IDX INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1646 of 2395

Parts Requiring Angular TighteningNBEM0001IUse an angle wrench for the final tightening of the following

engine parts:

a) Cylinder head bolts

b) Main bearing cap bolts

c) Connecting rod cap bolts

d) Crankshaft pulley bolt

IDo not use a torque value for final tightening.

IThe torque value for these parts are for a preliminary step.

IEnsure thread and seat surfaces are clean and coated with

engine oil.

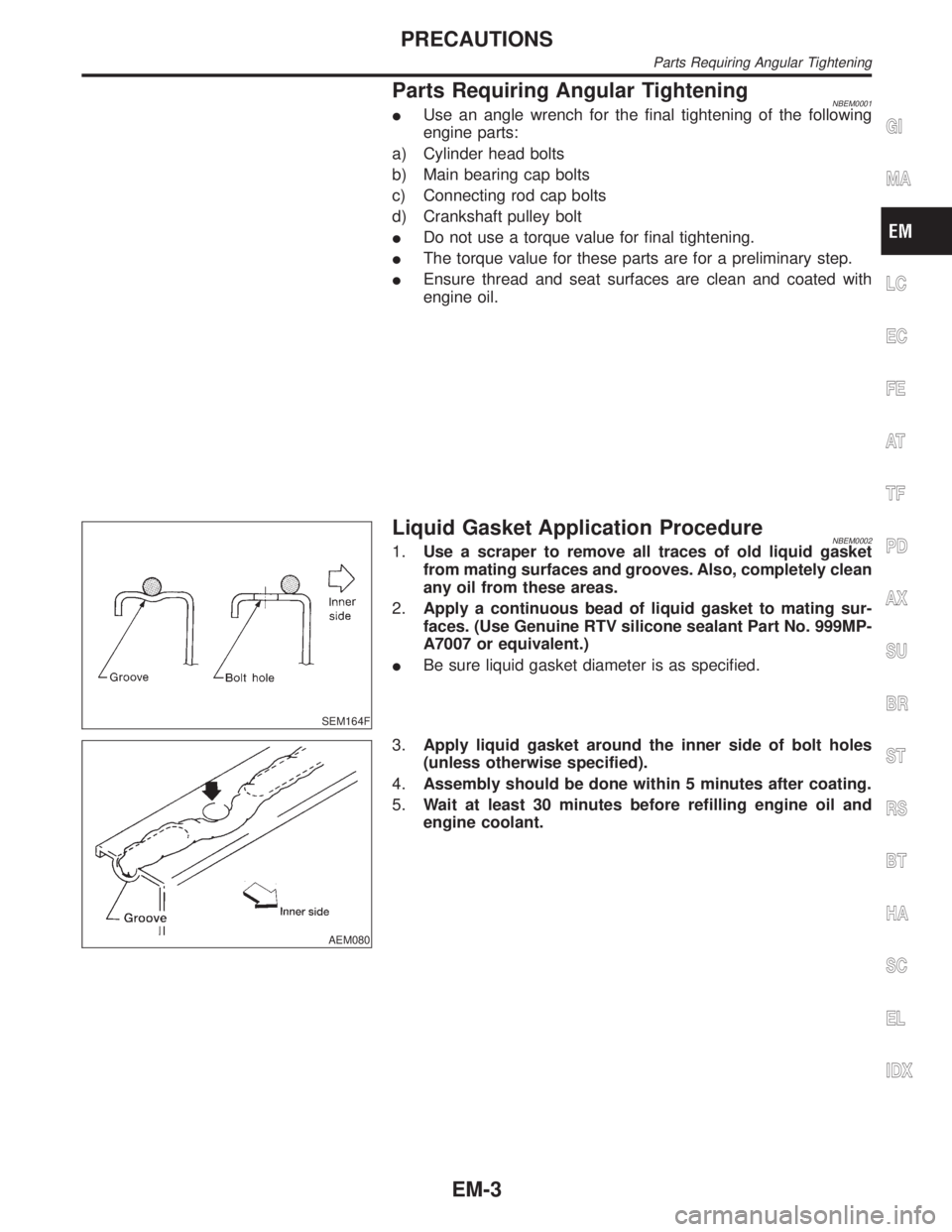

SEM164F

Liquid Gasket Application ProcedureNBEM00021.Use a scraper to remove all traces of old liquid gasket

from mating surfaces and grooves. Also, completely clean

any oil from these areas.

2.Apply a continuous bead of liquid gasket to mating sur-

faces. (Use Genuine RTV silicone sealant Part No. 999MP-

A7007 or equivalent.)

IBe sure liquid gasket diameter is as specified.

AEM080

3.Apply liquid gasket around the inner side of bolt holes

(unless otherwise specified).

4.Assembly should be done within 5 minutes after coating.

5.Wait at least 30 minutes before refilling engine oil and

engine coolant.

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PRECAUTIONS

Parts Requiring Angular Tightening

EM-3

Page 1648 of 2395

Tool number

(Kent-Moore No.)

Tool nameDescription

(J39386)

Valve oil seal drift

NT024

Installing valve oil seal

KV101151S0

(J38972)

Lifter stopper set

1 KV10115110

(J38972-1)

Camshaft pliers

2 KV10115120

(J38972-2)

Lifter stopper

NT041

Changing shims

EM03470000

(J8037)

Piston ring compressor

NT044

Installing piston assembly into cylinder bore

ST16610001

(J23907)

Pilot bushing puller

NT045

Removing crankshaft pilot bushing

KV101111 0 0

(J37228)

Seal cutter

NT046

Removing steel oil pan and rear timing chain case

WS39930000

(Ð)

Tube presser

NT052

Pressing the tube of liquid gasket

KV10112100

(BT8653-A)

Angle wrench

NT014

Tightening bolts for bearing cap, cylinder head, etc.

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PREPARATION

Special Service Tools (Cont'd)

EM-5

Page 1650 of 2395

Tool number

(Kent-Moore No.)

Tool nameDescription

Valve guide reamer

NT016

Reaming valve guide 1 or hole for oversize valve

guide 2

Intake & Exhaust:

d

1= 6.0 mm (0.236 in) dia.

d

2= 10.2 mm (0.402 in) dia.

(J-43897-18)

(J-43897-12)

Oxygen sensor thread

cleaner

AEM488

Reconditioning the exhaust system threads before

installing a new oxygen sensor (Use with anti-seize

lubricant shown below.)

a = J-43897-18 (18 mm dia.) for zirconia oxygen

sensor

b = J-43897-12 (12 mm dia.) for titania oxygen

sensor

Anti-seize lubricant

(Permatex 133AR or

equivalent meeting MIL

specification MIL-A-

907)

AEM489

Lubricating oxygen sensor thread cleaning tool

when reconditioning exhaust system threads

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PREPARATION

Commercial Service Tools (Cont'd)

EM-7

Page 1652 of 2395

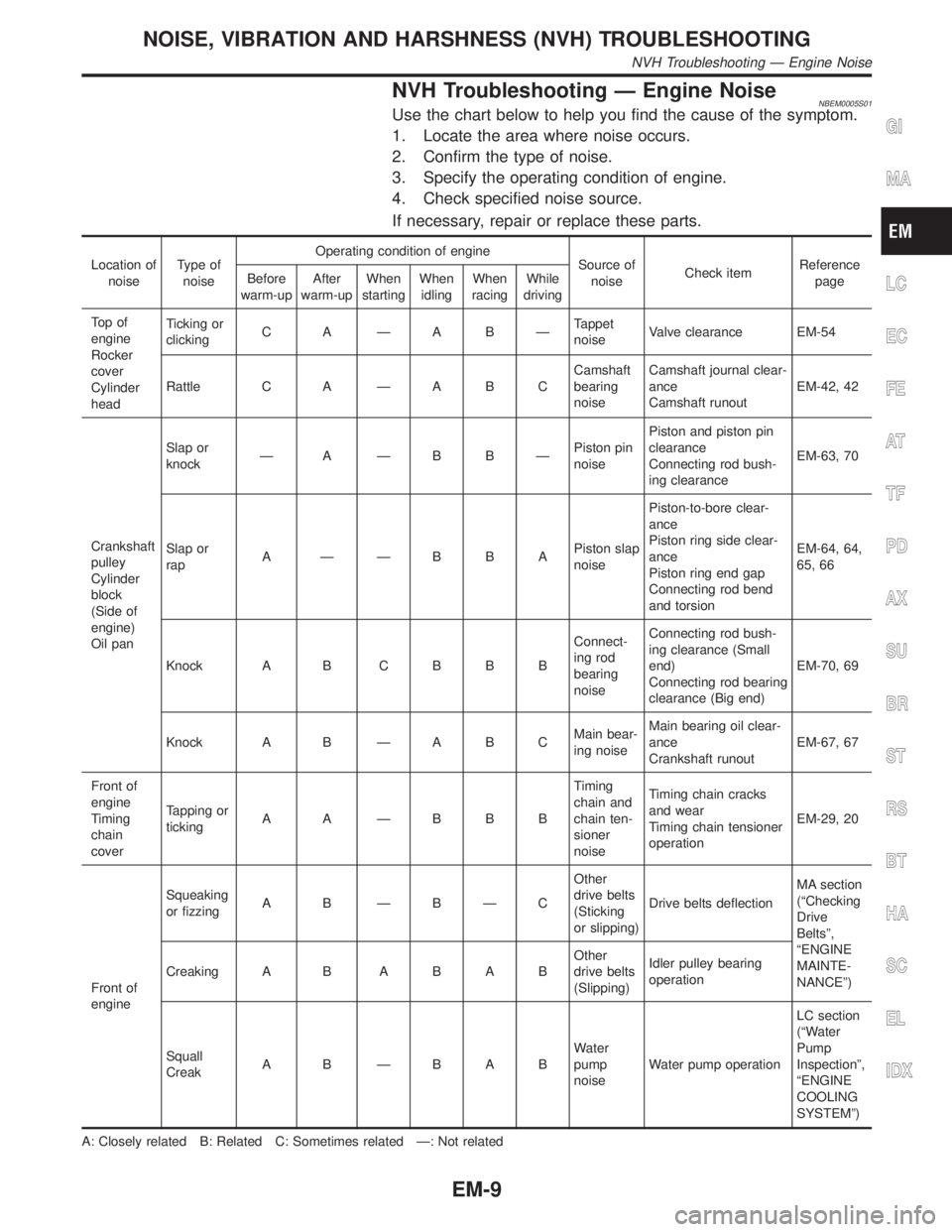

NVH Troubleshooting Ð Engine NoiseNBEM0005S01Use the chart below to help you find the cause of the symptom.

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of engine.

4. Check specified noise source.

If necessary, repair or replace these parts.

Location of

noiseType of

noiseOperating condition of engine

Source of

noiseCheck itemReference

page Before

warm-upAfter

warm-upWhen

startingWhen

idlingWhen

racingWhile

driving

To p o f

engine

Rocker

cover

Cylinder

headTicking or

clickingC A ÐA BÐTappet

noiseValve clearance EM-54

Rattle C A Ð A B CCamshaft

bearing

noiseCamshaft journal clear-

ance

Camshaft runoutEM-42, 42

Crankshaft

pulley

Cylinder

block

(Side of

engine)

Oil panSlap or

knockÐ A ÐB BÐPiston pin

noisePiston and piston pin

clearance

Connecting rod bush-

ing clearanceEM-63, 70

Slap or

rapA ÐÐBBAPiston slap

noisePiston-to-bore clear-

ance

Piston ring side clear-

ance

Piston ring end gap

Connecting rod bend

and torsionEM-64, 64,

65, 66

Knock A B C B B BConnect-

ing rod

bearing

noiseConnecting rod bush-

ing clearance (Small

end)

Connecting rod bearing

clearance (Big end)EM-70, 69

Knock A B Ð A B CMain bear-

ing noiseMain bearing oil clear-

ance

Crankshaft runoutEM-67, 67

Front of

engine

Timing

chain

coverTapping or

tickingA A ÐBBBTiming

chain and

chain ten-

sioner

noiseTiming chain cracks

and wear

Timing chain tensioner

operationEM-29, 20

Front of

engineSqueaking

or fizzingA B ÐBÐCOther

drive belts

(Sticking

or slipping)Drive belts deflectionMA section

(ªChecking

Drive

Beltsº,

ªENGINE

MAINTE-

NANCEº) Creaking A BABABOther

drive belts

(Slipping)Idler pulley bearing

operation

Squall

CreakA B ÐBABWater

pump

noiseWater pump operationLC section

(ªWater

Pump

Inspectionº,

ªENGINE

COOLING

SYSTEMº)

A: Closely related B: Related C: Sometimes related Ð: Not related

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Ð Engine Noise

EM-9

Page 1654 of 2395

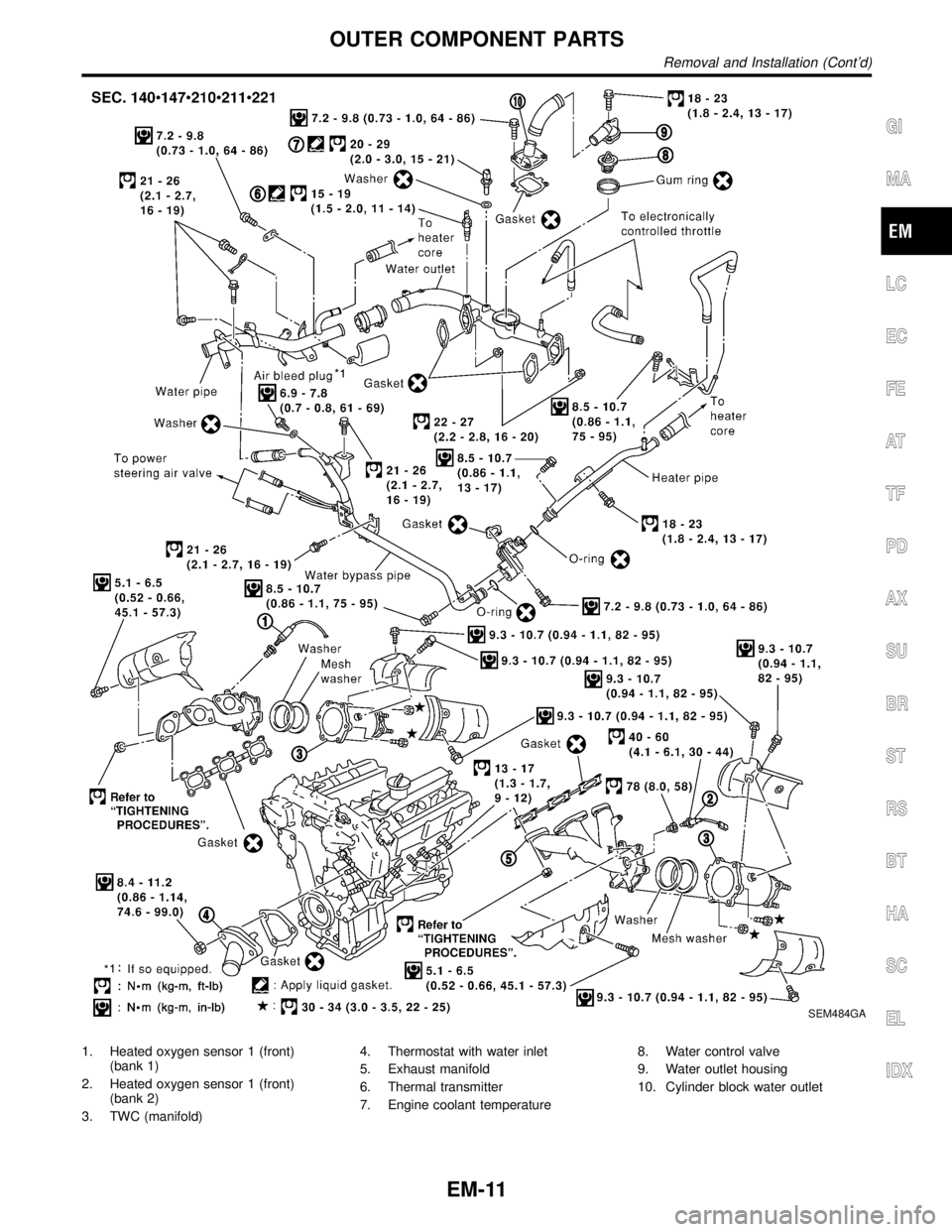

SEM484GA

1. Heated oxygen sensor 1 (front)

(bank 1)

2. Heated oxygen sensor 1 (front)

(bank 2)

3. TWC (manifold)4. Thermostat with water inlet

5. Exhaust manifold

6. Thermal transmitter

7. Engine coolant temperature8. Water control valve

9. Water outlet housing

10. Cylinder block water outlet

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

OUTER COMPONENT PARTS

Removal and Installation (Cont'd)

EM-11

Page 1656 of 2395

SEM477G

Lower Intake Manifold CollectorNBEM0006S0108Tighten bolts and nuts to 18 to 21 N´m (1.8 to 2.2 kg-m, 13 to 15

ft-lb) in numerical order shown in the figure.

SEM478G

SEM479G

Exhaust ManifoldNBEM0006S0109Tighten nuts to 28 to 32 N´m (2.9 to 3.3 kg-m, 21 to 24 ft-lb) in

numerical order shown in the figure.

SEM607G

TWC (Manifold)NBEM0006S0110IAlign the mating mark as shown for locating exhaust flange.

SEM609G

IInstall washer and mesh washer as shown.

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

OUTER COMPONENT PARTS

Removal and Installation (Cont'd)

EM-13

Page 1658 of 2395

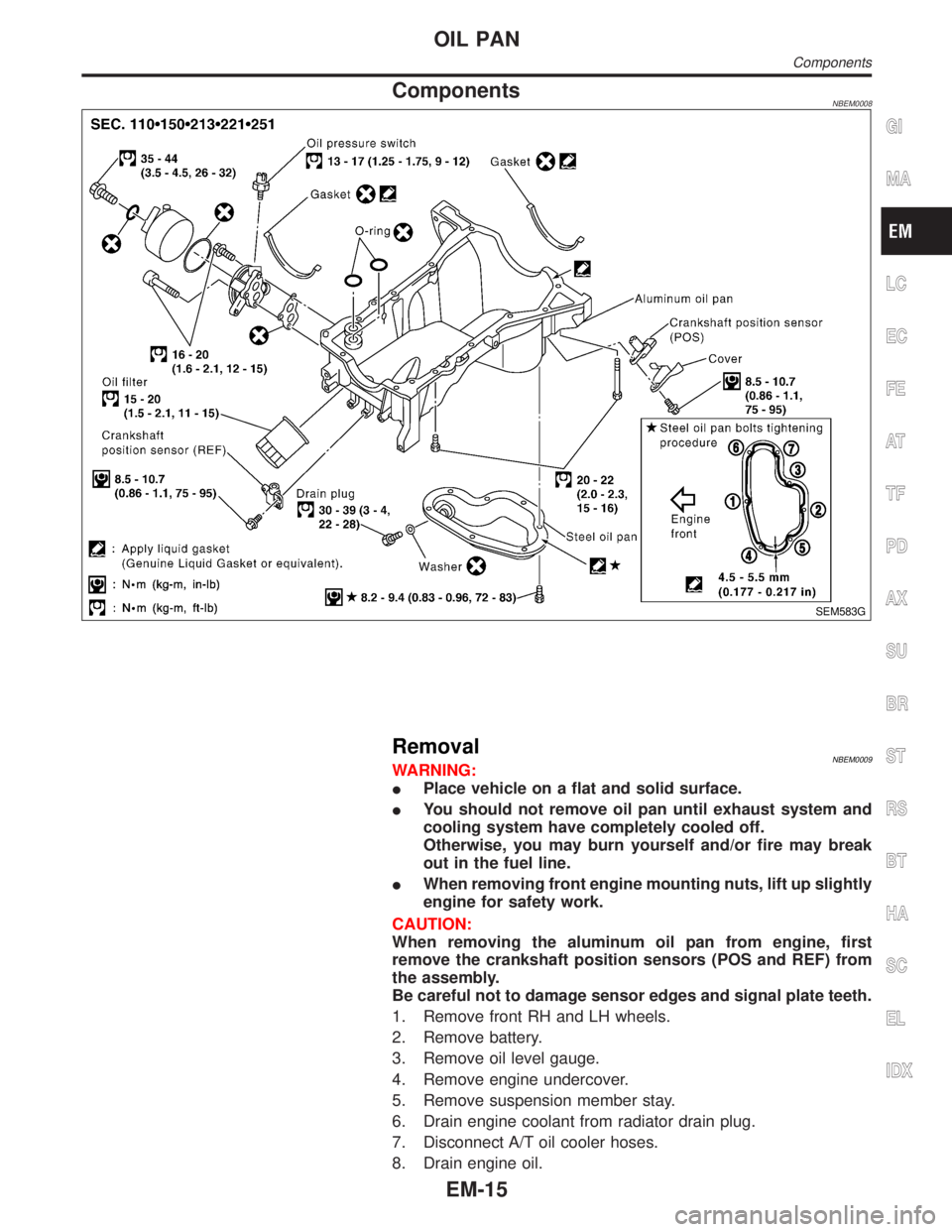

ComponentsNBEM0008

SEM583G

RemovalNBEM0009WARNING:

IPlace vehicle on a flat and solid surface.

IYou should not remove oil pan until exhaust system and

cooling system have completely cooled off.

Otherwise, you may burn yourself and/or fire may break

out in the fuel line.

IWhen removing front engine mounting nuts, lift up slightly

engine for safety work.

CAUTION:

When removing the aluminum oil pan from engine, first

remove the crankshaft position sensors (POS and REF) from

the assembly.

Be careful not to damage sensor edges and signal plate teeth.

1. Remove front RH and LH wheels.

2. Remove battery.

3. Remove oil level gauge.

4. Remove engine undercover.

5. Remove suspension member stay.

6. Drain engine coolant from radiator drain plug.

7. Disconnect A/T oil cooler hoses.

8. Drain engine oil.

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

OIL PAN

Components

EM-15

Page 1660 of 2395

SEM529G

SEM530G

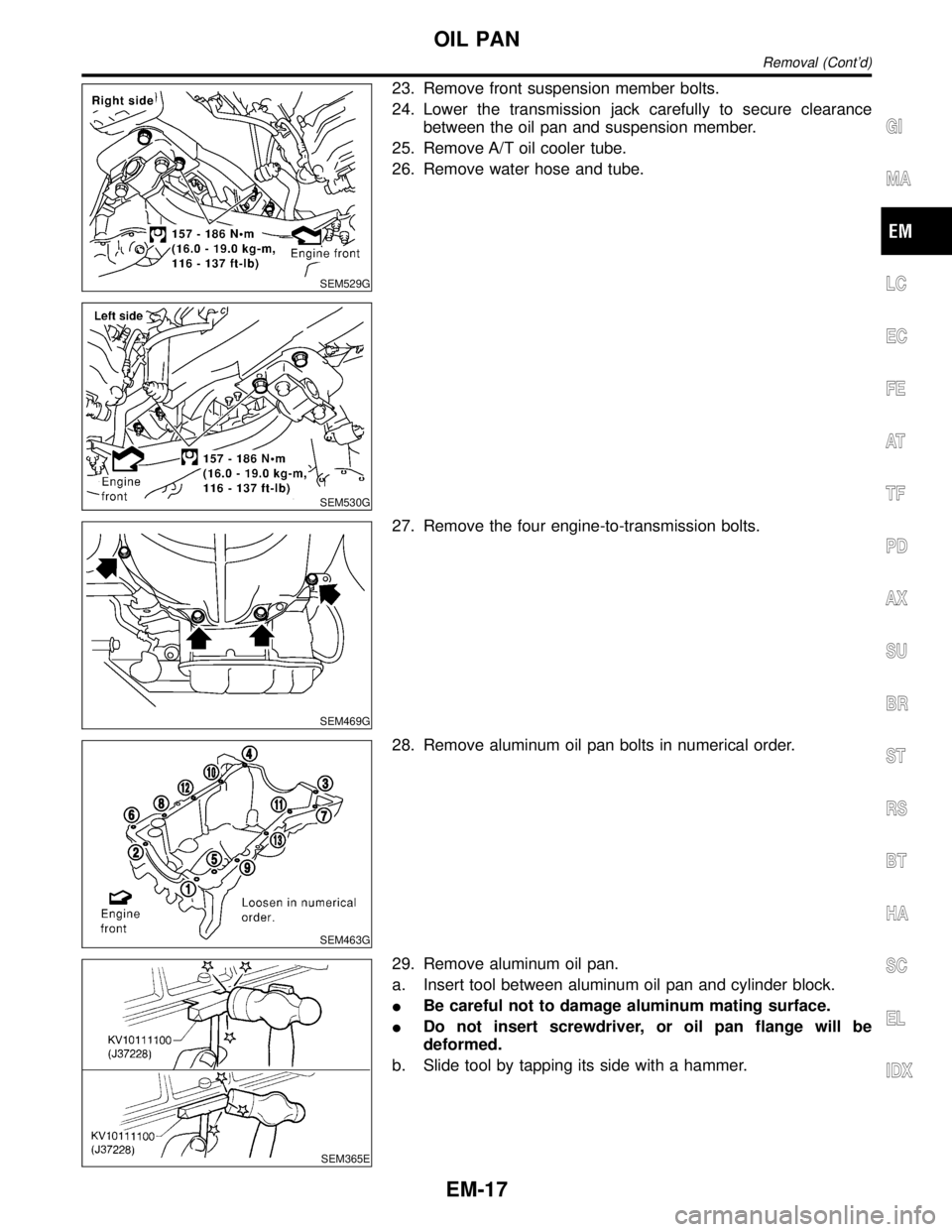

23. Remove front suspension member bolts.

24. Lower the transmission jack carefully to secure clearance

between the oil pan and suspension member.

25. Remove A/T oil cooler tube.

26. Remove water hose and tube.

SEM469G

27. Remove the four engine-to-transmission bolts.

SEM463G

28. Remove aluminum oil pan bolts in numerical order.

SEM365E

29. Remove aluminum oil pan.

a. Insert tool between aluminum oil pan and cylinder block.

IBe careful not to damage aluminum mating surface.

IDo not insert screwdriver, or oil pan flange will be

deformed.

b. Slide tool by tapping its side with a hammer.

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

OIL PAN

Removal (Cont'd)

EM-17

Page 1662 of 2395

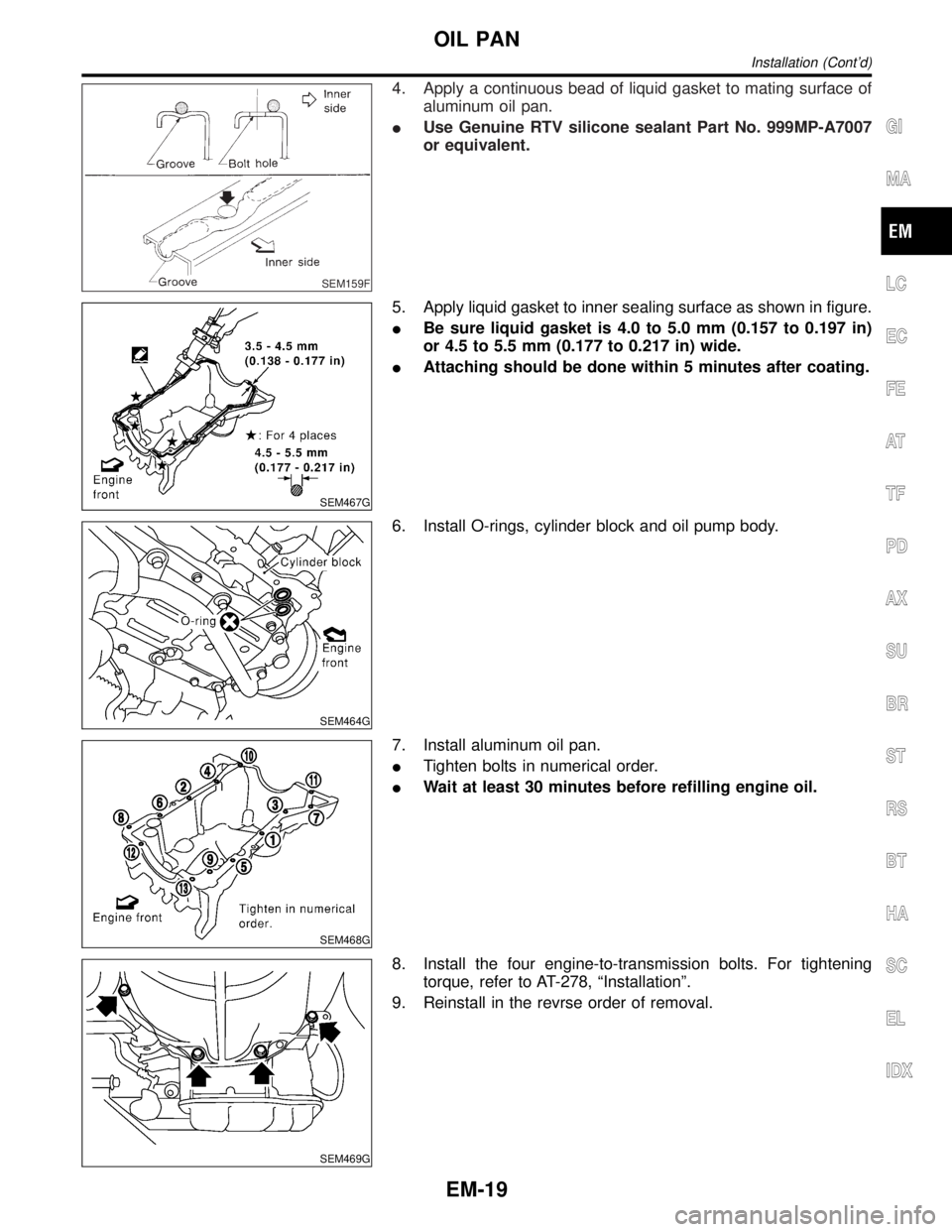

SEM159F

4. Apply a continuous bead of liquid gasket to mating surface of

aluminum oil pan.

IUse Genuine RTV silicone sealant Part No. 999MP-A7007

or equivalent.

SEM467G

5. Apply liquid gasket to inner sealing surface as shown in figure.

IBe sure liquid gasket is 4.0 to 5.0 mm (0.157 to 0.197 in)

or 4.5 to 5.5 mm (0.177 to 0.217 in) wide.

IAttaching should be done within 5 minutes after coating.

SEM464G

6. Install O-rings, cylinder block and oil pump body.

SEM468G

7. Install aluminum oil pan.

ITighten bolts in numerical order.

IWait at least 30 minutes before refilling engine oil.

SEM469G

8. Install the four engine-to-transmission bolts. For tightening

torque, refer to AT-278, ªInstallationº.

9. Reinstall in the revrse order of removal.

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

OIL PAN

Installation (Cont'd)

EM-19

Page 1664 of 2395

POSITION FOR APPLYING LIQUID GASKET=NBEM0011S01Refer to ªInstallationº in ªOIL PANº, EM-18.

IBefore installation, wipe off the protruding sealant.

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TIMING CHAIN

Components (Cont'd)

EM-21