fuel INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2110 of 3061

IDX-6

ALPHABETICAL INDEX

Line pressure solenoid valve ........................... AT-118

Line pressure switch (Transfer) .......... TF-154, TF-167

Line pressure test (A/T) ..................................... AT-52

Location of electrical units ................................. PG-65

Low coast brake solenoid valve ......... AT-151, AT-153

Low tire pressure warning system ...................... WT-8

Low tire pressure warning system - trouble diagnoses .

WT-11

Low tire pressure warning system - Wiring diagram .....

WT-11

Lubricant (R134a) A/C ..................................... ATC-22

Lubricants ......................................................... MA-11

Lubrication circuit (engine) ................................... LU-6

Lubrication oil A/C ............................................ ATC-22

Lubrication-locks, hinges and hood latches ...... MA-31

M

MAFS - Wiring diagram ..................... EC-200

, EC-208

Magnet clutch ............................... ATC-115, ATC-180

MAIN - Wiring diagram ...................... EC-150, AT-163

Main oil pump (Transfer) ..................... TF-154, TF-167

Mainshaft (Transfer) ........................... TF-154, TF-167

Maintenance (engine)Schedule 1 ....................... MA-7

Maintenance (engine)Schedule 2 ....................... MA-9

Major overhaul (Final drive) ............................. FFD-14

Major overhaul (Transfer) ................................ TF-146

Malfunction indicator lamp (MIL) ........................ EC-65

Map lamp .......................................................... LT-111

Mass air flow sensor (MAFS) ............. EC-197, EC-206

Meter ..................................................................... DI-5

METER - Wiring diagram ...................................... DI-9

MIL data link connectors circuit ....................... EC-697

MIL/DL - Wiring diagram .................................. EC-697

MIRROR - Wiring diagram ................................ GW-87

Misfire .............................................................. EC-350

Mode door control linkage adjustment ............. ATC-65

Mode door motor ............................ ATC-62, ATC-165

Model variation ................................................... GI-48

Multiport fuel injection (MFI) system .................. EC-25

Multiport fuel injection precautions ....................... GI-6

Multi-remote control system - See Remote keyless entry

system ............................................................... BL-40

N

NATS - Wiring diagram .................................... BL-130

NAVI - Wiring diagram ....................................... AV-86

NAVI Control Unit .............................................. AV-83

Navigation system ............................................. AV-81

Neutral-4LO switch ............................................ TF-61

NONDTC - Wiring diagram .............................. AT-172

NVH troubleshooting (AX) ................................. FAX-4

NVH troubleshooting (EM) ................................ EM-10

NVH troubleshooting (Final drive) ..................... RFD-7

NVH troubleshooting (Propeller shaft) ................. PR-3

NVH troubleshooting (RAX) .............................. RAX-4

NVH troubleshooting (RSU) .............................. RSU-5

NVH troubleshooting (ST) .................................... PS-5

NVH troubleshooting (Transfer) ......................... TF-10

NVH troubleshooting (WT)NVH troubleshooting (WT) ..

WT-4

NVIS (Nissan vehicle immobilizer system) precautions

GI-3

O

O2H2B1 - Wiring diagram ............................... EC-183

O2H2B2 - Wiring diagram ............................... EC-185

O2S2B1 - Wiring diagram ... EC-279, EC-290, EC-303

O2S2B2 - Wiring diagram ... EC-281, EC-292, EC-305

Oil cooler (engine) .............................................. LU-12

Oil filter ............................................................... LU-11

Oil filter (Transfer) ............................................ TF-143

Oil pan (engine) ................................................ EM-24

Oil pressure (engine) ........................................... LU-8

Oil pressure relief valve (engine) ......................... LU-6

Oil pump (engine) .............................................. LU-14

Oil seal replacement (engine) ........................... EM-60

Oil seal replacement (front of final drive) FFD-8, RFD-9

Oil seal replacement (side of final drive) ......... RFD-11

On board diagnostic system ............................. EC-49

ORVR (On-board Refueling Vapor Recovery) .. EC-40

Overheat ......................................................... EC-504

P

P/SCKT - Wiring diagram ................................. WW-46

Pantograph jack .................................................. GI-42

Park/Neutral position switch ............................ EC-487

Parking brake control ........................................... PB-4

PCV (positive crankcase ventilation) ................ EC-46

Periodic maintenance ......................................... MA-7

Personal lamp .................................................. LT-111

PGC/V - Wiring diagram ................... EC-397, EC-405

PHASE - Wiring diagram ................................ EC-371

PHONE - Wiring diagram ................................... AV-65

Pinion bearing preload diff. ............................. RFD-26

Piston pin inspection ......................................... EM-94

Piston ring inspection ........................................ EM-95

Piston to bore clearance ................................... EM-99

Planetary carrier (Transfer) ................. TF-149, TF-176

PNP/SW - Wiring diagram ... EC-489, AT-101, AT-102

POS - Wiring diagram ..................................... EC-364

POWER - Wiring diagram ................................... PG-6

Power door lock ................................................. BL-16

Power seat ......................................................... SE-81

Power steering fluid level .................................. MA-29

Power steering gear ........................................... PS-15

Power steering oil pump .................................... PS-22

Power steering pressure (PSP) sensor ........... EC-470

Power steering system bleeding .......................... PS-6

Power supply routing .......................................... PG-4

Power window .................................................. GW-15

PRE/SE - Wiring diagram ................. EC-429, EC-435

Precautions (General) ........................................... GI-4

Precautions in repairing high strength steel ..... BL-182

Pressure switch 1 ............................... AT-141, AT-155

Page 2176 of 3061

![INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS

LAN-45

< SERVICE INFORMATION >[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

Engine speed signal T R R R R R R

Engine status signal T R

Fuel consumption monitor signalTR

RT

ICC steering swit INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS

LAN-45

< SERVICE INFORMATION >[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

Engine speed signal T R R R R R R

Engine status signal T R

Fuel consumption monitor signalTR

RT

ICC steering swit](/img/42/57029/w960_57029-2175.png)

TROUBLE DIAGNOSIS

LAN-45

< SERVICE INFORMATION >[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

Engine speed signal T R R R R R R

Engine status signal T R

Fuel consumption monitor signalTR

RT

ICC steering switch signal T R

Malfunction indicator lamp signal T R

Wide open throttle position signal T R

A/T CHECK indicator lamp signal T R

A/T fluid temperature sensor signal T R

A/T position indicator lamp signal T R R

A/T self-diagnosis signal R T

Current gear position signal T R R

Output shaft revolution signal R T R

P range signal T R R R R

Turbine revolution signal R T R

ICC sensor signal T R

Buzzer output signalTR

TR

ICC OD cancel request signal R R T

ICC operation signal R R T

ICC system display signal T R

System setting signalTR

RT

A/C switch signal R T R

Blower fan motor switch signal R T

Day time running light request signal T R R

Door switch signal R T R R R

Front fog light request signal T R

Front wiper request signal R T R

High beam request signal T R R

Horn chirp signal T R

Ignition switch signal R T R

Key fob door unlock signal R T

Key fob ID signal R T

Key switch signal R T

Low beam request signal T R

Position light request signal T R R

Rear window defogger switch signal T R R

Sleep wake up signal R T R R

Theft warning horn request signal T R

Tire pressure data signal T R

Tire pressure signal T R R

Turn indicator signal T RSignal name/Connecting unit

ECM

TCM

LASER

ICC

ADP

BCM

DISP

HVAC

M&A

STRG

ABS

IPDM-E

Page 2177 of 3061

![INFINITI QX56 2007 Factory Service Manual LAN-46

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

NOTE:

CAN data of the air bag diagnosis sensor unit is not used by usual service work, thus it is omitted.

TYPE 3/TYPE 4

NOTE:

Refer to LAN-37, " INFINITI QX56 2007 Factory Service Manual LAN-46

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

NOTE:

CAN data of the air bag diagnosis sensor unit is not used by usual service work, thus it is omitted.

TYPE 3/TYPE 4

NOTE:

Refer to LAN-37, "](/img/42/57029/w960_57029-2176.png)

LAN-46

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

NOTE:

CAN data of the air bag diagnosis sensor unit is not used by usual service work, thus it is omitted.

TYPE 3/TYPE 4

NOTE:

Refer to LAN-37, "

Abbreviation List" for the abbreviations of the connecting units.

T: Transmit R: Receive

A/C switch/indicator signalTR

RT

1st position switch signal R T

4th position switch signal R T

Distance to empty signal R T

Fuel level low warning signal R T

Fuel level sensor signal R T

Parking brake switch signal R T

Stop lamp switch signal R T

Tow mode switch signal R T

Vehicle speed signalRR T

RRR RRR T

Steering angle sensor signalTR

ABS malfunction signal R T

ABS warning lamp signalRT

Brake pressure sensor signal R T

Brake warning lamp signalRT

SLIP indicator lamp signalRT

TCS malfunction signal R T

VDC malfunction signal R T

VDC OFF indicator lamp signal R R T

VDC operation signal R T

Front wiper stop position signal R T

High beam status signal RT

Hood switch signal R T

Low beam status signal RT

Rear window defogger control signal R R TSignal name/Connecting unit

ECM

TCM

LASER

ICC

ADP

BCM

DISP

HVAC

M&A

STRG

ABS

IPDM-E

Signal name/Connecting unitECM

TCM

LASER

ICC

ADP

BCM

DISP

HVAC

M&A

STRG

4WD

ABS

IPDM-E

A/C compressor request signal TR

Accelerator pedal position signal T R R R R

ASCD CRUISE lamp signal T R

ASCD OD cancel request signal T R

ASCD operation signal T R

ASCD SET lamp signal T R

Battery voltage signal T R

Closed throttle position signal T R R

Page 2178 of 3061

![INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS

LAN-47

< SERVICE INFORMATION >[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

Cooling fan speed request signal TR

Engine coolant temperature signal T R R

Engine speed signal T R R R R R R R

E INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS

LAN-47

< SERVICE INFORMATION >[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

Cooling fan speed request signal TR

Engine coolant temperature signal T R R

Engine speed signal T R R R R R R R

E](/img/42/57029/w960_57029-2177.png)

TROUBLE DIAGNOSIS

LAN-47

< SERVICE INFORMATION >[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

Cooling fan speed request signal TR

Engine coolant temperature signal T R R

Engine speed signal T R R R R R R R

Engine status signal T R

Fuel consumption monitor signalTR

RT

ICC steering switch signal T R

Malfunction indicator lamp signal T R

Wide open throttle position signal T R

A/T CHECK indicator lamp signal T R

A/T fluid temperature sensor signal T R

A/T position indicator lamp signal T R R R

A/T self-diagnosis signal R T

Current gear position signal T R R

Output shaft revolution signal R T R R

P range signal T R R R R

Turbine revolution signal R T R

ICC sensor signal T R

Buzzer output signalTR

TR

ICC OD cancel request signal R R T

ICC operation signal R R T

ICC system display signal T R

System setting signalTR

RT

A/C switch signal R T R

Blower fan motor switch signal R T

Day time running light request signal T R R

Door switch signal R T R R R

Front fog light request signal T R

Front wiper request signal R T R

High beam request signal T R R

Horn chirp signal T R

Ignition switch signal R T R

Key fob door unlock signal R T

Key fob ID signal R T

Key switch signal R T

Low beam request signal T R

Position light request signal T R R

Rear window defogger switch signal T R R

Sleep wake up signal R T R R

Theft warning horn request signal T R

Tire pressure data signal T RSignal name/Connecting unit

ECM

TCM

LASER

ICC

ADP

BCM

DISP

HVAC

M&A

STRG

4WD

ABS

IPDM-E

Page 2179 of 3061

![INFINITI QX56 2007 Factory Service Manual LAN-48

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

NOTE:

CAN data of the air bag diagnosis sensor unit is not used by usual service work, thus it is omitted.

Tire pressure signal T R R

Turn indica INFINITI QX56 2007 Factory Service Manual LAN-48

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

NOTE:

CAN data of the air bag diagnosis sensor unit is not used by usual service work, thus it is omitted.

Tire pressure signal T R R

Turn indica](/img/42/57029/w960_57029-2178.png)

LAN-48

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

NOTE:

CAN data of the air bag diagnosis sensor unit is not used by usual service work, thus it is omitted.

Tire pressure signal T R R

Turn indicator signal T R

A/C switch/indicator signalTR

RT

1st position switch signal R T

4th position switch signal R T

Distance to empty signal R T

Fuel level low warning signal R T

Fuel level sensor signal R T

Parking brake switch signal R T

Stop lamp switch signal R T

Tow mode switch signal R T

Vehicle speed signalRR R T

RRR RRR T

Steering angle sensor signalTR

ABS malfunction signal R T

ABS warning lamp signalRT

Brake pressure sensor signal R T

Brake warning lamp signalRT

SLIP indicator lamp signalRT

TCS malfunction signal R T

VDC malfunction signal R T

VDC OFF indicator lamp signal R R T

VDC operation signal R T

Front wiper stop position signal R T

High beam status signal RT

Hood switch signal R T

Low beam status signal RT

Rear window defogger control signal R R TSignal name/Connecting unit

ECM

TCM

LASER

ICC

ADP

BCM

DISP

HVAC

M&A

STRG

4WD

ABS

IPDM-E

Page 2228 of 3061

HEADLAMP (FOR USA)

LT-21

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

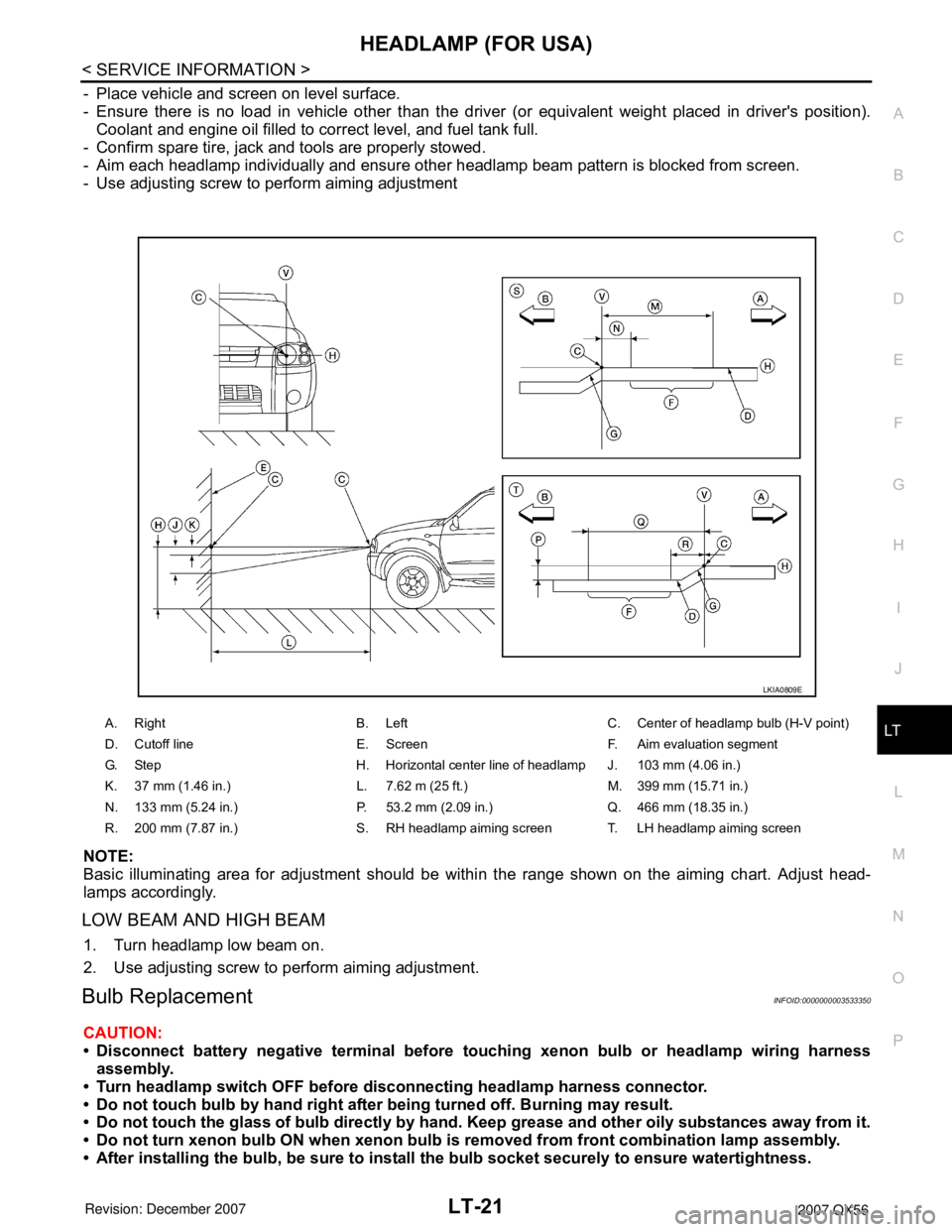

- Place vehicle and screen on level surface.

- Ensure there is no load in vehicle other than the driver (or equivalent weight placed in driver's position).

Coolant and engine oil filled to correct level, and fuel tank full.

- Confirm spare tire, jack and tools are properly stowed.

- Aim each headlamp individually and ensure other headlamp beam pattern is blocked from screen.

- Use adjusting screw to perform aiming adjustment

NOTE:

Basic illuminating area for adjustment should be within the range shown on the aiming chart. Adjust head-

lamps accordingly.

LOW BEAM AND HIGH BEAM

1. Turn headlamp low beam on.

2. Use adjusting screw to perform aiming adjustment.

Bulb ReplacementINFOID:0000000003533350

CAUTION:

• Disconnect battery negative terminal before touching xenon bulb or headlamp wiring harness

assembly.

• Turn headlamp switch OFF before disconnecting headlamp harness connector.

• Do not touch bulb by hand right after being turned off. Burning may result.

• Do not touch the glass of bulb directly by hand. Keep grease and other oily substances away from it.

• Do not turn xenon bulb ON when xenon bulb is removed from front combination lamp assembly.

• After installing the bulb, be sure to install the bulb socket securely to ensure watertightness.

A. Right B. Left C. Center of headlamp bulb (H-V point)

D. Cutoff line E. Screen F. Aim evaluation segment

G. Step H. Horizontal center line of headlamp J. 103 mm (4.06 in.)

K. 37 mm (1.46 in.) L. 7.62 m (25 ft.) M. 399 mm (15.71 in.)

N. 133 mm (5.24 in.) P. 53.2 mm (2.09 in.) Q. 466 mm (18.35 in.)

R. 200 mm (7.87 in.) S. RH headlamp aiming screen T. LH headlamp aiming screen

LKIA0809E

Page 2262 of 3061

FRONT FOG LAMP

LT-55

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

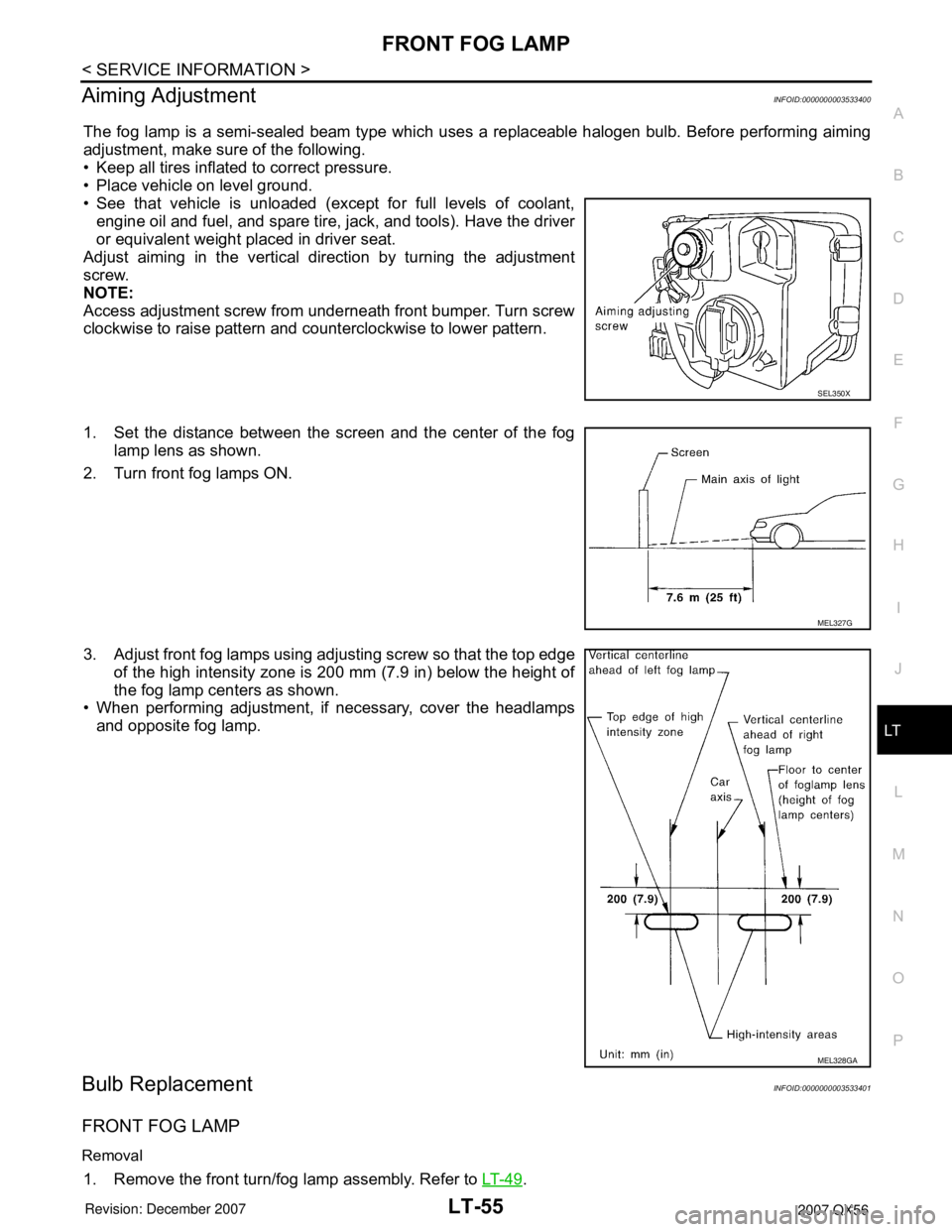

Aiming AdjustmentINFOID:0000000003533400

The fog lamp is a semi-sealed beam type which uses a replaceable halogen bulb. Before performing aiming

adjustment, make sure of the following.

• Keep all tires inflated to correct pressure.

• Place vehicle on level ground.

• See that vehicle is unloaded (except for full levels of coolant,

engine oil and fuel, and spare tire, jack, and tools). Have the driver

or equivalent weight placed in driver seat.

Adjust aiming in the vertical direction by turning the adjustment

screw.

NOTE:

Access adjustment screw from underneath front bumper. Turn screw

clockwise to raise pattern and counterclockwise to lower pattern.

1. Set the distance between the screen and the center of the fog

lamp lens as shown.

2. Turn front fog lamps ON.

3. Adjust front fog lamps using adjusting screw so that the top edge

of the high intensity zone is 200 mm (7.9 in) below the height of

the fog lamp centers as shown.

• When performing adjustment, if necessary, cover the headlamps

and opposite fog lamp.

Bulb ReplacementINFOID:0000000003533401

FRONT FOG LAMP

Removal

1. Remove the front turn/fog lamp assembly. Refer to LT- 4 9.

SEL350X

MEL327G

MEL328GA

Page 2363 of 3061

MA-1

MAINTENANCE

C

D

E

F

G

H

I

J

K

M

SECTION MA

A

B

MA

N

O

P

CONTENTS

MAINTENANCE

SERVICE INFORMATION ............................2

PRECAUTIONS ...................................................2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

2

PREPARATION ...................................................3

Special Service Tool .................................................3

Commercial Service Tool ..........................................3

GENERAL MAINTENANCE ................................4

General Maintenance ................................................4

PERIODIC MAINTENANCE ................................6

Introduction of Periodic Maintenance ........................6

Maintenance for Off-road Driving (4WD only) ...........6

Schedule 1 ................................................................6

Schedule 2 ................................................................8

RECOMMENDED FLUIDS AND LUBRI-

CANTS ................................................................

10

Fluids and Lubricants ..............................................10

SAE Viscosity Number ............................................10

ENGINE MAINTENANCE ...................................12

Checking Drive Belts ...............................................12

Changing Engine Coolant .......................................12

Checking Fuel Line .................................................15

Changing Fuel Filter ................................................15

Changing Engine Air Cleaner Filter .........................15

Changing Engine Oil ................................................16

Changing Oil Filter ...................................................16

Changing Spark Plugs .............................................18

Checking EVAP Vapor Line .....................................19

CHASSIS AND BODY MAINTENANCE ...........20

Changing In-cabin Microfilter ...................................20

Checking Exhaust System .......................................21

Checking Automatic Transmission Fluid (ATF) .......21

Changing Automatic Transmission Fluid (ATF) .......23

Changing Transfer Fluid ..........................................23

Checking Transfer Fluid ..........................................24

Checking Propeller Shaft .........................................24

Checking Final Drive Oil ..........................................24

Changing Final Drive Oil ..........................................25

Balancing Wheels ....................................................25

Tire Rotation ............................................................27

Checking Brake Fluid Level and Leaks ...................27

CheckingBrake Line and Cables .............................27

Checking Disc Brake ...............................................27

Checking Steering Gear and Linkage ......................28

Checking Power Steering Fluid and Line ................28

Checking Axle and Suspension Parts .....................29

Lubricating Locks, Hinges and Hood Latches .........30

Checking Seat Belts, Buckles, Retractors, An-

chors and Adjusters .................................................

30

Page 2367 of 3061

GENERAL MAINTENANCE

MA-5

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

MA

B

MA

N

O

P

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically (e.g. each time you check the engine oil or refuel).

BrakesCheck that the brake does not pull the vehicle to one side when applied. —

Brake pedal and

boosterCheck the pedal for smooth operation and make sure it has the proper distance

under it when depressed fully. Check the brake booster function. Keep the floor

mats away from the pedal.BR-5, "

Inspection and

Adjustment", BR-15,

"On-Vehicle Service"

Parking brakeCheck that the parking brake control has the proper travel and make sure that

the vehicle is held securely on a fairly steep hill when only the parking brake is

applied.PB-4

Automatic transmis-

sion “Park” mecha-

nismOn a fairly steep hill check that the vehicle is held securely with the selector lever

in the P position without applying the brakes. — ItemReference page

ItemReference page

Windshield washer

fluidCheck that there is adequate fluid in the tank.

—

Engine coolant levelCheck the coolant level when the engine is cold. —

Radiator and hosesCheck the front of the radiator and clean off any dirt, insects, leaves, etc., that

may have accumulated. Make sure the hoses have no cracks, deformation, de-

terioration or loose connections.—

Brake fluid levelMake sure that the brake fluid level is between the “MAX” and “MIN” lines on the

reservoirsMA-27

BatteryCheck the fluid level in each cell. It should be between the “MAX” and “MIN” lines.

Vehicles operated in high temperatures or under severe conditions require fre-

quent checks of the battery fluid level.—

Engine drive beltMake sure that no belt is frayed, worn, cracked or oily.MA-12

Engine oil levelCheck the level on the dipstick after parking the vehicle on a level spot and turn-

ing off the engine.—

Power steering fluid

level and linesCheck the level on the reservoir with the engine off. Check the lines for improper

attachment, leaks, cracks, etc.MA-28

Automatic transmis-

sion fluid levelCheck the level on the dipstick after putting the selector lever in “P” with the en-

gine idling.MA-21

Exhaust systemMake sure there are no loose supports, cracks or holes. If the sound of the ex-

haust seems unusual or there is a smell of exhaust fumes, immediately locate

the trouble and correct it.MA-21

UnderbodyThe underbody is frequently exposed to corrosive substances such as those

used on icy roads or to control dust. It is very important to remove these sub-

stances, otherwise rust will form on the floor pan, frame, fuel lines and around the

exhaust system. At the end of winter, the underbody should be thoroughly

flushed with plain water, being careful to clean those areas where mud and dirt

can easily accumulate.—

Fluid leaksCheck under the vehicle for fuel, oil, water or other fluid leaks after the vehicle

has been parked for a while. Water dripping from the air conditioner after use is

normal. If you should notice any leaks or gasoline fumes are evident, check for

the cause and correct it immediately.—

Page 2368 of 3061

MA-6

< SERVICE INFORMATION >

PERIODIC MAINTENANCE

PERIODIC MAINTENANCE

Introduction of Periodic MaintenanceINFOID:0000000003533860

Two different maintenance schedules are provided, and should be used, depending upon the conditions in

which the vehicle is mainly operated. After 60,000 miles (96,000 km) or 48 months, continue the periodic

maintenance at the same mileage or time intervals, whichever comes first.

Maintenance for Off-road Driving (4WD only)INFOID:0000000003533861

After driving the vehicle off-road through sand, mud, or water; more frequent maintenance may be required for

the following items:

Brake pads and rotors

Brake lines and hoses

Rear final drive oil, transmission fluid, and transfer fluid

Steering linkage

Drive shafts

Engine air cleaner filter

In-cabin microfilters

Schedule 1INFOID:0000000003533862

EMISSION CONTROL SYSTEM MAINTENANCE

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

Schedule 1Follow Periodic Maintenance Schedule 1 if your driving habits frequently includes

one or more of the following driving conditions:

• Repeated short trips of less than 5 miles (8 km).

• Repeated short trips of less than 10 miles (16 km) with outside temperatures re-

maining below freezing.

• Operating in hot weather in stop-and-go “rush hour” traffic.

• Extensive idling and/or low speed driving for long distances, such as police, taxi

or door-to-door delivery use.

• Driving in dusty conditions.

• Driving on rough, muddy, or salt spread roads.

• Towing a trailer or using a car-top carrier.Emission Control Sys-

tem MaintenanceMA-6

Chassis and Body

MaintenanceMA-6

Schedule 2Follow Periodic Maintenance Schedule 2 if none of the driving conditions shown

in Schedule 1 apply to the driving habits.Emission Control Sys-

tem MaintenanceMA-8Chassis and Body

MaintenanceMA-8

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

Section -

Page or -

Content Title Perform at number of miles, kilo-

meters or months, whichever

comes first.Miles x 1,000

(km x 1,000)

Months3.75

(6)

37.50

(12)

611 . 2 5

(18)

915

(24)

1218.75

(30)

1522.5

(36)

1826.25

(42)

2130

(48)

24

Drive belts NOTE (1)MA-12

Air cleaner filter NOTE (2) [R]MA-15

EVAP vapor linesI*MA-19

Fuel linesI*MA-15

Fuel filter NOTE (3)—

Engine coolant NOTE (4)MA-12

Engine oil R R R R R R R RMA-16

Engine oil filter R R R R R R R RMA-16

Spark plugs (double PLATINUM-

TIPPED type)Replace every 105,000 miles (169,000 km).EM-29

Intake and exhaust valve clear-

ance*NOTE (5)EM-103