IDX INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1726 of 2395

PISTON RING=NBEM0036S02Unit: mm (in)

Standard Limit

Side clearanceTop 0.040 - 0.080 (0.0016 - 0.0031) 0.11 (0.0043)

2nd 0.030 - 0.070 (0.0012 - 0.0028) 0.1 (0.004)

Oil ring 0.015 - 0.050 (0.0006 - 0.0020) Ð

End gapTop 0.23 - 0.33 (0.0091 - 0.0130) 0.54 (0.0213)

2nd 0.33 - 0.48 (0.0130 - 0.0189) 0.80 (0.0315)

Oil (rail ring) 0.20 - 0.80 (0.0079 - 0.0315) 0.95 (0.0374)

PISTON PINNBEM0036S03Unit: mm (in)

Piston pin outer diameterGrade No. 0 21.989 - 21.995 (0.8657 - 0.8659)

Grade No. 1 21.995 - 22.001 (0.8659 - 0.8662)

Interference fit of piston pin to piston 0.002 - 0.006 (0.0001 - 0.0002)

Piston pin to connecting rod bushing clearanceStandard 0.005 - 0.017 (0.0002 - 0.0007)

Limit 0.030 (0.0012)

*: Values measured at ambient temperature of 20ÉC (68ÉF)

Connecting RodNBEM0037Unit: mm (in)

Center distance144.15 - 144.25 (5.6752 - 5.6791)

Bend [per 100 (3.94)] Limit 0.15 (0.0059)

Torsion [per 100 (3.94)] Limit 0.30 (0.0118)

Connecting rod small end inner diameter 23.980 - 24.000 (0.9441 - 0.9449)

Piston pin bushing inner diameter*Grade No. 0 22.000 - 22.006 (0.8661 - 0.8664)

Grade No. 1 22.006 - 22.012 (0.8664 - 0.8666)

Connecting rod big end inner diameter 55.000 - 55.013 (2.1654 - 2.1659)

Side clearanceStandard 0.20 - 0.35 (0.0079 - 0.0138)

Limit 0.40 (0.0157)

*: After installing in connecting rod

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

SERVICE DATA AND SPECIFICATIONS (SDS)

Piston, Piston Ring and Piston Pin (Cont'd)

EM-83

Page 1728 of 2395

Available Main BearingNBEM0039

SEM175F

Grade number Thickness ªTº mm (in)Width ªWº

mm (in)Identification color

(UPR/LWR)Remarks

0 2.000 - 2.003 (0.0787 - 0.0789)

19.9 - 20.1

(0.783 - 0.791)Black

Grade is the same for

upper and lower bearings. 1 2.003 - 2.006 (0.0789 - 0.0790) Brown

2 2.006 - 2.009 (0.0790 - 0.0791) Green

3 2.009 - 2.012 (0.0791 - 0.0792) Yellow

4 2.012 - 2.015 (0.0792 - 0.0793) Blue

5 2.015 - 2.018 (0.0793 - 0.0794) Pink

6 2.018 - 2.021 (0.0794 - 0.0796) Purple

7 2.021 - 2.024 (0.0796 - 0.0797) White

01UPP 2.003 - 2.006 (0.0789 - 0.0790)

Brown/Black

Grade is different for upper

and lower bearings. LWR 2.000 - 2.003 (0.0787 - 0.0789)

12UPR 2.006 - 2.009 (0.0790 - 0.0791)

Green/Brown

LWR 2.003 - 2.006 (0.0789 - 0.0790)

23UPR 2.009 - 2.012 (0.0791 - 0.0792)

Yellow/Green

LWR 2.006 - 2.009 (0.0790 - 0.0791)

34UPR 2.012 - 2.015 (0.0792 - 0.0793)

Blue/Yellow

LWR 2.009 - 2.012 (0.0791 - 0.0792)

45UPR 2.015 - 2.018 (0.0793 - 0.0794)

Pink/Blue

LWR 2.012 - 2.015 (0.0792 - 0.0793)

56UPR 2.018 - 2.021 (0.0794 - 0.0796)

Purple/Pink

LWR 2.015 - 2.018 (0.0793 - 0.0794)

67UPR 2.021 - 2.024 (0.0796 - 0.0797)

White/Purple

LWR 2.018 - 2.021 (0.0794 - 0.0796)

UNDERSIZENBEM0039S01Unit: mm (in)

Thickness Main journal diameter ªDmº

0.25 (0.0098) 2.132 - 2.140 (0.0839 - 0.0843)Grind so that bearing clearance is the specified

value.

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

SERVICE DATA AND SPECIFICATIONS (SDS)

Available Main Bearing

EM-85

Page 1730 of 2395

ACCELERATOR CONTROL, FUEL &

EXHAUST SYSTEMS

SECTION

FE

CONTENTS

PREPARATION...............................................................2

Special Service Tool ....................................................2

Commercial Service Tools ...........................................2

ACCELERATOR CONTROL SYSTEM...........................3

Removal and Installation .............................................3

Adjusting Accelerator Wire ..........................................3FUEL SYSTEM................................................................4

Removal and Installation .............................................4

FUEL TANK...............................................................5

FUEL PUMP AND GAUGE.........................................6

EXHAUST SYSTEM........................................................8

Removal and Installation .............................................8

GI

MA

EM

LC

EC

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

Page 1732 of 2395

Removal and InstallationNBFE0002CAUTION:

IWhen removing accelerator wire, make a mark to indicate lock nut's initial position.

ICheck that throttle valve opens fully when accelerator pedal is fully depressed. Also check that it

returns to idle position when pedal is released.

ICheck accelerator control parts for improper contact with any adjacent parts.

IWhen connecting accelerator wire, be careful not to twist or scratch its inner wire.

IRefer to EL-240, ªAUTOMATIC SPEED CONTROL DEVICEº for ASCD wire adjustment.

SFE635A

SEF793W

SFE249AE

Adjusting Accelerator WireNBFE00031. Remove the vacuum hose connected to the throttle opener.

2. Connect suitable vacuum hose to vacuum pump as shown left.

3. Apply vacuum [more than þ40.0 kPa (þ300 mmHg, þ11.81

inHg)] until the throttle drum becomes free from the rod of the

throttle opener.

Make sure that there is clearance between the throttle

drum and rod.

If NG, refer to EC-101, ªBasic Inspectionº.

If OK, go to following step.

4. Loosen lock nut.

5. Tighten accelerator adjusting nut until throttle drum starts to

move.

6. From that position, turn back adjusting nut 1.5 to 2 turns, and

secure lock nut.

7. Release vacuum from the throttle opener.

8. Remove vacuum pump and vacuum hose from the throttle

opener.

9. Reinstall the original vacuum hose to the throttle opener

securely.

GI

MA

EM

LC

EC

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ACCELERATOR CONTROL SYSTEM

Removal and Installation

FE-3

Page 1734 of 2395

SFE419AA

SFE420A

FUEL TANKNBFE0004S011. Release fuel pressure from fuel line.

Refer to MA-16, ªChanging Fuel Filterº.

2. Remove inspection hole cover located behind the rear seat.

3. Disconnect harness connectors under inspection hole cover.

4. Disconnect fuel hoses.

IPut mating marks on hoses for correct installation.

SFE468A

5. Disconnect filler hose, vent hose and evaporation hose at fuel

tank side.

GI

MA

EM

LC

EC

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FUEL SYSTEM

Removal and Installation (Cont'd)

FE-5

Page 1736 of 2395

SFE544A

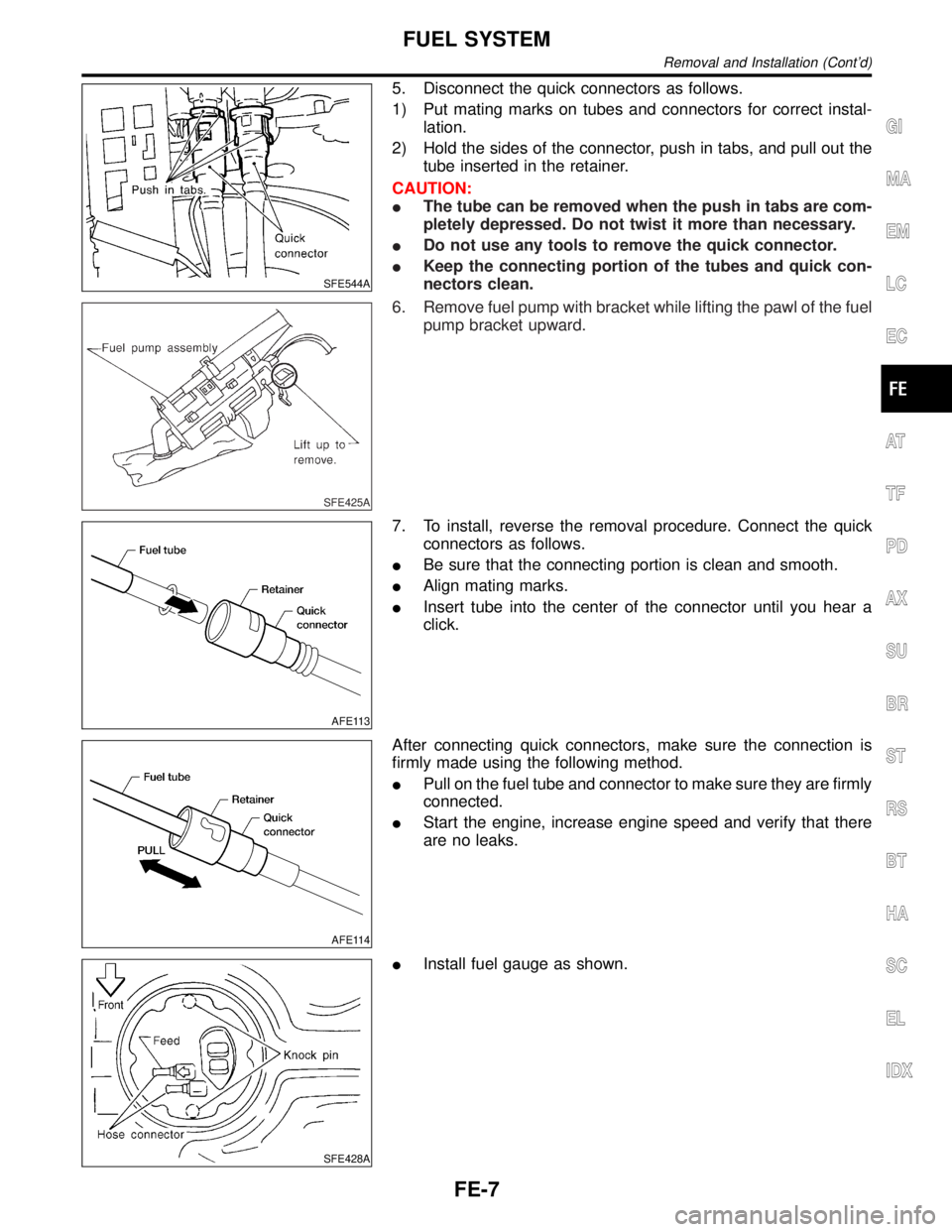

5. Disconnect the quick connectors as follows.

1) Put mating marks on tubes and connectors for correct instal-

lation.

2) Hold the sides of the connector, push in tabs, and pull out the

tube inserted in the retainer.

CAUTION:

IThe tube can be removed when the push in tabs are com-

pletely depressed. Do not twist it more than necessary.

IDo not use any tools to remove the quick connector.

IKeep the connecting portion of the tubes and quick con-

nectors clean.

SFE425A

6. Remove fuel pump with bracket while lifting the pawl of the fuel

pump bracket upward.

AFE113

7. To install, reverse the removal procedure. Connect the quick

connectors as follows.

IBe sure that the connecting portion is clean and smooth.

IAlign mating marks.

IInsert tube into the center of the connector until you hear a

click.

AFE114

After connecting quick connectors, make sure the connection is

firmly made using the following method.

IPull on the fuel tube and connector to make sure they are firmly

connected.

IStart the engine, increase engine speed and verify that there

are no leaks.

SFE428A

IInstall fuel gauge as shown.

GI

MA

EM

LC

EC

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FUEL SYSTEM

Removal and Installation (Cont'd)

FE-7

Page 1738 of 2395

SFE636A

1. Heated oxygen sensor 2 (rear)

(bank 1)

2. Front tube

3. Heated oxygen sensor 2 (rear)

(bank 2)4. Dynamic damper (If so equipped)

5. Mounting rubber

6. Clamp

7. Mounting bracket8. Mounting rubber

9. Main muffler

10. Post muffler

11. TWC (under floor)

GI

MA

EM

LC

EC

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

EXHAUST SYSTEM

Removal and Installation (Cont'd)

FE-9

Page 1746 of 2395

GENERAL INFORMATION

SECTION

GI

CONTENTS

PRECAUTIONS...............................................................3

Precautions ..................................................................3

PRECAUTIONS FOR SUPPLEMENTAL

RESTRAINT SYSTEM (SRS)²AIR BAG²AND

²SEAT BELT PRE-TENSIONER²

.................................3

PRECAUTIONS FOR IVIS (INFINITI VEHICLE

IMMOBILIZER SYSTEM - NATS)

.................................3

PRECAUTIONS FOR INFINITI COMMUNICATOR

(IVCS)

.......................................................................4

GENERAL PRECAUTIONS.........................................5

PRECAUTIONS FOR MULTIPORT FUEL

INJECTION SYSTEM OR ENGINE CONTROL

SYSTEM

...................................................................6

PRECAUTIONS FOR THREE WAY CATALYST...........6

PRECAUTIONS FOR HOSES.....................................7

PRECAUTIONS FOR ENGINE OILS...........................8

PRECAUTIONS FOR FUEL........................................8

PRECAUTIONS FOR AIR CONDITIONING..................8

HOW TO USE THIS MANUAL........................................9

HOW TO READ WIRING DIAGRAMS.......................... 11

Sample/Wiring Diagram - EXAMPL - ........................ 11

OPTIONAL SPLICE..................................................12

Description .................................................................13

CONNECTOR SYMBOLS.........................................15

HARNESS INDICATION...........................................16

COMPONENT INDICATION......................................16

SWITCH POSITIONS...............................................16

DETECTABLE LINES AND NON-DETECTABLE

LINES

.....................................................................17

MULTIPLE SWITCH.................................................18

REFERENCE AREA.................................................19

HOW TO CHECK TERMINAL.......................................21

Connector and Terminal Pin Kit.................................21

How to Probe Connectors .........................................21

PROBING FROM HARNESS SIDE............................21

PROBING FROM TERMINAL SIDE...........................21

How to Check Enlarged Contact Spring of

Terminal .....................................................................22

Waterproof Connector Inspection ..............................23

RUBBER SEAL INSPECTION...................................23

WIRE SEAL INSPECTION........................................23Terminal Lock Inspection ...........................................23

HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT...............................24

Work Flow ..................................................................24

Incident Simulation Tests ...........................................25

INTRODUCTION......................................................25

VEHICLE VIBRATION..............................................25

HEAT SENSITIVE....................................................26

FREEZING..............................................................26

WATER INTRUSION................................................27

ELECTRICAL LOAD.................................................27

COLD OR HOT START UP.......................................27

Circuit Inspection .......................................................27

INTRODUCTION......................................................27

TESTING FOR²OPENS²IN THE CIRCUIT................28

TESTING FOR²SHORTS²IN THE CIRCUIT..............29

GROUND INSPECTION...........................................30

VOLTAGE DROP TESTS..........................................30

CONTROL UNIT CIRCUIT TEST...............................32

HOW TO FOLLOW TROUBLE DIAGNOSIS................34

How to Follow Test Groups in Trouble Diagnosis .....35

Key to Symbols Signifying Measurements or

Procedures.................................................................36

CONSULT-II CHECKING SYSTEM...............................38

Function and System Application ..............................38

Nickel Metal Hydride Battery Replacement...............39

Checking Equipment..................................................39

CONSULT-II Data Link Connector (DLC) Circuit ......40

INSPECTION PROCEDURE.....................................40

IDENTIFICATION INFORMATION................................41

Model Variation ..........................................................41

PREFIX AND SUFFIX DESIGNATIONS.....................41

Identification Number .................................................41

VEHICLE IDENTIFICATION NUMBER

ARRANGEMENT

.....................................................42

IDENTIFICATION PLATE..........................................42

ENGINE SERIAL NUMBER.......................................43

AUTOMATIC TRANSMISSION NUMBER...................43

TRANSFER SERIAL NUMBER..................................43

Dimensions ................................................................43

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

Page 1748 of 2395

PrecautionsNBGI0001Observe the following precautions to ensure safe and proper

servicing. These precautions are not described in each indi-

vidual section.

SGI646

PRECAUTIONS FOR SUPPLEMENTAL RESTRAINT

SYSTEM (SRS) ªAIR BAGº AND ªSEAT BELT

PRE-TENSIONERº

NBGI0001S01The Supplemental Restraint System such as ªAIR BAGº and ªSEAT

BELT PRE-TENSIONERº used along with a seat belt, helps to

reduce the risk or severity of injury to the driver and front passen-

ger for certain types of collision. The SRS system composition

which is available to INFINITI QX4 is as follows:

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag

module (located in the center of the steering wheel), front pas-

senger air bag module (located on the instrument panel on

passenger side), seat belt pre-tensioners, a diagnosis sensor

unit, warning lamp, wiring harness and spiral cable.

IFor a side collision

The Supplemental Restraint System consists of side air bag

module (located in the outer side of front seat), satellite sensor,

diagnosis sensor unit (one of components of air bags for a

frontal collision), wiring harness, warning lamp (one of compo-

nents of air bags for a frontal collision).

Information necessary to service the system safely is included in

theRS sectionof this Service Manual.

WARNING:

ITo avoid rendering the SRS inoperative, which could

increase the risk of personal injury or death in the event

of a collision which would result in air bag inflation, all

maintenance must be performed by an authorized INFINITI

dealer.

IImproper maintenance, including incorrect removal and

installation of the SRS, can lead to personal injury caused

by unintentional activation of the system. For removal of

Spiral Cable and Air Bag Module, see the RS section.

IDo not use electrical test equipment on any circuit related

to the SRS unless instructed to in this Service Manual.

Spiral cable and wiring harnesses covered with yellow

insulation tape either just before the harness connectors

or for the complete harness are related to the SRS.

PRECAUTIONS FOR IVIS (INFINITI VEHICLE

IMMOBILIZER SYSTEM Ð NATS)

NBGI0001S08IVIS (NATS) will immobilize the engine if someone tries to start it

without the registered key of IVIS (NATS).

Both of the originally supplied ignition key IDs have been IVIS

(NATS) registered.

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PRECAUTIONS

Precautions

GI-3

Page 1750 of 2395

SGI285

GENERAL PRECAUTIONSNBGI0001S02IDo not operate the engine for an extended period of time

without proper exhaust ventilation.

Keep the work area well ventilated and free of any inflammable

materials. Special care should be taken when handling any

inflammable or poisonous materials, such as gasoline, refrig-

erant gas, etc. When working in a pit or other enclosed area,

be sure to properly ventilate the area before working with haz-

ardous materials.

Do not smoke while working on the vehicle.

SGI231

IBefore jacking up the vehicle, apply wheel chocks or other tire

blocks to the wheels to prevent the vehicle from moving. After

jacking up the vehicle, support the vehicle weight with safety

stands at the points designated for proper lifting before work-

ing on the vehicle.

These operations should be done on a level surface.

IWhen removing a heavy component such as the engine or

transaxle/transmission, be careful not to lose your balance and

drop it. Also, do not allow it to strike adjacent parts, especially

the brake tubes and master cylinder.

SEF289H

IBefore starting repairs which do not require battery power:

Turn off ignition switch.

Disconnect the negative battery terminal.

SGI233

ITo prevent serious burns:

Avoid contact with hot metal parts.

Do not remove the radiator cap when the engine is hot.

SGI234

IBefore servicing the vehicle:

Protect fenders, upholstery and carpeting with appropriate cov-

ers.

Take caution that keys, buckles or buttons do not scratch paint.

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PRECAUTIONS

Precautions (Cont'd)

GI-5