high beam INFINITI QX56 2007 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2208 of 3061

LT-1

ELECTRICAL

C

D

E

F

G

H

I

J

L

M

SECTION LT

A

B

LT

N

O

P

CONTENTS

LIGHTING SYSTEM

SERVICE INFORMATION ............................4

PRECAUTIONS ...................................................4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

4

General precautions for service operations ..............4

HEADLAMP (FOR USA) .....................................5

Component Parts and Harness Connector Loca-

tion ............................................................................

5

System Description ...................................................5

CAN Communication System Description .................7

Schematic .................................................................7

Wiring Diagram - H/LAMP - .......................................8

Terminal and Reference Value for BCM .................11

Terminal and Reference Value for IPDM E/R .........11

How to Proceed with Trouble Diagnosis .................12

Preliminary Check ...................................................12

CONSULT-II Function (BCM) ..................................12

CONSULT-II Function (IPDM E/R) ..........................13

Headlamp HI Does Not Illuminate (Both Sides) ......14

Headlamp HI Does Not Illuminate (One Side) ........15

High Beam Indicator Lamp Does Not Illuminate .....16

Headlamp LO Does Not Illuminate (Both Sides) .....17

Headlamp LO Does Not Illuminate (One Side) .......18

Headlamps Do Not Turn OFF .................................19

Aiming Adjustment ..................................................20

Bulb Replacement ...................................................21

Removal and Installation .........................................22

Disassembly and Assembly ....................................23

HEADLAMP (FOR CANADA) - DAYTIME

LIGHT SYSTEM - ...............................................

24

Component Parts and Harness Connector Loca-

tion ..........................................................................

24

System Description .................................................24

CAN Communication System Description ...............25

Schematic ...............................................................26

Wiring Diagram - DTRL - .........................................27

Terminal and Reference Value for BCM .................30

How to Proceed with Trouble Diagnosis ..................30

Preliminary Check ...................................................31

CONSULT-II Function for BCM ...............................32

CONSULT-II Function for IPDM E/R .......................32

Daytime Light Control Does Not Operate Properly

(Normal Headlamps Operate Properly) ...................

32

Aiming Adjustment ...................................................33

Bulb Replacement ...................................................33

Removal and Installation .........................................33

Disassembly and Assembly .....................................33

AUTO LIGHT SYSTEM .....................................34

Component Parts and Harness Connector Loca-

tion ...........................................................................

34

System Description ..................................................34

CAN Communication System Description ...............35

Major Component and Functions ............................35

Schematic ................................................................36

Wiring Diagram - AUTO/L - .....................................37

Terminal and Reference Value for BCM ..................39

Terminal and Reference Value for IPDM E/R ..........39

How to Proceed with Trouble Diagnosis ..................40

Preliminary Check ...................................................40

CONSULT-II Function (BCM) ..................................40

CONSULT-II Function (IPDM E/R) ..........................41

Trouble Diagnosis Chart by Symptom .....................42

Lighting Switch Inspection .......................................42

Optical Sensor System Inspection ...........................43

Optical Sensor .........................................................44

HEADLAMP AIMING CONTROL ......................45

System Description ..................................................45

Wiring Diagram - H/AIM - ........................................46

Headlamp Aiming Switch .........................................47

Switch Circuit Inspection .........................................48

FRONT FOG LAMP ..........................................49

Component Parts and Harness Connector Loca-

tion ...........................................................................

49

System Description ..................................................49

CAN Communication System Description ...............50

Page 2213 of 3061

LT-6

< SERVICE INFORMATION >

HEADLAMP (FOR USA)

• to BCM terminal 38.

Ground is supplied

• to BCM terminal 67

• through grounds M57, M61 and M79, and

• to IPDM E/R terminals 38 and 59

• through grounds E9, E15 and E24.

Low Beam Operation

With the lighting switch in 2ND position, the BCM receives input requesting the headlamps to illuminate. This

input is communicated to the IPDM E/R across the CAN communication lines. The CPU of the IPDM E/R con-

trols the headlamp low relay coil. When energized, this relay directs power

• through 15A fuse (No. 41, located in the IPDM E/R)

• through IPDM E/R terminal 54

• to front combination lamp RH terminal 5, and

• through 15A fuse (No. 40, located in the IPDM E/R)

• through IPDM E/R terminal 52

• to front combination lamp LH terminal 5.

Ground is supplied

• to front combination lamp LH and RH terminal 1

• through grounds E9, E15 and E24.

With power and ground supplied, low beam headlamps illuminate.

High Beam Operation/Flash-to-Pass Operation

With the lighting switch in 2ND position and placed in HIGH or PASS position, the BCM receives input request-

ing the headlamp high beams to illuminate. This input is communicated to the IPDM E/R across the CAN com-

munication lines. The CPU of the combination meter controls the ON/OFF status of the HIGH BEAM indicator.

The CPU of the IPDM E/R controls the headlamp high relay coil. When energized, this relay directs power

• through 10A fuse (No. 34, located in the IPDM E/R)

• through IPDM E/R terminal 56

• to front combination lamp RH terminal 6, and

• through 10A fuse (No. 35, located in the IPDM E/R)

• through IPDM E/R terminal 55

• to front combination lamp LH terminal 6.

Ground is supplied

• to front combination lamp LH and RH terminal 2

• through grounds E9, E15 and E24.

With power and ground supplied, the high beam headlamps illuminate.

XENON HEADLAMP

Xenon type headlamp is adopted to the low beam headlamps. Xenon bulbs do not use a filament. Instead,

they produce light when a high voltage current is passed between two tungsten electrodes through a mixture

of xenon (an inert gas) and certain other metal halides. In addition to added lighting power, electronic control

of the power supply gives the headlamps stable quality and tone color.

Following are some of the many advantages of the xenon type headlamp.

• The light produced by the headlamps is a white color comparable to sunlight that is easy on the eyes.

• Light output is nearly double that of halogen headlamps, affording increased area of illumination.

• The light features a high relative spectral distribution at wavelengths to which the human eye is most sensi-

tive. This means that even in the rain, more light is reflected back from the road surface toward the vehicle,

for added visibility.

• Power consumption is approximately 25 percent less than halogen headlamps, reducing battery load.

BATTERY SAVER CONTROL

When the combination switch (lighting switch) is in the 2ND position (ON), and the ignition switch is turned

from ON or ACC to OFF, the battery saver control feature is activated.

Under this condition, the headlamps remain illuminated for 5 minutes, unless the combination switch (lighting

switch) position is changed. If the combination switch (lighting switch) position is changed, then the headlamps

are turned off.

AUTO LIGHT OPERATION

Refer to LT-34, "System Description" for auto light operation.

VEHICLE SECURITY SYSTEM (PANIC ALARM)

Page 2214 of 3061

HEADLAMP (FOR USA)

LT-7

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

The vehicle security system (panic alarm) will flash the high beams if the system is triggered. Refer to BL-61,

"System Description".

CAN Communication System DescriptionINFOID:0000000003533334

Refer to LAN-4, "CAN Communication System".

SchematicINFOID:0000000003533335

WKWA3637E

Page 2219 of 3061

LT-12

< SERVICE INFORMATION >

HEADLAMP (FOR USA)

How to Proceed with Trouble Diagnosis

INFOID:0000000003533339

1. Confirm the symptom or customer complaint.

2. Understand operation description and function description. Refer to LT- 5 , "

System Description" .

3. Perform the Preliminary Check.

4. Check symptom and repair or replace the component.

5. Does the headlamp operate normally? If YES: GO TO 6. If NO: GO TO 4.

6. Inspection End.

Preliminary CheckINFOID:0000000003533340

CHECK POWER SUPPLY AND GROUND CIRCUIT FOR BCM

Refer to BCS-15, "BCM Power Supply and Ground Circuit Inspection" .

CHECK POWER SUPPLY AND GROUND CIRCUIT FOR IPDM E/R

Refer to PG-26, "IPDM E/R Power/Ground Circuit Inspection" .

CONSULT-II Function (BCM)INFOID:0000000003533341

Refer to BCS-16, "CONSULT-II Function (BCM)" .

CONSULT-II START PROCEDURE

Refer to GI-36, "CONSULT-II Start Procedure" .

WORK SUPPORT

Display Item List

DATA MONITOR

Display Item List

Item Description CONSULT-II Factory setting

BATTERY SAVER SETExterior lamp battery saver control mode can be changed

in this mode. Selects exterior lamp battery saver control

mode between ON/OFF.ON×

OFF —

Monitor item Contents

IGN ON SW "ON/OFF" Displays "IGN position (ON)/OFF, ACC position (OFF)" judged from the ignition switch signal.

ACC ON SW "ON/OFF" Displays "ACC (ON)/OFF, Ignition OFF (OFF)" status judged from ignition switch signal.

HI BEAM SW "ON/OFF"Displays status (high beam switch: ON/Others: OFF) of high beam switch judged from lighting

switch signal.

HEAD LAMP SW 1 "ON/OFF"Displays status (headlamp switch 1: ON/Others: OFF) of headlamp switch 2 judged from lighting

switch signal.

HEAD LAMP SW 2 "ON/OFF"Displays status (headlamp switch 2: ON/Others: OFF) of headlamp switch 2 judged from lighting

switch signal.

LIGHT SW 1ST "ON/OFF"Displays status (lighting switch 1st position: ON/Others: OFF) of lighting switch judged from

lighting switch signal.

AUTO LIGHT SW "ON/OFF"Displays status of the lighting switch as judged from the lighting switch signal. (AUTO position:

ON/Other than AUTO position: OFF)

PASSING SW "ON/OFF"Displays status (flash-to-pass switch: ON/Others: OFF) of flash-to-pass switch judged from light-

ing switch signal.

FR FOG SW "ON/OFF"Displays status (front fog lamp switch: ON/Others: OFF) of front fog lamp switch judged from

lighting switch signal.

DOOR SW-DR "ON/OFF"Displays status of the front door LH as judged from the front door LH switch signal. (Door is

open: ON/Door is closed: OFF)

DOOR SW-AS "ON/OFF"Displays status of the front door RH as judged from the front door RH switch signal. (Door is

open: ON/Door is closed: OFF)

Page 2220 of 3061

HEADLAMP (FOR USA)

LT-13

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

ACTIVE TEST

Display Item List

SELF-DIAGNOSTIC RESULTS

Display Item List

CONSULT-II Function (IPDM E/R)INFOID:0000000003533342

Refer to PG-18, "CONSULT-II Function (IPDM E/R)" .

CONSULT-II START PROCEDURE

Refer to GI-36, "CONSULT-II Start Procedure".

DATA MONITOR

All Items, Main Items, Select Item Menu

NOTE:

Perform monitoring of IPDM E/R data with the ignition switch ON. When the ignition switch is at ACC, the dis-

play may not be correct.

DOOR SW-RR "ON/OFF"Displays status of the rear door as judged from the rear door switch (RH) signal. (Door is open:

ON/Door is closed: OFF)

DOOR SW-RL "ON/OFF"Displays status of the rear door as judged from the rear door switch (LH) signal. (Door is open:

ON/Door is closed: OFF)

BACK DOOR SW "ON/OFF"Displays status of the back door as judged from the back door switch signal. (Door is open: ON/

Door is closed: OFF)

TURN SIGNAL R "ON/OFF" Displays status (Turn right: ON/Others: OFF) as judged from lighting switch signal.

TURN SIGNAL L "ON/OFF" Displays status (Turn left: ON/Others: OFF) as judged from lighting switch signal.

CARGO LAMP SW "ON/OFF" Displays status of cargo lamp switch.

OPTICAL SENSOR [0 - 5V] Displays "ambient light (close to 5V when dark/close to 0V when light)" judged from optical sen-

sor signal. Monitor item Contents

Te s t i t e m D e s c r i p t i o n

TAIL LAMP Allows tail lamp relay to operate by switching ON-OFF.

HEAD LAMP Allows headlamp relay (HI, LO) to operate by switching ON-OFF.

FR FOG LAMP Allows fog lamp relay to operate by switching ON-OFF.

CARGO LAMP Allows cargo lamp to operate by switching ON-OFF.

CORNERING LAMP Not used.

Monitored item CONSULT-ll display Description

CAN communication CAN communication [U1000] Malfunction is detected in CAN communication.

CAN communication system CAN communication system 1 to 6 [U1000] Malfunction is detected in CAN system.

Item nameCONSULT-II

screen displayDisplay or

unitMonitor item selection

Description

ALL

SIGNALSMAIN

SIGNALSSELECTION

FROM MENU

Parking, license plate

and tail lamps requestTAIL&CLR REQ ON/OFF×× ×Signal status input from BCM

Headlamp low beam re-

questHL LO REQ ON/OFF×× ×Signal status input from BCM

Headlamp high beam re-

questHL HI REQ ON/OFF×× ×Signal status input from BCM

Daytime lights request DTRL REQ ON/OFF×–×Signal status input from BCM

Front fog lamps request FR FOG REQ ON/OFF×× ×Signal status input from BCM

Page 2221 of 3061

LT-14

< SERVICE INFORMATION >

HEADLAMP (FOR USA)

ACTIVE TEST

Headlamp HI Does Not Illuminate (Both Sides)INFOID:0000000003533343

1.CHECK COMBINATION SWITCH INPUT SIGNAL

Select "BCM" on CONSULT-II. With "HEAD LAMP" data monitor,

make sure "HI BEAM SW" turns ON-OFF linked with operation of

lighting switch.

OK or NG

OK >> GO TO 2.

NG >> Check lighting switch. Refer to LT-73, "

Combination

Switch Inspection" .

2.HEADLAMP ACTIVE TEST

1. Select "IPDM E/R" on CONSULT-II, and select "ACTIVE TEST"

on "SELECT DIAG MODE" screen.

2. Select "EXTERNAL LAMPS" on "SELECT TEST ITEM" screen.

3. Touch "HI" on "ACTIVE TEST" screen.

4. Make sure headlamp high beam operates.

OK or NG

OK >> GO TO 3.

NG >> GO TO 4.

3.CHECK IPDM E/R

1. Select "IPDM E/R" on CONSULT-II, and select "DATA MONI-

TOR" on "SELECT DIAG MODE" screen.

2. Make sure "HL LO REQ" and "HL HI REQ" turns ON when light-

ing switch is in HIGH position.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-28, "Removal and

Installation of IPDM E/R" .

NG >> Replace BCM. Refer to BCS-24, "

BCM" .

4.CHECK HEADLAMP INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect front combination lamp RH and LH connectors.

3. Turn ignition switch ON.

4. Select "IPDM E/R" on CONSULT-II, and select "ACTIVE TEST" on "SELECT DIAG MODE" screen.

5. Select "EXTERNAL LAMPS" on "SELECT TEST ITEM" screen.

Test item CONSULT-II screen display Description

Headlamp relay (HI, LO) out-

put

EXTERNAL LAMPSAllows headlamp relay (HI, LO) to operate by switching operation (OFF,

HI, LO) at your option (Headlamp high beam repeats ON-OFF every 1

second).

Front fog lamp relay (FOG)

outputAllows fog lamp relay (FOG) to operate by switching operation ON-OFF

at your option.

Tail lamp relay outputAllows tail lamp relay to operate by switching operation ON-OFF at your

option.

When lighting switch is in

HIGH position: HI BEAM SW ON

SKIA4193E

Headlamp high beam should operate.

WKIA1438E

When lighting switch is in

HIGH position: HL LO REQ ON

: HL HI REQ ON

SKIA5775E

Page 2222 of 3061

HEADLAMP (FOR USA)

LT-15

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

6. Touch "HI" on "ACTIVE TEST" screen.

7. When headlamp high beam is operating, check voltage between

front combination lamp RH and LH harness connector and

ground.

OK or NG

OK >> GO TO 6.

NG >> GO TO 5.

5.CHECK HEADLAMP CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector E123

terminal 56 and front combination lamp RH harness connector

E107 terminal 6.

4. Check continuity between IPDM E/R harness connector E123

terminal 55 and front combination lamp LH harness connector

E11 terminal 6.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-28, "Removal and Installation of IPDM E/R" .

NG >> Repair harness or connector.

6.CHECK HEADLAMP GROUND

1. Turn ignition switch OFF.

2. Check continuity between front combination lamp RH harness

connector E107 terminal 2 and ground.

3. Check continuity between front combination lamp LH harness

connector E11 terminal 2 (B) and ground.

OK or NG

OK >> Check front combination lamp connector for damage or

poor connection. Repair as necessary.

NG >> Repair harness or connector.

Headlamp HI Does Not Illuminate (One Side)INFOID:0000000003533344

1.BULB INSPECTION

Inspect inoperative headlamp bulb.

OK or NG

OK >> GO TO 2.

NG >> Replace headlamp bulb. Refer to LT-21, "

Bulb Replacement" .

2.CHECK POWER TO HEADLAMP

Front combination lamp

(–) Voltage (+)

Connector Terminal

RH E107

6 Ground Battery voltage

LH E11

WKIA1852E

56 - 6 : Continuity should exist.

55 - 6 : Continuity should exist.

WKIA1853E

2 - Ground : Continuity should exist.

2 - Ground : Continuity should exist.

WKIA1854E

Page 2223 of 3061

LT-16

< SERVICE INFORMATION >

HEADLAMP (FOR USA)

1. Disconnect inoperative front combination lamp connector.

2. Turn the high beam headlamps ON.

3. Check voltage between inoperative front combination lamp ter-

minal and ground.

OK or NG

OK >> GO TO 3.

NG >> GO TO 4.

3.CHECK HEADLAMP GROUND

1. Turn the high beam headlamps OFF.

2. Check continuity between inoperative front combination lamp

connector and ground.

OK or NG

OK >> Check front combination lamp connector for damage or

poor connection. Repair as necessary.

NG >> Repair open circuit in harness between inoperative front combination lamp and ground.

4.INSPECTION BETWEEN IPDM E/R AND HEADLAMPS

1. Disconnect IPDM E/R connector and inoperative front combination lamp connector.

2. Check continuity between harness connector terminal of IPDM

E/R and harness connector terminal of inoperative front combi-

nation lamp.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-28, "Removal and

Installation of IPDM E/R" .

NG >> Check for short and open circuits in harness between IPDM E/R and headlamps. Repair as nec-

essary.

High Beam Indicator Lamp Does Not IlluminateINFOID:0000000003533345

1.BULB INSPECTION

Inspect CAN communication system. Refer to LAN-4, "

CAN Communication System" .

OK or NG

OK >> Replace combination meter. Refer to DI-21, "Removal and Installation of Combination Meter" .

NG >> Repair as necessary.

Te r m i n a l s

(–)Vo l ta g e

(Approx.) (+)

Connector Terminal

RH E107

6 Ground Battery voltage

LH E11

WKIA3608E

Te r m i n a l s

Continuity

Connector Terminal

RH E107

2 Ground Yes

LH E11

WKIA1854E

IPDM E/R Front combination lamp Continuity

Connector Terminal Connector Terminal

E12356 RH E107

6Yes

55 LH E11

WKIA1853E

Page 2228 of 3061

HEADLAMP (FOR USA)

LT-21

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

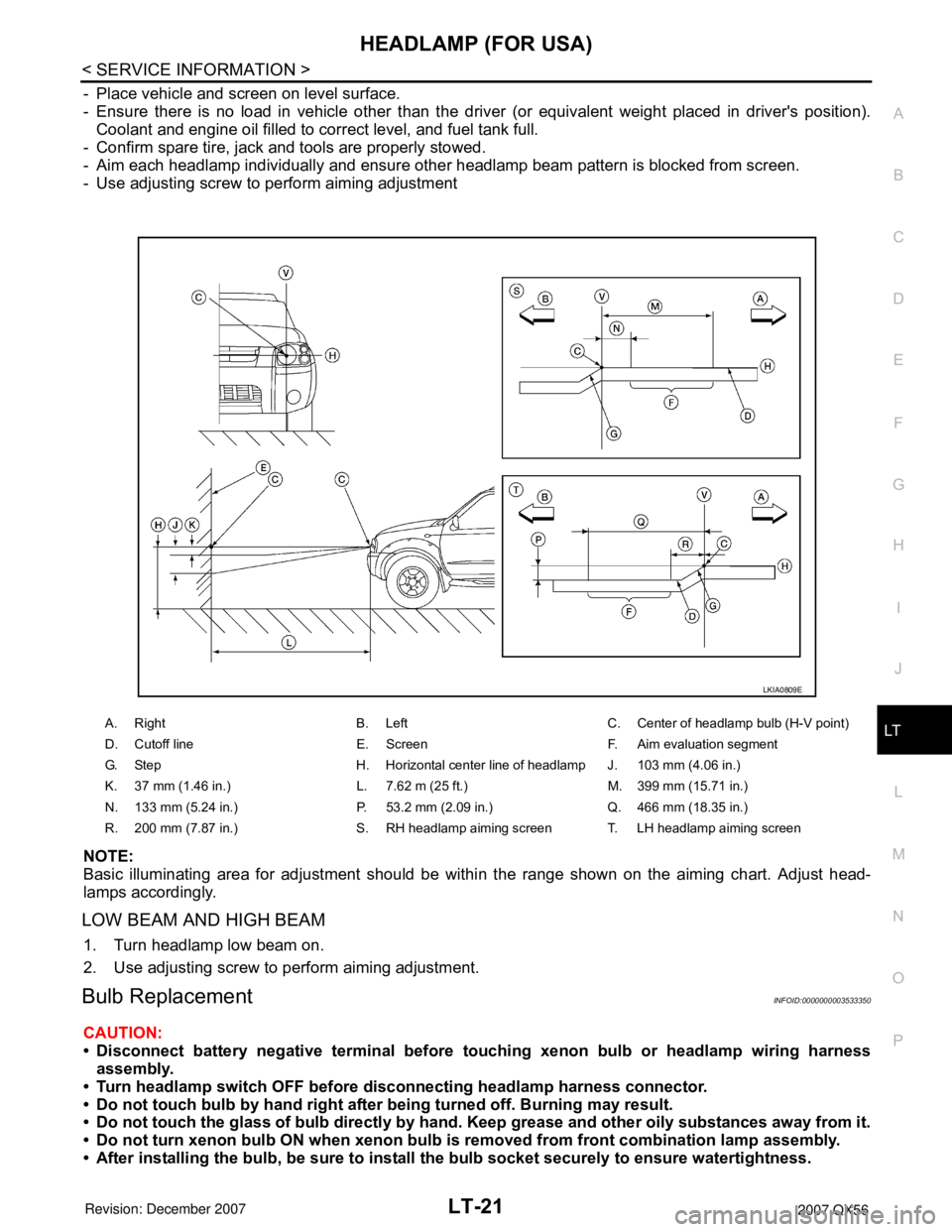

- Place vehicle and screen on level surface.

- Ensure there is no load in vehicle other than the driver (or equivalent weight placed in driver's position).

Coolant and engine oil filled to correct level, and fuel tank full.

- Confirm spare tire, jack and tools are properly stowed.

- Aim each headlamp individually and ensure other headlamp beam pattern is blocked from screen.

- Use adjusting screw to perform aiming adjustment

NOTE:

Basic illuminating area for adjustment should be within the range shown on the aiming chart. Adjust head-

lamps accordingly.

LOW BEAM AND HIGH BEAM

1. Turn headlamp low beam on.

2. Use adjusting screw to perform aiming adjustment.

Bulb ReplacementINFOID:0000000003533350

CAUTION:

• Disconnect battery negative terminal before touching xenon bulb or headlamp wiring harness

assembly.

• Turn headlamp switch OFF before disconnecting headlamp harness connector.

• Do not touch bulb by hand right after being turned off. Burning may result.

• Do not touch the glass of bulb directly by hand. Keep grease and other oily substances away from it.

• Do not turn xenon bulb ON when xenon bulb is removed from front combination lamp assembly.

• After installing the bulb, be sure to install the bulb socket securely to ensure watertightness.

A. Right B. Left C. Center of headlamp bulb (H-V point)

D. Cutoff line E. Screen F. Aim evaluation segment

G. Step H. Horizontal center line of headlamp J. 103 mm (4.06 in.)

K. 37 mm (1.46 in.) L. 7.62 m (25 ft.) M. 399 mm (15.71 in.)

N. 133 mm (5.24 in.) P. 53.2 mm (2.09 in.) Q. 466 mm (18.35 in.)

R. 200 mm (7.87 in.) S. RH headlamp aiming screen T. LH headlamp aiming screen

LKIA0809E

Page 2229 of 3061

LT-22

< SERVICE INFORMATION >

HEADLAMP (FOR USA)

• Do not leave bulb out of front combination lamp assembly for a long time because dust, moisture,

smoke, etc. may affect the performance of the lamp. When replacing bulb, be sure to replace it with a

new one.

HEADLAMP (OUTER SIDE), FOR LOW BEAM

Removal

1. Position fender protector aside.

2. Turn headlamp switch OFF.

3. Disconnect battery negative terminal.

4. Remove ballast.

5. Disconnect headlamp electrical connector.

6. Release bulb retaining spring and pull bulb straight out.

Installation

Installation is in the reverse order of removal.

HEADLAMP (INNER SIDE), FOR HIGH BEAM

Removal

1. Turn headlamp switch OFF.

2. Disconnect headlamp electrical connector.

3. Turn the bulb counterclockwise to remove it.

Installation

Installation is in the reverse order of removal.

FRONT PARKING LAMP (INNER OR OUTER)

Removal

1. Turn the bulb socket counterclockwise to unlock it.

2. Pull the bulb to remove it from the socket.

Installation

Installation is in the reverse order of removal.

SIDE MARKER LAMP (FRONT)

Removal

1. Position fender protector aside.

2. Turn the side marker lamp (front) bulb socket counterclockwise and remove side marker lamp (front) bulb

socket.

3. Pull to remove side marker lamp (front) from the side marker lamp (front) bulb socket.

Installation

Installation is in the reverse order of removal.

Removal and InstallationINFOID:0000000003533351

FRONT COMBINATION LAMP ASSEMBLY

CAUTION:

• Disconnect battery negative terminal before touching xenon bulb or headlamp wiring harness

assembly.

• Turn headlamp switch OFF before disconnecting headlamp harness connector.

• Do not touch bulb by hand right after being turned off. Burning may result.

• Do not touch the glass of bulb directly by hand. Keep grease and other oily substances away from it.

• Do not turn xenon bulb ON when xenon bulb is removed from front combination lamp assembly.

• After installing the bulb, be sure to install the bulb socket securely to ensure watertightness.

• Do not leave bulb out of front combination lamp assembly for a long time because dust, moisture,

smoke, etc. may affect the performance of the lamp. When replacing bulb, be sure to replace it with a

new one.

Removal