IDX INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1812 of 2395

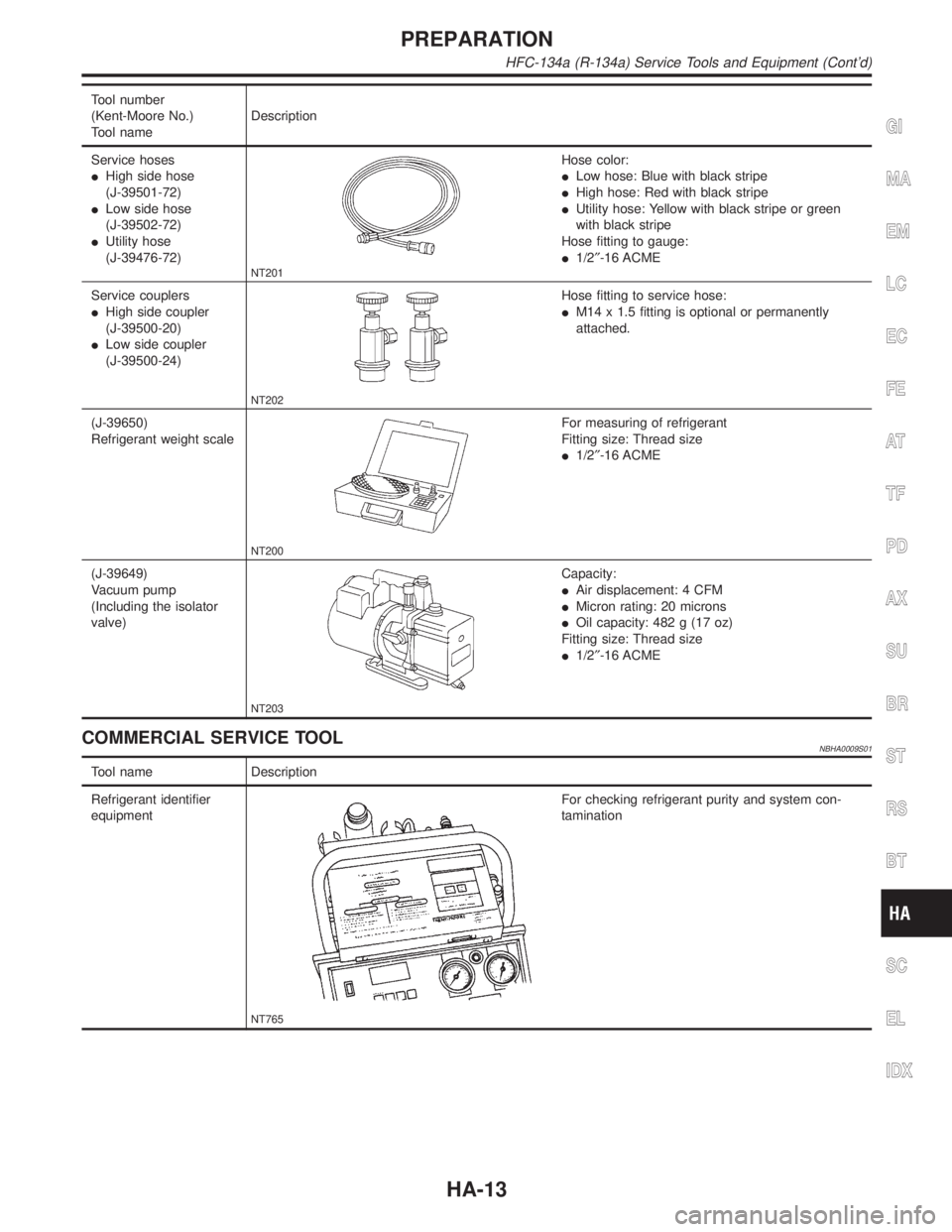

Tool number

(Kent-Moore No.)

Tool nameDescription

Service hoses

IHigh side hose

(J-39501-72)

ILow side hose

(J-39502-72)

IUtility hose

(J-39476-72)

NT201

Hose color:

ILow hose: Blue with black stripe

IHigh hose: Red with black stripe

IUtility hose: Yellow with black stripe or green

with black stripe

Hose fitting to gauge:

I1/2²-16 ACME

Service couplers

IHigh side coupler

(J-39500-20)

ILow side coupler

(J-39500-24)

NT202

Hose fitting to service hose:

IM14 x 1.5 fitting is optional or permanently

attached.

(J-39650)

Refrigerant weight scale

NT200

For measuring of refrigerant

Fitting size: Thread size

I1/2²-16 ACME

(J-39649)

Vacuum pump

(Including the isolator

valve)

NT203

Capacity:

IAir displacement: 4 CFM

IMicron rating: 20 microns

IOil capacity: 482 g (17 oz)

Fitting size: Thread size

I1/2²-16 ACME

COMMERCIAL SERVICE TOOLNBHA0009S01

Tool name Description

Refrigerant identifier

equipment

NT765

For checking refrigerant purity and system con-

tamination

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

PREPARATION

HFC-134a (R-134a) Service Tools and Equipment (Cont'd)

HA-13

Page 1814 of 2395

V-6 Variable Displacement Compressor

GENERAL INFORMATION=NBHA00861. The V-6 variable compressor differs from previous units. The vent temperatures of the V-6 variable com-

press do not drop too far below 5ÉC (41ÉF) when:

Ievaporator intake air temperature is less than 20ÉC (68ÉF)

Iengine is running at speeds less than 1,500 rpm.

This is because the V-6 compressor provides a means of ªcapacityº control.

2. The V-6 variable compressor provides refrigerant control under varying conditions. During cold winters, it

may not produce high refrigerant pressure discharge (compared to previous units) when used with air

conditioning systems.

3. A ªclankingº sound may occasionally be heard during refrigerant charge. The sound indicates that the tilt

angle of the swash plate has changed and is not a problem.

4. For air conditioning systems with the V-6 compressor, the clutch remains engaged unless: the system main

switch, fan switch or ignition switch is turned OFF. When ambient (outside) temperatures are low or when

the amount of refrigerant is insufficient, the clutch is disengaged to protect the compressor.

5. A constant range of suction pressure is maintained when engine speed is greater than a certain value. It

normally ranges from 147 to 177 kPa (1.5 to 1.8 kg/cm

2, 21 to 26 psi) under varying conditions.

In previous compressors, however, suction pressure was reduced with increases in engine speed.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

DESCRIPTION

V-6 Variable Displacement Compressor

HA-15

Page 1816 of 2395

Operation=NBHA0087S021. Operation Control ValveNBHA0087S0201Operation control valve is located in the suction port (low-pressure) side, and opens or closes in response to

changes in refrigerant suction pressure.

Operation of the valve controls the internal pressure of the crankcase.

The angle of the swash plate is controlled between the crankcase's internal pressure and the piston cylinder

pressure.

2. Maximum Cooling

NBHA0087S0202Refrigerant pressure on the low-pressure side increases with an increase in heat loads.

When this occurs, the control valve's bellows compress to open the low-pressure side valve and close the

high-pressure side valve.

This causes the following pressure changes:

Ithe crankcase's internal pressure to equal the pressure on the low-pressure side;

Ithe cylinder's internal pressure to be greater than the crankcase's internal pressure.

Under this condition, the swash plate is set to the maximum stroke position.

RHA473C

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

DESCRIPTION

V-6 Variable Displacement Compressor (Cont'd)

HA-17

Page 1818 of 2395

Component LayoutNBHA0012

RHA451G

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

DESCRIPTION

Component Layout

HA-19

Page 1820 of 2395

RHA441GA

Transmission Data and Transmission OrderNBHA0014S0802Amplifier data is transmitted consecutively to each of the door motors following the form shown in figure below.

Start: Initial compulsory signal sent to each of the door motors.

Address: Data sent from the auto amplifier is selected according to data-based decisions made by the air mix

door motor and mode door motor.

If the addresses are identical, the opening angle data and error check signals are received by the door motor

LCUs. The LCUs then make the appropriate error decision. If the opening angle data is normal, door control

begins.

If an error exists, the received data is rejected and corrected data received. Finally, door control is based upon

the corrected opening angle data.

Opening angle: Data that shows the indicated door opening angle of each door motor.

Error check: Procedure by which sent and received data is checked for errors. Error data is then compiled.

The error check prevents corrupted data from being used by the air mix door motor and mode door motor.

Error data can be related to the following problems.

IAbnormal electrical frequency

IPoor electrical connections

ISignal leakage from transmission lines

ISignal level fluctuation

Stop signal: At the end of each transmission, a stop operation, in-operation, or internal problem message is

delivered to the auto amplifier. This completes one data transmission and control cycle.

RHA442G

Air Mix Door Control (Automatic Temperature Control)NBHA0014S0803The air mix door is automatically controlled so that in-vehicle temperature is maintained at a predetermined

value by: The temperature setting, ambient temperature, in-vehicle temperature and amount of sunload.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

DESCRIPTION

Features (Cont'd)

HA-21

Page 1822 of 2395

Overview of Control System=NBHA0015The control system consists of input sensors, switches, the automatic amplifier (microcomputer) and outputs.

The relationship of these components is shown in the diagram below:

RHA856H

Control OperationNBHA0016

RHA452GA

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

DESCRIPTION

Overview of Control System

HA-23

Page 1824 of 2395

Discharge Air FlowNBHA0017

RHA043G

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

DESCRIPTION

Discharge Air Flow

HA-25

Page 1826 of 2395

Component LocationNBHA0033ENGINE COMPARTMENTNBHA0033S01

SHA281FA

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

TROUBLE DIAGNOSES

Component Location

HA-27

Page 1828 of 2395

With Navigation SystemNBHA0033S0202

RHA857H

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

TROUBLE DIAGNOSES

Component Location (Cont'd)

HA-29

Page 1830 of 2395

Wiring Diagram Ð A/C, A Ð (Without

Navigation System)

NBHA0035

MHA974A

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

TROUBLE DIAGNOSES

Wiring Diagram Ð A/C, A Ð (Without Navigation System)

HA-31