ECU INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 958 of 3061

![INFINITI QX56 2007 Factory Service Manual BRC-30

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Item

(Unit)Data monitor item selection

Remarks

ECU INPUT

SIGNALSMAIN

SIGNALSSELECTION

FROM MENU

GEAR×××Gear position judged by PNP swi INFINITI QX56 2007 Factory Service Manual BRC-30

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Item

(Unit)Data monitor item selection

Remarks

ECU INPUT

SIGNALSMAIN

SIGNALSSELECTION

FROM MENU

GEAR×××Gear position judged by PNP swi](/img/42/57029/w960_57029-957.png)

BRC-30

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Item

(Unit)Data monitor item selection

Remarks

ECU INPUT

SIGNALSMAIN

SIGNALSSELECTION

FROM MENU

GEAR×××Gear position judged by PNP switch

signal is displayed.

FR RH SENSOR

(km/h, MPH)×××Wheel speed calculated by front RH

wheel sensor signal is displayed.

FR LH SENSOR

(km/h, MPH)×××Wheel speed calculated by front LH

wheel sensor signal is displayed.

RR RH SENSOR

(km/h, MPH)×××Wheel speed calculated by rear RH

wheel sensor signal is displayed.

RR LH SENSOR

(km/h, MPH)×××Wheel speed calculated by rear LH

wheel sensor signal is displayed.

BATTERY VOLT

(V)×××Voltage supplied to ABS actuator

and electric unit (control unit) is dis-

played.

N POSI SIG – –×Shift position judged by PNP switch

signal.

P POSI SIG – –×Shift position judged by PNP switch

signal.

ACCEL POS SIG

(%)×–×Throttle valve open/close status

judged by CAN communication sig-

nal is displayed.

ENGINE SPEED

(rpm)×××Engine speed judged by CAN com-

munication signal is displayed.

STR ANGLE SIG

(deg)×–×Steering angle detected by steering

angle sensor is displayed.

YAW RATE SEN

(d/s)×××Yaw rate detected by yaw rate sen-

sor is displayed.

DECEL G-SEN

(d/s)×××Longitudinal acceleration detected

by decel G-sensor is displayed.

SIDE G-SENSOR

(m/s

2)×– ×Transverse acceleration detected

by side G-sensor is displayed.

STOP LAMP SW

(ON/OFF)×××Stop lamp switch (ON/OFF) status

is displayed.

OFF SW

(ON/OFF) ×× ×VDC OFF switch (ON/OFF) status

is displayed.

ABS WARN LAMP

(ON/OFF)–××ABS warning lamp (ON/OFF) status

is displayed.

SLIP LAMP

(ON/OFF)–××SLIP indicator lamp (ON/OFF) sta-

tus is displayed.

FR LH IN SOL

(ON/OFF)–××Front LH IN ABS solenoid (ON/

OFF) status is displayed.

FR LH OUT SOL

(ON/OFF)–××Front LH OUT ABS solenoid (ON/

OFF) status is displayed.

RR RH IN SOL

(ON/OFF)–××Rear RH IN ABS solenoid (ON/

OFF) status is displayed.

RR RH OUT SOL

(ON/OFF) –××Rear RH OUT ABS solenoid (ON/

OFF) status is displayed.

FR RH IN SOL

(ON/OFF)–××Front RH IN ABS solenoid (ON/

OFF) status is displayed.

FR RH OUT SOL

(ON/OFF)–××Front RH OUT ABS solenoid (ON/

OFF) status is displayed.

Page 959 of 3061

![INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS

BRC-31

< SERVICE INFORMATION >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

RR LH IN SOL

(ON/OFF)–××Rear LH IN ABS solenoid (ON/OFF)

status is displayed.

RR LH OUT SOL

(ON/OFF) INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS

BRC-31

< SERVICE INFORMATION >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

RR LH IN SOL

(ON/OFF)–××Rear LH IN ABS solenoid (ON/OFF)

status is displayed.

RR LH OUT SOL

(ON/OFF)](/img/42/57029/w960_57029-958.png)

TROUBLE DIAGNOSIS

BRC-31

< SERVICE INFORMATION >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

RR LH IN SOL

(ON/OFF)–××Rear LH IN ABS solenoid (ON/OFF)

status is displayed.

RR LH OUT SOL

(ON/OFF)–××Rear LH OUT ABS solenoid (ON/

OFF) status is displayed.

OFF LAMP

(ON/OFF)–××OFF Lamp (ON/OFF) status is dis-

played.

MOTOR RELAY

(ON/OFF)–××ABS motor relay signal (ON/OFF)

status is displayed.

ACTUATOR RLY

(ON/OFF)– ××ABS actuator relay signal (ON/OFF)

status is displayed.

CV1

(ON/OFF)––×Front side switch-over solenoid

valve (cut valve) (ON/OFF) status is

displayed.

CV2

(ON/OFF)––×Rear side switch-over solenoid

valve (cut-valve) (ON/OFF) status is

displayed.

SV1

(ON/OFF)––×Front side switch-over solenoid

valve (suction valve) (ON/OFF) sta-

tus is displayed.

SV2

(ON/OFF)––×Rear side switch-over solenoid

valve (suction valve) (ON/OFF) sta-

tus is displayed.

VDC FAIL SIG

(ON/OFF)––×VDC fail signal (ON/OFF) status is

displayed.

TCS FAIL SIG

(ON/OFF)––×TCS fail signal (ON/OFF) status is

displayed.

ABS FAIL SIG

(ON/OFF)––×ABS fail signal (ON/OFF) status is

displayed.

EBD FAIL SIG

(ON/OFF)––×EBD fail signal (ON/OFF) status is

displayed.

FLUID LEV SW

(ON/OFF)×–×Brake fluid level switch (ON/OFF)

status is displayed.

EBD SIGNAL

(ON/OFF)––×EBD operation (ON/OFF) status is

displayed.

ABS SIGNAL

(ON/OFF)––×ABS operation (ON/OFF) status is

displayed.

TCS SIGNAL

(ON/OFF)––×TCS operation (ON/OFF) status is

displayed.

VDC SIGNAL

(ON/OFF)––×VDC operation (ON/OFF) status is

displayed.

EBD WARN LAMP – –×Brake warning lamp (ON/OFF) sta-

tus is displayed.

SLCT LVR POSI×××Shift position judged by PNP switch

signal.

R POSI SIG – –×Shift position judged by PNP switch

signal.

4WD FAIL REQ – –×The state of 4WD controller is dis-

played by CAN communication sig-

nal.

2WD/4WD – –×It recognizes on software whether it

is 2WD and whether it is in 4WD

state. Item

(Unit)Data monitor item selection

Remarks

ECU INPUT

SIGNALSMAIN

SIGNALSSELECTION

FROM MENU

Page 960 of 3061

![INFINITI QX56 2007 Factory Service Manual BRC-32

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

×: Applicable

–: Not applicable

ACTIVE TEST

CAUTION:

• Do not perform active test while driving.

• Make sure to completely bleed ai INFINITI QX56 2007 Factory Service Manual BRC-32

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

×: Applicable

–: Not applicable

ACTIVE TEST

CAUTION:

• Do not perform active test while driving.

• Make sure to completely bleed ai](/img/42/57029/w960_57029-959.png)

BRC-32

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

×: Applicable

–: Not applicable

ACTIVE TEST

CAUTION:

• Do not perform active test while driving.

• Make sure to completely bleed air from the brake system.

• The ABS and brake (EBD) warning lamps turn on during the active test.

Solenoid Valve Operation Chart

BST OPER SIG – –×Active booster operation (ON/OFF)

status is displayed.

PRESS SENSOR×–×Brake pressure detected by pres-

sure sensor is displayed.

CRANKING SIG – –×The input state of the key SW

START position signal is displayed.

PRESS SEN 2 – –×Brake pressure detected by pres-

sure sensor is displayed.

DELTA S SEN – –×The amount of stroke sensor move-

ments in the active booster detected

by DELTA S SEN is displayed.

RELEASE SW NO – –×Release switch signal (ON/OFF)

status is displayed. "ON" indicates

that the brake pedal is depressed.

"OFF" is that the brake pedal is re-

leased.

RELEASE SW NC – –×Release switch signal (ON/OFF)

status is displayed. "OFF" indicates

that the brake pedal is depressed

on. "ON" is that the brake pedal is

released.

OHB FAIL – –×OHB fail status is displayed.

HBA FAIL – –×HBA fail status is displayed.

OHB SIG – –×OHB operation (ON/OFF) status is

displayed.

HBA SIG – –×HBA operation (ON/OFF) status is

displayed.

PRES CTRL ACC – –×Pressure control state (ON/OFF) is

displayed. It is applied only to an

ICC vehicle.

PRES FAIL ACC – –×Pressure control fail state (ON/OFF)

is displayed. It is applied only to an

ICC vehicle.

STP OFF RLY – –×Stop lamp relay signal (ON/OFF)

status is displayed. Item

(Unit)Data monitor item selection

Remarks

ECU INPUT

SIGNALSMAIN

SIGNALSSELECTION

FROM MENU

OperationABS solenoid valve ABS solenoid valve (ACT)

UP KEEP DOWN UPACTUA-

TOR UPACTUA-

TOR KEEP

FR RH SOL

FR RH ABS SOLE-

NOID (ACT)FR RH IN SOL OFF ON ON OFF OFF OFF

FR RH OUT SOL OFF OFF ON* OFF OFF OFF

Page 1010 of 3061

THERMOSTAT AND WATER PIPING

CO-21

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

3. Remove the engine room cover using power tool.

4. Disconnect the heater hose (heater core side).

5. Remove the heater hose bracket.

6. Disconnect the water cut valve connector.

7. Remove the water cut valve.

INSPECTION AFTER REMOVAL

• Place a thread so that it is caught in the valve of the thermostat.

Immerse fully in a container filled with water. Heat while stirring.

• The valve opening temperature is the temperature at which the

valve opens and falls from the thread.

• Continue heating. Check the full-open lift amount.

• After checking the full-open lift amount, lower the water tempera-

ture and check the valve closing temperature.

Standard values:

INSTALLATION

Installation is in the reverse order of removal.

Installation of Thermostat

• Install the thermostat with the whole circumference of each flange

part fit securely inside the rubber ring as shown.

• Install the thermostat with the jiggle valve facing upwards.

Installation of Water Outlet Pipe and Heater Pipe

First apply a neutral detergent to the O-rings, then quickly insert the insertion parts of the water outlet pipe and

heater pipe into the installation holes.

INSPECTION AFTER INSTALLATION

• Check for leaks of the engine coolant. Refer to CO-9, "Inspection".

• Start and warm up the engine. Visually check for leaks of the engine coolant.

SLC252B

Thermostat

Valve opening temperature 80 - 84°C (176 - 183° F)

Full-open lift amount More than 10 mm/ 95°C (0.39 in/ 203°F)

Valve closing temperature 77°C (171°F) or higher

KBIA2502E

Page 1022 of 3061

COMBINATION METERSDI-11

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

Combination Meter Harness Connector Terminal LayoutINFOID:0000000003533484

Terminal and Reference Va lue for Combination MeterINFOID:0000000003533485

LKIA0698E

Te r m i n a l

No. Wire

color Item Condition

Reference value (V)

(Approx.)

Ignition

switch Operation or condition

1 O Ignition switch ACC or ON ON — Battery voltage

8 Y/R Battery power supply OFF — Battery voltage

9 R/G Stop lamp switch ON Brake pedal depressed Battery voltage

Brake pedal released 0

10 P/B Brake fluid level switch ON Brake fluid level low 0

Brake fluid level normal Battery voltage

11 L C A N - H — — —

12 P CAN-L — — —

14 P/L Seat belt buckle switch

RH ONUnfastened (ON) 0

Fastened (OFF) Battery voltage

15 Y/L Fuel level sensor signal — — Refer to

DI-18, "

Fuel Level Sensor

Unit Inspection".

16 B/P Fuel level sensor and oil

pressure sensor ground ON — 0V

17 B Ground — — 0V

18 BR Illumination control switch — Lighting switch ON Refer to

LT- 1 2 0 , "

System Descrip-

tion".

23 G Parking Brake switch ON Parking brake applied 0

Parking brake released Battery voltage

24 O/L Ignition switch ON or

START ON — Battery voltage

27 O/B Seat belt buckle pre-ten-

sioner assembly LH (seat

belt buckle switch) ON

Unfastened (ON) 0

Fastened (OFF) Battery voltage

28 G/O Security indicator input OFF Security indicator ON 0

Security indicator

OFF Battery voltage

29 W/R Vehicle speed signal

(8-pulse) ONSpeedometer operated

[When vehicle speed is ap-

prox. 40 km/h (25 MPH)]

PKIA1935E

Page 1051 of 3061

DI-40

< SERVICE INFORMATION >

WARNING CHIME

How to Proceed with Trouble Diagnosis

INFOID:0000000003533516

1. Confirm the symptom or customer complaint.

2. Understand operation description and function description. Refer to DI-36, "

System Description".

3. Perform the preliminary check. Refer to DI-40, "

Preliminary Check".

4. Check symptom and repair or replace the cause of malfunction.

5. Does the warning chime operate properly? If so, go to 6. If not, go to 3.

6. Inspection End.

Preliminary CheckINFOID:0000000003533517

INSPECTION FOR POWER SUPPLY AND GROUND CIRCUIT

Refer to BCS-15, "BCM Power Supply and Ground Circuit Inspection".

CONSULT-II Function (BCM)INFOID:0000000003533518

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

CONSULT-II START PROCEDURE

Refer to GI-36, "CONSULT-II Start Procedure".

DATA MONITOR

Display Item List

ACTIVE TEST

Display Item List

SELF-DIAGNOSTIC RESULTS

BCM

diagnostic test itemDiagnostic mode Description

Inspection by partWORK SUPPORTSupports inspections and adjustments. Commands are transmitted to the BCM

for setting the status suitable for required operation, input/output signals are re-

ceived from the BCM and received data is displayed.

DATA MONITOR Displays BCM input/output data in real time.

ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF-DIAG RESULTS Displays BCM self-diagnosis results.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

ECU PART NUMBER BCM part number can be read.

CONFIGURATION Performs BCM configuration read/write functions.

Monitored item Description

IGN ON SW Indicates [ON/OFF] condition of ignition switch.

KEY ON SW Indicates [ON/OFF] condition of key switch.

DOOR SW-DR Indicates [ON/OFF] condition of front door switch (driver side).

LIGHT SW 1ST Indicates [ON/OFF] condition of lighting switch.

Test item Malfunction is detected when

LIGHT WARN ALMThis test is able to check light warning chime operation. Light warning chime sounds for 2 seconds

after touching “ON” on CONSULT-II screen.

IGN KEY WARN ALMThis test is able to check key warning chime operation. Key warning chime sounds for 2 seconds

after touching “ON” on CONSULT-II screen.

SEAT BELT WARN TESTThis test is able to check seat belt warning chime operation. Seat belt warning chime sounds for 2

seconds after touching “ON” on CONSULT-II screen.

Page 1076 of 3061

REAR VIEW MONITOR

DI-65

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

CONSULT-II START PROCEDURE

Refer to GI-36, "CONSULT-II Start Procedure".

WORK SUPPORT

Refer to DI-65, "Side Distance Guideline Correction" for details.

DATA MONITOR

Display Item List

Side Distance Guideline CorrectionINFOID:0000000003533545

This mode is used to modify the side distance guidelines if they are dislocated from the rear view monitor

image, because of variations of body/camera mounting conditions.

SIDE DISTANCE GUIDELINE CORRECTION PROCEDURE

1. Create a correction line to modify the screen.

Draw lines on the rearward of the vehicle passing through the

following points: 200 mm (7.87 inch) from both sides of the vehi-

cle, and

• *1: 0.5 m (1.5 feet)

• *2: 1 m (3 feet)

• *3: 2 m (7 feet)

• *4: 3 m (10 feet)

and from the rear end of the bumper

2. With the ignition switch OFF, connect CONSULT-II and CON-

SULT-II CONVERTER to the data link connector, then turn igni-

tion switch ON. Touch “REARVIEW CAMERA” on “SELECT

SYSTEM” screen.

CAUTION:

Stop engine for safety when correcting side distance guide-

line.

REARVIEW CAMERA

diagnostic modeDescription

WORK SUPPORTSupports inspection and adjustments. Commands are transmitted to the rearview camera control unit

for setting the status suitable for required operation, input/output signals are received from the rearview

camera control unit and received data is displayed.

DATA MONITOR Displays rearview camera control unit input/output data in real time.

ECU PART NUMBER Rearview camera control unit part number can be read.

Display item [Unit]ALL SIG-

NALSSELECTION

FROM MENUContents

R POSI SIG [ON/OFF] X X Indicates [ON/OFF] condition of R position signal input.

SKIA5637E

Page 1100 of 3061

PRECAUTIONS

EC-17

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003531580

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

On Board Diagnosis (OBD) System of Engine and A/TINFOID:0000000003531581

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

• Be sure to turn the ignition switch OFF and disconnect the negative battery cable before any repair

or inspection work. The open/short circuit of related switches, sensors, solenoid valves, etc. will

cause the MIL to light up.

• Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MIL to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

• Certain systems and components, especially those related to OBD, may use a new style slide-lock-

ing type harness connector. For description and how to disconnect, refer to PG-66

.

• Be sure to route and secure the harnesses properly after work. The interference of the harness with

a bracket, etc. may cause the MIL to light up due to the short circuit.

• Be sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to the malfunction of the EVAP system or fuel injection system,

etc.

• Be sure to erase the unnecessary malfunction information (repairs completed) from the ECM and

TCM (Transmission control module) before returning the vehicle to the customer.

PrecautionINFOID:0000000003531582

•Always use a 12 volt battery as power source.

•Do not attempt to disconnect battery cables while engine is

running.

•Before connecting or disconnecting the ECM harness con-

nector, turn ignition switch OFF and disconnect negative bat-

tery cable. Failure to do so may damage the ECM because

battery voltage is applied to ECM even if ignition switch is

turned OFF.

•Before removing parts, turn ignition switch OFF and then dis-

connect negative battery cable.

SEF289H

Page 1101 of 3061

EC-18

< SERVICE INFORMATION >

PRECAUTIONS

•Do not disassemble ECM.

•If a battery cable is disconnected, the memory will return to

the ECM value.

The ECM will now start to self-control at its initial value.

Engine operation can vary slightly when the terminal is dis-

connected. However, this is not an indication of a malfunc-

tion. Do not replace parts because of a slight variation.

•If the battery is disconnected, the following emission-related

diagnostic information will be lost within 24 hours.

-Diagnostic trouble codes

-1st trip diagnostic trouble codes

-Freeze frame data

-1st trip freeze frame data

-System readiness test (SRT) codes

-Test values

•When connecting ECM harness connector, fasten it securely

with a lever as far as it will go as shown in the figure.

•When connecting or disconnecting pin connectors into or

from ECM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on ECM pin

terminal, when connecting pin connectors.

•Securely connect ECM harness connectors.

A poor connection can cause an extremely high (surge) volt-

age to develop in coil and condenser, thus resulting in dam-

age to ICs.

•Keep engine control system harness at least 10 cm (4 in) away

from adjacent harness, to prevent engine control system mal-

functions due to receiving external noise, degraded operation

of ICs, etc.

•Keep engine control system parts and harness dry.

•Before replacing ECM, perform ECM Terminals and Reference

Value inspection and make sure ECM functions properly.

Refer to EC-103, "

ECM Terminal and Reference Value" .

•Handle mass air flow sensor carefully to avoid damage.

•Do not disassemble mass air flow sensor.

•Do not clean mass air flow sensor with any type of detergent.

•Do not disassemble electric throttle control actuator.

•Even a slight leak in the air intake system can cause serious

incidents.

•Do not shock or jar the camshaft position sensor (PHASE),

crankshaft position sensor (POS).

PBIB1164E

BBIA0387E

PBIB0090E

MEF040D

Page 1121 of 3061

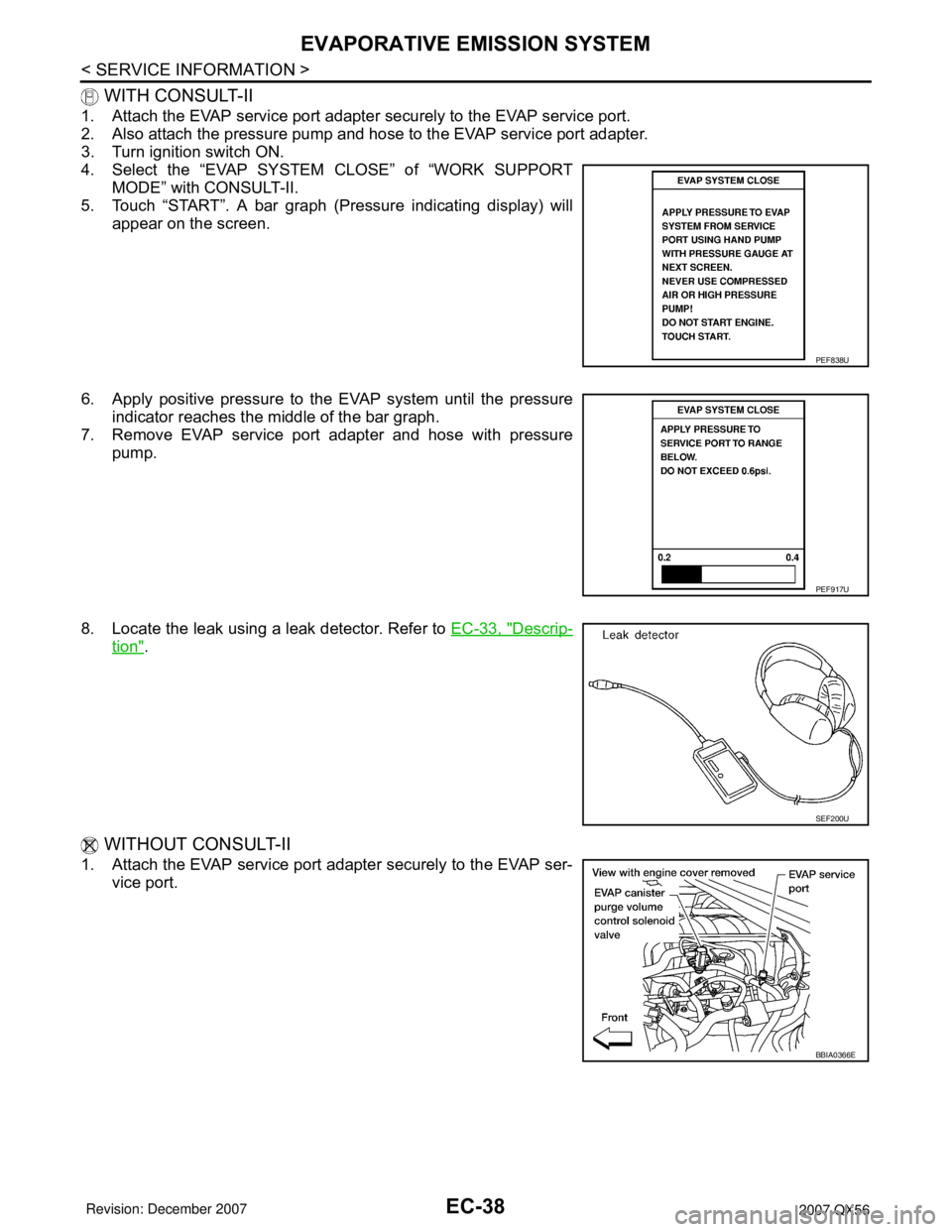

EC-38

< SERVICE INFORMATION >

EVAPORATIVE EMISSION SYSTEM

WITH CONSULT-II

1. Attach the EVAP service port adapter securely to the EVAP service port.

2. Also attach the pressure pump and hose to the EVAP service port adapter.

3. Turn ignition switch ON.

4. Select the “EVAP SYSTEM CLOSE” of “WORK SUPPORT

MODE” with CONSULT-II.

5. Touch “START”. A bar graph (Pressure indicating display) will

appear on the screen.

6. Apply positive pressure to the EVAP system until the pressure

indicator reaches the middle of the bar graph.

7. Remove EVAP service port adapter and hose with pressure

pump.

8. Locate the leak using a leak detector. Refer to EC-33, "

Descrip-

tion".

WITHOUT CONSULT-II

1. Attach the EVAP service port adapter securely to the EVAP ser-

vice port.

PEF838U

PEF917U

SEF200U

BBIA0366E