turn signal INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1536 of 3061

DTC P0850 PNP SWITCH

EC-453

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

3. Select “DATA MONITOR” mode with CONSULT-II.

4. Start engine and warm it up to normal operating temperature.

5. Maintain the following conditions for at least 60 consecutive sec-

onds.

6. If 1st trip DTC is detected, go to EC-455, "

Diagnosis Procedure".

Overall Function CheckINFOID:0000000003531969

Use this procedure to check the overall function of the park/neutral position (PNP) switch circuit. During this

check, a 1st trip DTC might not be confirmed.

WITH GST

1. Turn ignition switch ON.

2. Check voltage between ECM terminal 102 (PNP switch signal)

and ground under the following conditions.

3. If NG, go to EC-455, "

Diagnosis Procedure".

ENG SPEED 1,000 - 6,375 rpm

COOLAN TEMP/S More than 70°C (158°F)

B/FUEL SCHDL 2.0 - 31.8 msec

VHCL SPEED SE More than 64 km/h (40 MPH)

Selector lever Suitable position

SEF213Y

Condition (Gear position) Voltage V (Known-good data)

P or N position Approx. 0

Except the above positionBATTERY VOLTAGE

(11 - 14V)

MBIB0043E

Page 1538 of 3061

DTC P0850 PNP SWITCH

EC-455

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Diagnosis ProcedureINFOID:0000000003531971

1.CHECK DTC WITH TCM

Refer to AT-39, "

OBD-II Diagnostic Trouble Code (DTC)".

OK or NG

OK >> GO TO 2.

NG >> Repair or replace.

2.CHECK STARTING SYSTEM

Turn ignition switch OFF, then turn it to START.

Does starter motor operate?

Ye s o r N o

Yes >> GO TO 3.

No >> Refer to SC-9

.

3.CHECK PNP SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT-I

1. Turn ignition switch OFF.

2. Disconnect A/T assembly harness connector.

3. Disconnect combination meter harness connector.

4. Check harness continuity between A/T assembly terminal 9 and combination meter terminal 39.

Refer to Wiring Diagram.

5. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors F14, E5

• Harness connectors E152, M31

• Harness for open or short between A/T assembly and combination meter

>> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK PNP SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT-II

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 102 and combination meter terminal 40.

Refer to Wiring Diagram.

3. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 7.

NG >> GO TO 6.

TER-

MI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

102 GR/R PNP switch[Ignition switch: ON]

• Selector lever: P or NApproximately 0V

[Ignition switch: ON]

• Except the above gear positionBATTERY VOLTAGE

(11 - 14V)

Continuity should exist.

Continuity should exist.

Page 1540 of 3061

DTC P1140, P1145 IVT CONTROL POSITION SENSOR

EC-457

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

DTC P1140, P1145 IVT CONTROL POSITION SENSOR

Component DescriptionINFOID:0000000003531972

Intake valve timing control position sensors are located in the front of

cylinder heads in both bank 1 and bank 2.

This sensor uses a Hall IC.

The cam position is determined by the intake camshaft sprocket con-

cave (in four places). The ECM provides feedback to the intake valve

timing control for appropriate target valve open-close timing accord-

ing to drive conditions based on detected cam position.

CONSULT-II Reference Value in Data Monitor ModeINFOID:0000000003531973

Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000003531974

DTC Confirmation ProcedureINFOID:0000000003531975

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Maintain the following conditions for at least 10 seconds.

4. If 1st trip DTC is detected, go to EC-461, "

Diagnosis Procedure".

SEF359Z

MONITOR ITEM CONDITION SPECIFICATION

INT/V TIM (B1)

INT/V TIM (B2)• Engine: After warming up

• Selector lever: P or N

• Air conditioner switch: OFF

•No loadIdle−5° - 5°CA

2,000 rpm Approx. 0° - 20°CA

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1140

11 4 0

(Bank 1)

Intake valve timing control

position sensor circuitAn excessively high or low voltage from the

sensor is sent to ECM.• Harness or connectors

(Intake valve timing control position

sensor circuit is open or shorted)

• Intake valve timing control position

sensor

• Crankshaft position sensor (POS)

• Camshaft position sensor (PHASE)

• Accumulation of debris to the signal

pick-up portion of the camshaft sprock-

et P1145

11 4 5

(Bank 2)

ENG SPEED More than idle speed

Selector lever P or N position

SEF058Y

Page 1542 of 3061

DTC P1140, P1145 IVT CONTROL POSITION SENSOR

EC-459

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)TER-

MI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

72 YIntake valve timing control

position sensor (Bank 1)[Engine is running]

•Warm-up condition

• Idle speed0 - 1.0V

[Engine is running]

• Engine speed: 2,000rpm0 - 1.0V

111 W / BECM relay

(Self shut-off)[Engine is running]

[Ignition switch: OFF]

• For a few seconds after turning ignition

switch OFF0 - 1.5V

[Ignition switch: OFF]

• More than a few seconds after turning igni-

tion switch OFFBATTERY VOLTAGE

(11 - 14V)

11 9

120BR

BRPower supply for ECM[Ignition switch: ON]BATTERY VOLTAGE

(11 - 14V)

PBIB2046E

Page 1544 of 3061

DTC P1140, P1145 IVT CONTROL POSITION SENSOR

EC-461

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

Diagnosis ProcedureINFOID:0000000003531977

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten three ground screws on the body.

Refer to EC-143, "

Ground Inspection".

OK or NG

OK >> GO TO 2.

NG >> Repair or replace ground connections.

2.CHECK INTAKE VALVE TIMING CONTROL POSITION SENSOR POWER SUPPLY CIRCUIT

1. Disconnect intake valve timing control position sensor harness connector.

TER-

MI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

53 LIntake valve timing control

position sensor (Bank 2)[Engine is running]

•Warm-up condition

• Idle speed0 - 1.0V

[Engine is running]

• Engine speed: 2,000 rpm0 - 1.0V

111 W / BECM relay

(Self shut-off)[Engine is running]

[Ignition switch: OFF]

• For a few seconds after turning ignition

switch OFF0 - 1.5V

[Ignition switch: OFF]

• More than a few seconds after turning igni-

tion switch OFFBATTERY VOLTAGE

(11 - 14V)

11 9

120BR

BRPower supply for ECM[Ignition switch: ON]BATTERY VOLTAGE

(11 - 14V)

PBIB2046E

BBIA0354E

Page 1551 of 3061

EC-468

< SERVICE INFORMATION >

DTC P1212 TCS COMMUNICATION LINE

DTC P1212 TCS COMMUNICATION LINE

DescriptionINFOID:0000000003531985

NOTE:

•If DTC P1212 is displayed with DTC U1000 or U1001, first perform the trouble diagnosis for DTC

U1000, U1001. Refer to EC-145

.

•If DTC P1212 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer

to EC-147

.

This CAN communication line is used to control the smooth engine operation during the TCS operation. Pulse

signals are exchanged between ECM and “ABS actuator and electric unit (control unit)”.

Be sure to erase the malfunction information such as DTC not only for “ABS actuator and electric unit

(control unit)” but also for ECM after TCS related repair.

On Board Diagnosis LogicINFOID:0000000003531986

Freeze frame data is not stored in the ECM for this self-diagnosis.

The MIL will not light up for this self-diagnosis.

DTC Confirmation ProcedureINFOID:0000000003531987

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10.5V at idle.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Start engine and let it idle for at least 10 seconds.

4. If 1st trip DTC is detected, go to EC-468, "

Diagnosis Procedure"

.

WITH GST

Follow the procedure “WITH CONSULT-II” above.

Diagnosis ProcedureINFOID:0000000003531988

Go to BRC-11.

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1212

1212TCS communication lineECM can not receive the information from

“ABS actuator and electric unit (control

unit)” continuously.• Harness or connectors

(The CAN communication line is open or short-

ed.)

• ABS actuator and electric unit (control unit)

• Dead (Weak) battery

SEF058Y

Page 1560 of 3061

DTC P1225 TP SENSOR

EC-477

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

DTC P1225 TP SENSOR

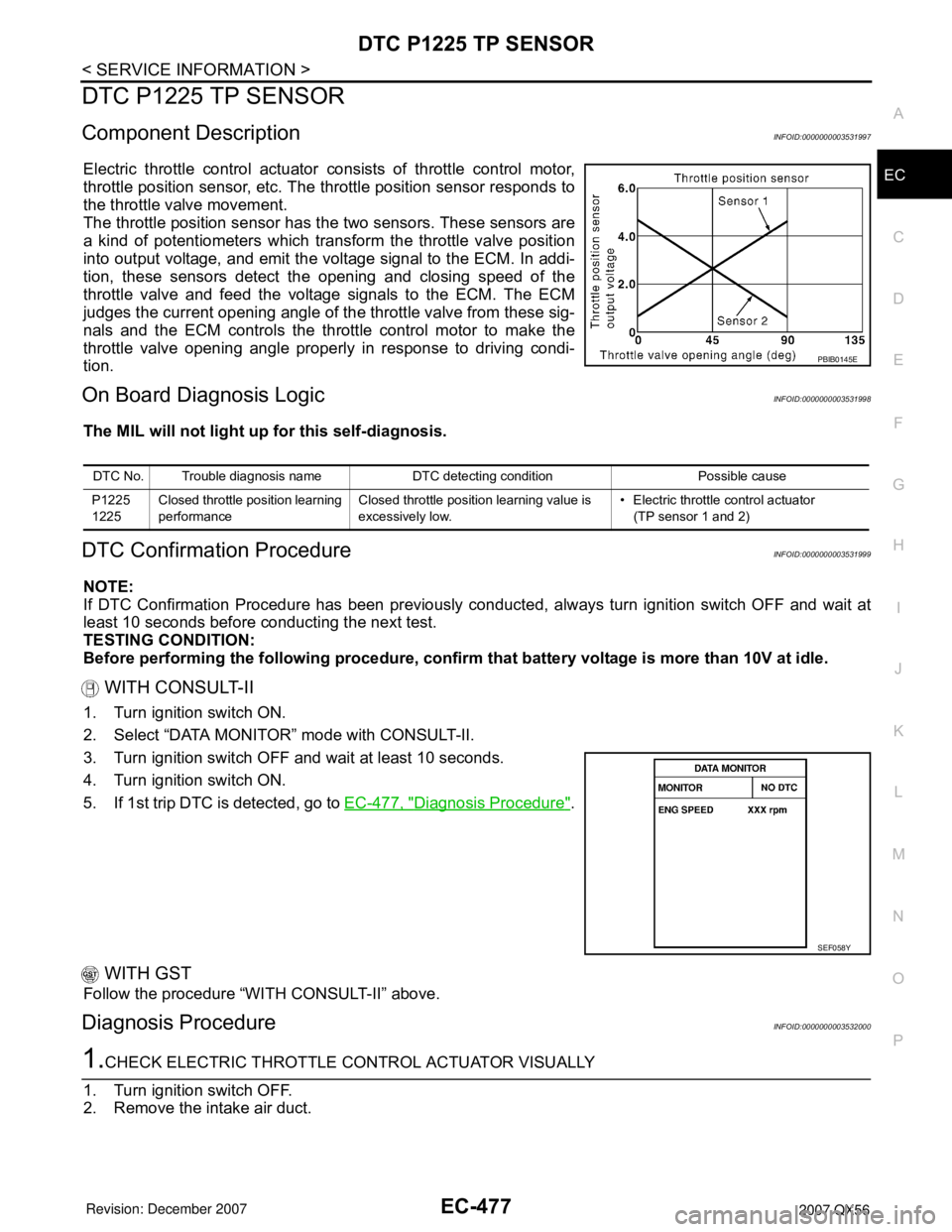

Component DescriptionINFOID:0000000003531997

Electric throttle control actuator consists of throttle control motor,

throttle position sensor, etc. The throttle position sensor responds to

the throttle valve movement.

The throttle position sensor has the two sensors. These sensors are

a kind of potentiometers which transform the throttle valve position

into output voltage, and emit the voltage signal to the ECM. In addi-

tion, these sensors detect the opening and closing speed of the

throttle valve and feed the voltage signals to the ECM. The ECM

judges the current opening angle of the throttle valve from these sig-

nals and the ECM controls the throttle control motor to make the

throttle valve opening angle properly in response to driving condi-

tion.

On Board Diagnosis LogicINFOID:0000000003531998

The MIL will not light up for this self-diagnosis.

DTC Confirmation ProcedureINFOID:0000000003531999

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10V at idle.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Turn ignition switch ON.

5. If 1st trip DTC is detected, go to EC-477, "

Diagnosis Procedure".

WITH GST

Follow the procedure “WITH CONSULT-II” above.

Diagnosis ProcedureINFOID:0000000003532000

1.CHECK ELECTRIC THROTTLE CONTROL ACTUATOR VISUALLY

1. Turn ignition switch OFF.

2. Remove the intake air duct.

PBIB0145E

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1225

1225Closed throttle position learning

performanceClosed throttle position learning value is

excessively low.• Electric throttle control actuator

(TP sensor 1 and 2)

SEF058Y

Page 1562 of 3061

DTC P1226 TP SENSOR

EC-479

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

DTC P1226 TP SENSOR

Component DescriptionINFOID:0000000003532002

Electric throttle control actuator consists of throttle control motor,

throttle position sensor, etc. The throttle position sensor responds to

the throttle valve movement.

The throttle position sensor has the two sensors. These sensors are

a kind of potentiometers which transform the throttle valve position

into output voltage, and emit the voltage signal to the ECM. In addi-

tion, these sensors detect the opening and closing speed of the

throttle valve and feed the voltage signals to the ECM. The ECM

judges the current opening angle of the throttle valve from these sig-

nals and the ECM controls the throttle control motor to make the

throttle valve opening angle properly in response to driving condi-

tion.

On Board Diagnosis LogicINFOID:0000000003532003

The MIL will not light up for this self-diagnosis.

DTC Confirmation ProcedureINFOID:0000000003532004

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10V at idle.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Turn ignition switch ON.

5. Repeat steps 3 and 4 for 32 times.

6. If 1st trip DTC is detected, go to EC-479, "

Diagnosis Procedure".

WITH GST

Follow the procedure “WITH CONSULT-II” above.

Diagnosis ProcedureINFOID:0000000003532005

1.CHECK ELECTRIC THROTTLE CONTROL ACTUATOR VISUALLY

1. Turn ignition switch OFF.

2. Remove the intake air duct.

PBIB0145E

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1226

1226Closed throttle position learning

performanceClosed throttle position learning is not performed

successfully, repeatedly.• Electric throttle control actuator

(TP sensor 1 and 2)

SEF058Y

Page 1566 of 3061

DTC P1550 BATTERY CURRENT SENSOR

EC-483

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

DTC P1550 BATTERY CURRENT SENSOR

Component DescriptionINFOID:0000000003532011

The power generation voltage variable control enables fuel con-

sumption to be decreased by reducing the engine load which is

caused by the power generation of the generator. The battery cur-

rent sensor (1) is installed to the battery cable at the negative termi-

nal. The sensor measures the charging/discharging current of the

battery. Based on the sensor signal, ECM judges whether or not the

power generation voltage variable control is performed. When per-

forming the power generation voltage variable control, ECM calcu-

lates the target power generation voltage based on the sensor

signal. And ECM sends the calculated value as the power genera-

tion command value to IPDM E/R. For the details of the power gen-

eration voltage variable control, refer to SC section.

CAUTION:

Do not connect the electrical component or the ground wire directly to the battery terminal. The con-

nection causes the malfunction of the power generation voltage variable control, and then the battery

discharge may occur.

CONSULT-II Reference Value in Data Monitor ModeINFOID:0000000003532012

Specification data are reference values.

*: Before measuring the terminal voltage, confirm that the battery is fully charged. Refer to SC-4, "How to Handle Battery".

On Board Diagnosis LogicINFOID:0000000003532013

The MIL will not light up for this self-diagnosis.

NOTE:

If DTC P1550 is displayed with DTC P0643, first perform the trouble diagnosis for DTC P0643. Refer to

EC-447

.

DTC Confirmation ProcedureINFOID:0000000003532014

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 8V at idle.

WITH CONSULT-II

1. Turn ignition switch ON.

BBIA0744E

MONITOR ITEM CONDITION SPECIFICATION

BAT CUR SEN• Engine speed: Idle

• Battery: Fully charged*

• Selector lever: P or N

• Air conditioner switch: OFF

•No loadApprox. 2,600 - 3,500mV

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1550

1550Battery current sensor circuit

range/performanceThe output voltage of the battery current

sensor remains within the specified

range while engine is running.• Harness or connectors

(The sensor circuit is open or shorted.)

• Battery current sensor

Page 1570 of 3061

DTC P1550 BATTERY CURRENT SENSOR

EC-487

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

3. Check voltage between battery current sensor terminal 1 and

ground with CONSULT-II or tester.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E5, F14

• Harness for open or short between battery current sensor and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK BATTERY CURRENT SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between battery current sensor terminal 2 and ECM terminal 67.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 6.

NG >> GO TO 5.

5.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E5, F14

• Harness for open or short between battery current sensor and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors.

6.CHECK BATTERY CURRENT SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between battery current sensor terminal 3 and ECM terminal 71.

Refer to Wiring Diagram.

2. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 8.

NG >> GO TO 7.

7.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E2, F32

• Harness for open or short between battery current sensor and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors.

8.CHECK BATTERY CURRENT SENSOR

Refer to EC-488, "

Component Inspection". Voltage: Approximately 5V

PBIA9891J

Continuity should exist.

Continuity should exist.