change time INFINITI QX56 2007 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2680 of 3061

SE-8

< SERVICE INFORMATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the console panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the console at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lense loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 2788 of 3061

SRS-18

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

CONSULT-II Function

INFOID:0000000003532866

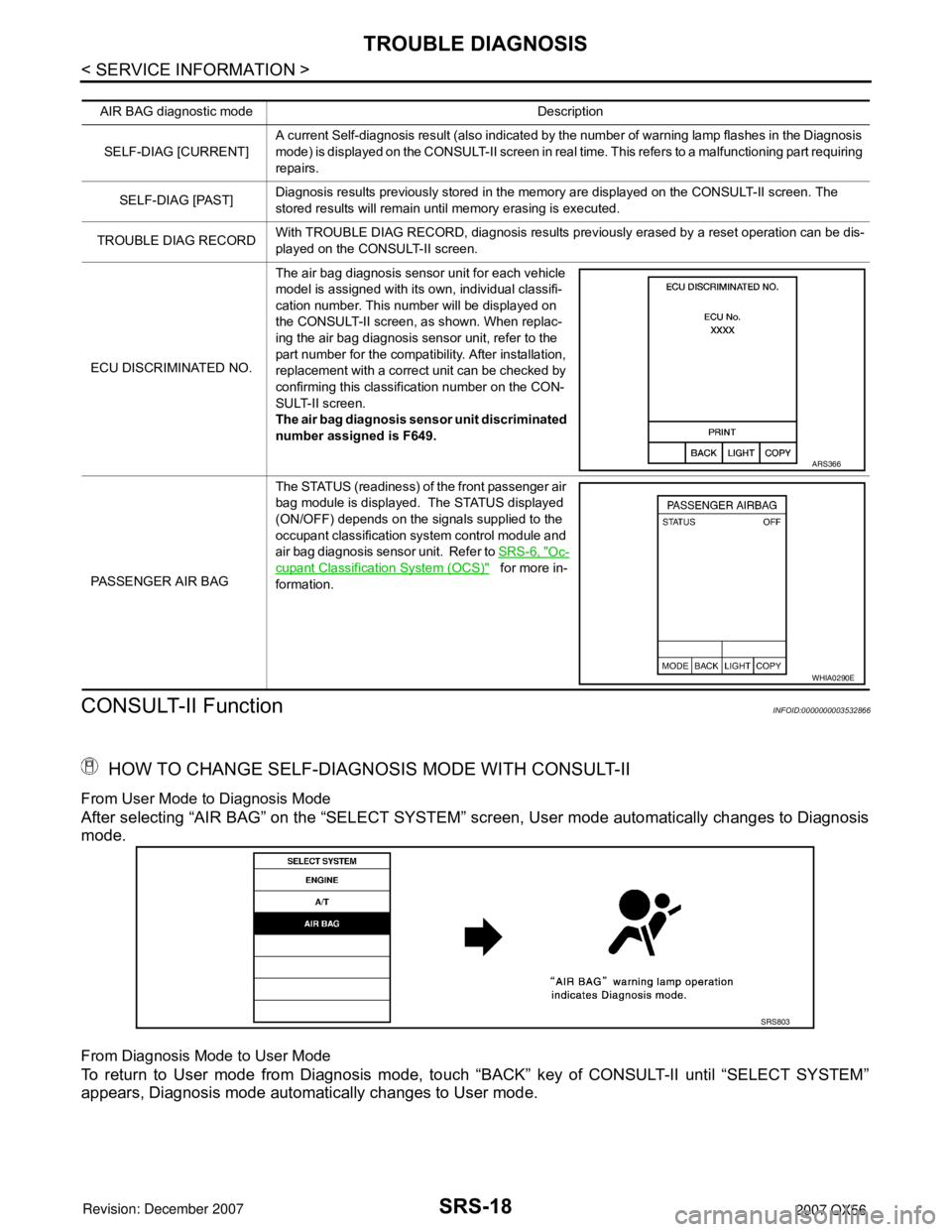

HOW TO CHANGE SELF-DIAGNOSIS MODE WITH CONSULT-II

From User Mode to Diagnosis Mode

After selecting “AIR BAG” on the “SELECT SYSTEM” screen, User mode automatically changes to Diagnosis

mode.

From Diagnosis Mode to User Mode

To return to User mode from Diagnosis mode, touch “BACK” key of CONSULT-II until “SELECT SYSTEM”

appears, Diagnosis mode automatically changes to User mode.

AIR BAG diagnostic mode Description

SELF-DIAG [CURRENT]A current Self-diagnosis result (also indicated by the number of warning lamp flashes in the Diagnosis

mode) is displayed on the CONSULT-II screen in real time. This refers to a malfunctioning part requiring

repairs.

SELF-DIAG [PAST]Diagnosis results previously stored in the memory are displayed on the CONSULT-II screen. The

stored results will remain until memory erasing is executed.

TROUBLE DIAG RECORDWith TROUBLE DIAG RECORD, diagnosis results previously erased by a reset operation can be dis-

played on the CONSULT-II screen.

ECU DISCRIMINATED NO.The air bag diagnosis sensor unit for each vehicle

model is assigned with its own, individual classifi-

cation number. This number will be displayed on

the CONSULT-II screen, as shown. When replac-

ing the air bag diagnosis sensor unit, refer to the

part number for the compatibility. After installation,

replacement with a correct unit can be checked by

confirming this classification number on the CON-

SULT-II screen.

The air bag diagnosis sensor unit discriminated

number assigned is F649.

PASSENGER AIR BAGThe STATUS (readiness) of the front passenger air

bag module is displayed. The STATUS displayed

(ON/OFF) depends on the signals supplied to the

occupant classification system control module and

air bag diagnosis sensor unit. Refer to SRS-6, "

Oc-

cupant Classification System (OCS)" for more in-

formation.

ARS366

WHIA0290E

SRS803

Page 2790 of 3061

SRS-20

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

HOW TO CHANGE SELF-DIAGNOSIS MODE

HOW TO ERASE SELF-DIAGNOSIS RESULTS

After a malfunction is repaired, turn the ignition switch OFF for at least one second, then back ON. Diagnosis

mode returns to the User mode. At that time, the self-diagnostic result is cleared.

SRS Operation CheckINFOID:0000000003532868

DIAGNOSTIC PROCEDURE 1

Checking SRS Operation Using “AIR BAG” Warning Lamp—User Mode

1. Turn the ignition switch from OFF to ON, and check that the air bag warning lamp blinks.

2. Compare the SRS air bag warning lamp blinking pattern with the

examples.

SHIA0183E

BF-1845D

Page 2856 of 3061

TF-34

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Trouble Diagnosis Chart by Symptom

INFOID:0000000003532525

If 4WD warning lamp turns ON, perform self-diagnosis. Refer to TF-48, "Self-Diagnosis Procedure" .

NOTE:

• Light tight-corner braking symptom may occur depending on driving conditions in AUTO mode. This is not a

malfunction.

Symptom Condition Check item Reference page

4WD shift indicator lamp and 4LO indicator

lamp do not turn ON

(4WD shift indicator lamp and 4LO indicator

lamp check)Ignition switch: ONPower supply and ground for transfer

control unit

TF-102

Transfer shut off relay

Combination meter

4WD warning lamp does not turn ON

(4WD warning lamp check)Ignition switch: ONPower supply and ground for transfer

control unit

TF-104

Transfer shut off relay

Combination meter

4WD shift indicator lamp or 4LO indicator

lamp does not changeEngine running4WD shift switch

TF-107

Wait detection switch

Neutral-4LO switch

ATP switch

2-4WD solenoid

Transfer control device

Actuator motor

Actuator position switch

Transfer inner parts

ATP warning lamp turns ON Engine runningCAN communication line

TF-109

4WD shift switch

PNP switch signal

ATP switch

Combination meter

Transfer inner parts

4LO indicator lamp repeats flashing Engine runningWait detection switch

TF-110

Neutral-4LO switch

Transfer inner parts

4WD warning lamp flashes rapidly (2 times/

second)While drivingTransfer fluid temperature

TF-111

Tire size is different between front and

rear of vehicle

4WD warning lamp flashes slowly

(1 time/2 seconds)While drivingTire size is different between front and

rear of vehicle.

TF-112

Transfer fluid temperature

Clutch pressure switch

Heavy tight-corner braking symptom occurs

(See NOTE.)• While driving

•AUTO mode

• Steering wheel is

turned fully to either

sideCAN communication line

TF-113

4WD shift switch

Accelerator pedal position signal

Clutch pressure solenoid

Transfer inner parts

4WD system does not operate While driving4WD shift switch

TF-114

Clutch pressure switch

Transfer inner parts

Page 2869 of 3061

TROUBLE DIAGNOSIS

TF-47

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

TF

N

O

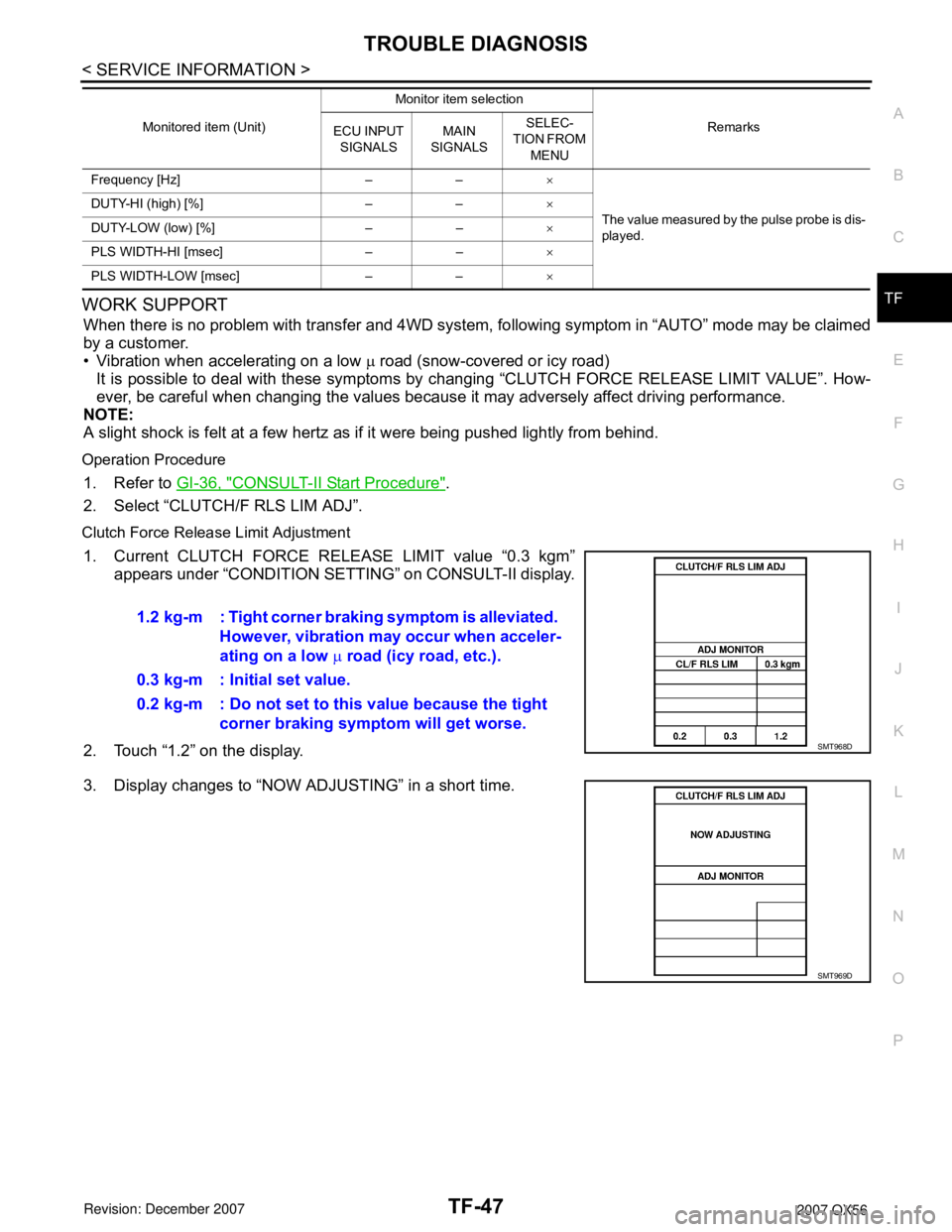

PWORK SUPPORT

When there is no problem with transfer and 4WD system, following symptom in “AUTO” mode may be claimed

by a customer.

• Vibration when accelerating on a low µ road (snow-covered or icy road)

It is possible to deal with these symptoms by changing “CLUTCH FORCE RELEASE LIMIT VALUE”. How-

ever, be careful when changing the values because it may adversely affect driving performance.

NOTE:

A slight shock is felt at a few hertz as if it were being pushed lightly from behind.

Operation Procedure

1. Refer to GI-36, "CONSULT-II Start Procedure".

2. Select “CLUTCH/F RLS LIM ADJ”.

Clutch Force Release Limit Adjustment

1. Current CLUTCH FORCE RELEASE LIMIT value “0.3 kgm”

appears under “CONDITION SETTING” on CONSULT-II display.

2. Touch “1.2” on the display.

3. Display changes to “NOW ADJUSTING” in a short time.

Frequency [Hz] – –×

The value measured by the pulse probe is dis-

played. DUTY-HI (high) [%] – –×

DUTY-LOW (low) [%] – –×

PLS WIDTH-HI [msec] – –×

PLS WIDTH-LOW [msec] – –× Monitored item (Unit)Monitor item selection

Remarks

ECU INPUT

SIGNALSMAIN

SIGNALSSELEC-

TION FROM

MENU

1.2 kg-m : Tight corner braking symptom is alleviated.

However, vibration may occur when acceler-

ating on a low µ road (icy road, etc.).

0.3 kg-m : Initial set value.

0.2 kg-m : Do not set to this value because the tight

corner braking symptom will get worse.

SMT968D

SMT969D

Page 3028 of 3061

FRONT WIPER AND WASHER SYSTEM

WW-11

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

WW

N

O

P

CONSULT-II Function (BCM)INFOID:0000000003533560

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

CONSULT-II START PROCEDURE

Refer to GI-36, "CONSULT-II Start Procedure".

WORK SUPPORT

Operation Procedure

1. Touch "WIPER" on the "SELECT TEST ITEM" screen.

2. Touch "WORK SUPPORT" on the "SELECT DIAG MODE" screen.

3. Touch "WIPER SPEED SETTING" on the "SELECT WORK ITEM" screen.

4. Touch "START".

5. Touch "CHANGE SETT".

6. The setting will be changed and "CUSTOMIZING COMPLETE" will be displayed.

7. Touch "END".

Work Support Setting Item

DATA MONITOR

Display Item List

BCM diagnostic

test itemDiagnostic mode Description

Inspection by partWORK SUPPORTSupports inspections and adjustments. Commands are transmitted to the BCM for

setting the status suitable for required operation, input/output signals are received

from the BCM and received data is displayed.

DATA MONITOR Displays BCM input/output data in real time.

ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF-DIAG RESULTS Displays BCM self-diagnosis results.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

ECU PART NUMBER BCM part number can be read.

CONFIGURATION Performs BCM configuration read/write functions.

Item Description CONSULT-II

WIPER SPEED SETTINGWhen wiper switch is at INTERMITTENT, front wiper intermittent

time can be selected according to vehicle speed.

• ON (Operated)/OFF (Not operated)ON/OFF

ALL SIGNALS Monitors all the items.

SELECTION FROM MENU Selects and monitors the individual item selected.

Monitor item name

"OPERATION OR UNIT"Contents

IGN ON SW "ON/OFF"Displays "IGN Position (ON)/OFF, ACC Position (OFF)" status as judged from ignition

switch signal.

IGN SW CAN "ON/OFF"Displays "IGN switch ON (ON)/Other OFF or ACC (OFF)" status as judged from CAN

communications.

FR WIPER HI "ON/OFF" Displays "Front Wiper HI (ON)/Other (OFF)" status as judged from wiper switch signal.

FR WIPER LOW "ON/OFF"Displays "Front Wiper LOW (ON)/Other (OFF)" status as judged from wiper switch sig-

nal.

FR WIPER INT "ON/OFF" Displays "Front Wiper INT (ON)/Other (OFF)" status as judged from wiper switch signal.

Page 3037 of 3061

WW-20

< SERVICE INFORMATION >

FRONT WIPER AND WASHER SYSTEM

1.COMBINATION SWITCH TO BCM INSPECTION

Select "BCM" on CONSULT-II. With "WIPER" data monitor, check

that "FR WASHER SW" turns ON-OFF according to operation of

front washer switch.

OK or NG

OK >> Replace BCM. Refer to BCS-24, "BCM".

NG >> Replace wiper switch. Refer to WW-23, "

Wiper and

Washer Switch".

Front Wipers Operate For 10 Seconds, Stop For 20 Seconds, And After Repeating This Operation

Five Times, They Become Inoperative

CAUTION:

• When auto stop signal has not varied for 10 seconds or longer while IPDM E/R is operating front wip-

ers, IPDM E/R considers front wipers locked and stops wiper output, which causes this symptom.

• This status can be checked by using IPDM E/R "DATA MONITOR". Under this condition, "WIP PROT"

reads "BLOCK".

1.CHECK IPDM E/R TO FRONT WIPER MOTOR

With CONSULT-II

Select "IPDM E/R" with CONSULT-II. With data monitor, confirm that

"WIP AUTO STOP" changes from "ACT P" to "STOP P" according to

wiper operation.

Without CONSULT-II

GO TO 2.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-28, "Removal and

Installation of IPDM E/R".

NG >> GO TO 2.

2.IPDM E/R TO FRONT WIPER MOTOR AUTO STOP CIRCUIT INSPECTION

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector and front wiper motor connector.

3. Check continuity between IPDM E/R harness connector terminal

and front wiper motor harness connector terminal.

WKIA1018E

SKIA5301E

Te r m i n a l s

Continuity

Connector Terminal Connector Terminal

E122 43 E23 6 Yes

WKIA2084E