change time INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2 of 3061

-2

This manual contains maintenance and repair procedures for the

2007 INFINITI QX56.

In order to assure your safety and the efficient functioning of the vehicle,

this manual should be read thoroughly. It is especially important that the

PRECAUTIONS in the GI section be completely understood before starting

any repair task.

All information in this manual is based on the latest product information

at the time of publication. The right is reserved to make changes in specifi-

cations and methods at any time without notice.

IMPORTANT SAFETY NOTICE

The proper performance of service is essential for both the safety of

the technician and the efficient functioning of the vehicle.

The service methods in this Service Manual are described in such a

manner that the service may be performed safely and accurately.

Service varies with the procedures used, the skills of the technician

and the tools and parts available. Accordingly, anyone using service

procedures, tools or parts which are not specifically recommended

by NISSAN must first be completely satisfied that neither personal

safety nor the vehicle’s safety will be jeopardized by the service

method selected.

Page 106 of 3061

AT-36

< SERVICE INFORMATION >

A/T CONTROL SYSTEM

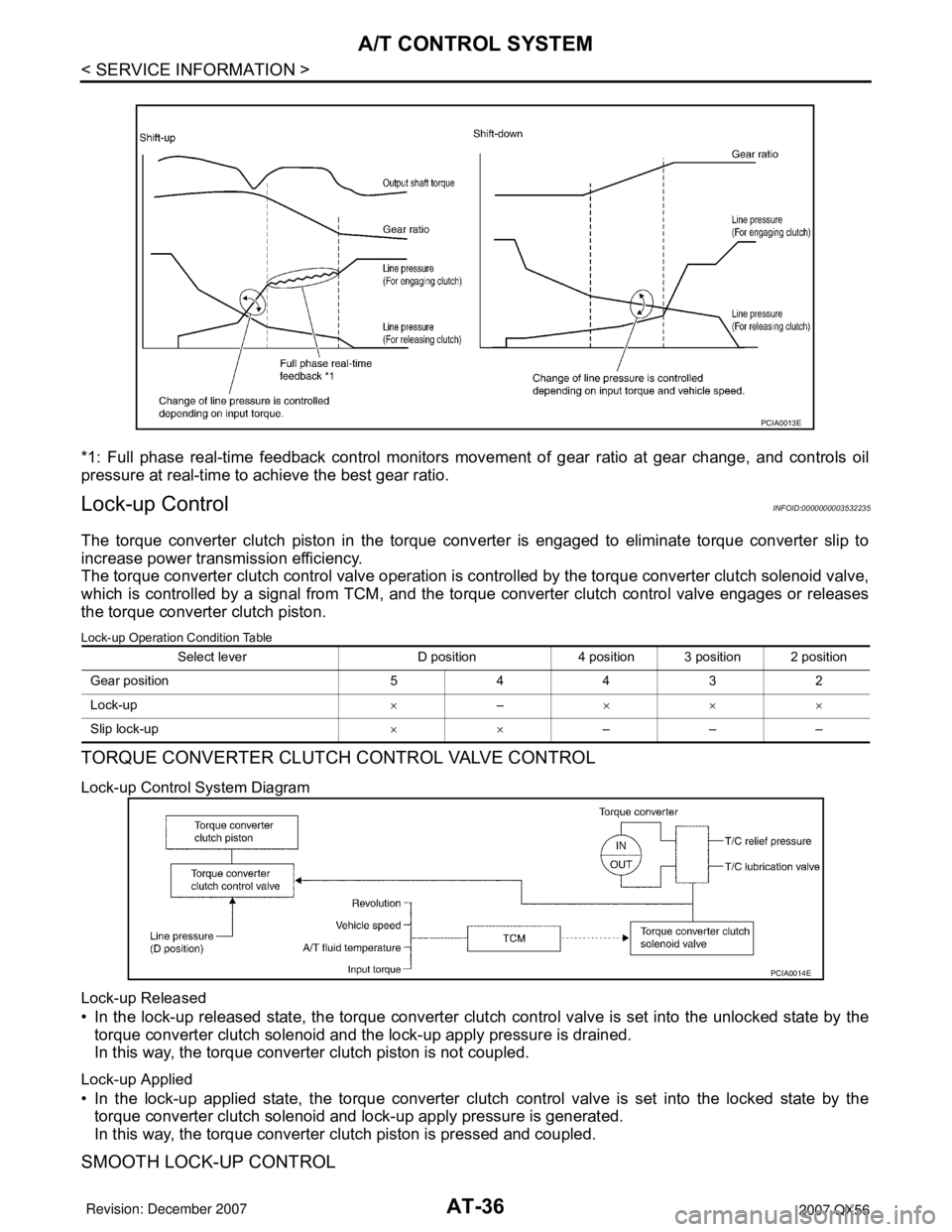

*1: Full phase real-time feedback control monitors movement of gear ratio at gear change, and controls oil

pressure at real-time to achieve the best gear ratio.

Lock-up ControlINFOID:0000000003532235

The torque converter clutch piston in the torque converter is engaged to eliminate torque converter slip to

increase power transmission efficiency.

The torque converter clutch control valve operation is controlled by the torque converter clutch solenoid valve,

which is controlled by a signal from TCM, and the torque converter clutch control valve engages or releases

the torque converter clutch piston.

Lock-up Operation Condition Table

TORQUE CONVERTER CLUTCH CONTROL VALVE CONTROL

Lock-up Control System Diagram

Lock-up Released

• In the lock-up released state, the torque converter clutch control valve is set into the unlocked state by the

torque converter clutch solenoid and the lock-up apply pressure is drained.

In this way, the torque converter clutch piston is not coupled.

Lock-up Applied

• In the lock-up applied state, the torque converter clutch control valve is set into the locked state by the

torque converter clutch solenoid and lock-up apply pressure is generated.

In this way, the torque converter clutch piston is pressed and coupled.

SMOOTH LOCK-UP CONTROL

PCIA0013E

Select lever D position 4 position 3 position 2 position

Gear position 5 4 4 3 2

Lock-up×–×××

Slip lock-up××–––

PCIA0014E

Page 153 of 3061

TROUBLE DIAGNOSIS

AT-83

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

PCONSULT-II Function (A/T)INFOID:0000000003532259

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

CONSULT-II REFERENCE VALUE

NOTICE:

1. The CONSULT-II electrically displays shift timing and lock-up timing (that is, operation timing of each sole-

noid).

Check for time difference between actual shift timing and the CONSULT-II display. If the difference is

noticeable, mechanical parts (except solenoids, sensors, etc.) may be malfunctioning. Check mechanical

parts using applicable diagnostic procedures.

2. Shift schedule (which implies gear position) displayed on CONSULT-II and that indicated in Service Man-

ual may differ slightly. This occurs because of the following reasons:

- Actual shift schedule has more or less tolerance or allowance,

- Shift schedule indicated in Service Manual refers to the point where shifts start, and

- Gear position displayed on CONSULT-II indicates the point where shifts are completed.

3. Display of solenoid valves on CONSULT-II changes at the start of shifting, while gear position is displayed

upon completion of shifting (which is computed by TCM).

9 B/R Starter relaySelector lever in “N”,“ P” positions. Battery voltage

Selector lever in other positions. 0V

10 B Ground Always 0V Te r m i n a l

No.Wire

colorItem Condition Data (Pyrex.)

TCM diagnostic mode Description

WORK SUPPORTSupports inspections and adjustments. Commands are transmitted to the TCM for setting the status

suitable for required operation, input/output signals are received from the TCM and received data is

displayed.

SELF-DIAG RESULTS Displays TCM self-diagnosis results.

DATA MONITOR Displays TCM input/output data in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

FUNCTION TEST Conducted by CONSULT-II instead of a technician to determine whether each system is “OK” or “NG”.

ECU PART NUMBER TCM part number can be read.

Item name Condition Display value (Approx.)

ATF TEMP SE 1

0°C (32° F) - 20°C (68°F) - 80°C (176°F)3.3 - 2.7 - 0.9 V

ATF TEMP SE 23.3 - 2.5 - 0.7 V

TCC SOLENOIDWhen perform slip lock-up 0.2 - 0.4 A

When perform lock-up 0.4 - 0.6 A

SLCT LVR POSISelector lever in “N”,“P” position. N/P

Selector lever in “R” position. R

Selector lever in “D” position. D

Selector lever in “4” position. 4

Selector lever in “3” position. 3

Selector lever in “2” position. 2

Selector lever in “1” position. 1

VHCL/S SE·A/T During drivingApproximately matches the

speedometer reading.

ENGINE SPEED Engine runningClosely matches the tachometer

reading.

Page 420 of 3061

ATC-50

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Operational Check (Front)

INFOID:0000000003533249

The purpose of the operational check is to confirm that the system operates properly.

CHECKING MEMORY FUNCTION

1. Set the temperature to 90 °F or 32 °C.

2. Turn front blower control dial counterclockwise until system shuts OFF.

3. Turn ignition switch OFF.

4. Turn ignition switch ON.

5. Press the AUTO switch.

6. Confirm that the set temperature remains at previous temperature.

7. Turn front blower control counterclockwise until system shuts OFF.

If NG, go to trouble diagnosis procedure for ATC-112, "

Memory Function".

If OK, continue with next check.

CHECKING BLOWER

1. Turn front blower control clockwise, blower s hould operate on low speed. The blower symbol should have

one blade lit (on display).

2. Turn the front blower control dial again, and c ontinue checking blower speed and blower symbol until all

speeds are checked.

3. Leave blower on MAX speed.

If NG, go to trouble diagnosis procedure for ATC-78, "

Front Blower Motor Circuit".

If OK, continue with next check.

CHECKING DISCHARGE AIR

1. Press MODE switch four times and the DEF ( ) switch.

2. Each position indicator should change shape (on display).

3. Confirm that discharge air comes out according to the air distribution table. Refer to ATC-26, "

Discharge

Air Flow".

Mode door position is checked in the next step.

If NG, go to trouble diagnosis procedure for ATC-54, "

Mode Door Motor Circuit" .

If OK, continue the check.

NOTE:

Confirm that the compressor clutch is engaged (sound or vis ual inspection) and intake door position is at fresh

when the DEF or D/F is selected.

CHECKING RECIRCULATION ( , ONLY)

1. Press recirculation ( ) switch one time. Recirculation indicator should illuminate.

2. Press recirculation ( ) switch one more time. Recirculation indicator should go off.

3. Listen for intake door position change (blower sound should change slightly).

If NG, go to trouble diagnosis procedure for ATC-70, "

Intake Door Motor Circuit" .

If OK, continue the check.

NOTE:

Confirm that the compressor clutch is engaged (sound or vis ual inspection) and intake door position is at fresh

when the DEF or D/F is selected. REC ( ) is not allowed in DEF ( ) D/F ( ) or FOOT ( ).

CHECKING TEMPERATURE DECREASE

90 Stuck button ATC-123, "Removal and Installation"

92 Mode door motor circuit failureAT C - 5 4 , "Mode Door Motor Circuit"

Code No. Reference page

Conditions : Engine running and at normal operating temperature

Page 424 of 3061

ATC-54

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

1. Turn ignition switch OFF.

2. Check continuity between front air control harness connectorM49 terminal 1 and ground.

OK or NG

OK >> Replace front air control. Refer to ATC-123, "Removal

and Installation" .

NG >> Repair harness or connector.

Mode Door Motor CircuitINFOID:0000000003533252

SYMPTOM:

• Air outlet does not change.

• Mode door motor does not operate normally.

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING OP ERATIONAL CHECK - DISCHARGE AIR

1. Press mode switch four times and then press the (DEF) switch. Each position indicator should change shape (on display).

2. Confirm that discharge air comes out according to the air distribution table. Refer to ATC-26, "

Discharge

Air Flow".

NOTE:

Confirm that the compressor clutch is engaged (visual inspection) and intake door position is at FRESH

when DEF ( ) or D/F ( ) is selected.

Can a symptom be duplicated?

YES >> GO TO 3.

NO >> GO TO 2.

2.PERFORM COMPLETE OPERATIONAL CHECK

Perform a complete operational check and check for any symptoms. Refer to ATC-50, "

Operational Check

(Front)".

Can a symptom be duplicated?

YES >> Refer to ATC-32, "How to Perform Trouble Diagnosis for Quick and Accurate Repair".

NO >> System OK.

3.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 4.

4.CHECK MODE DOOR OPERATION

Check and verify mode door mechanism for smooth operation in each mode.

OK or NG

OK >> GO TO 5.

NG >> Repair as necessary.

5.PERFORM SELF-DIAGNOSIS

Perform self-diagnosis to check for any codes. Refer to ATC-48, "

A/C System Self-Diagnosis Function".

Are any self-diagnosis codes present?

YES >> Refer to ATC-48, "A/C System Self-Diagnosis Function".

NO >> GO TO 6.

6.CHECK THE MODE DOOR MOTOR PBR CIRCUIT 1 - Ground : Continuity should exist.

WJIA1351E

Page 476 of 3061

ATC-106

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

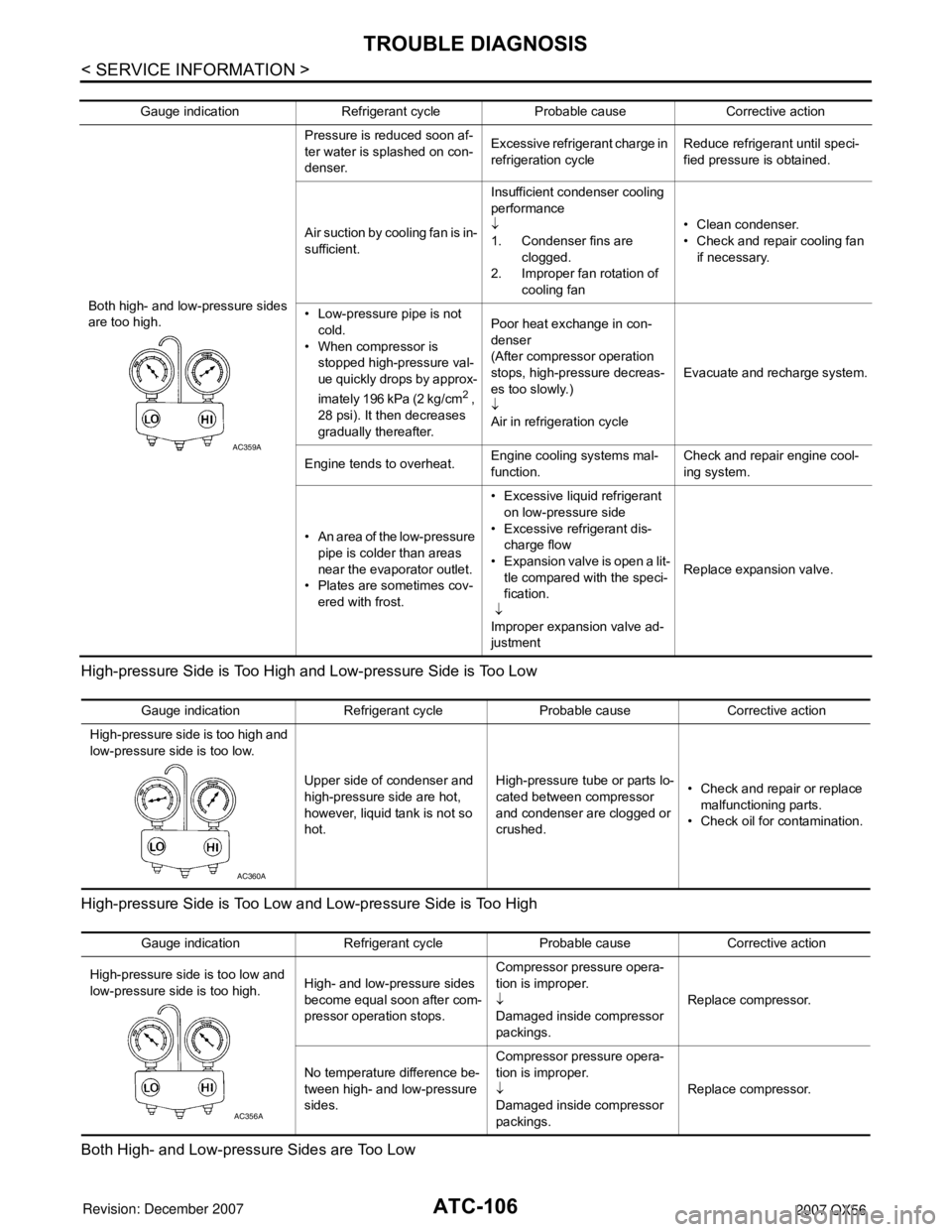

High-pressure Side is Too High and Low-pressure Side is Too Low

High-pressure Side is Too Low and Low-pressure Side is Too High

Both High- and Low-pressure Sides are Too Low

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high- and low-pressure sides

are too high. Pressure is reduced soon af-

ter water is splashed on con-

denser.

Excessive refrigerant charge in

refrigeration cycle

Reduce refrigerant until speci-

fied pressure is obtained.

Air suction by cooling fan is in-

sufficient. Insufficient condenser cooling

performance

↓

1. Condenser fins are

clogged.

2. Improper fan rotation of cooling fan • Clean condenser.

• Check and repair cooling fan

if necessary.

• Low-pressure pipe is not cold.

• When compressor is stopped high-pressure val-

ue quickly drops by approx-

imately 196 kPa (2 kg/cm

2 ,

28 psi). It then decreases

gradually thereafter. Poor heat exchange in con-

denser

(After compressor operation

stops, high-pressure decreas-

es too slowly.)

↓

Air in refrigeration cycle

Evacuate and recharge system.

Engine tends to overheat. Engine cooling systems mal-

function. Check and repair engine cool-

ing system.

• An area of the low-pressure pipe is colder than areas

near the evaporator outlet.

• Plates are sometimes cov- ered with frost. • Excessive liquid refrigerant

on low-pressure side

• Excessive refrigerant dis- charge flow

• Expansion valve is open a lit- tle compared with the speci-

fication.

↓

Improper expansion valve ad-

justment Replace expansion valve.

AC359A

Gauge indication Refrigerant cycle Probable cause Corrective action

High-pressure side is too high and

low-pressure side is too low.

Upper side of condenser and

high-pressure side are hot,

however, liquid tank is not so

hot.High-pressure tu

be or parts lo-

cated between compressor

and condenser are clogged or

crushed. • Check and repair or replace

malfunctioning parts.

• Check oil for contamination.

AC360A

Gauge indication Refrigerant cycle Probable cause Corrective action

High-pressure side is too low and

low-pressure side is too high. High- and low-pressure sides

become equal soon after com-

pressor operation stops.Compressor pressure opera-

tion is improper.

↓

Damaged inside compressor

packings.

Replace compressor.

No temperature difference be-

tween high- and low-pressure

sides. Compressor pressure opera-

tion is improper.

↓

Damaged inside compressor

packings.

Replace compressor.

AC356A

Page 489 of 3061

TROUBLE DIAGNOSISATC-119

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

COMPONENT INSPECTION

In-vehicle Sensor

After disconnecting in-vehicle sensor connector M32, measure resis-

tance between terminals 1 and 4 at sensor component side, using

the table below.

If NG, replace in-vehicle sensor.

Optical Sensor CircuitINFOID:0000000003533268

COMPONENT DESCRIPTION

The optical sensor is located in t he center of the defroster grille. It

detects sunload entering through windshield by means of a photo

diode. The sensor converts the sunload into a current value which is

then input into the front air control.

OPTICAL INPUT PROCESS

The front air control includes a processing circuit whic h averages the variations in detected sunload over a

period of time. This prevents adjustments in the ATC system operation due to small or quick variations in

detected sunload.

For example, consider driving along a road bordered by an occasional group of large trees. The sunload

detected by the optical sensor will vary whenever the tr ees obstruct the sunlight. The processing circuit aver-

ages the detected sunload over a period of time, so that the (insignificant) effect of the trees momentarily

obstructing the sunlight does not cause any change in t he ATC system operation. On the other hand, shortly

after entering a long tunnel, the system will recognize t he change in sunload, and the system will react accord-

ingly.

DIAGNOSTIC PROCEDURE FOR OPTICAL SENSOR

Temperature °C ( °F) Resistance k Ω

− 15 (5) 21.40

− 10 (14) 16.15

− 5 (23) 12.29

0 (32) 9.41

5 (41) 7.27

10 (50) 5.66

15 (59) 4.45

20 (68) 3.51

25 (77) 2.79

30 (86) 2.24

35 (95) 1.80

40 (104) 1.45 45 (113) 1.18

WJIA0825E

WJIA0569E

Page 546 of 3061

AV-6

< SERVICE INFORMATION >

AUDIO

System Description

INFOID:0000000003533664

Refer to Owner's Manual for audio system operating instructions.

Power is supplied at all times

• through 15A fuse [No. 17, located in the fuse block (J/B)]

• to subwoofer terminal 6

• through 20A fuse [No. 31, located in the fuse and fusible link box]

• to audio unit terminal 6

• to BOSE speaker amp. terminal 1

• to AV switch terminal 1 and

• to display control unit terminal 1.

With the ignition switch in the ACC or ON position, power is supplied

• through 10A fuse [No. 4, located in the fuse block (J/B)]

• to audio unit terminal 10 and

• to AV switch terminal 2 and

• to display control unit terminal 10.

With the ignition switch in the ON or START position, power is supplied

• through 10A fuse [No. 12, located in the fuse block (J/B)]

• to display control unit terminal 12.

Ground is supplied through the case of the audio unit.

Ground is also supplied

• to subwoofer terminal 5

• through body grounds B7 and B19 and

• to BOSE speaker amp. terminal 17

• to AV switch terminal 5 and

• to display unit terminal 1 and

• to display control unit terminal 3

• through body grounds M57, M61 and M79.

Then audio signals are supplied

• through audio unit terminals 1, 2, 3, 4, 13, 14, 15 and 16

• to BOSE speaker amp. terminals 23, 24, 25, 26, 27, 28, 29 and 30.

Audio signals are amplified by the BOSE speaker amp.

The amplified audio signals are supplied

• through BOSE speaker amp. terminals 2, 3, 9,10,11,12, 13, 14, 15, 16, 18 and 19

• to terminals + and - of front door speaker LH and RH and

• to terminals + and - of front tweeter LH and RH and

• to terminals + and - of center speaker and

• to terminals + and - of rear door speaker LH and RH and

• to terminals + and - of rear door tweeter LH and RH and

• to terminals 1 and 2 of subwoofer.

When one of steering wheel audio control switches is pushed, the resistance in steering switch circuit changes

depending on which button is pushed.

Rear Audio Remote Control Unit

Power is supplied

• from audio unit terminal 32

• to rear audio remote control unit terminal 13.

Ground is supplied

• to rear audio remote control unit terminal 15

7. Display control unit

M94, M958. Front tweeter RH

M 1119. AV Switch

M98

10. Audio unit

M43, M44, M45, M4611. BOSE speaker amp

M112, M11312. Satellite radio tuner (pre-wiring or factory

installed, if equipped)

M41

13. Steering wheel audio control switches 14. Front door speaker LH, RH

D12, D11215. Rear door tweeter LH, RH

D208, D308

16. Rear door speaker LH, RH

D207, D30717. Driver seat 18. Subwoofer

B72

19. Rear audio remote control unit

R204

Page 597 of 3061

TELEPHONE

AV-57

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

AV

N

O

P

Bluetooth telephone system allows users who have a Bluetooth cellular telephone to make a wireless connec-

tion between their cellular telephone and the Bluetooth control unit. Hands-free cellular telephone calls can be

sent and received. Personal memos can be created using the Infinity Voice Recognition system. Some Blue-

tooth cellular telephones may not be recognized by the Bluetooth control unit. When a cellular telephone or

the Bluetooth control unit is replaced, the telephone must be paired with the Bluetooth control unit. Different

cellular telephones may have different pairing procedures. Refer to the cellular telephone operating manual.

Bluetooth Telephone System Diagram

Bluetooth Control Unit

When the ignition switch is turned to ACC or ON, the Bluetooth control unit will power up. During power up, the

Bluetooth control unit is initialized and performs various self checks. Initialization may take up to 10 seconds.

During this time the Bluetooth ON indicator will flash until initialization is complete. Infinity Voice Recognition

will then become active and the Bluetooth ON indicator will remain on. Bluetooth telephone functions can be

turned off using the voice recognition system.

BCM

The BCM supplies power for the Bluetooth ON indicator.

Steering Wheel Audio Control Switches

When buttons on the steering wheel audio control switch are pushed, the resistance in steering wheel audio

control switch circuit changes depending on which button is pushed. The Bluetooth control module uses this

signal to perform various functions while navigating through the voice recognition system.

The following functions can be performed using the steering wheel audio control switch:

• Initiate Self Diagnosis of the Bluetooth telephone system

• Start a voice recognition session

• Answer and end telephone calls

• Adjust the volume of calls

• Record memos

AV Switch

Call volume can be adjusted using the AV switch.

Microphone

The microphone is located in the roof console assembly. The microphone sends a signal to the Bluetooth con-

trol unit.

Combination Meter

The combination meter supplies speed signals to the Bluetooth control unit. Vehicle speed signals are used to

determine which voice command functions will be disabled based on driving conditions.

Bluetooth ON Indicator

The Bluetooth ON indicator is located in the overhead console. The indicator will flash during power up while

the Bluetooth control unit is initializing. This process may take up to 10 seconds. After initialization, the indica-

tor will remain on to indicate that the system is ready for voice commands.

WKIA4569E

Page 614 of 3061

AV-74

< SERVICE INFORMATION >

NAVIGATION SYSTEM

Map-matching is a function that repositions the vehicle on the road

map when a new location is judged to be the most accurate. This is

done by comparing the current vehicle position, calculated by the

method described in the position detection principle, with the road

map data around the vehicle, read from the map DVD-ROM stored in

the DVD-ROM drive.

Therefore, the vehicle position may not be corrected after the vehicle

is driven over a certain distance or time in which GPS information is

hard to receive. In this case, the current-location mark on the display

must be corrected manually.

CAUTION:

The road map data is based on data stored in the map DVD-

ROM.

• In map-matching, alternative routes to reach the destination will be

shown and prioritized, after the road on which the vehicle is cur-

rently driven has been judged and the current-location mark has

been repositioned.

If there is an error in distance and/or direction, the alternative

routes will be shown in different order of priority, and the wrong

road can be avoided.

If two roads are running in parallel, they are of the same priority.

Therefore, the current-location mark may appear on either of them

alternately, depending on maneuvering of the steering wheel and

configuration of the road.

• Map-matching does not function correctly when the road on which

the vehicle is driving is new and not recorded in the map DVD-

ROM, or when the road pattern stored in the map data and the

actual road pattern are different due to repair.

When driving on a road not present in the map, the map-matching

function may find another road and position the current-location

mark on it. Then, when the correct road is detected, the current-

location mark may leap to it.

• Effective range for comparing the vehicle position and travel direc-

tion calculated by the distance and direction with the road data

read from the map DVD-ROM is limited. Therefore, when there is

an excessive gap between the current vehicle position and the

position on the map, correction by map-matching is not possible.

GPS (GLOBAL POSITIONING SYSTEM)

GPS (Global Positioning System) has been developed and con-

trolled by the US Department of Defense. The system utilizes GPS

satellite (NAVSTAR), sending out radio waves while flying on an orbit

around the earth at the height of approx. 21,000 km (13,000 miles).

The GPS receiver calculates the vehicle's position in three dimen-

sions (latitude/longitude/altitude) according to the time lag of the

radio waves received from four or more GPS satellites (three-dimen-

sional positioning). If radio waves were received only from three

GPS satellites, the GPS receiver calculates the vehicle's position in

two dimensions (latitude/longitude), utilizing the altitude data calcu-

lated previously by using radio waves from four or more GPS satel-

lites (two-dimensional positioning).

Accuracy of the GPS will deteriorate under the following conditions.

• In two-dimensional positioning, the GPS accuracy will deteriorate when the altitude of the vehicle position

changes.

• There may be an error of approximately 10 m (30 ft) in position detected by three-dimensional positioning,

which is more accurate than two-dimensional positioning. The accuracy can be even lower depending on the

arrangement of the GPS satellites utilized for the positioning.

• Position detection is not possible when the vehicle is in an area where radio waves from the GPS satellite do

not reach, such as in a tunnel, parking lot in a building, and under an elevated highway. Radio waves from

the GPS satellites may not be received when some object is located over the GPS antenna.

SEL685V

SEL686V

SKIA0613E

SEL526V