related data value which were stored by ECM

during the freeze frame. [For details, refer to ªFreeze Frame Dataº (EC-85).]

MODE 3 DTCsThis mode gains access to emission-related power train trouble codes which were

stored by ECM.

MODE 4 CLEAR DIAG INFOThis mode can clear all emission-related diagnostic information. This includes:

IClear number of diagnostic trouble codes (MODE 1)

IClear diagnostic trouble codes (MODE 3)

IClear trouble code for freeze frame data (MODE 1)

IClear freeze frame data (MODE 2)

IReset status of system monitoring test (MODE 1)

IClear on board monitoring test results (MODE 6 and 7)

MODE 6 (ON BOARD TESTS)This mode accesses the results of on board diagnostic monitoring tests of specific

components/systems that are not continuously monitored.

MODE 7 (ON BOARD TESTS)This mode enables the off board test drive to obtain test results for emission-related

powertrain components/systems that are continuously monitored during normal driving

conditions.

MODE 8 ÐThis mode can close EVAP system in ignition switch ªONº position (Engine stopped).

When this mode is performed, the following parts can be opened or closed.

IEVAP canister vent control valve open

IVacuum cut valve bypass valve closed

In the following conditions, this mode cannot function.

ILow ambient temperature

ILow battery voltage

IEngine running

IIgnition switch ªOFFº

ILow fuel temperature

IToo much pressure is applied to EVAP system

MODE 9 (CALIBRATION ID)This mode enables the off-board test device to request specific vehicle information

such as Vehicle Identification Number (VIN) and Calibration IDs.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Generic Scan Tool (GST) (Cont'd)

EC-96