ECU INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1168 of 3061

TROUBLE DIAGNOSIS

EC-85

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

7.PERFORM DATA MONITOR (SPEC) MODE

With CONSULT-II

Make sure that “MAS A/F SE-B1”, “B/FUEL SCHDL”, and “A/F

ALPHA-B1”, “A/F ALPHA-B2” are within the SP value using CON-

SULT-II “DATA MONITOR (SPEC)” mode. Refer to EC-129

.

Are they within the SP value?

Yes >> GO TO 9.

No >> GO TO 8.

8.DETECT MALFUNCTIONING PART BY TROUBLE DIAGNOSIS - SPECIFICATION VALUE

Detect malfunctioning part according to EC-130, "

Diagnosis Procedure" .

Is malfunctioning part detected?

Yes >> GO TO 11.

No >> GO TO 9.

9.DETECT MALFUNCTIONING SYSTEM BY SYMPTOM MATRIX CHART

Detect malfunctioning system according to EC-90, "

Symptom Matrix Chart" based on the confirmed symptom

in step 4, and determine the trouble diagnosis order based on possible causes and symptom.

>> GO TO 10.

10.DETECT MALFUNCTIONING PART BY DIAGNOSTIC PROCEDURE

Inspect according to Diagnostic Procedure of the system.

NOTE:

The Diagnostic Procedure in EC section described based on open circuit inspection. A short circuit inspection

is also required for the circuit check in the Diagnostic Procedure. For details, refer to Circuit Inspection in GI-

25, "How to Perform Efficient Diagnosis for an Electrical Incident".

Is malfunctioning part detected?

Yes >> GO TO 11.

No >> Monitor input data from related sensors or check voltage of related ECM terminals using CON-

SULT-II. Refer to EC-103, "

ECM Terminal and Reference Value" , EC-124, "CONSULT-II Refer-

ence Value in Data Monitor Mode" .

11 .REPAIR OR REPLACE THE MALFUNCTIONING PART

1. Repair or replace the malfunctioning part.

2. Reconnect parts or connectors disconnected during Diagnostic Procedure again after repair and replace-

ment.

3. Check DTC. If DTC is displayed, erase it, refer to EC-49, "

Emission-related Diagnostic Information" .

>> GO TO 12.

12.FINAL CHECK

When DTC was detected in step 2, perform DTC Confirmation Procedure or Overall Function Check again,

and then make sure that the malfunction have been repaired securely.

When symptom was described from the customer, refer to confirmed symptom in step 3 or 4, and make sure

that the symptom is not detected.

OK or NG

NG (DTC*1 is detected)>>GO TO 10.

NG (Symptom remains)>>GO TO 6.

OK >> 1. Before returning the vehicle to the customer, make sure to erase unnecessary DTC*

1 in ECM

and TCM (Transmission Control Module). (Refer to EC-49, "

Emission-related Diagnostic

Information" and AT-39, "OBD-II Diagnostic Trouble Code (DTC)".)

SEF601Z

Page 1197 of 3061

EC-114

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

*: This function is not necessary in the usual service procedure.

SELF-DIAG RESULTS MODE

Self Diagnostic Item

Regarding items of DTC and 1st trip DTC, refer to EC-49, "Emission-related Diagnostic Information".

Freeze Frame Data and 1st Trip Freeze Frame Data

EVAP SYSTEM CLOSE CLOSE THE EVAP CANISTER VENT CONTROL VALVE IN

ORDER TO MAKE EVAP SYSTEM CLOSE UNDER THE

FOLLOWING CONDITIONS.

• IGN SW ON

• ENGINE NOT RUNNING

• AMBIENT TEMPERATURE IS ABOVE 0°C (32°F).

• NO VACUUM AND NO HIGH PRESSURE IN EVAP SYS-

TEM

• FUEL TANK TEMP. IS MORE THAN 0°C (32°F).

• WITHIN 10 MINUTES AFTER STARTING “EVAP SYS-

TEM CLOSE”

• WHEN TRYING TO EXECUTE “EVAP SYSTEM CLOSE”

UNDER THE CONDITION EXCEPT ABOVE, CONSULT-

II WILL DISCONTINUE IT AND DISPLAY APPROPRIATE

INSTRUCTION.

NOTE:

WHEN STARTING ENGINE, CONSULT-II MAY DISPLAY

“BATTERY VOLTAGE IS LOW. CHARGE BATTERY”,

EVEN IN USING CHARGED BATTERY.When detecting EVAP vapor leak

point of EVAP system

VIN REGISTRATION • IN THIS MODE, VIN IS REGISTERED IN ECM When registering VIN in ECM

TARGET IDLE RPM ADJ* • IDLE CONDITION When setting target idle speed

TARGET IGN TIM ADJ* • IDLE CONDITION When adjusting target ignition tim-

ing WORK ITEM CONDITION USAGE

Freeze frame data

item*Description

DIAG TROUBLE

CODE

[PXXXX]• The engine control component part/control system has a trouble code, it is displayed as PXXXX. (Refer to

EC-9

.)

FUEL SYS-B1 • “Fuel injection system status” at the moment a malfunction is detected is displayed.

• One mode in the following is displayed.

Mode2: Open loop due to detected system malfunction

Mode3: Open loop due to driving conditions (power enrichment, deceleration enleanment)

Mode4: Closed loop - using oxygen sensor(s) as feedback for fuel control

Mode5: Open loop - has not yet satisfied condition to go to closed loop FUEL SYS-B2

CAL/LD VALUE [%] • The calculated load value at the moment a malfunction is detected is displayed.

COOLANT TEMP

[°C] or [°F]• The engine coolant temperature at the moment a malfunction is detected is displayed.

L-FUEL TRM-B1 [%] • “Long-term fuel trim” at the moment a malfunction is detected is displayed.

• The long-term fuel trim indicates much more gradual feedback compensation to the base fuel schedule than

short-term fuel trim. L-FUEL TRM-B2 [%]

S-FUEL TRM-B1 [%] • “Short-term fuel trim” at the moment a malfunction is detected is displayed.

• The short-term fuel trim indicates dynamic or instantaneous feedback compensation to the base fuel sched-

ule. S-FUEL TRM-B2 [%]

ENGINE SPEED [rpm] • The engine speed at the moment a malfunction is detected is displayed.

VEHICL SPEED

[km/h] or [mph]• The vehicle speed at the moment a malfunction is detected is displayed.

ABSOL TH-P/S

[%]• The throttle valve opening at the moment a malfunction is detected is displayed.

Page 1221 of 3061

EC-138

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT

DescriptionINFOID:0000000003531634

Intermittent incidents may occur. In many cases, the malfunction resolves itself (the part or circuit function

returns to normal without intervention). It is important to realize that the symptoms described in the customer's

complaint often do not recur on (1st trip) DTC visits. Realize also that the most frequent cause of intermittent

incidents occurrences is poor electrical connections. Because of this, the conditions under which the incident

occurred may not be clear. Therefore, circuit checks made as part of the standard diagnostic procedure may

not indicate the specific malfunctioning area.

Common Intermittent Incidents Report Situations

Diagnosis ProcedureINFOID:0000000003531635

1.INSPECTION START

Erase (1st trip) DTCs. Refer to EC-49, "

Emission-related Diagnostic Information" .

>> GO TO 2.

2.CHECK GROUND TERMINALS

Check ground terminals for corroding or loose connection.

Refer to EC-143, "

Ground Inspection" .

OK or NG

OK >> GO TO 3.

NG >> Repair or replace.

3.SEARCH FOR ELECTRICAL INCIDENT

Perform GI-25, "

How to Perform Efficient Diagnosis for an Electrical Incident", “INCIDENT SIMULATION

TESTS”.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace.

4.CHECK CONNECTOR TERMINALS

Refer to GI-22, "

How to Check Terminal", “HOW TO PROBE CONNECTORS”, “How to Check Enlarged Con-

tact Spring of Terminal”.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace connector.

STEP in Work Flow Situation

2 The CONSULT-II is used. The SELF-DIAG RESULTS screen shows time data other than [0] or [1t].

3 or 4 The symptom described by the customer does not recur.

5 (1st trip) DTC does not appear during the DTC Confirmation Procedure.

10 The Diagnostic Procedure for PXXXX does not indicate the malfunctioning area.

Page 1226 of 3061

POWER SUPPLY AND GROUND CIRCUIT

EC-143

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

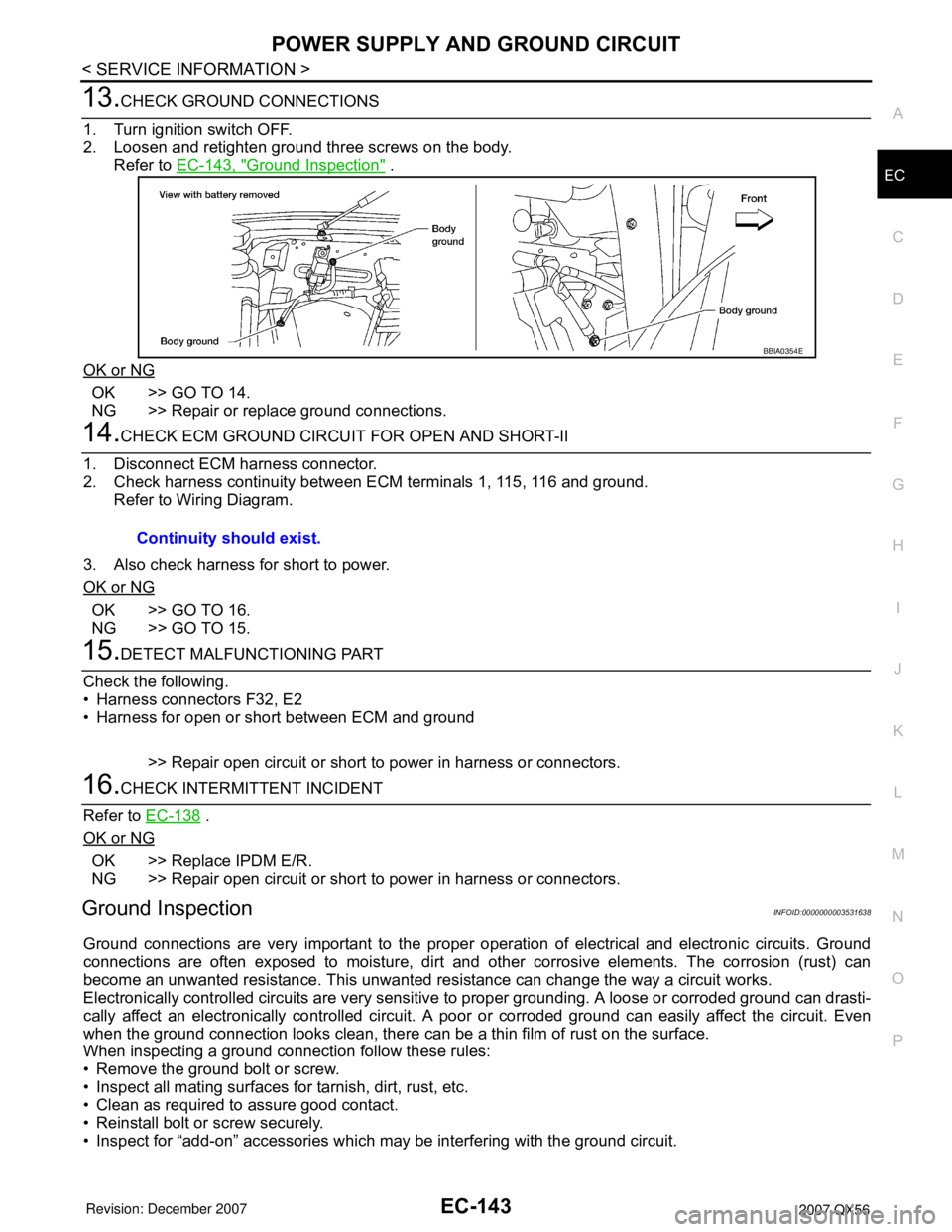

13.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten ground three screws on the body.

Refer to EC-143, "

Ground Inspection" .

OK or NG

OK >> GO TO 14.

NG >> Repair or replace ground connections.

14.CHECK ECM GROUND CIRCUIT FOR OPEN AND SHORT-II

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminals 1, 115, 116 and ground.

Refer to Wiring Diagram.

3. Also check harness for short to power.

OK or NG

OK >> GO TO 16.

NG >> GO TO 15.

15.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors F32, E2

• Harness for open or short between ECM and ground

>> Repair open circuit or short to power in harness or connectors.

16.CHECK INTERMITTENT INCIDENT

Refer to EC-138

.

OK or NG

OK >> Replace IPDM E/R.

NG >> Repair open circuit or short to power in harness or connectors.

Ground InspectionINFOID:0000000003531638

Ground connections are very important to the proper operation of electrical and electronic circuits. Ground

connections are often exposed to moisture, dirt and other corrosive elements. The corrosion (rust) can

become an unwanted resistance. This unwanted resistance can change the way a circuit works.

Electronically controlled circuits are very sensitive to proper grounding. A loose or corroded ground can drasti-

cally affect an electronically controlled circuit. A poor or corroded ground can easily affect the circuit. Even

when the ground connection looks clean, there can be a thin film of rust on the surface.

When inspecting a ground connection follow these rules:

• Remove the ground bolt or screw.

• Inspect all mating surfaces for tarnish, dirt, rust, etc.

• Clean as required to assure good contact.

• Reinstall bolt or screw securely.

• Inspect for “add-on” accessories which may be interfering with the ground circuit.

BBIA0354E

Continuity should exist.

Page 1227 of 3061

EC-144

< SERVICE INFORMATION >

POWER SUPPLY AND GROUND CIRCUIT

• If several wires are crimped into one ground eyelet terminal, check for proper crimps. Make sure all of the

wires are clean, securely fastened and providing a good ground path. If multiple wires are cased in one eye-

let make sure no ground wires have excess wire insulation.

For detailed ground distribution information, refer to PG-29, "

Ground Distribution".

PBIB1870E

Page 1234 of 3061

DTC P0011, P0021 IVT CONTROL

EC-151

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

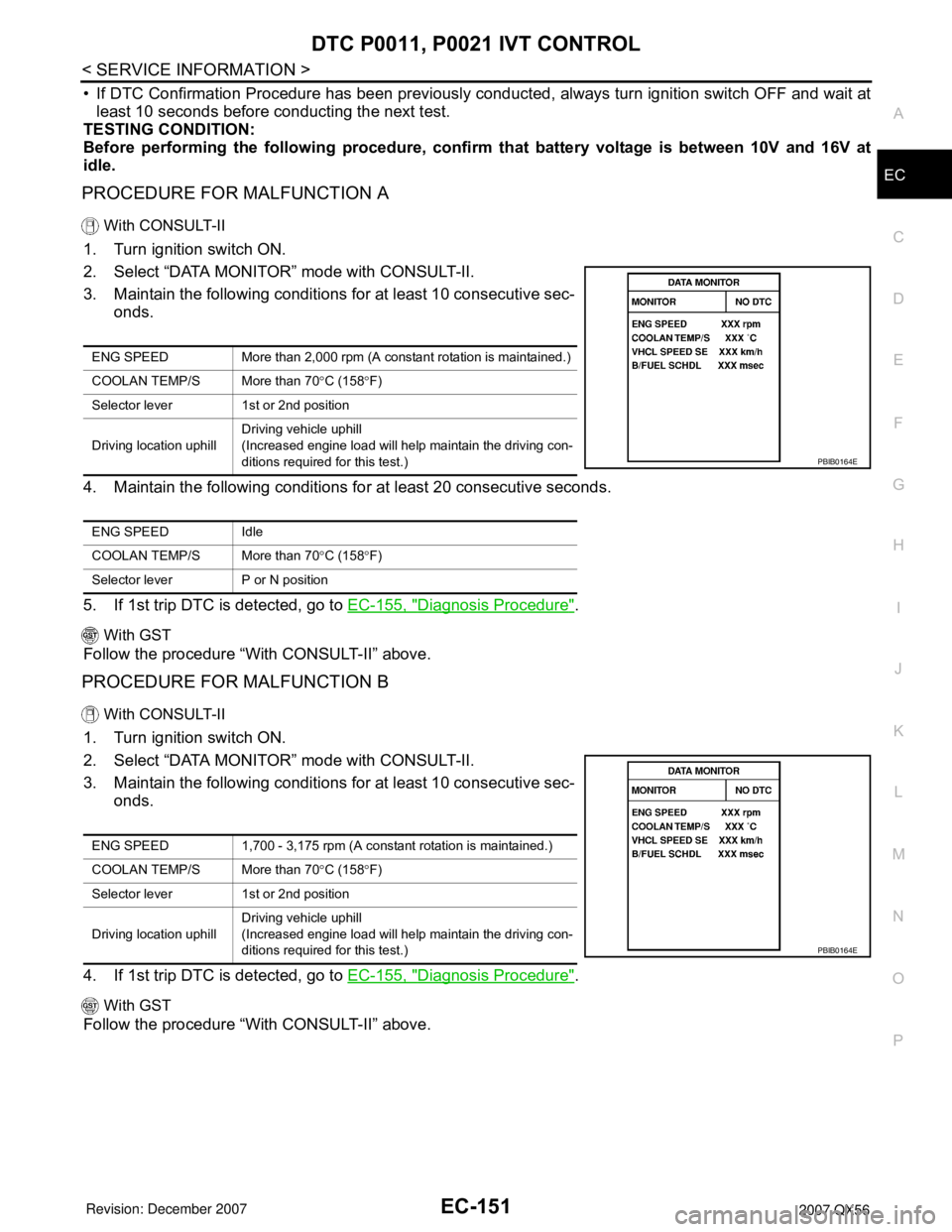

• If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is between 10V and 16V at

idle.

PROCEDURE FOR MALFUNCTION A

With CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Maintain the following conditions for at least 10 consecutive sec-

onds.

4. Maintain the following conditions for at least 20 consecutive seconds.

5. If 1st trip DTC is detected, go to EC-155, "

Diagnosis Procedure".

With GST

Follow the procedure “With CONSULT-II” above.

PROCEDURE FOR MALFUNCTION B

With CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Maintain the following conditions for at least 10 consecutive sec-

onds.

4. If 1st trip DTC is detected, go to EC-155, "

Diagnosis Procedure".

With GST

Follow the procedure “With CONSULT-II” above.

ENG SPEED More than 2,000 rpm (A constant rotation is maintained.)

COOLAN TEMP/S More than 70°C (158°F)

Selector lever 1st or 2nd position

Driving location uphillDriving vehicle uphill

(Increased engine load will help maintain the driving con-

ditions required for this test.)

ENG SPEED Idle

COOLAN TEMP/S More than 70°C (158°F)

Selector lever P or N position

PBIB0164E

ENG SPEED 1,700 - 3,175 rpm (A constant rotation is maintained.)

COOLAN TEMP/S More than 70°C (158°F)

Selector lever 1st or 2nd position

Driving location uphillDriving vehicle uphill

(Increased engine load will help maintain the driving con-

ditions required for this test.)

PBIB0164E

Page 1271 of 3061

EC-188

< SERVICE INFORMATION >

DTC P0101 MAF SENSOR

7. Maintain the following conditions for at least 10 consecutive sec-

onds.

8. If 1st trip DTC is detected, go to EC-190, "

Diagnosis Procedure".

Overall Function CheckINFOID:0000000003531684

PROCEDURE FOR MALFUNCTION B

Use this procedure to check the overall function of the mass air flow sensor circuit. During this check, a 1st trip

DTC might not be confirmed.

With GST

1. Start engine and warm it up to normal operating temperature.

2. Select Service $01 with GST.

3. Check the mass air flow sensor signal with Service $01.

4. Check for linear mass air flow sensor signal value rise in

response to increases to about 4,000 rpm in engine speed.

5. If NG, go to EC-190, "

Diagnosis Procedure".

ENG SPEED More than 2,000 rpm

THRTL SEN 1 More than 3V

THRTL SEN 2 More than 3V

Selector lever Suitable position

Driving locationDriving vehicle uphill (Increased engine load) will help

maintain the driving conditions required for this test.

PBIB0199E

SEF534P

Page 1304 of 3061

DTC P0127 IAT SENSOR

EC-221

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

b. Select “DATA MONITOR” mode with CONSULT-II.

c. Check the engine coolant temperature.

d. If the engine coolant temperature is not less than 90°C (194°F),

turn ignition switch OFF and cool down engine.

• Perform the following steps before engine coolant temperature

is above 90°C (194°F).

2. Turn ignition switch ON.

3. Select “DATA MONITOR” mode with CONSULT-II.

4. Start engine.

5. Hold vehicle speed at more than 70 km/h (43 MPH) for 100 con-

secutive seconds.

6. If 1st trip DTC is detected, go to EC-221, "

Diagnosis Procedure" .

WITH GST

Follow the procedure “WITH CONSULT-II” above.

Diagnosis ProcedureINFOID:0000000003531728

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten three ground screws on the body.

Refer to EC-143, "

Ground Inspection" .

OK or NG

OK >> GO TO 2.

NG >> Repair or replace ground connections.

2.CHECK INTAKE AIR TEMPERATURE SENSOR

Refer to EC-221, "

Component Inspection" .

OK or NG

OK >> GO TO 3.

NG >> Replace mass air flow sensor (with intake air temperature sensor).

3.CHECK INTERMITTENT INCIDENT

Refer to EC-138

.

Refer to EC-202, "

Wiring Diagram" .

>>INSPECTION END

Component InspectionINFOID:0000000003531729

INTAKE AIR TEMPERATURE SENSOR

SEF189Y

BBIA0354E

Page 1306 of 3061

DTC P0128 THERMOSTAT FUNCTION

EC-223

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

DTC P0128 THERMOSTAT FUNCTION

On Board Diagnosis LogicINFOID:0000000003531731

Engine coolant temperature has not risen enough to open the thermostat even though the engine has run long

enough.

This is due to a leak in the seal or the thermostat stuck open.

DTC Confirmation ProcedureINFOID:0000000003531732

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

•For best results, perform at ambient temperature of –10°C (14°F) or higher.

•For best results, perform at engine coolant temperature of –10°C (14°F) to 72°C (162°F).

WITH CONSULT-II

1. Replace thermostat with new one. Refer to CO-20 . Use only a genuine NISSAN thermostat as a replace-

ment. If an incorrect thermostat is used, the MIL may come on.

2. Turn ignition switch ON.

3. Select “COOLAN TEMP/S” in “DATA MONITOR” mode with CONSULT-II.

4. Check that the “COOLAN TEMP/S” is above 72°C (162°F).

If it is below 72°C (162°F), go to following step.

If it is above 72°C (162°F), cool down the engine to less than 72°C (162°F), then retry from step 1.

5. Drive vehicle for 10 consecutive minutes under the following conditions.

If 1st trip DTC is detected, go to EC-223, "

Diagnosis Procedure" .

WITH GST

1. Follow the procedure “WITH CONSULT-II” above.

Diagnosis ProcedureINFOID:0000000003531733

1.CHECK ENGINE COOLANT TEMPERATURE SENSOR

Refer to EC-223, "

Component Inspection" .

OK or NG

OK >>INSPECTION END

NG >> Replace engine coolant temperature sensor.

Component InspectionINFOID:0000000003531734

ENGINE COOLANT TEMPERATURE SENSOR

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0128

0128Thermostat functionThe engine coolant temperature does not

reach to specified temperature even though

the engine has run long enough.•Thermostat

• Leakage from sealing portion of thermostat

• Engine coolant temperature sensor

VHCL SPEED SE 80 - 120 km/h (50 - 75 MPH)

Page 1318 of 3061

DTC P0131, P0151 A/F SENSOR 1

EC-235

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

3. Check “A/F SEN1 (B1)” or “A/F SEN1 (B2)” indication.

If the indication is constantly approx. 0V, go to EC-239, "

Diagno-

sis Procedure".

If the indication is not constantly approx. 0V, go to next step.

4. Turn ignition switch OFF, wait at least 10 seconds and then

restart engine.

5. Drive and accelerate vehicle to more than 40 km/h (25 MPH)

within 20 seconds after restarting engine.

6. Maintain the following conditions for about 20 consecutive sec-

onds.

NOTE:

•Keep the accelerator pedal as steady as possible during the cruising.

•If this procedure is not completed within 1 minute after restarting engine at step 4, return to step

4.

7. If 1st trip DTC is displayed, go to EC-239, "

Diagnosis Procedure".

WITH GST

Follow the procedure “WITH CONSULT-II” above.

ENG SPEED 1,000 - 3,200 rpm

VHCL SPEED SE More than 40 km/h (25 MPH)

B/FUEL SCHDL 1.5 - 9.0 msec

Gear position Suitable position

SEF581Z