change time INFINITI QX56 2007 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1031 of 3061

DI-20

< SERVICE INFORMATION >

COMBINATION METERS

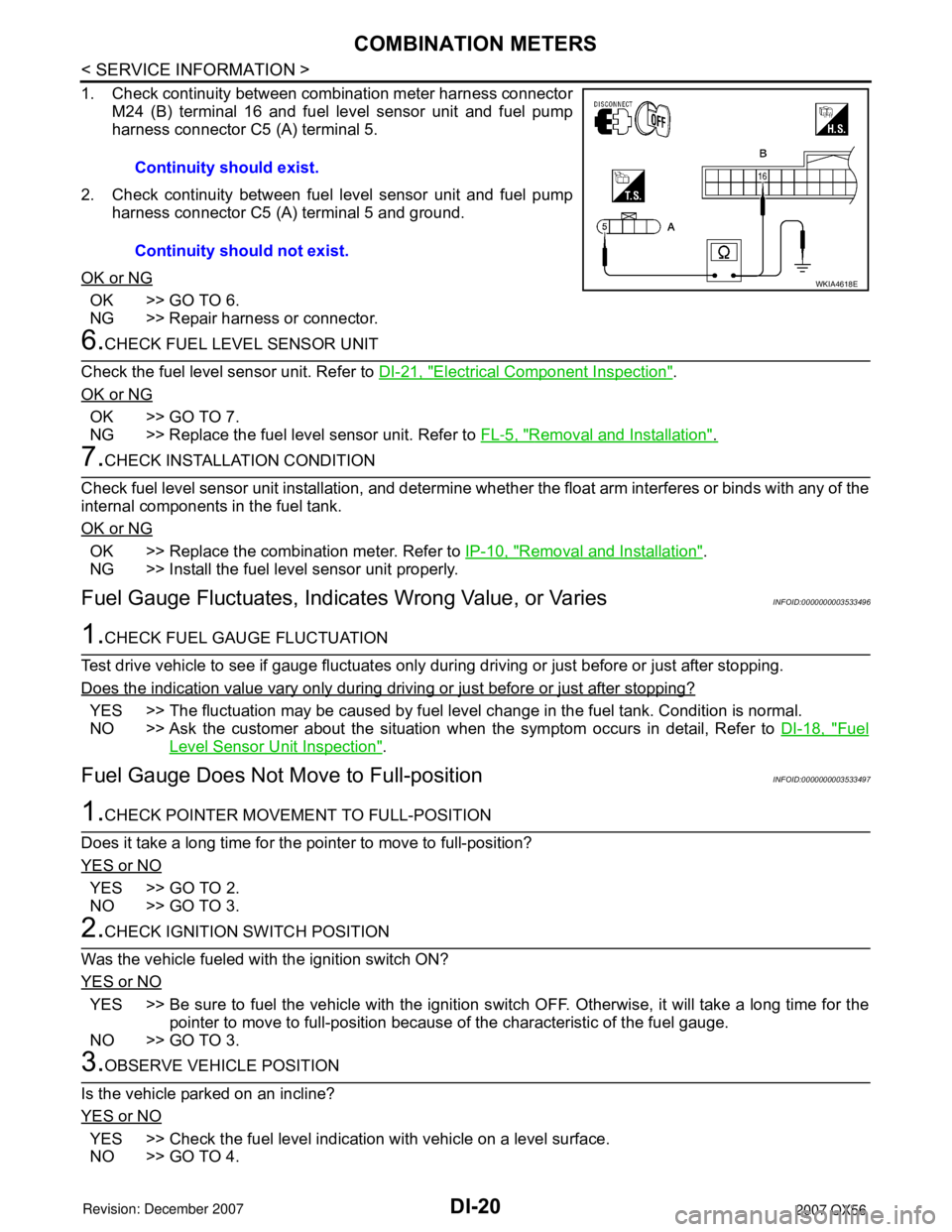

1. Check continuity between combination meter harness connectorM24 (B) terminal 16 and fuel level sensor unit and fuel pump

harness connector C5 (A) terminal 5.

2. Check continuity between fuel level sensor unit and fuel pump harness connector C5 (A) terminal 5 and ground.

OK or NG

OK >> GO TO 6.

NG >> Repair harness or connector.

6.CHECK FUEL LEVEL SENSOR UNIT

Check the fuel level sensor unit. Refer to DI-21, "

Electrical Component Inspection".

OK or NG

OK >> GO TO 7.

NG >> Replace the fuel level sensor unit. Refer to FL-5, "

Removal and Installation".

7.CHECK INSTALLATION CONDITION

Check fuel level sensor unit installation, and determine whet her the float arm interferes or binds with any of the

internal components in the fuel tank.

OK or NG

OK >> Replace the combination meter. Refer to IP-10, "Removal and Installation".

NG >> Install the fuel level sensor unit properly.

Fuel Gauge Fluctuat es, Indicates Wrong Value, or VariesINFOID:0000000003533496

1.CHECK FUEL GAUGE FLUCTUATION

Test drive vehicle to see if gauge fluctuates only during driving or just before or just after stopping.

Does the indication value vary only during driving or just before or just after stopping?

YES >> The fluctuation may be caused by fuel leve l change in the fuel tank. Condition is normal.

NO >> Ask the customer about the situation when the symptom occurs in detail, Refer to DI-18, "

Fuel

Level Sensor Unit Inspection".

Fuel Gauge Does Not Move to Full-positionINFOID:0000000003533497

1.CHECK POINTER MOVEME NT TO FULL-POSITION

Does it take a long time for the pointer to move to full-position?

YES or NO

YES >> GO TO 2.

NO >> GO TO 3.

2.CHECK IGNITION SWITCH POSITION

Was the vehicle fueled with the ignition switch ON?

YES or NO

YES >> Be sure to fuel the vehicle with the ignition s witch OFF. Otherwise, it will take a long time for the

pointer to move to full-position because of the characteristic of the fuel gauge.

NO >> GO TO 3.

3.OBSERVE VEHICLE POSITION

Is the vehicle parked on an incline?

YES or NO

YES >> Check the fuel level indication with vehicle on a level surface.

NO >> GO TO 4. Continuity should exist.

Continuity should not exist.

WKIA4618E

Page 1035 of 3061

DI-24

< SERVICE INFORMATION >

COMPASS AND THERMOMETER

1. Turn the ignition switch to the ON position.

2. Cool down ambient sensor 2 with water or ice.

Does the indicated temperature drop?

YES >> GO TO 2.

NO >> The system is malfunctioning. Check the system following “INSPECTION/COMPASS AND THER-

MOMETER”. Refer to "INSPECTION/COMPASS AND THERMOMETER".

2.WARM UP CHECK

1. Leave the vehicle for 10 minutes.

2. With the ignition switch in the ON position, disconnect and reconnect ambient sensor 2 connector.

Does the indicated temperature rise?

YES >> The system is OK.

NO >> The system is malfunctioning. Check the system following “INSPECTION/COMPASS AND THER-

MOMETER”. Refer to "INSPECTION/COMPASS AND THERMOMETER".

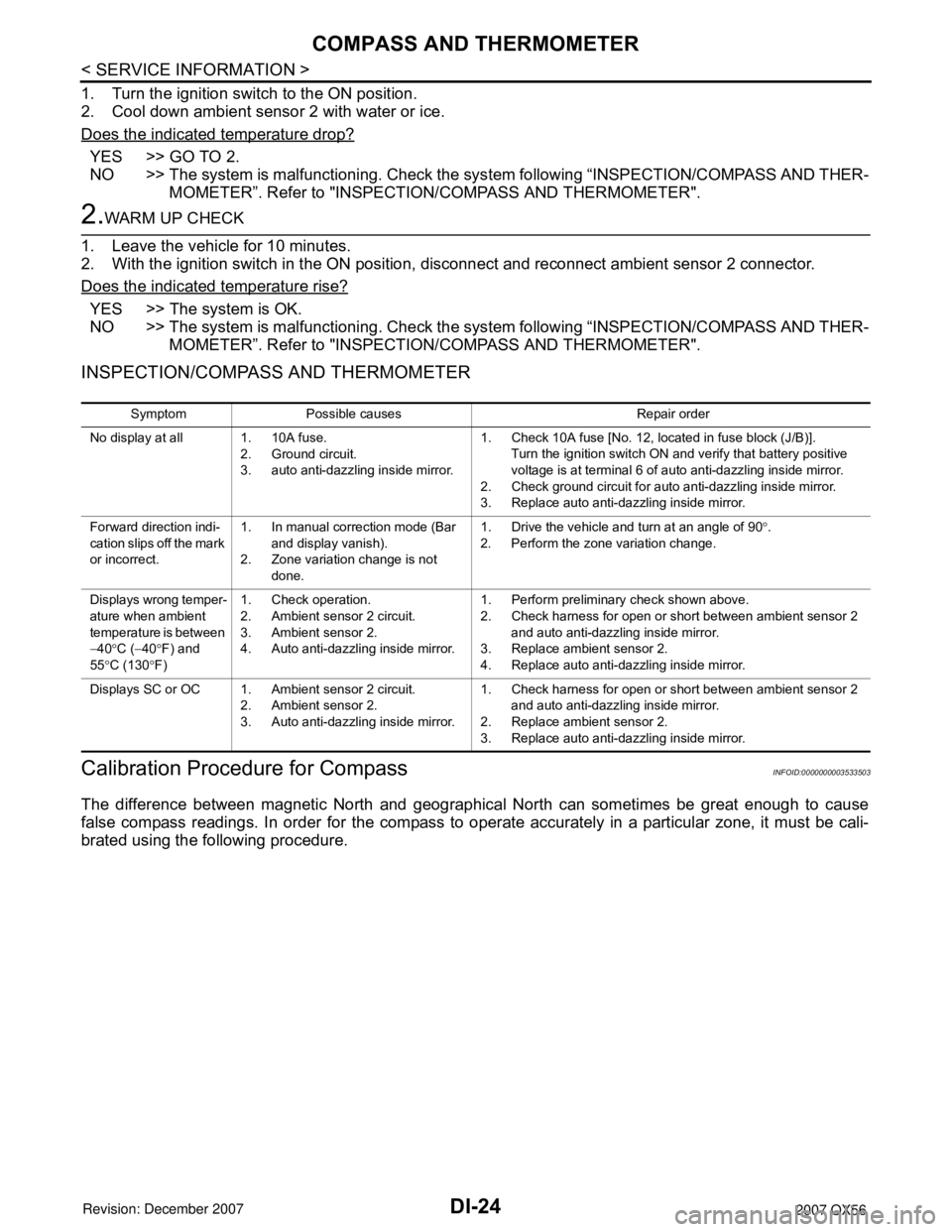

INSPECTION/COMPASS AND THERMOMETER

Calibration Procedure for CompassINFOID:0000000003533503

The difference between magnetic North and geographical North can sometimes be great enough to cause

false compass readings. In order for the compass to operate accurately in a particular zone, it must be cali-

brated using the following procedure.

Symptom Possible causes Repair order

No display at all 1. 10A fuse.

2. Ground circuit.

3. auto anti-dazzling inside mirror.1. Check 10A fuse [No. 12, located in fuse block (J/B)].

Turn the ignition switch ON and verify that battery positive

voltage is at terminal 6 of auto anti-dazzling inside mirror.

2. Check ground circuit for auto anti-dazzling inside mirror.

3. Replace auto anti-dazzling inside mirror.

Forward direction indi-

cation slips off the mark

or incorrect.1. In manual correction mode (Bar

and display vanish).

2. Zone variation change is not

done.1. Drive the vehicle and turn at an angle of 90°.

2. Perform the zone variation change.

Displays wrong temper-

ature when ambient

temperature is between

−40°C (−40°F) and

55°C (130°F)1. Check operation.

2. Ambient sensor 2 circuit.

3. Ambient sensor 2.

4. Auto anti-dazzling inside mirror.1. Perform preliminary check shown above.

2. Check harness for open or short between ambient sensor 2

and auto anti-dazzling inside mirror.

3. Replace ambient sensor 2.

4. Replace auto anti-dazzling inside mirror.

Displays SC or OC 1. Ambient sensor 2 circuit.

2. Ambient sensor 2.

3. Auto anti-dazzling inside mirror.1. Check harness for open or short between ambient sensor 2

and auto anti-dazzling inside mirror.

2. Replace ambient sensor 2.

3. Replace auto anti-dazzling inside mirror.

Page 1108 of 3061

ENGINE CONTROL SYSTEM

EC-25

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

*1: This sensor is not used to control the engine system. This is used only for the on board diagnosis.

*2: This signal is sent to the ECM through CAN communication line.

*3: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION

The amount of fuel injected from the fuel injector is determined by the ECM. The ECM controls the length of

time the valve remains open (injection pulse duration). The amount of fuel injected is a program value in the

ECM memory. The program value is preset by engine operating conditions. These conditions are determined

by input signals (for engine speed and intake air) from both the crankshaft position sensor and the mass air

flow sensor.

VARIOUS FUEL INJECTION INCREASE/DECREASE COMPENSATION

In addition, the amount of fuel injected is compensated to improve engine performance under various operat-

ing conditions as listed below.

• When starting the engine

• During acceleration

• Hot-engine operation

• When selector lever is changed from N to D

• High-load, high-speed operation

• During deceleration

• During high engine speed operation

MIXTURE RATIO FEEDBACK CONTROL (CLOSED LOOP CONTROL)

Sensor Input signal to ECM ECM function Actuator

Crankshaft position sensor (POS)

Engine speed*

3

Piston position

Fuel injection

& mixture ratio

controlFuel injector Camshaft position sensor (PHASE)

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Air fuel ratio (A/F) sensor 1 Density of oxygen in exhaust gas

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Park/neutral position (PNP) switch Gear position

Knock sensor Engine knocking condition

Battery

Battery voltage*

3

Power steering pressure sensor Power steering operation

Heated oxygen sensor 2*

1Density of oxygen in exhaust gas

ABS actuator and electric unit (control unit)

VDC/TCS operation command*

2

Air conditioner switch

Air conditioner operation*2

Wheel sensor

Vehicle speed*2

PBIB3020E

Page 1109 of 3061

EC-26

< SERVICE INFORMATION >

ENGINE CONTROL SYSTEM

The mixture ratio feedback system provides the best air-fuel mixture ratio for driveability and emission control.

The three way catalyst (manifold) can then better reduce CO, HC and NOx emissions. This system uses air

fuel ratio (A/F) sensor 1 in the exhaust manifold to monitor whether the engine operation is rich or lean. The

ECM adjusts the injection pulse width according to the sensor voltage signal. For more information about air

fuel ratio (A/F) sensor 1, refer to EC-225

. This maintains the mixture ratio within the range of stoichiometric

(ideal air-fuel mixture).

This stage is referred to as the closed loop control condition.

Heated oxygen sensor 2 is located downstream of the three way catalyst (manifold). Even if the switching

characteristics of air fuel ratio (A/F) sensor 1 shift, the air-fuel ratio is controlled to stoichiometric by the signal

from heated oxygen sensor 2.

Open Loop Control

The open loop system condition refers to when the ECM detects any of the following conditions. Feedback

control stops in order to maintain stabilized fuel combustion.

• Deceleration and acceleration

• High-load, high-speed operation

• Malfunction of A/F sensor 1 or its circuit

• Insufficient activation of A/F sensor 1 at low engine coolant temperature

• High engine coolant temperature

• During warm-up

• After shifting from N to D

• When starting the engine

MIXTURE RATIO SELF-LEARNING CONTROL

The mixture ratio feedback control system monitors the mixture ratio signal transmitted from A/F sensor 1.

This feedback signal is then sent to the ECM. The ECM controls the basic mixture ratio as close to the theoret-

ical mixture ratio as possible. However, the basic mixture ratio is not necessarily controlled as originally

designed. Both manufacturing differences (i.e., mass air flow sensor hot wire) and characteristic changes dur-

ing operation (i.e., injector clogging) directly affect mixture ratio.

Accordingly, the difference between the basic and theoretical mixture ratios is monitored in this system. This is

then computed in terms of “injection pulse duration” to automatically compensate for the difference between

the two ratios.

“Fuel trim” refers to the feedback compensation value compared against the basic injection duration. Fuel trim

includes short term fuel trim and long term fuel trim.

“Short term fuel trim” is the short-term fuel compensation used to maintain the mixture ratio at its theoretical

value. The signal from A/F sensor 1 indicates whether the mixture ratio is RICH or LEAN compared to the the-

oretical value. The signal then triggers a reduction in fuel volume if the mixture ratio is rich, and an increase in

fuel volume if it is lean.

“Long term fuel trim” is overall fuel compensation carried out long-term to compensate for continual deviation

of the short term fuel trim from the central value. Such deviation will occur due to individual engine differences,

wear over time and changes in the usage environment.

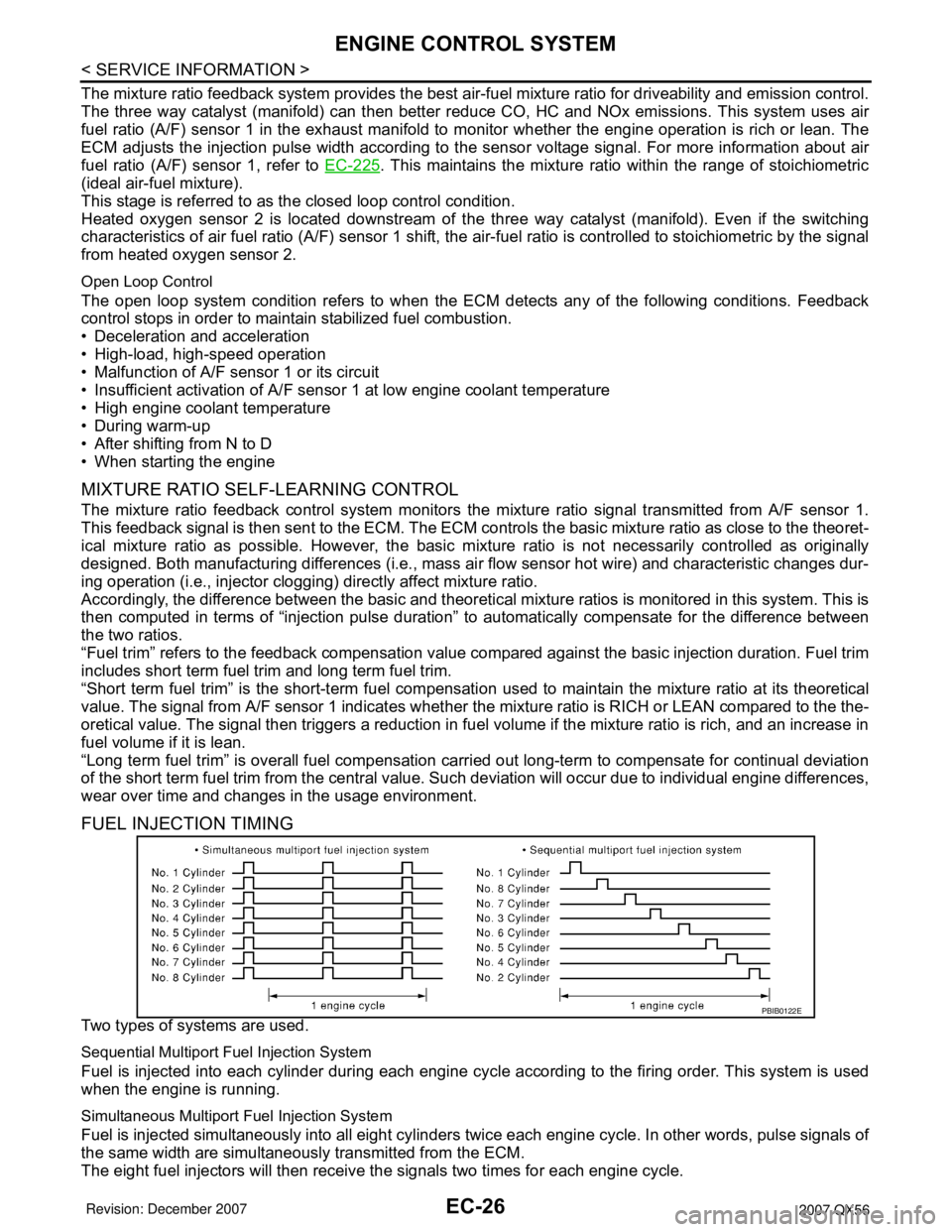

FUEL INJECTION TIMING

Two types of systems are used.

Sequential Multiport Fuel Injection System

Fuel is injected into each cylinder during each engine cycle according to the firing order. This system is used

when the engine is running.

Simultaneous Multiport Fuel Injection System

Fuel is injected simultaneously into all eight cylinders twice each engine cycle. In other words, pulse signals of

the same width are simultaneously transmitted from the ECM.

The eight fuel injectors will then receive the signals two times for each engine cycle.

PBIB0122E

Page 1113 of 3061

EC-30

< SERVICE INFORMATION >

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

System DescriptionINFOID:0000000003531591

INPUT/OUTPUT SIGNAL CHART

*: This signal is sent to the ECM through CAN communication line

BASIC ASCD SYSTEM

Refer to Owner's Manual for ASCD operating instructions.

Automatic Speed Control Device (ASCD) allows a driver to keep vehicle at predetermined constant speed

without depressing accelerator pedal. Driver can set vehicle speed in advance between approximately 40 km/

h (25 MPH) and 144 km/h (89 MPH).

ECM controls throttle angle of electric throttle control actuator to regulate engine speed.

Operation status of ASCD is indicated by CRUISE indicator and SET indicator in combination meter. If any

malfunction occurs in ASCD system, it automatically deactivates control.

NOTE:

Always drive vehicle in safe manner according to traffic conditions and obey all traffic laws.

SET OPERATION

Press MAIN switch. (The CRUISE indicator in combination meter illuminates.)

When vehicle speed reaches a desired speed between approximately 40 km/h (25 MPH) and 144 km/h (89

MPH), press SET/COAST switch. (Then SET indicator in combination meter illuminates.)

ACCELERATE OPERATION

If the RESUME/ACCELERATE switch is pressed during cruise control driving, increase the vehicle speed until

the switch is released or vehicle speed reaches maximum speed controlled by the system.

And then ASCD will keep the new set speed.

CANCEL OPERATION

When any of following conditions exist, cruise operation will be canceled.

• CANCEL switch is pressed

• More than 2 switches at ASCD steering switch are pressed at the same time (Set speed will be cleared)

• Brake pedal is depressed

• Selector lever is changed to N, P, R position

• Vehicle speed decreased to 13 km/h (8 MPH) lower than the set speed

• VDC system is operated

When the ECM detects any of the following conditions, the ECM will cancel the cruise operation and inform

the driver by blinking indicator lamp.

• Engine coolant temperature is slightly higher than the normal operating temperature, CRUISE lamp may

blink slowly.

When the engine coolant temperature decreases to the normal operating temperature, CRUISE lamp will

stop blinking and the cruise operation will be able to work by pressing SET/COAST switch or RESUME/

ACCELERATE switch.

• Malfunction for some self-diagnoses regarding ASCD control: SET lamp will blink quickly.

If MAIN switch is turned to OFF during ASCD is activated, all of ASCD operations will be canceled and vehicle

speed memory will be erased.

COAST OPERATION

When the SET/COAST switch is pressed during cruise control driving, decrease vehicle set speed until the

switch is released. And then ASCD will keep the new set speed.

RESUME OPERATION

Sensor Input signal to ECM ECM function Actuator

ASCD brake switch Brake pedal operation

ASCD vehicle speed controlElectric throttle control

actuator Stop lamp switch Brake pedal operation

ASCD steering switch ASCD steering switch operation

Park/neutral position (PNP) switch Gear position

Wheel sensor Vehicle speed*

TCM Powertrain revolution*

Page 1137 of 3061

EC-54

< SERVICE INFORMATION >

ON BOARD DIAGNOSTIC (OBD) SYSTEM

A sample of CONSULT-II display for DTC and 1st trip DTC is shown below. DTC or 1st trip DTC of a malfunc-

tion is displayed in SELF-DIAGNOSTIC RESULTS mode of CONSULT-II. Time data indicates how many times

the vehicle was driven after the last detection of a DTC.

If the DTC is being detected currently, the time data will be [0].

If a 1st trip DTC is stored in the ECM, the time data will be [1t].

FREEZE FRAME DATA AND 1ST TRIP FREEZE FRAME DATA

The ECM records the driving conditions such as fuel system status, calculated load value, engine coolant tem-

perature, short term fuel trim, long term fuel trim, engine speed, vehicle speed, absolute throttle position, base

fuel schedule and intake air temperature at the moment a malfunction is detected.

Data which are stored in the ECM memory, along with the 1st trip DTC, are called 1st trip freeze frame data.

The data, stored together with the DTC data, are called freeze frame data and displayed on CONSULT-II or

GST. The 1st trip freeze frame data can only be displayed on the CONSULT-II screen, not on the GST. For

details, see E C - 111 , "

CONSULT-II Function (ENGINE)".

Only one set of freeze frame data (either 1st trip freeze frame data or freeze frame data) can be stored in the

ECM. 1st trip freeze frame data is stored in the ECM memory along with the 1st trip DTC. There is no priority

for 1st trip freeze frame data and it is updated each time a different 1st trip DTC is detected. However, once

freeze frame data (2nd trip detection/MIL on) is stored in the ECM memory, 1st trip freeze frame data is no

longer stored. Remember, only one set of freeze frame data can be stored in the ECM. The ECM has the fol-

lowing priorities to update the data.

For example, the EGR malfunction (Priority: 2) was detected and the freeze frame data was stored in the 2nd

trip. After that when the misfire (Priority: 1) is detected in another trip, the freeze frame data will be updated

from the EGR malfunction to the misfire. The 1st trip freeze frame data is updated each time a different mal-

function is detected. There is no priority for 1st trip freeze frame data. However, once freeze frame data is

stored in the ECM memory, 1st trip freeze data is no longer stored (because only one freeze frame data or 1st

trip freeze frame data can be stored in the ECM). If freeze frame data is stored in the ECM memory and freeze

frame data with the same priority occurs later, the first (original) freeze frame data remains unchanged in the

ECM memory.

Both 1st trip freeze frame data and freeze frame data (along with the DTCs) are cleared when the ECM mem-

ory is erased. Procedures for clearing the ECM memory are described in "HOW TO ERASE EMISSION-

RELATED DIAGNOSTIC INFORMATION".

SYSTEM READINESS TEST (SRT) CODE

System Readiness Test (SRT) code is specified in Service $01 of SAE J1979.

As part of an enhanced emissions test for Inspection & Maintenance (I/M), certain states require the status of

SRT be used to indicate whether the ECM has completed self-diagnosis of major emission systems and com-

ponents. Completion must be verified in order for the emissions inspection to proceed.

If a vehicle is rejected for a State emissions inspection due to one or more SRT items indicating “INCMP”, use

the information in this Service Manual to set the SRT to “CMPLT”.

In most cases the ECM will automatically complete its self-diagnosis cycle during normal usage, and the SRT

status will indicate “CMPLT” for each application system. Once set as “CMPLT”, the SRT status remains

“CMPLT” until the self-diagnosis memory is erased.

Occasionally, certain portions of the self-diagnostic test may not be completed as a result of the customer's

normal driving pattern; the SRT will indicate “INCMP” for these items.

PBIB0911E

Priority Items

1Freeze frame data Misfire — DTC: P0300 - P0308

Fuel Injection System Function — DTC: P0171, P0172, P0174, P0175

2 Except the above items (Includes A/T related items)

3 1st trip freeze frame data

Page 1148 of 3061

ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-65

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

displayed, they may be either DTCs or 1st trip DTCs. DTC No. is same as that of 1st trip DTC. These uniden-

tified codes can be identified by using the CONSULT-II or GST. A DTC will be used as an example for how to

read a code.

A particular trouble code can be identified by the number of four-digit numeral flashes. The “zero” is indicated

by the number of ten flashes. The “A” is indicated by the number of eleven flash.The length of time the

1,000th-digit numeral flashes on and off is 1.2 seconds consisting of an ON (0.6-second) - OFF (0.6-second)

cycle.

The 100th-digit numeral and lower digit numerals consist of a 0.3-second ON and 0.3-second OFF cycle.

A change from one digit numeral to another occurs at an interval of 1.0-second OFF. In other words, the later

numeral appears on the display 1.3 seconds after the former numeral has disappeared.

A change from one trouble code to another occurs at an interval of 1.8-second OFF.

In this way, all the detected malfunctions are classified by their DTC numbers. The DTC 0000 refers to no mal-

function. (See EC-9

)

How to Erase Diagnostic Test Mode II (Self-diagnostic Results)

The DTC can be erased from the back up memory in the ECM by depressing accelerator pedal. Refer to "How

to Erase Diagnostic Test Mode II (Self-diagnostic Results)".

•If the battery is disconnected, the DTC will be lost from the backup memory within 24 hours.

•Be careful not to erase the stored memory before starting trouble diagnoses.

OBD System Operation ChartINFOID:0000000003531608

RELATIONSHIP BETWEEN MIL, 1ST TRIP DTC, DTC, AND DETECTABLE ITEMS

• When a malfunction is detected for the first time, the 1st trip DTC and the 1st trip freeze frame data are

stored in the ECM memory.

• When the same malfunction is detected in two consecutive trips, the DTC and the freeze frame data are

stored in the ECM memory, and the MIL will come on. For details, refer to EC-48, "

Two Trip Detection Logic".

• The MIL will go off after the vehicle is driven 3 times (driving pattern B) with no malfunction. The drive is

counted only when the recorded driving pattern is met (as stored in the ECM). If another malfunction occurs

while counting, the counter will reset.

• The DTC and the freeze frame data will be stored until the vehicle is driven 40 times (driving pattern A) with-

out the same malfunction recurring (except for Misfire and Fuel Injection System). For Misfire and Fuel Injec-

PBIB3005E

Page 1163 of 3061

EC-80

< SERVICE INFORMATION >

BASIC SERVICE PROCEDURE

3.Check that downstream of throttle valve is free from air leakage.

4.When the above three items check out OK, engine component parts and their installation condi-

tion are questionable. Check and eliminate the cause of the incident.

It is useful to perform EC-129

.

5.If any of the following conditions occur after the engine has started, eliminate the cause of the

incident and perform Idle Air Volume Learning all over again:

•Engine stalls.

•Erroneous idle.

Fuel Pressure CheckINFOID:0000000003531616

FUEL PRESSURE RELEASE

With CONSULT-II

1. Turn ignition switch ON.

2. Perform “FUEL PRESSURE RELEASE” in “WORK SUPPORT”

mode with CONSULT-II.

3. Start engine.

4. After engine stalls, crank it two or three times to release all fuel

pressure.

5. Turn ignition switch OFF.

Without CONSULT-II

1. Remove fuel pump fuse located in IPDM E/R.

2. Start engine.

3. After engine stalls, crank it two or three times to release all fuel

pressure.

4. Turn ignition switch OFF.

5. Reinstall fuel pump fuse after servicing fuel system.

FUEL PRESSURE CHECK

CAUTION:

• Before disconnecting fuel line, release fuel pressure from fuel line to eliminate danger.

• Be careful not to scratch or get the fuel hose connection area dirty when servicing, so that the quick

connector o-ring maintains sealability.

• Use Fuel Pressure Gauge Kit J-44321 and Fuel Pressure Adapter J-44321-6 to check fuel pressure.

• Do not perform fuel pressure check with electrical system operating (i.e. lights, rear defog, A/C, etc.).

Fuel pressure gauge may indicate false readings due to varying engine loads and changes in mani-

fold vacuum.

NOTE:

Prepare pans or saucers under the disconnected fuel line because the fuel may spill out. The fuel pres-

sure cannot be completely released because JA60 models do not have fuel return system.

1. Release fuel pressure to zero. Refer to "FUEL PRESSURE RELEASE" .

2. Remove engine cover.

3. Remove fuel hose using Quick Connector Release J-45488. Refer to EM-17

.

• Do not twist or kink fuel hose because it is plastic hose.

• Do not remove fuel hose from quick connector.

• Keep fuel hose connections clean.

SEF214Y

BBIA0380E

Page 1203 of 3061

EC-120

< SERVICE INFORMATION >

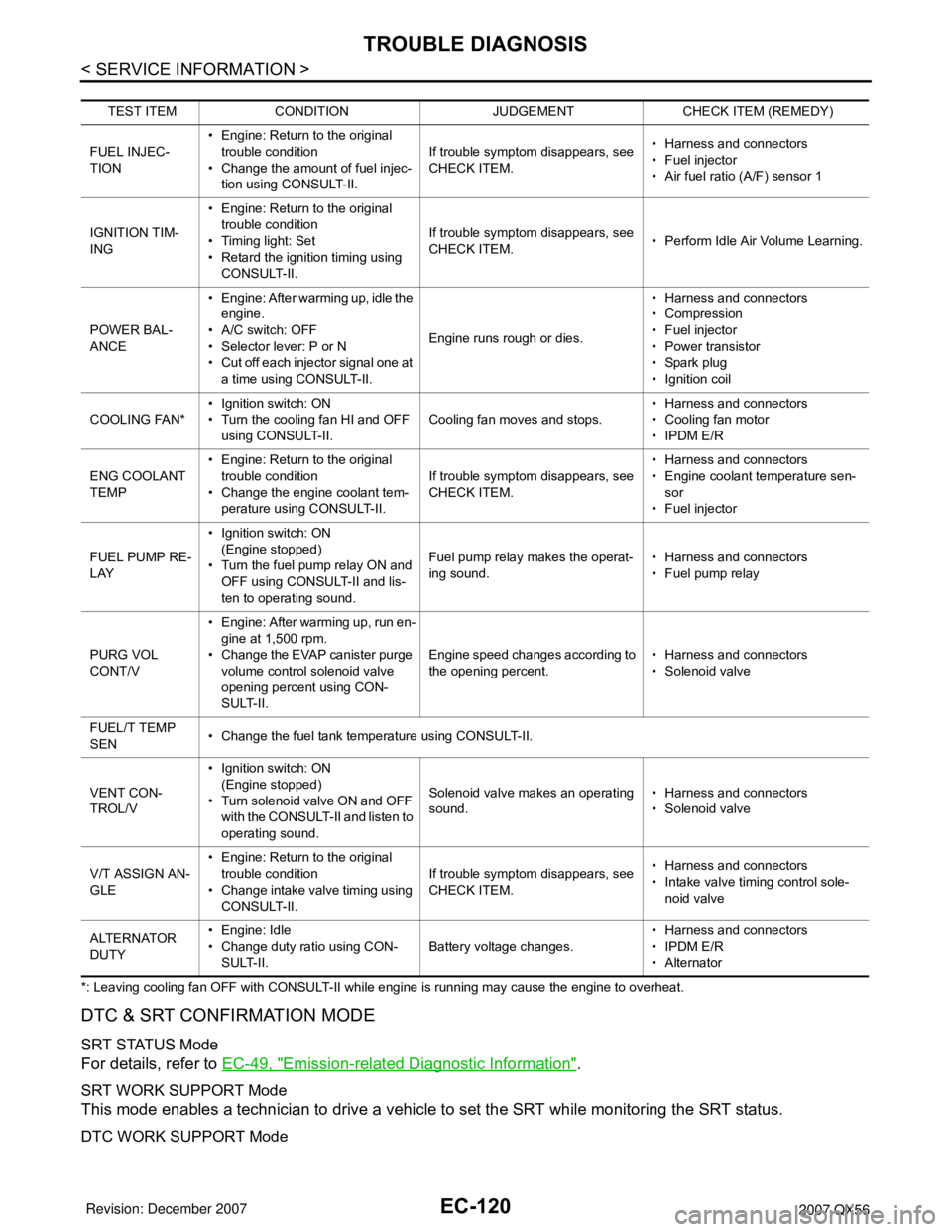

TROUBLE DIAGNOSIS

*: Leaving cooling fan OFF with CONSULT-II while engine is running may cause the engine to overheat.

DTC & SRT CONFIRMATION MODE

SRT STATUS Mode

For details, refer to EC-49, "Emission-related Diagnostic Information".

SRT WORK SUPPORT Mode

This mode enables a technician to drive a vehicle to set the SRT while monitoring the SRT status.

DTC WORK SUPPORT Mode

TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY)

FUEL INJEC-

TION• Engine: Return to the original

trouble condition

• Change the amount of fuel injec-

tion using CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.• Harness and connectors

• Fuel injector

• Air fuel ratio (A/F) sensor 1

IGNITION TIM-

ING• Engine: Return to the original

trouble condition

• Timing light: Set

• Retard the ignition timing using

CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.• Perform Idle Air Volume Learning.

POWER BAL-

ANCE• Engine: After warming up, idle the

engine.

• A/C switch: OFF

• Selector lever: P or N

• Cut off each injector signal one at

a time using CONSULT-II.Engine runs rough or dies.• Harness and connectors

• Compression

• Fuel injector

• Power transistor

•Spark plug

• Ignition coil

COOLING FAN*• Ignition switch: ON

• Turn the cooling fan HI and OFF

using CONSULT-II.Cooling fan moves and stops.• Harness and connectors

• Cooling fan motor

• IPDM E/R

ENG COOLANT

TEMP• Engine: Return to the original

trouble condition

• Change the engine coolant tem-

perature using CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.• Harness and connectors

• Engine coolant temperature sen-

sor

• Fuel injector

FUEL PUMP RE-

LAY• Ignition switch: ON

(Engine stopped)

• Turn the fuel pump relay ON and

OFF using CONSULT-II and lis-

ten to operating sound.Fuel pump relay makes the operat-

ing sound.• Harness and connectors

•Fuel pump relay

PURG VOL

CONT/V• Engine: After warming up, run en-

gine at 1,500 rpm.

• Change the EVAP canister purge

volume control solenoid valve

opening percent using CON-

SULT-II.Engine speed changes according to

the opening percent.• Harness and connectors

• Solenoid valve

FUEL/T TEMP

SEN• Change the fuel tank temperature using CONSULT-II.

VENT CON-

TROL/V• Ignition switch: ON

(Engine stopped)

• Turn solenoid valve ON and OFF

with the CONSULT-II and listen to

operating sound.Solenoid valve makes an operating

sound.• Harness and connectors

• Solenoid valve

V/T ASSIGN AN-

GLE• Engine: Return to the original

trouble condition

• Change intake valve timing using

CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.• Harness and connectors

• Intake valve timing control sole-

noid valve

ALTERNATOR

DUTY•Engine: Idle

• Change duty ratio using CON-

SULT-II.Battery voltage changes.• Harness and connectors

• IPDM E/R

•Alternator

Page 1204 of 3061

TROUBLE DIAGNOSIS

EC-121

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

*: DTC P1442 and P1456 does not apply to JA60 models but appears in DTC Work Support Mode screens.

REAL TIME DIAGNOSIS IN DATA MONITOR MODE (RECORDING VEHICLE DATA)

Description

CONSULT-II has two kinds of triggers and they can be selected by touching “SETTING” in “DATA MONITOR”

mode.

1. “AUTO TRIG” (Automatic trigger):

• The malfunction will be identified on the CONSULT-II screen in

real time.

In other words, DTC/1st trip DTC and malfunction item will be

displayed if the malfunction is detected by ECM.

At the moment a malfunction is detected by ECM, “MONITOR”

in “DATA MONITOR” screen is changed to “Recording Data ...

xx%” as shown in the figure, and the data after the malfunction

detection is recorded. Then when the percentage reached

100%, “REAL-TIME DIAG” screen is displayed. If “STOP” is

touched on the screen during “Recording Data ... xx%”,

“REAL-TIME DIAG” screen is also displayed.

The recording time after the malfunction detection and the

recording speed can be changed by “TRIGGER POINT” and

“Recording Speed”. Refer to CONSULT-II Operation Manual.

2. “MANU TRIG” (Manual trigger):

• DTC/1st trip DTC and malfunction item will not be displayed

automatically on CONSULT-II screen even though a malfunc-

tion is detected by ECM.

DATA MONITOR can be performed continuously even though

a malfunction is detected.

Operation

1. “AUTO TRIG”

• While trying to detect the DTC/1st trip DTC by performing the DTC Confirmation Procedure, be sure to

select to “DATA MONITOR (AUTO TRIG)” mode. You can confirm the malfunction at the moment it is

detected.

• While narrowing down the possible causes, CONSULT-II should be set in “DATA MONITOR (AUTO

TRIG)” mode, especially in case the incident is intermittent.

Test mode Test item Corresponding DTC No. Reference page

EVAPORATIVE

SYSTEMPURG FLOW P0441 P0441EC-354

EVP SML LEAK P0442/P1442*P0442EC-359P0455EC-408

EVP V/S LEAK P0456/P1456* P0456EC-415

PURG VOL CN/V P1444 P0443EC-366

A/F SEN1A/F SEN1 (B1) P1276 P0130EC-225A/F SEN1 (B1) P1278/P1279 P0133EC-250

A/F SEN1 (B2) P1286 P0150EC-225

A/F SEN1 (B2) P1288/P1289 P0153EC-250

HO2S2HO2S2 (B1) P0139 P0139EC-282

HO2S2 (B1) P1146 P0138EC-270

HO2S2 (B1) P1147 P0137EC-260

HO2S2 (B2) P0159 P0159EC-282

HO2S2 (B2) P1166 P0158EC-270

HO2S2 (B2) P1167 P0157EC-260

SEF705Y

SEF707X