ECU INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1809 of 3061

TIMING CHAINEM-39

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

4. Obtain compression TDC of No. 1 cylinder as follows:

a. Turn the crankshaft pulley clockwise to align the TDC identifica-

tion notch (without paint mark) with the timing indicator on the

front cover.

b. At this time, make sure both intake and exhaust cam lobes of No. 1 cylinder (top front on LH bank) point outside.

• If they do not point outside, turn crankshaft pulley once more.

5. Remove the crankshaft pulley.

a. Loosen the crankshaft pulley bolts using a hammer handle to secure the crankshaft.

b. Remove the crankshaft pulley from the crankshaft using tool. • Remove the crankshaft pulley using suitable tool. Set the boltsin the two bolt holes [M6 x 1.0 mm (0.04 in)] on the front sur-

face.

NOTE:

The dimension between the centers of the two bolt holes is 61

mm (2.40 in).

6. Remove the front cover.

a. Loosen and remove the bolts in the reverse of order shown.

b. Cut the liquid gasket and remove the covers using Tool. CAUTION:

Do not damage mating surfaces.

7. Remove the front oil seal using suitable tool. CAUTION:

Do not damage front cover.

KBIA2476E

KBIA0400J

PBIC0053E

KBIA2477E

Tool number : KV10111100 (J-37228)

KBIA2478E

Page 1810 of 3061

EM-40

< SERVICE INFORMATION >

TIMING CHAIN

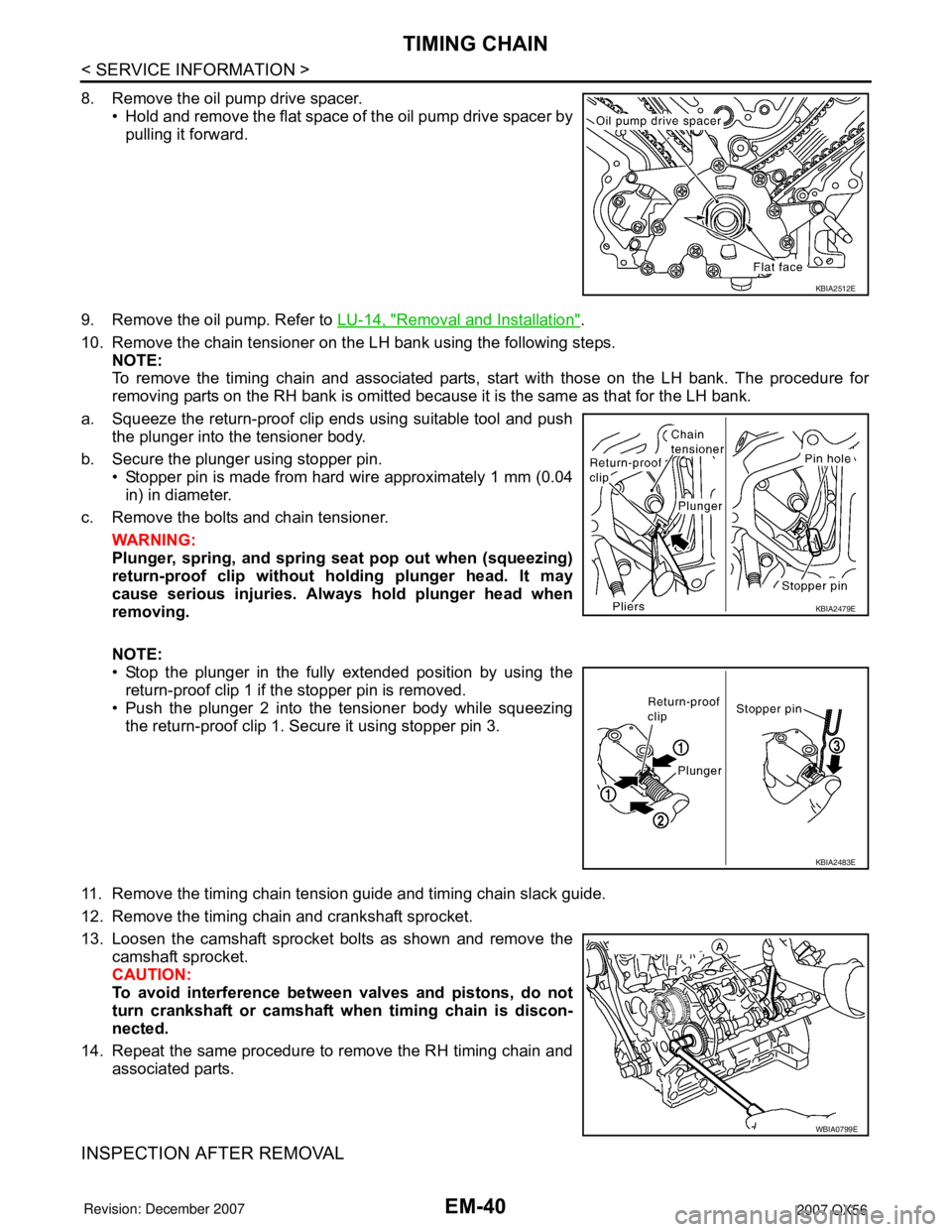

8. Remove the oil pump drive spacer.• Hold and remove the flat space of the oil pump drive spacer bypulling it forward.

9. Remove the oil pump. Refer to LU-14, "

Removal and Installation".

10. Remove the chain tensioner on the LH bank using the following steps. NOTE:

To remove the timing chain and associated parts, start with those on the LH bank. The procedure for

removing parts on the RH bank is omitted because it is the same as that for the LH bank.

a. Squeeze the return-proof clip ends using suitable tool and push the plunger into the tensioner body.

b. Secure the plunger using stopper pin. • Stopper pin is made from hard wire approximately 1 mm (0.04

in) in diameter.

c. Remove the bolts and chain tensioner.

WARNING:

Plunger, spring, and spring seat pop out when (squeezing)

return-proof clip without holding plunger head. It may

cause serious injuries. Alw ays hold plunger head when

removing.

NOTE:

• Stop the plunger in the fully extended position by using the return-proof clip 1 if the stopper pin is removed.

• Push the plunger 2 into the tensioner body while squeezing

the return-proof clip 1. Secure it using stopper pin 3.

11. Remove the timing chain tension guide and timing chain slack guide.

12. Remove the timing chain and crankshaft sprocket.

13. Loosen the camshaft sprocket bolts as shown and remove the camshaft sprocket.

CAUTION:

To avoid interference between valves and pistons, do not

turn crankshaft or camshaft wh en timing chain is discon-

nected.

14. Repeat the same procedure to remove the RH timing chain and associated parts.

INSPECTION AFTER REMOVAL

KBIA2512E

KBIA2479E

KBIA2483E

WBIA0799E

Page 1817 of 3061

CAMSHAFTEM-47

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

b. At this time, make sure both intake and exhaust cam lobes of

No. 1 cylinder (top front on LH bank) point outside.

• If they do not point outside, turn crankshaft pulley once more.

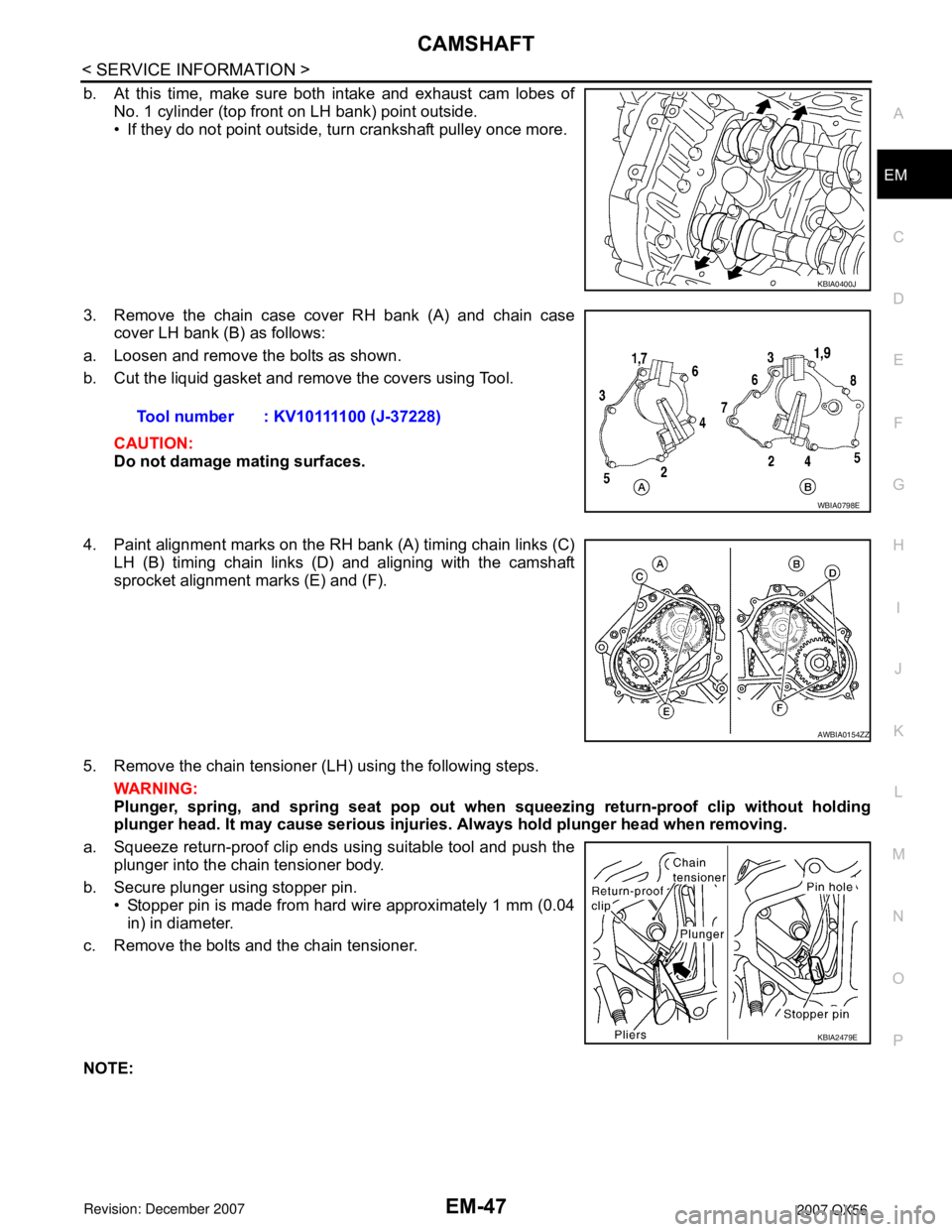

3. Remove the chain case cover RH bank (A) and chain case cover LH bank (B) as follows:

a. Loosen and remove the bolts as shown.

b. Cut the liquid gasket and remove the covers using Tool.

CAUTION:

Do not damage mating surfaces.

4. Paint alignment marks on the RH bank (A) timing chain links (C) LH (B) timing chain links (D) and aligning with the camshaft

sprocket alignment marks (E) and (F).

5. Remove the chain tensioner (LH) using the following steps. WARNING:

Plunger, spring, and spring seat pop out when squeezing return -proof clip without holding

plunger head. It may cause serious injuries. Always hold plunger head when removing.

a. Squeeze return-proof clip ends using suitable tool and push the plunger into the chain tensioner body.

b. Secure plunger using stopper pin. • Stopper pin is made from hard wire approximately 1 mm (0.04in) in diameter.

c. Remove the bolts and the chain tensioner.

NOTE:

KBIA0400J

Tool number : KV10111100 (J-37228)

WBIA0798E

AWBIA0154ZZ

KBIA2479E

Page 1818 of 3061

EM-48

< SERVICE INFORMATION >

CAMSHAFT

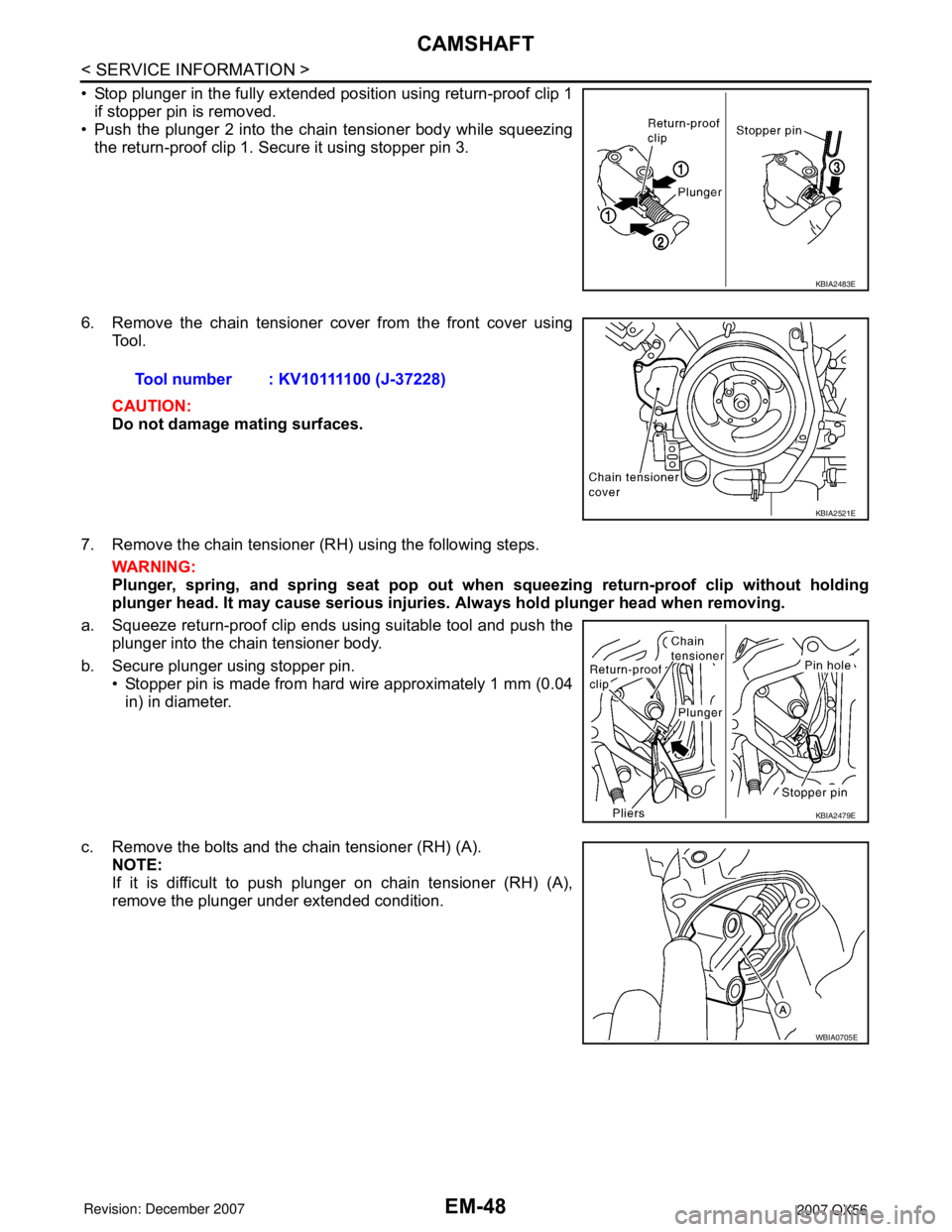

• Stop plunger in the fully extended position using return-proof clip 1if stopper pin is removed.

• Push the plunger 2 into the chain tensioner body while squeezing

the return-proof clip 1. Secure it using stopper pin 3.

6. Remove the chain tensioner cover from the front cover using Tool.

CAUTION:

Do not damage mating surfaces.

7. Remove the chain tensioner (RH) using the following steps. WARNING:

Plunger, spring, and spring seat pop out when squeezing return-proof clip without holding

plunger head. It may cause serious injuries. Always hold plunger head when removing.

a. Squeeze return-proof clip ends using suitable tool and push the plunger into the chain tensioner body.

b. Secure plunger using stopper pin. • Stopper pin is made from hard wire approximately 1 mm (0.04

in) in diameter.

c. Remove the bolts and the chain tensioner (RH) (A). NOTE:

If it is difficult to push plunger on chain tensioner (RH) (A),

remove the plunger under extended condition.

KBIA2483E

Tool number : KV10111100 (J-37228)

KBIA2521E

KBIA2479E

WBIA0705E

Page 1845 of 3061

ENGINE ASSEMBLY

EM-75

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

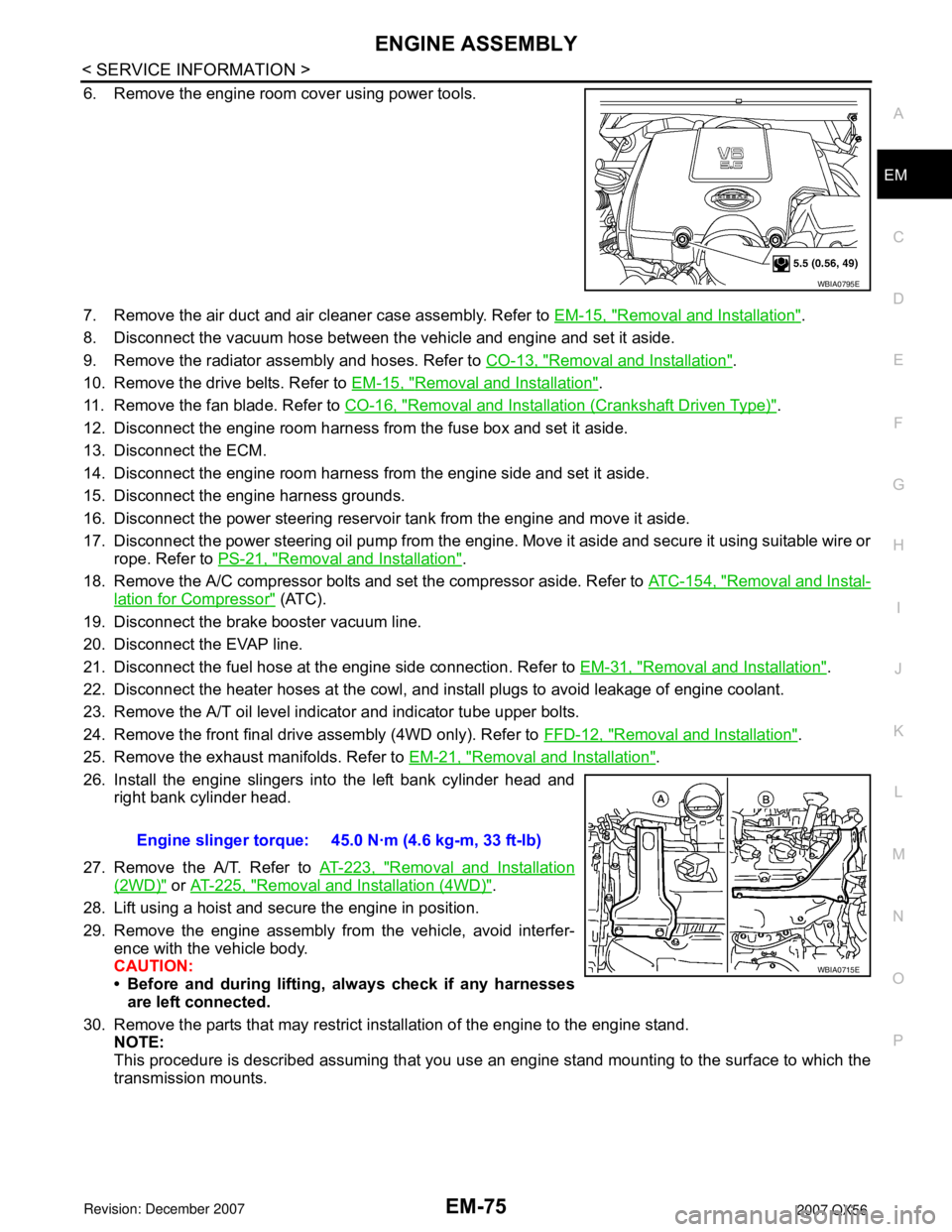

6. Remove the engine room cover using power tools.

7. Remove the air duct and air cleaner case assembly. Refer to EM-15, "

Removal and Installation".

8. Disconnect the vacuum hose between the vehicle and engine and set it aside.

9. Remove the radiator assembly and hoses. Refer to CO-13, "

Removal and Installation".

10. Remove the drive belts. Refer to EM-15, "

Removal and Installation".

11. Remove the fan blade. Refer to CO-16, "

Removal and Installation (Crankshaft Driven Type)".

12. Disconnect the engine room harness from the fuse box and set it aside.

13. Disconnect the ECM.

14. Disconnect the engine room harness from the engine side and set it aside.

15. Disconnect the engine harness grounds.

16. Disconnect the power steering reservoir tank from the engine and move it aside.

17. Disconnect the power steering oil pump from the engine. Move it aside and secure it using suitable wire or

rope. Refer to PS-21, "

Removal and Installation".

18. Remove the A/C compressor bolts and set the compressor aside. Refer to ATC-154, "

Removal and Instal-

lation for Compressor" (ATC).

19. Disconnect the brake booster vacuum line.

20. Disconnect the EVAP line.

21. Disconnect the fuel hose at the engine side connection. Refer to EM-31, "

Removal and Installation".

22. Disconnect the heater hoses at the cowl, and install plugs to avoid leakage of engine coolant.

23. Remove the A/T oil level indicator and indicator tube upper bolts.

24. Remove the front final drive assembly (4WD only). Refer to FFD-12, "

Removal and Installation".

25. Remove the exhaust manifolds. Refer to EM-21, "

Removal and Installation".

26. Install the engine slingers into the left bank cylinder head and

right bank cylinder head.

27. Remove the A/T. Refer to AT-223, "

Removal and Installation

(2WD)" or AT-225, "Removal and Installation (4WD)".

28. Lift using a hoist and secure the engine in position.

29. Remove the engine assembly from the vehicle, avoid interfer-

ence with the vehicle body.

CAUTION:

• Before and during lifting, always check if any harnesses

are left connected.

30. Remove the parts that may restrict installation of the engine to the engine stand.

NOTE:

This procedure is described assuming that you use an engine stand mounting to the surface to which the

transmission mounts.

WBIA0795E

Engine slinger torque: 45.0 N·m (4.6 kg-m, 33 ft-lb)

WBIA0715E

Page 1896 of 3061

FAX-10

< SERVICE INFORMATION >

DRIVE SHAFT

• Check the ball sliding surface for any compression scars, cracks, or fractures.

• Check for any damage to the serrated part.

CAUTION:

If any defective conditions are found, install a new housing, ball cage, steel ball, and inner race as a

set.

ASSEMBLY

Final Drive Side

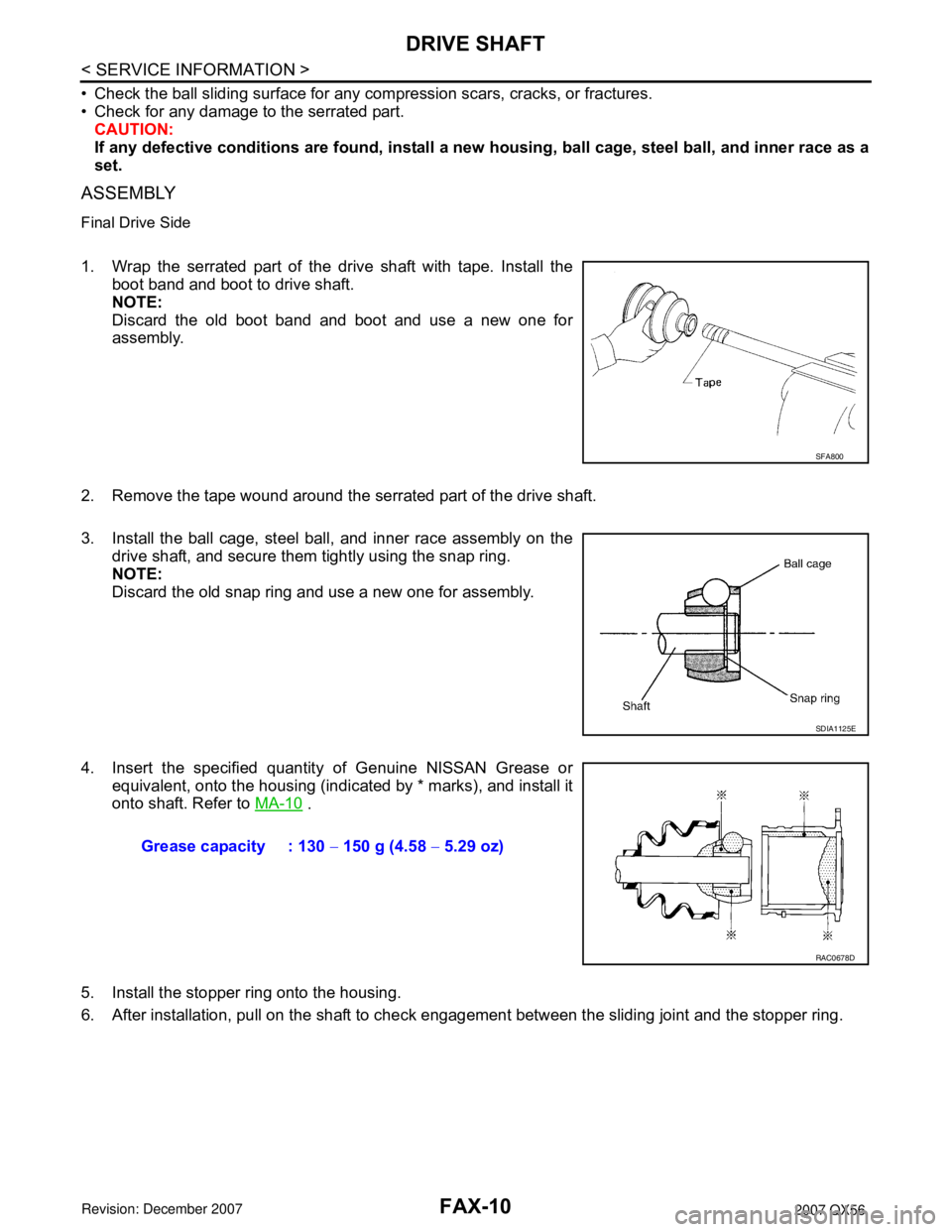

1. Wrap the serrated part of the drive shaft with tape. Install the

boot band and boot to drive shaft.

NOTE:

Discard the old boot band and boot and use a new one for

assembly.

2. Remove the tape wound around the serrated part of the drive shaft.

3. Install the ball cage, steel ball, and inner race assembly on the

drive shaft, and secure them tightly using the snap ring.

NOTE:

Discard the old snap ring and use a new one for assembly.

4. Insert the specified quantity of Genuine NISSAN Grease or

equivalent, onto the housing (indicated by * marks), and install it

onto shaft. Refer to MA-10

.

5. Install the stopper ring onto the housing.

6. After installation, pull on the shaft to check engagement between the sliding joint and the stopper ring.

SFA800

SDIA1125E

Grease capacity : 130 − 150 g (4.58 − 5.29 oz)

RAC0678D

Page 1897 of 3061

DRIVE SHAFT

FAX-11

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

FA X

N

O

P

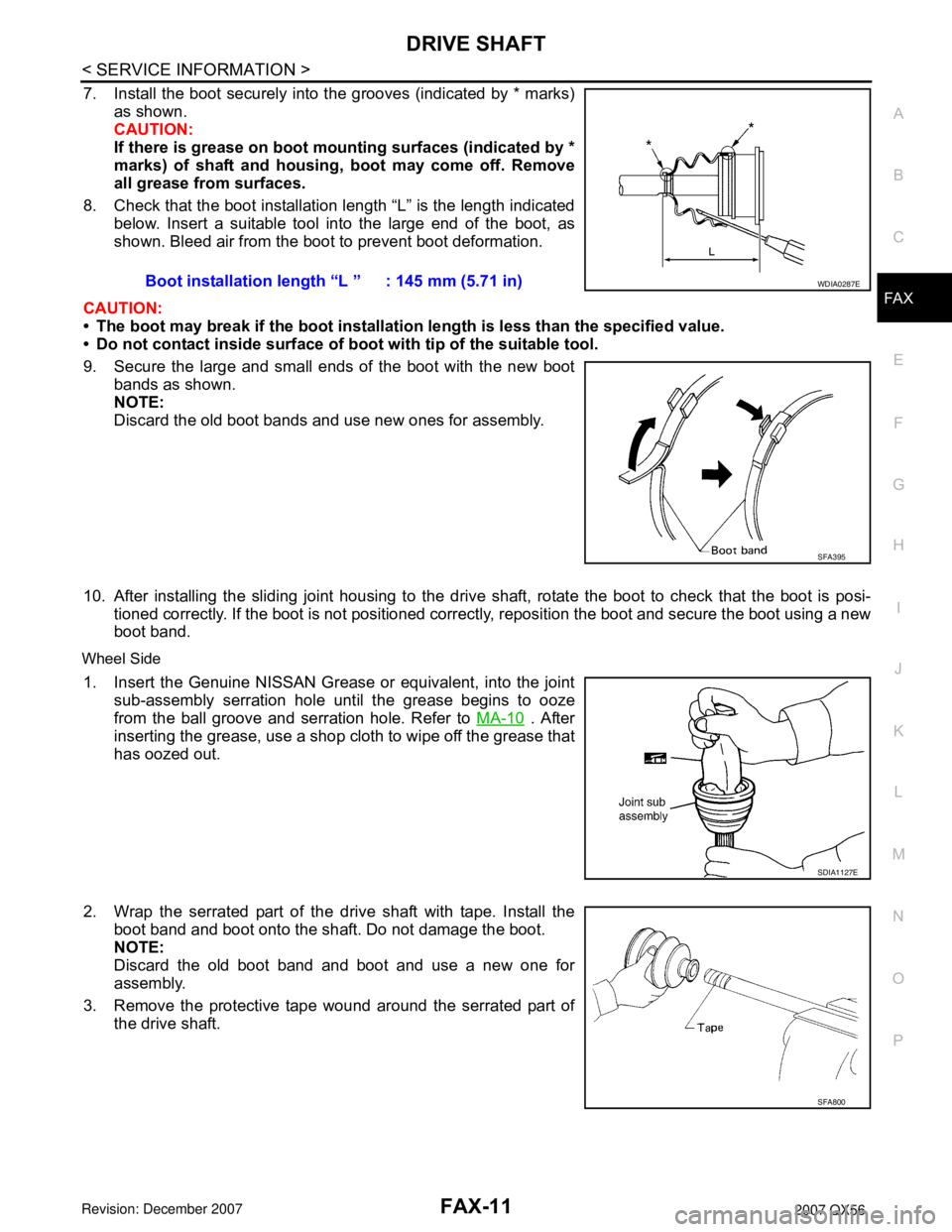

7. Install the boot securely into the grooves (indicated by * marks)

as shown.

CAUTION:

If there is grease on boot mounting surfaces (indicated by *

marks) of shaft and housing, boot may come off. Remove

all grease from surfaces.

8. Check that the boot installation length “L” is the length indicated

below. Insert a suitable tool into the large end of the boot, as

shown. Bleed air from the boot to prevent boot deformation.

CAUTION:

• The boot may break if the boot installation length is less than the specified value.

• Do not contact inside surface of boot with tip of the suitable tool.

9. Secure the large and small ends of the boot with the new boot

bands as shown.

NOTE:

Discard the old boot bands and use new ones for assembly.

10. After installing the sliding joint housing to the drive shaft, rotate the boot to check that the boot is posi-

tioned correctly. If the boot is not positioned correctly, reposition the boot and secure the boot using a new

boot band.

Wheel Side

1. Insert the Genuine NISSAN Grease or equivalent, into the joint

sub-assembly serration hole until the grease begins to ooze

from the ball groove and serration hole. Refer to MA-10

. After

inserting the grease, use a shop cloth to wipe off the grease that

has oozed out.

2. Wrap the serrated part of the drive shaft with tape. Install the

boot band and boot onto the shaft. Do not damage the boot.

NOTE:

Discard the old boot band and boot and use a new one for

assembly.

3. Remove the protective tape wound around the serrated part of

the drive shaft.Boot installation length “L ” : 145 mm (5.71 in)

WDIA0287E

SFA395

SDIA1127E

SFA800

Page 1898 of 3061

FAX-12

< SERVICE INFORMATION >

DRIVE SHAFT

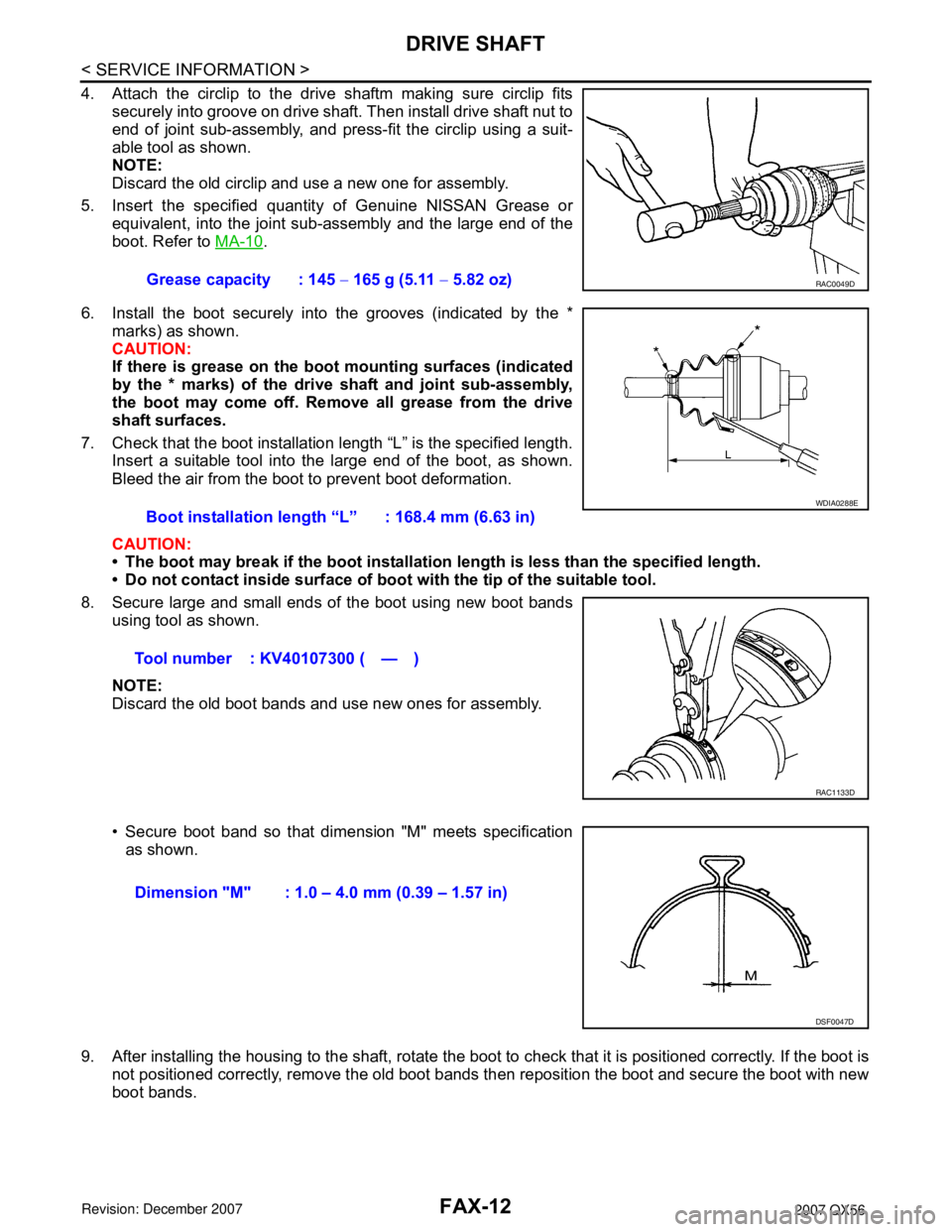

4. Attach the circlip to the drive shaftm making sure circlip fits

securely into groove on drive shaft. Then install drive shaft nut to

end of joint sub-assembly, and press-fit the circlip using a suit-

able tool as shown.

NOTE:

Discard the old circlip and use a new one for assembly.

5. Insert the specified quantity of Genuine NISSAN Grease or

equivalent, into the joint sub-assembly and the large end of the

boot. Refer to MA-10

.

6. Install the boot securely into the grooves (indicated by the *

marks) as shown.

CAUTION:

If there is grease on the boot mounting surfaces (indicated

by the * marks) of the drive shaft and joint sub-assembly,

the boot may come off. Remove all grease from the drive

shaft surfaces.

7. Check that the boot installation length “L” is the specified length.

Insert a suitable tool into the large end of the boot, as shown.

Bleed the air from the boot to prevent boot deformation.

CAUTION:

• The boot may break if the boot installation length is less than the specified length.

• Do not contact inside surface of boot with the tip of the suitable tool.

8. Secure large and small ends of the boot using new boot bands

using tool as shown.

NOTE:

Discard the old boot bands and use new ones for assembly.

• Secure boot band so that dimension "M" meets specification

as shown.

9. After installing the housing to the shaft, rotate the boot to check that it is positioned correctly. If the boot is

not positioned correctly, remove the old boot bands then reposition the boot and secure the boot with new

boot bands.Grease capacity : 145 − 165 g (5.11 − 5.82 oz)

RAC0049D

Boot installation length “L” : 168.4 mm (6.63 in)

Tool number : KV40107300 ( — )

WDIA0288E

RAC1133D

Dimension "M" : 1.0 – 4.0 mm (0.39 – 1.57 in)

DSF0047D

Page 1928 of 3061

FRONT FINAL DRIVE ASSEMBLY

FFD-29

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

FFD

N

O

P

10. Install side bearing adjusters into gear carrier.

11. Apply differential gear oil to the side bearings, and install the dif-

ferential case assembly with the side bearing outer races into

the gear carrier.

CAUTION:

Do not reuse side bearing outer race when replacing side

bearing inner race (replace as a set).

12. Install the side bearing caps with the matching marks aligned.

NOTE:

Do not tighten at this step. This allows further tightening of side

bearing adjusters.

13. Tighten each side bearing adjuster alternately turning drive gear.

14. Check and adjust tooth contact, backlash, drive gear runout and total preload torque.

Recheck above items.

• After adjusting tooth contact and backlash secure side bearing

adjuster with screws and tighten side bearing cap bolt to the

specified torque.

15. Apply multi-purpose grease to the lips of the new side oil seal. Then drive the new side oil seal in evenly to

the gear carrier using suitable tool.

CAUTION:

• Do not reuse side oil seal.

• Do not incline the new side oil seal when installing.

• Apply multi-purpose grease to the lips of the new side oil seal.

SPD527

PDIA0700E

SDIA2265E

SDIA2263E

Page 1935 of 3061

FL-4

< SERVICE INFORMATION >

FUEL SYSTEM

FUEL SYSTEM

Checking Fuel LineINFOID:0000000003532203

Inspect fuel lines, fuel filler cap and fuel tank for improper attach-

ment, leaks, cracks, damage, loose connections, chafing or deterio-

ration.

If necessary, repair or replace damaged parts.

General PrecautionINFOID:0000000003532204

WARNING:

When replacing fuel line parts, be sure to observe the following.

• Put a “CAUTION: INFLAMMABLE” sign in the workshop.

• Be sure to work in a well ventilated area and furnish workshop with a CO

2 fire extinguisher.

• Do not smoke while servicing fuel system. Keep open flames and sparks away from the work area.

CAUTION:

• Before removing fuel line parts, carry out the following procedures:

- Put drained fuel in an explosion-proof container and put the lid on securely. Keep the container in

safe area.

- Release fuel pressure from the fuel lines. Refer to EC-80, "

Fuel Pressure Check" .

- Disconnect the battery negative terminal.

• Always replace O-rings and clamps with new ones.

• Do not kink or twist hoses when they are being installed.

• After connecting the fuel tube quick connectors, make sure

the quick connectors are secure.

Ensure that the connector and resin tube do not contact any

adjacent parts.

• After installing tubes, make sure there is no fuel leakage at

connections in the following steps.

- Apply fuel pressure to fuel lines with turning ignition switch

ON (with engine stopped). Then check for fuel leaks at con-

nections.

- Start the engine and rev it up and check for fuel leaks at con-

nections.

• Use only a Genuine NISSAN fuel filler cap as a replacement. If

an incorrect fuel filler cap is used, the MIL may come on.

• For servicing “Evaporative Emission System” parts, refer to

EC-33

.

• For servicing “On Board Refueling Vapor Recovery (ORVR)”

parts, refer to EC-40

.

SMA803A

PBIC1268E