fuel INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1801 of 3061

FUEL INJECTOR AND FUEL TUBEEM-31

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

FUEL INJECTOR AND FUEL TUBE

Removal and InstallationINFOID:0000000003531531

CAUTION:

Do not remove or disassemble parts unless instructed as shown.

REMOVAL

1. Remove the engine room cover using power tool. Refer to

EM-12, "Removal and Installation".

2. Release the fuel pressure. Refer to EC-80, "

Fuel Pressure Check".

3. Disconnect the negative battery terminal.

4. Disconnect the fuel injector harness connectors.

5. Disconnect the fuel hose assembly from the fuel tubes (RH and LH).

CAUTION:

• While hoses are disconnected, plug th em to prevent fuel from draining.

• Do not separate the fuel connector and fuel hose.

6. Remove the fuel injectors with the fuel tube assembly.

1. Fuel tube (RH) 2. Cap 3. Fuel damper

4. O-ring 5. O-ring (b lue) 6. Fuel injector

7. Clip 8. O-ring (brown) 9. O-ring

10. Fuel hose assembly 11. Fuel tube (LH)

KBIA2472E

Page 1802 of 3061

EM-32

< SERVICE INFORMATION >

FUEL INJECTOR AND FUEL TUBE

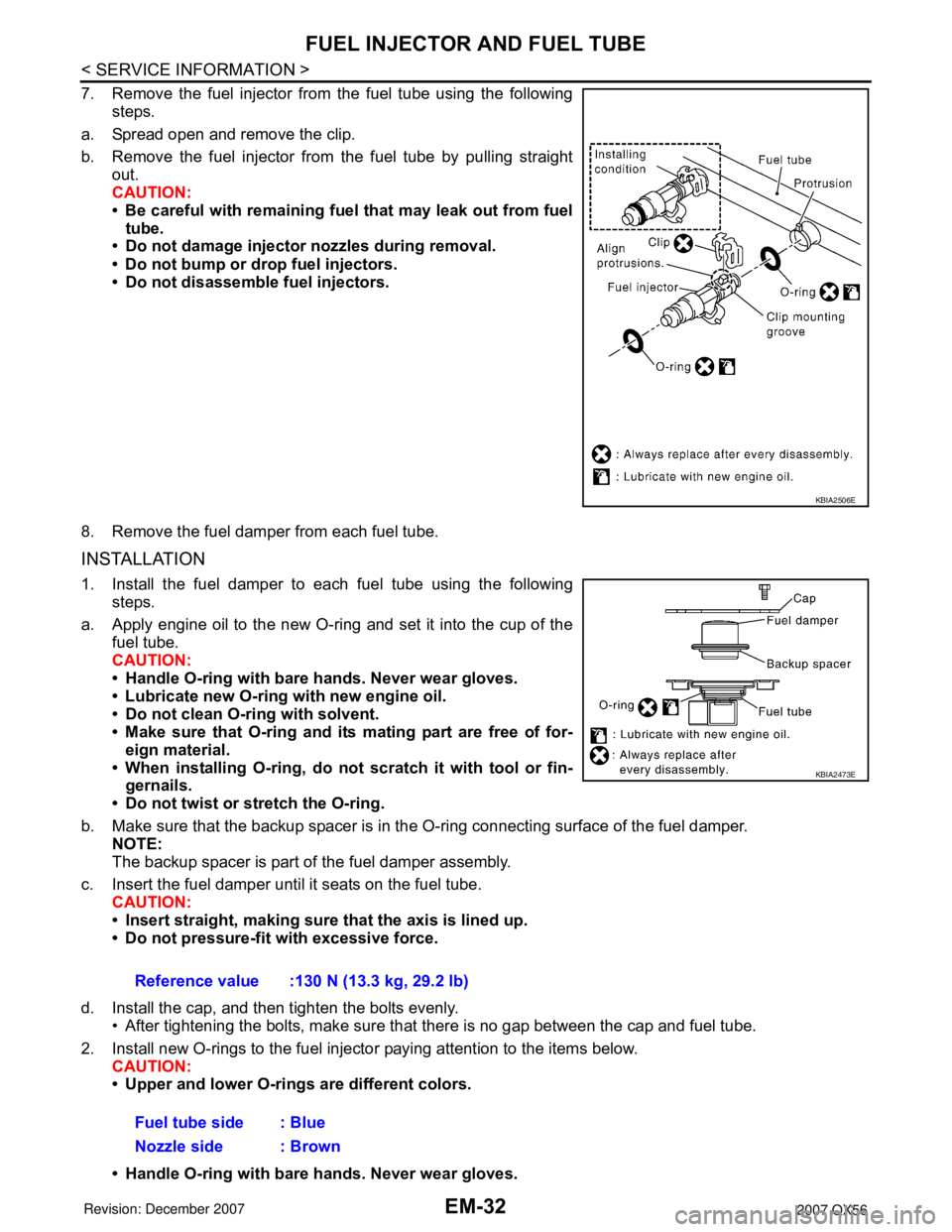

7. Remove the fuel injector from the fuel tube using the followingsteps.

a. Spread open and remove the clip.

b. Remove the fuel injector from the fuel tube by pulling straight out.

CAUTION:

• Be careful with remaining fuel that may leak out from fueltube.

• Do not damage injector nozzles during removal.

• Do not bump or drop fuel injectors.

• Do not disassemble fuel injectors.

8. Remove the fuel damper from each fuel tube.

INSTALLATION

1. Install the fuel damper to each fuel tube using the following steps.

a. Apply engine oil to the new O-ring and set it into the cup of the fuel tube.

CAUTION:

• Handle O-ring with bare hands. Never wear gloves.

• Lubricate new O-ring with new engine oil.

• Do not clean O-ring with solvent.

• Make sure that O-ring and its mating part are free of for-eign material.

• When installing O-ring, do not scratch it with tool or fin-

gernails.

• Do not twist or stretch the O-ring.

b. Make sure that the backup spacer is in the O-ring connecting surface of the fuel damper.

NOTE:

The backup spacer is part of the fuel damper assembly.

c. Insert the fuel damper until it seats on the fuel tube. CAUTION:

• Insert straight, making sure that the axis is lined up.

• Do not pressure-fit with excessive force.

d. Install the cap, and then tighten the bolts evenly. • After tightening the bolts, make sure that there is no gap between the cap and fuel tube.

2. Install new O-rings to the fuel injector paying attention to the items below. CAUTION:

• Upper and lower O-rings are different colors.

• Handle O-ring with bare hands. Never wear gloves.

KBIA2506E

Reference value :130 N (13.3 kg, 29.2 lb)

Fuel tube side : Blue

Nozzle side : Brown

KBIA2473E

Page 1803 of 3061

FUEL INJECTOR AND FUEL TUBEEM-33

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

• Lubricate new O-ring with new engine oil.

• Do not clean O-ring with solvent.

• Make sure that O-ring and its mating

part are free of foreign material.

• When installing O-ring, be careful not to scratch it with tool or fingernails. Also be careful not to

twist or stretch O-ring.

• If O-ring was stretched while it was being att ached, do not insert it quickly into fuel tube.

• Insert O-ring straight into fuel tube. Do not angle or twist it.

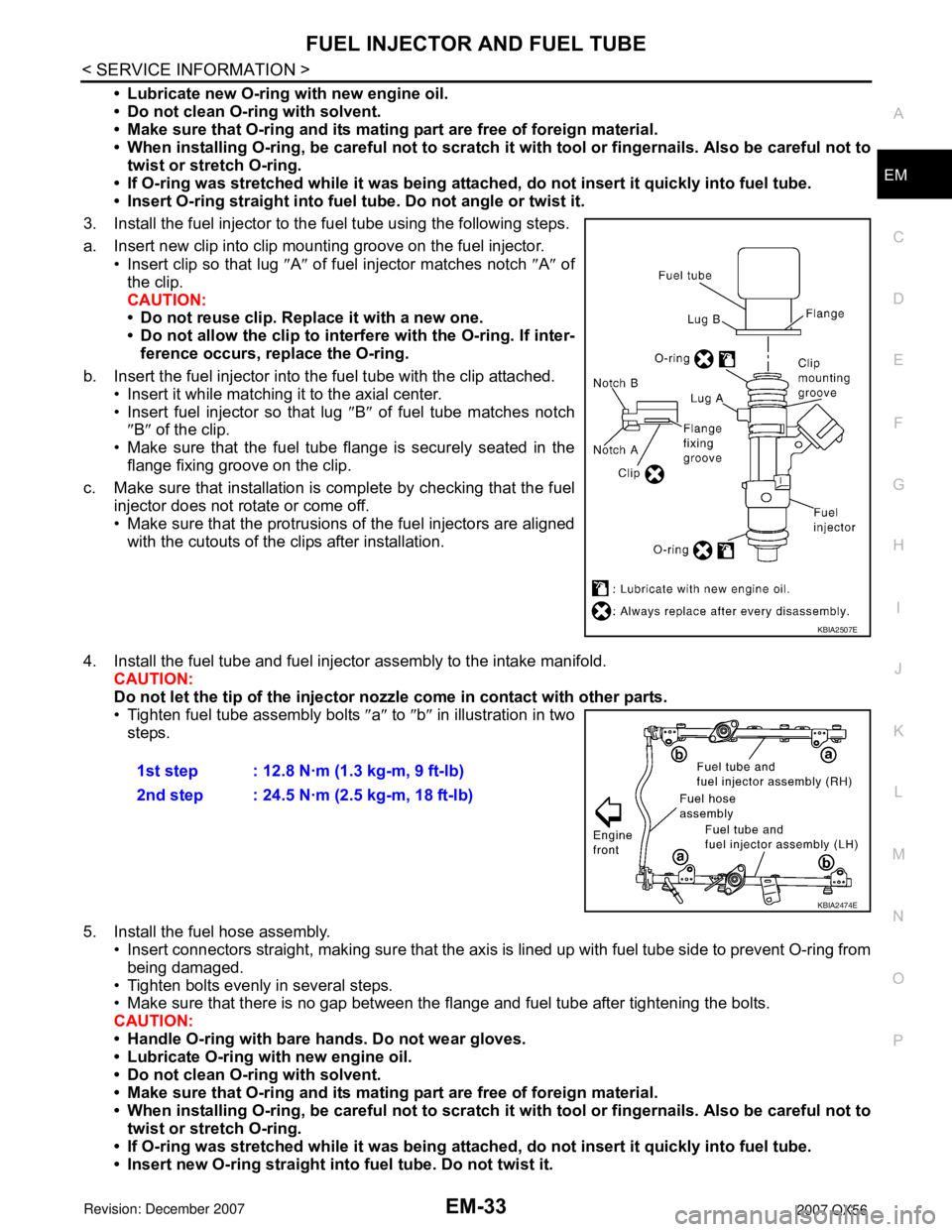

3. Install the fuel injector to the fuel tube using the following steps.

a. Insert new clip into clip mounting groove on the fuel injector. • Insert clip so that lug ″A ″ of fuel injector matches notch ″A ″ of

the clip.

CAUTION:

• Do not reuse clip. Replace it with a new one.

• Do not allow the clip to interf ere with the O-ring. If inter-

ference occurs, replace the O-ring.

b. Insert the fuel injector into the fuel tube with the clip attached. • Insert it while matching it to the axial center.

• Insert fuel injector so that lug ″B ″ of fuel tube matches notch

″ B ″ of the clip.

• Make sure that the fuel tube flange is securely seated in the flange fixing groove on the clip.

c. Make sure that installation is complete by checking that the fuel injector does not rotate or come off.

• Make sure that the protrusions of the fuel injectors are alignedwith the cutouts of the clips after installation.

4. Install the fuel tube and fuel injector assembly to the intake manifold. CAUTION:

Do not let the tip of the injector nozz le come in contact with other parts.

• Tighten fuel tube assembly bolts ″a ″ to ″b ″ in illustration in two

steps.

5. Install the fuel hose assembly. • Insert connectors straight, making su re that the axis is lined up with fuel tube side to prevent O-ring from

being damaged.

• Tighten bolts evenly in several steps.

• Make sure that there is no gap between the flange and fuel tube after tightening the bolts.

CAUTION:

• Handle O-ring with bare hands. Do not wear gloves.

• Lubricate O-ring with new engine oil.

• Do not clean O-ring with solvent.

• Make sure that O-ring and its mating part are free of foreign material.

• When installing O-ring, be careful not to scratch it with tool or fingernails. Also be careful not to

twist or stretch O-ring.

• If O-ring was stretched while it was being att ached, do not insert it quickly into fuel tube.

• Insert new O-ring straight into fuel tube. Do not twist it.

KBIA2507E

1st step : 12.8 N·m (1.3 kg-m, 9 ft-lb)

2nd step : 24.5 N·m (2.5 kg-m, 18 ft-lb)

KBIA2474E

Page 1804 of 3061

EM-34

< SERVICE INFORMATION >

FUEL INJECTOR AND FUEL TUBE

6. Installation of the remaining components is in the reverse order of removal.

INSPECTION AFTER INSTALLATION

After installing the fuel tubes, make sure there are no fuel leaks at the connections using the following steps.

1. Apply fuel pressure to the fuel lines by turning ignition switch ON (with engine stopped). Then check for fuel leaks at the connections.

NOTE:

Use mirrors for checking on hidden points.

2. Start the engine and rev it up and check for fuel leaks at the connections. CAUTION:

Do not touch the engine immediately after stopping, as engine becomes extremely hot.

Page 1826 of 3061

EM-56

< SERVICE INFORMATION >

CAMSHAFT

2. Perform the following procedure so as to prevent the engine from being unintentionally started while

checking.

a. Release fuel pressure. Refer to EC-80, "

Fuel Pressure Check".

b. Disconnect ignition coil and injector harness connectors if practical.

3. Remove IVT control solenoid valve.

4. Crank engine, and then make sure that engine oil comes out from IVT control cover oil hole. End cranking

after checking.

WARNING:

Be careful not to touch rotating parts (drive be lts, idler pulley, and crankshaft pulley, etc.).

CAUTION:

• Engine oil may squirt from IVT control soleno id valve installation hole during cranking. Use a

shop cloth to prevent engine oil from splashin g on worker, engine components and vehicle.

• Do not allow engine oil to get on rubber compon ents such as drive belts or engine mount insula-

tors. Immediately wipe off any splashed engine oil.

5. Clean oil groove between oil strainer and IVT control solenoid valve if engine oil does not come out from IVT control valve cover oil hole. Refer to LU-7, "

Schematic".

6. Remove components between IVT control solenoid va lve and camshaft sprocket (INT), and then check

each oil groove for clogging.

• Clean oil groove if necessary.

7. After inspection, installation of the remaining components is in the reverse order of removal.

Valve ClearanceINFOID:0000000003531536

INSPECTION

NOTE:

Perform the following inspection after removal, installation or replacement of camshaft or valve-related parts,

or if there are unusual engine conditions due to changes in valve clearance over time (starting, idling, and/or

noise).

1. Warm up the engine. Then stop the engine.

2. Remove the engine cover and. Refer to EM-12, "

Removal and Installation".

3. Remove the battery cover. Refer to SC-8, "

Removal and Installation".

4. Remove the air cleaner and air duct assembly EM-15, "

Removal and Installation".

5. Remove the RH bank and LH bank rocker covers using power tool. Refer to EM-35, "

Removal and Instal-

lation".

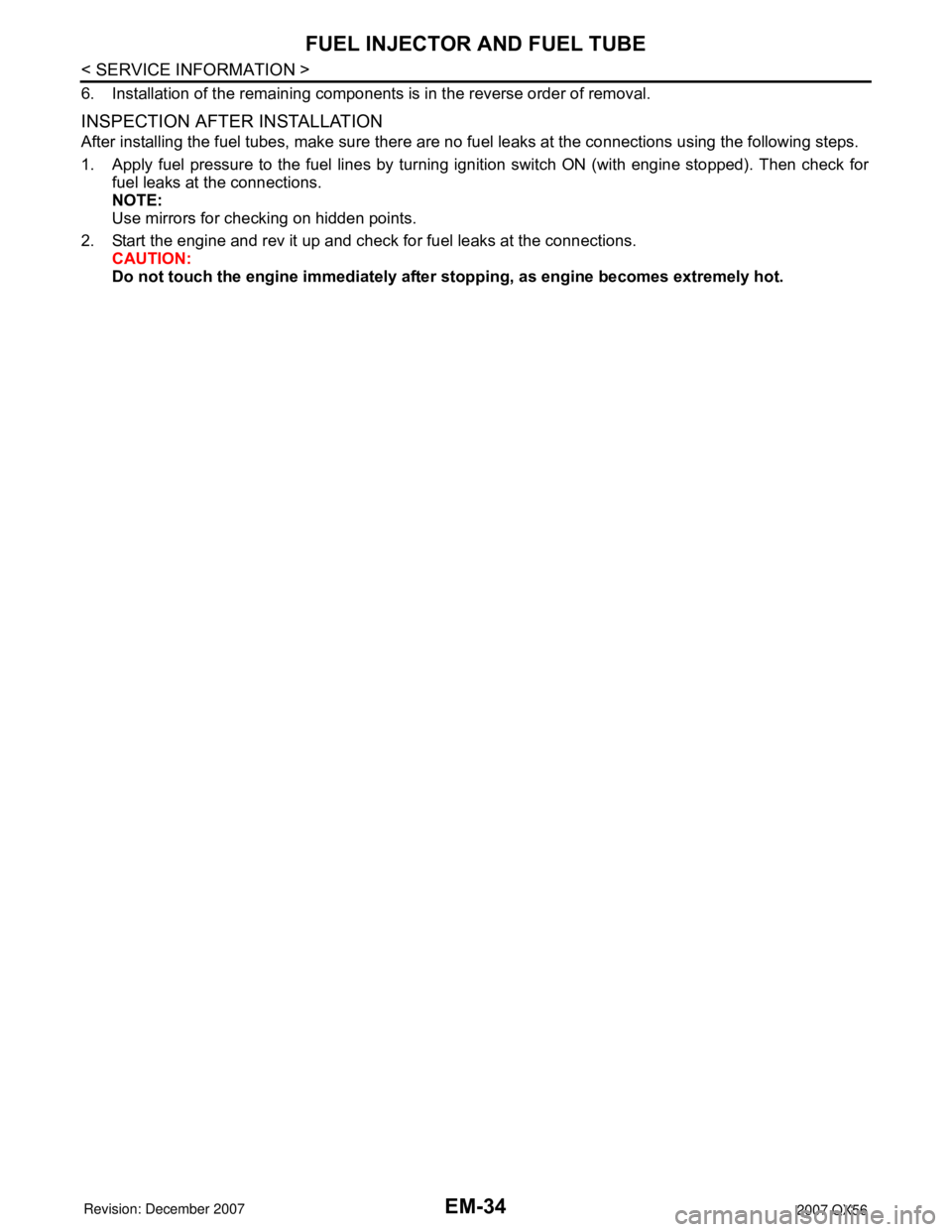

6. Turn the crankshaft pulley in the normal direction (clockwise when viewed from engine front) to align TDC identification notch

(without paint mark) with timing indicator.

KBIA2476E

Page 1834 of 3061

EM-64

< SERVICE INFORMATION >

CYLINDER HEAD

CYLINDER HEAD

On-Vehicle ServiceINFOID:0000000003531540

CHECKING COMPRESSION PRESSURE

1. Warm up the engine thoroughly. Then stop the engine.

2. Release the fuel pressure. Refer to EC-80, "

Fuel Pressure Check".

CAUTION:

If CONSULT-II is not used to release fuel pressure leave the fu el pump fuse disconnected until

step 7.

3. Remove the spark plug from each cylinder. Refer to EM-29, "

Removal and Installation".

4. Connect the engine tachometer (not required in use of CONSULT-II).

5. Install the compression tester with Tool into the spark plug hole.

6. With the accelerator pedal fully depressed, turn the ignition switch to “START” for cranking. When the gauge pointer stabi-

lizes, read the compression pressure and engine rpm. Perform

these steps to check each cylinder.

Unit: kPa (kg/cm2, psi) /rpm

CAUTION:

Always use a fully charged battery to obtain specified engine speed.

• If the engine speed is out of the specified range, che ck the battery liquid for proper gravity. Check the

engine speed again with normal battery gravity.

• If the compression pressure is below the minimum value, check the valve clearances and parts associ- ated with the combustion chamber (valve, valve seat , piston, piston ring, cylinder bore, cylinder head,

cylinder head gasket). After checking, measure the compression pressure again.

• If some cylinders have low compression pressure, pour a small amount of engine oil into the spark plug hole of the cylinder to re-check it for compression.

- If the added engine oil improves the compression, t he piston rings may be worn out or damaged. Check

the piston rings and replace if necessary.

- If the compression pressure remains at a low level despite the addition of engine oil, the valves may be

malfunctioning. Check the valves for damage. R eplace the valve or valve seat accordingly.

• If two adjacent cylinders have respectively low co mpression pressure and their compression remains

low even after the addition of engine oil, the gaskets may be leaking, or a valve in adjacent cylinders

may be damaged. Inspect and repair as required.

7. Install the components in the reverse order of removal.

8. Start the engine and confirm that it runs smoothly.

9. Perform trouble diagnosis. If DTC appears, erase it. Refer to EC-32

.

Tool number : EG15050500 (J-45402)

Standard Minimum

Deference limit be-

tween cylinders

1,520 (15.5, 220) / 200 1,324 (13.5, 192) / 200 98 (1.0, 14) / 200WBIA0605E

Page 1835 of 3061

CYLINDER HEADEM-65

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

Removal and InstallationINFOID:0000000003531541

REMOVAL

1. Remove the engine assembly from the vehicle. Refer to

EM-74, "Removal and Installation".

2. Remove the following components and related parts: • Drive belt auto tensioner drive belts and idler pulley. Refer to EM-13, "

Removal and Installation".

• Thermostat housing and hose. Refer to CO-20, "

Removal and Installation".

• Oil pan and oil strainer. Refer to EM-24, "

Removal and Installation".

• Fuel tube and fuel injector assembly. Refer to EM-31, "

Removal and Installation".

• Intake manifold. Refer to EM-17, "

Removal and Installation".

• Ignition coil. Refer to EM-28, "

Removal and Installation".

• Rocker cover. Refer to EM-35, "

Removal and Installation".

3. Remove the crankshaft pulley, front cover, oil pump, and timing chain. Refer to EM-38, "

Removal and

Installation".

4. Remove the camshaft sprockets and camshafts. Refer to EM-46, "

Removal and Installation".

5. Remove the cylinder head bolts in reverse of order shown.

INSPECTION AFTER REMOVAL

Cylinder Head Bolts Diameter

1. Harness bracket 2. Engine coolant temperature sensor 3. Washer

4. Cylinder head gasket (LH) 5. Cylinder head (RH) 6. Cylinder head bolt

7. Cylinder head gasket (RH) 8. Cylinder head (LH)

KBIA2528E

PBIC0068E

Page 1844 of 3061

EM-74

< SERVICE INFORMATION >

ENGINE ASSEMBLY

ENGINE ASSEMBLY

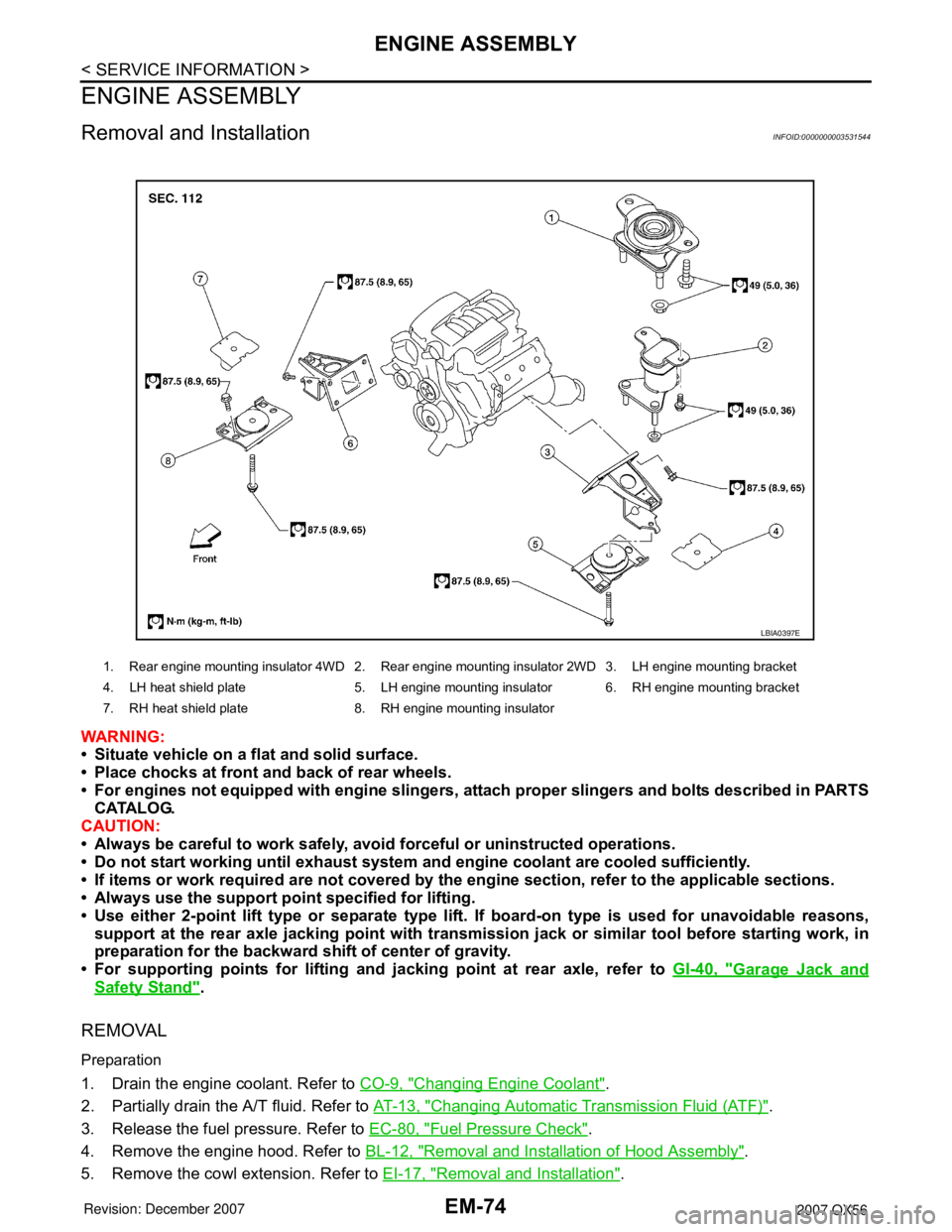

Removal and InstallationINFOID:0000000003531544

WARNING:

• Situate vehicle on a flat and solid surface.

• Place chocks at front and back of rear wheels.

• For engines not equipped with engine slingers, attach proper slingers and bolts described in PARTS

CATALOG.

CAUTION:

• Always be careful to work safely, avoid forceful or uninstructed operations.

• Do not start working until exhaust system and engine coolant are cooled sufficiently.

• If items or work required are not covered by the engine section, refer to the applicable sections.

• Always use the support point specified for lifting.

• Use either 2-point lift type or separate type lift. If board-on type is used for unavoidable reasons,

support at the rear axle jacking point with transmission jack or similar tool before starting work, in

preparation for the backward shift of center of gravity.

• For supporting points for lifting and jacking point at rear axle, refer to GI-40, "

Garage Jack and

Safety Stand".

REMOVAL

Preparation

1. Drain the engine coolant. Refer to CO-9, "Changing Engine Coolant".

2. Partially drain the A/T fluid. Refer to AT-13, "

Changing Automatic Transmission Fluid (ATF)".

3. Release the fuel pressure. Refer to EC-80, "

Fuel Pressure Check".

4. Remove the engine hood. Refer to BL-12, "

Removal and Installation of Hood Assembly".

5. Remove the cowl extension. Refer to EI-17, "

Removal and Installation".

1. Rear engine mounting insulator 4WD 2. Rear engine mounting insulator 2WD 3. LH engine mounting bracket

4. LH heat shield plate 5. LH engine mounting insulator 6. RH engine mounting bracket

7. RH heat shield plate 8. RH engine mounting insulator

LBIA0397E

Page 1845 of 3061

ENGINE ASSEMBLY

EM-75

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

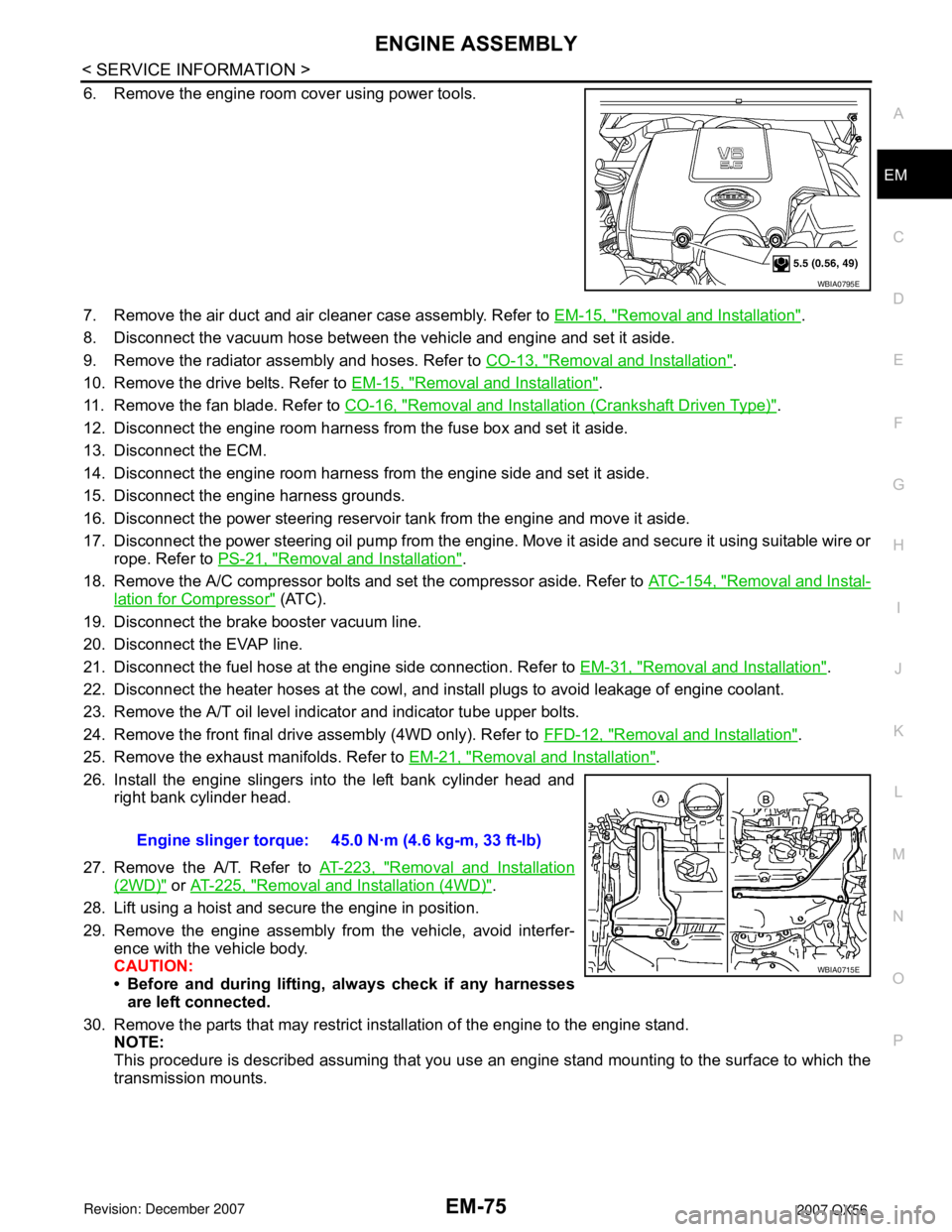

6. Remove the engine room cover using power tools.

7. Remove the air duct and air cleaner case assembly. Refer to EM-15, "

Removal and Installation".

8. Disconnect the vacuum hose between the vehicle and engine and set it aside.

9. Remove the radiator assembly and hoses. Refer to CO-13, "

Removal and Installation".

10. Remove the drive belts. Refer to EM-15, "

Removal and Installation".

11. Remove the fan blade. Refer to CO-16, "

Removal and Installation (Crankshaft Driven Type)".

12. Disconnect the engine room harness from the fuse box and set it aside.

13. Disconnect the ECM.

14. Disconnect the engine room harness from the engine side and set it aside.

15. Disconnect the engine harness grounds.

16. Disconnect the power steering reservoir tank from the engine and move it aside.

17. Disconnect the power steering oil pump from the engine. Move it aside and secure it using suitable wire or

rope. Refer to PS-21, "

Removal and Installation".

18. Remove the A/C compressor bolts and set the compressor aside. Refer to ATC-154, "

Removal and Instal-

lation for Compressor" (ATC).

19. Disconnect the brake booster vacuum line.

20. Disconnect the EVAP line.

21. Disconnect the fuel hose at the engine side connection. Refer to EM-31, "

Removal and Installation".

22. Disconnect the heater hoses at the cowl, and install plugs to avoid leakage of engine coolant.

23. Remove the A/T oil level indicator and indicator tube upper bolts.

24. Remove the front final drive assembly (4WD only). Refer to FFD-12, "

Removal and Installation".

25. Remove the exhaust manifolds. Refer to EM-21, "

Removal and Installation".

26. Install the engine slingers into the left bank cylinder head and

right bank cylinder head.

27. Remove the A/T. Refer to AT-223, "

Removal and Installation

(2WD)" or AT-225, "Removal and Installation (4WD)".

28. Lift using a hoist and secure the engine in position.

29. Remove the engine assembly from the vehicle, avoid interfer-

ence with the vehicle body.

CAUTION:

• Before and during lifting, always check if any harnesses

are left connected.

30. Remove the parts that may restrict installation of the engine to the engine stand.

NOTE:

This procedure is described assuming that you use an engine stand mounting to the surface to which the

transmission mounts.

WBIA0795E

Engine slinger torque: 45.0 N·m (4.6 kg-m, 33 ft-lb)

WBIA0715E

Page 1846 of 3061

EM-76

< SERVICE INFORMATION >

ENGINE ASSEMBLY

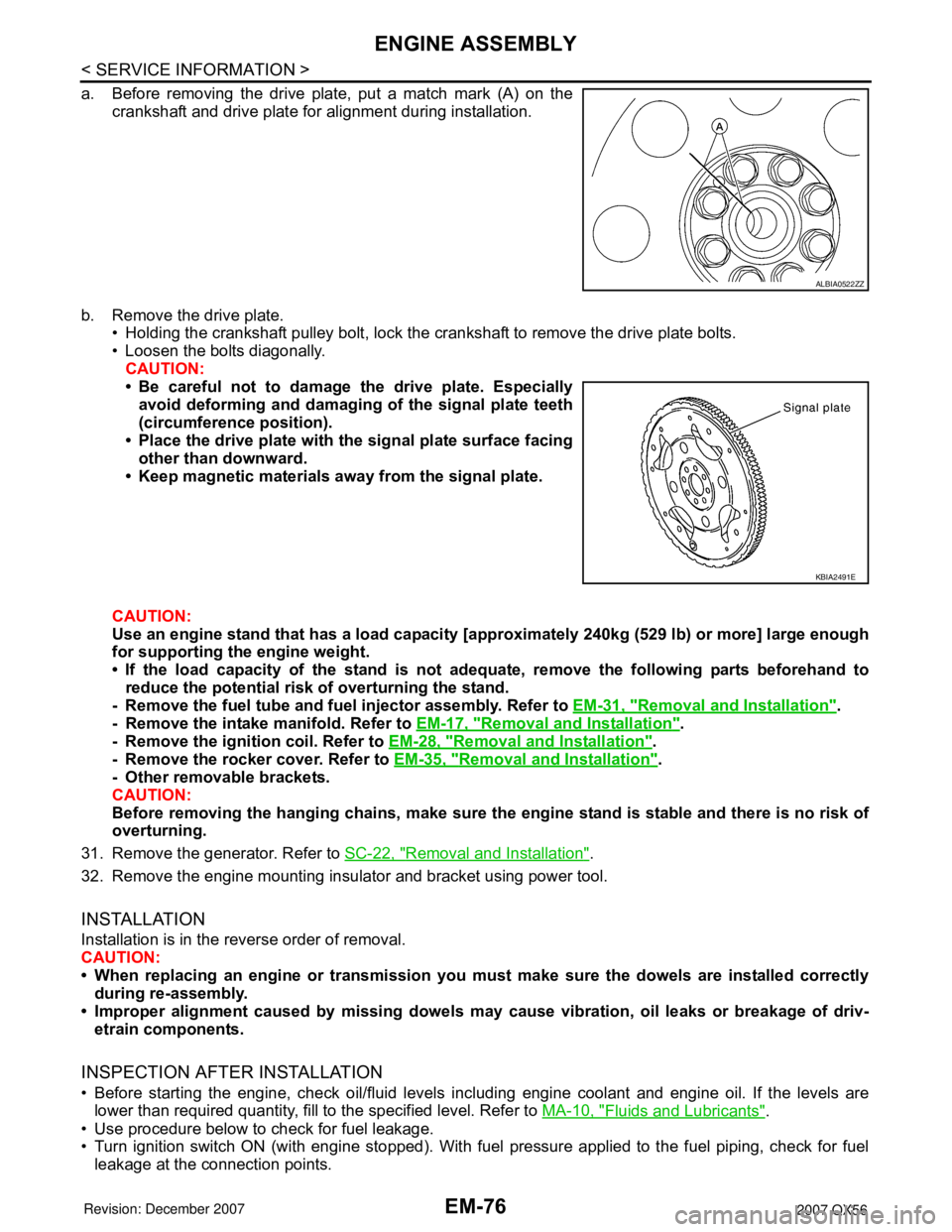

a. Before removing the drive plate, put a match mark (A) on the

crankshaft and drive plate for alignment during installation.

b. Remove the drive plate.

• Holding the crankshaft pulley bolt, lock the crankshaft to remove the drive plate bolts.

• Loosen the bolts diagonally.

CAUTION:

• Be careful not to damage the drive plate. Especially

avoid deforming and damaging of the signal plate teeth

(circumference position).

• Place the drive plate with the signal plate surface facing

other than downward.

• Keep magnetic materials away from the signal plate.

CAUTION:

Use an engine stand that has a load capacity [approximately 240kg (529 lb) or more] large enough

for supporting the engine weight.

• If the load capacity of the stand is not adequate, remove the following parts beforehand to

reduce the potential risk of overturning the stand.

- Remove the fuel tube and fuel injector assembly. Refer to EM-31, "

Removal and Installation".

- Remove the intake manifold. Refer to EM-17, "

Removal and Installation".

- Remove the ignition coil. Refer to EM-28, "

Removal and Installation".

- Remove the rocker cover. Refer to EM-35, "

Removal and Installation".

- Other removable brackets.

CAUTION:

Before removing the hanging chains, make sure the engine stand is stable and there is no risk of

overturning.

31. Remove the generator. Refer to SC-22, "

Removal and Installation".

32. Remove the engine mounting insulator and bracket using power tool.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• When replacing an engine or transmission you must make sure the dowels are installed correctly

during re-assembly.

• Improper alignment caused by missing dowels may cause vibration, oil leaks or breakage of driv-

etrain components.

INSPECTION AFTER INSTALLATION

• Before starting the engine, check oil/fluid levels including engine coolant and engine oil. If the levels are

lower than required quantity, fill to the specified level. Refer to MA-10, "

Fluids and Lubricants".

• Use procedure below to check for fuel leakage.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to the fuel piping, check for fuel

leakage at the connection points.

ALBIA0522ZZ

KBIA2491E