height INFINITI QX56 2007 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1342 of 3061

DTC P0133, P0153 A/F SENSOR 1

EC-259

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

5. Also check harness for short to power.

OK or NG

OK >> GO TO 9.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

9.CHECK AIR FUEL RATIO (A/F) SENSOR 1 HEATER

Refer to EC-168, "

Component Inspection".

OK or NG

OK >> GO TO 10.

NG >> GO TO 13.

10.CHECK MASS AIR FLOW SENSOR

Refer to EC-192, "

Component Inspection".

OK or NG

OK >> GO TO 11.

NG >> Replace mass air flow sensor.

11 .CHECK PCV VALVE

Refer to EC-45, "

Component Inspection".

OK or NG

OK >> GO TO 12.

NG >> Repair or replace PCV valve.

12.CHECK INTERMITTENT INCIDENT

Perform EC-138

.

OK or NG

OK >> GO TO 13.

NG >> Repair or replace.

13.REPLACE AIR FUEL RATIO (A/F) SENSOR 1

Replace malfunctioning air fuel ratio (A/F) sensor 1.

CAUTION:

• Discard any air fuel ratio (A/F) sensor which has been dropped from a height of more than 0.5 m

(19.7 in) onto a hard surface such as a concrete floor; use a new one.

• Before installing new air fuel ratio (A/F) sensor, clean exhaust system threads (using Oxygen Sensor

Thread Cleaner tool J-43897-18 or J-43897-12) and approved anti-seize lubricant.

>>INSPECTION END

Removal and InstallationINFOID:0000000003531764

AIR FUEL RATIO (A/F) SENSOR 1

Refer to EM-21.

Page 1351 of 3061

EC-268

< SERVICE INFORMATION >

DTC P0137, P0157 HO2S2

6. Select “FUEL INJECTION” in “ACTIVE TEST” mode, and select

“HO2S2 (B1)/(B2)” as the monitor item with CONSULT-II.

7. Check “HO2S2 (B1)/(B2)” at idle speed when adjusting “FUEL INJECTION” to ±25%.

“HO2S2 (B1)/(B2)” should be above 0.58V at least once when the “FUEL INJECTION” is +25%.

“HO2S2 (B1)/(B2)” should be below 0.18V at least once when the “FUEL INJECTION” is −25%.

CAUTION:

• Discard any heated oxygen sensor which has been dropped from a height of more than 0.5 m (19.7

in) onto a hard surface such as a concrete floor; use a new one.

• Before installing new oxygen sensor, clean exhaust system threads using Oxygen Sensor Thread

Cleaner tool J-43897-18 or J-43897-12 and approved anti-seize lubricant.

Without CONSULT-II

1. Start engine and warm it up to the normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

4. Let engine idle for 1 minute.

5. Set voltmeter probes between ECM terminal 55 [HO2S2 (B1) signal] or 74 [HO2S2 (B2) signal] and

ground.

6. Check the voltage when revving up to 4,000 rpm under no load

at least 10 times.

(Depress and release accelerator pedal as soon as possible.)

The voltage should be above 0.58V at least once during this

procedure.

If the voltage is above 0.58V at step 6, step 7 is not neces-

sary.

7. Keep vehicle at idling for 10 minutes, then check voltage. Or

check the voltage when coasting from 80 km/h (50 MPH) in D

position.

The voltage should be below 0.18V at least once during this

procedure.

8. If NG, replace heated oxygen sensor 2.

CAUTION:

• Discard any heated oxygen sensor which has been dropped from a height of more than 0.5 m (19.7

in) onto a hard surface such as a concrete floor; use a new one.

• Before installing new oxygen sensor, clean exhaust system threads using Oxygen Sensor Thread

Cleaner tool J-43897-18 or J-43897-12 and approved anti-seize lubricant.

PBIB1672E

PBIB2636E

PBIB2054E

Page 1364 of 3061

DTC P0138, P0158 HO2S2

EC-281

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

“HO2S2 (B1)/(B2)” should be above 0.58V at least once when the “FUEL INJECTION” is +25%.

“HO2S2 (B1)/(B2)” should be below 0.18V at least once when the “FUEL INJECTION” is −25%.

CAUTION:

• Discard any heated oxygen sensor which has been dropped from a height of more than 0.5 m (19.7

in) onto a hard surface such as a concrete floor; use a new one.

• Before installing new oxygen sensor, clean exhaust system threads using Oxygen Sensor Thread

Cleaner tool J-43897-18 or J-43897-12 and approved anti-seize lubricant.

Without CONSULT-II

1. Start engine and warm it up to the normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

4. Let engine idle for 1 minute.

5. Set voltmeter probes between ECM terminal 55 [HO2S2 (B2) signal] or 74 [HO2S2 (B1) signal] and

ground.

6. Check the voltage when revving up to 4,000 rpm under no load

at least 10 times.

(Depress and release accelerator pedal as soon as possible.)

The voltage should be above 0.58V at least once during this

procedure.

If the voltage is above 0.58V at step 6, step 7 is not neces-

sary.

7. Keep vehicle at idling for 10 minutes, then check voltage. Or

check the voltage when coasting from 80 km/h (50 MPH) in D

position.

The voltage should be below 0.18V at least once during this

procedure.

8. If NG, replace heated oxygen sensor 2.

CAUTION:

• Discard any heated oxygen sensor which has been dropped from a height of more than 0.5 m (19.7

in) onto a hard surface such as a concrete floor; use a new one.

• Before installing new oxygen sensor, clean exhaust system threads (using Oxygen Sensor Thread

Cleaner tool J-43897-18 or J-43897-12) and approved anti-seize lubricant.

Removal and InstallationINFOID:0000000003531782

HEATED OXYGEN SENSOR 2

Refer to EM-21.

PBIB2054E

Page 1373 of 3061

EC-290

< SERVICE INFORMATION >

DTC P0139, P0159 HO2S2

6. Select “FUEL INJECTION” in “ACTIVE TEST” mode, and select

“HO2S2 (B1)/(B2)” as the monitor item with CONSULT-II.

7. Check “HO2S2 (B1)/(B2)” at idle speed when adjusting “FUEL INJECTION” to ±25%.

“HO2S2 (B1)/(B2)” should be above 0.58V at least once when the “FUEL INJECTION” is +25%.

“HO2S2 (B1)/(B2)” should be below 0.18V at least once when the “FUEL INJECTION” is −25%.

CAUTION:

• Discard any heated oxygen sensor which has been dropped from a height of more than 0.5 m (19.7

in) onto a hard surface such as a concrete floor; use a new one.

• Before installing new oxygen sensor, clean exhaust system threads using Oxygen Sensor Thread

Cleaner tool J-43897-18 or J-43897-12 and approved anti-seize lubricant.

Without CONSULT-II

1. Start engine and warm it up to the normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

4. Let engine idle for 1 minute.

5. Set voltmeter probes between ECM terminal 55 [HO2S2 (B1) signal] or 74 [HO2S2 (B2) signal] and

ground.

6. Check the voltage when revving up to 4,000 rpm under no load

at least 10 times.

(Depress and release accelerator pedal as soon as possible.)

The voltage should be above 0.58V at least once during this

procedure.

If the voltage is above 0.58V at step 6, step 7 is not neces-

sary.

7. Keep vehicle at idling for 10 minutes, then check voltage. Or

check the voltage when coasting from 80 km/h (50 MPH) in D

position.

The voltage should be below 0.18V at least once during this

procedure.

8. If NG, replace heated oxygen sensor 2.

CAUTION:

• Discard any heated oxygen sensor which has been dropped from a height of more than 0.5 m (19.7

in) onto a hard surface such as a concrete floor; use a new one.

• Before installing new oxygen sensor, clean exhaust system threads using Oxygen Sensor Thread

Cleaner tool J-43897-18 or J-43897-12 and approved anti-seize lubricant.

PBIB1672E

PBIB2636E

PBIB2054E

Page 1413 of 3061

EC-330

< SERVICE INFORMATION >

DTC P0300 - P0308 MULTIPLE CYLINDER MISFIRE, NO. 1 - 8 CYLINDER MIS-

FIRE

5. Check harness continuity between the following terminals and ground.

Refer to Wiring Diagram.

6. Also check harness for short to power.

OK or NG

OK >> GO TO 14.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

14.CHECK A/F SENSOR 1 HEATER

Refer to EC-168, "

Component Inspection" .

OK or NG

OK >> GO TO 16.

NG >> GO TO 15.

15.REPLACE AIR FUEL RATIO (A/F) SENSOR 1

Replace malfunctioning air fuel ratio (A/F) sensor 1.

CAUTION:

• Discard any air fuel ratio (A/F) sensor which has been dropped from a height of more than 0.5 m

(19.7 in) onto a hard surface such as a concrete floor; use a new one.

• Before installing new air fuel ratio (A/F) sensor, clean exhaust system threads (using Oxygen Sensor

Thread Cleaner tool J-43897-18 or J-43897-12) and approved anti-seize lubricant.

>>INSPECTION END

16.CHECK MASS AIR FLOW SENSOR

Check mass air flow sensor signal in “DATA MONITOR” mode with CONSULT-II.

With GST

Check mass air flow sensor signal in Service $01 with GST.

OK or NG

OK >> GO TO 17.

NG >> Check connectors for rusted terminals or loose connections in the mass air flow sensor circuit or

ground. Refer to EC-186

.

17.CHECK SYMPTOM MATRIX CHART

Check items on the rough idle symptom in EC-90, "

Symptom Matrix Chart" .

OK or NG

OK >> GO TO 18.

Bank 2116

275

Continuity should exist.

Bank 1 Bank 2

A/F sensor 1 terminal ECM terminal A/F sensor 1 terminal ECM terminal

135116

256275

Continuity should not exist.

3.0 - 9.0 g·m/sec: at idling

9.0 - 28.0 g·m/sec: at 2,500 rpm

3.0 - 9.0 g·m/sec: at idling

9.0 - 28.0 g·m/sec: at 2,500 rpm

Page 1679 of 3061

EC-596

< SERVICE INFORMATION >

DTC P2A00, P2A03 A/F SENSOR 1

OK >> GO TO 10.

NG >> GO TO 11.

10.CHECK INTERMITTENT INCIDENT

Perform EC-138

.

OK or NG

OK >> GO TO 11.

NG >> Repair or replace.

11 .REPLACE AIR FUEL RATIO (A/F) SENSOR 1

Replace malfunctioning air fuel ratio (A/F) sensor 1.

CAUTION:

• Discard any A/F sensor which has been dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

• Before installing new A/F sensor, clean exhaust system threads using Oxygen Sensor Thread

Cleaner tool J-43897-18 or J-43897-12 and approved anti-seize lubricant.

>> GO TO 12.

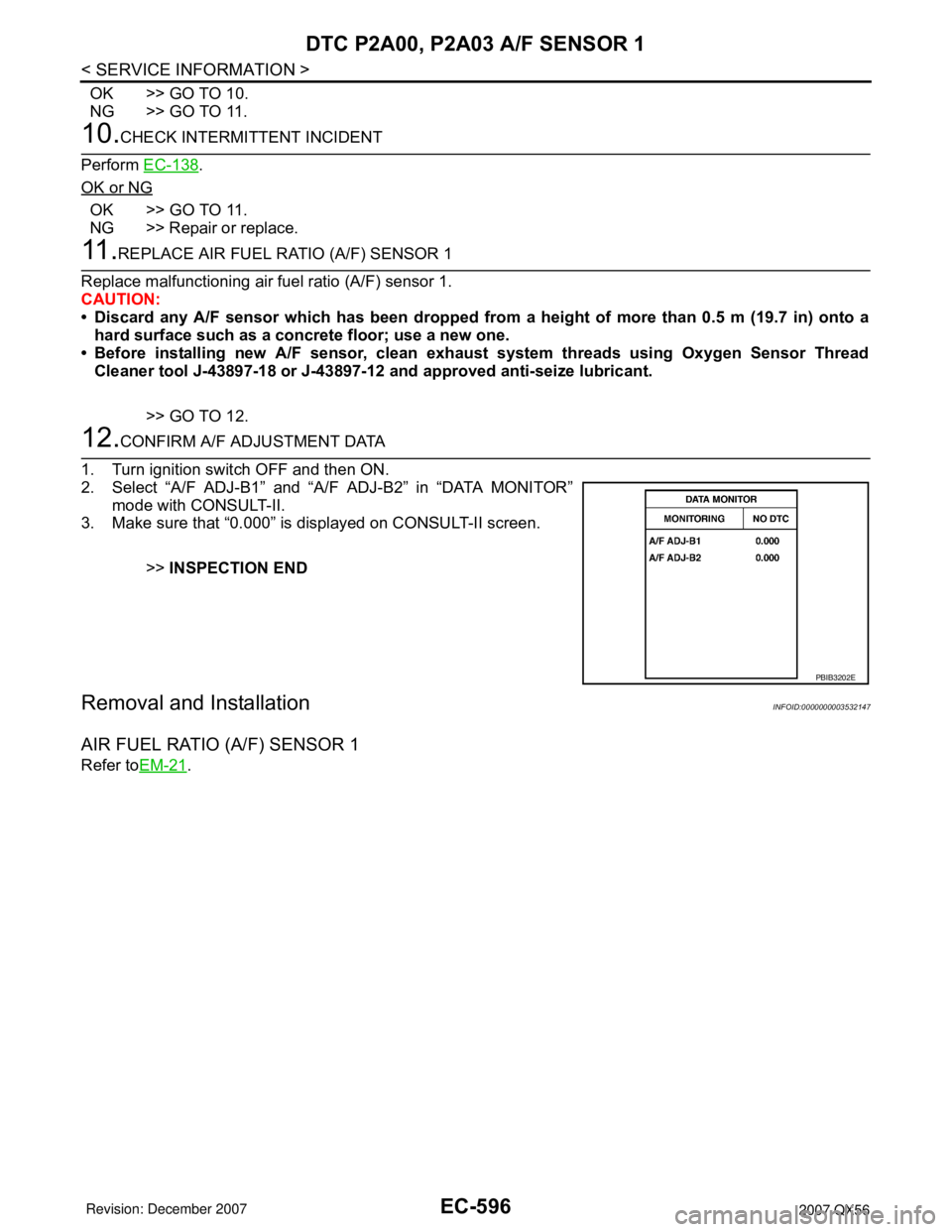

12.CONFIRM A/F ADJUSTMENT DATA

1. Turn ignition switch OFF and then ON.

2. Select “A/F ADJ-B1” and “A/F ADJ-B2” in “DATA MONITOR”

mode with CONSULT-II.

3. Make sure that “0.000” is displayed on CONSULT-II screen.

>>INSPECTION END

Removal and InstallationINFOID:0000000003532147

AIR FUEL RATIO (A/F) SENSOR 1

Refer toEM-21.

PBIB3202E

Page 1820 of 3061

EM-50

< SERVICE INFORMATION >

CAMSHAFT

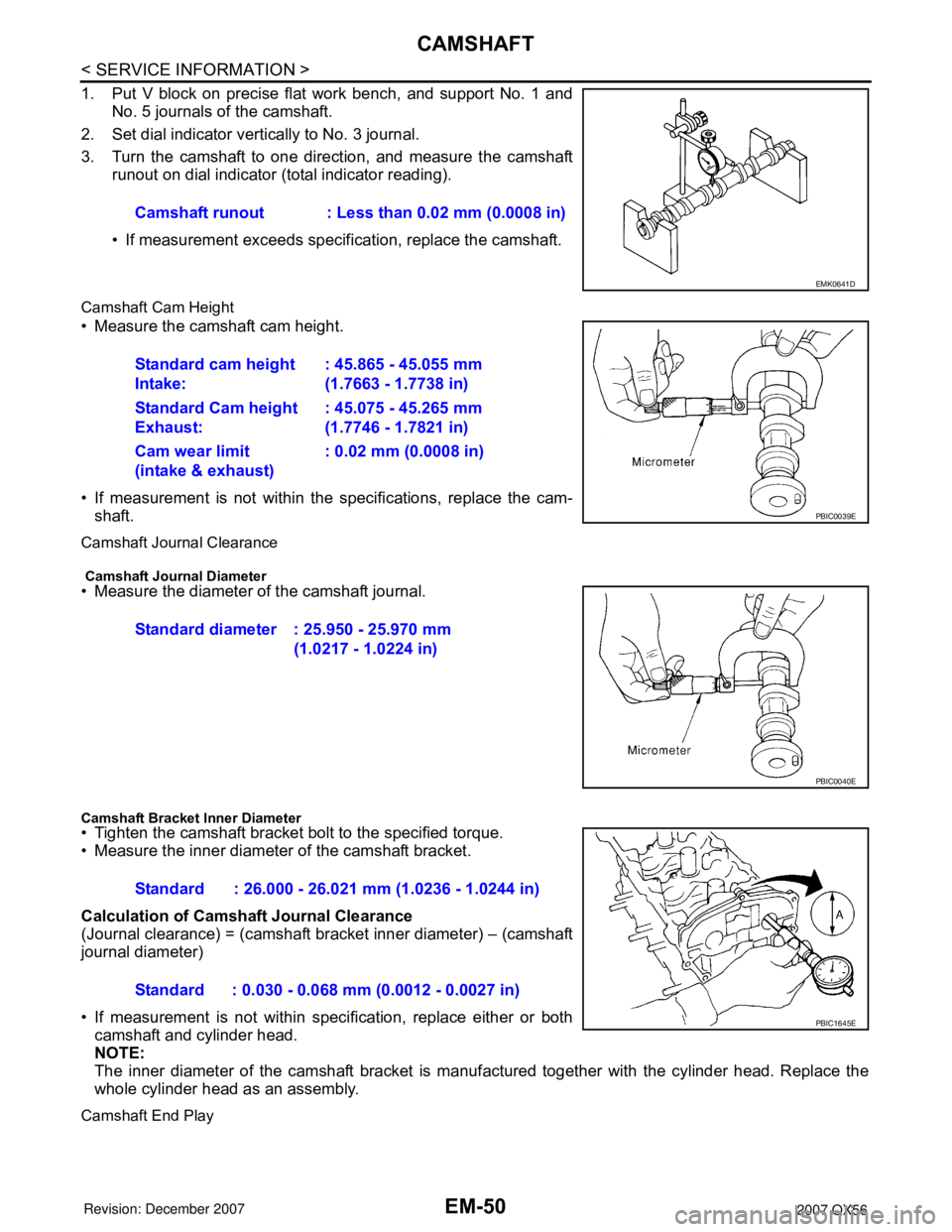

1. Put V block on precise flat work bench, and support No. 1 andNo. 5 journals of the camshaft.

2. Set dial indicator vertically to No. 3 journal.

3. Turn the camshaft to one direction, and measure the camshaft runout on dial indicator (total indicator reading).

• If measurement exceeds specif ication, replace the camshaft.

Camshaft Cam Height

• Measure the camshaft cam height.

• If measurement is not within the specifications, replace the cam-

shaft.

Camshaft Journal Clearance

Camshaft Journal Diameter• Measure the diameter of the camshaft journal.

Camshaft Bracket Inner Diameter• Tighten the camshaft bracket bolt to the specified torque.

• Measure the inner diameter of the camshaft bracket.

Calculation of Camshaft Journal Clearance

(Journal clearance) = (camshaft bracket inner diameter) – (camshaft

journal diameter)

• If measurement is not within spec ification, replace either or both

camshaft and cylinder head.

NOTE:

The inner diameter of the camshaft bracket is manuf actured together with the cylinder head. Replace the

whole cylinder head as an assembly.

Camshaft End Play

Camshaft runout : Less than 0.02 mm (0.0008 in)

EMK0641D

Standard cam height

Intake: : 45.865 - 45.055 mm

(1.7663 - 1.7738 in)

Standard Cam height

Exhaust: : 45.075 - 45.265 mm

(1.7746 - 1.7821 in)

Cam wear limit

(intake & exhaust) : 0.02 mm (0.0008 in)

PBIC0039E

Standard diameter : 25.950 - 25.970 mm

(1.0217 - 1.0224 in)

PBIC0040E

Standard : 26.000 - 26.021 mm (1.0236 - 1.0244 in)

Standard : 0.030 - 0.068 mm (0.0012 - 0.0027 in)

PBIC1645E

Page 1831 of 3061

OIL SEALEM-61

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

OIL SEAL

Removal and Installation of Valve Oil SealINFOID:0000000003531537

REMOVAL

1. Remove the camshaft relating to the valve oil seal to be removed. Refer to

EM-46, "Removal and Installa-

tion".

2. Remove the valve lifters. Refer to EM-65, "

Removal and Installation".

• Correctly identify the location where each part is removed from. Keep parts organized to avoid mixing

them up.

3. Turn the crankshaft until the cylinder requiring new oil seals is at TDC. This will prevent the valve from

dropping into the cylinder.

4. Remove the valve collet using Tool.

CAUTION:

Do not damage the valve lifter holes.

5. Remove the valve spring retainer and valve spring. CAUTION:

Do not remove the valve spring seat from the valve spring.

6. Remove the valve oil seal using Tool.

INSTALLATION

Installation is in the reverse order of removal.

• Install the valve oil seal using Tool.

• Apply new engine oil on the new valve oil seal joint and seal lip.

• Install the valve oil seal to the specified height "H".

Removal and Installati on of Front Oil SealINFOID:0000000003531538

REMOVAL

1. Remove the engine. Refer to EM-74, "Removal and Installation".

2. Remove the crankshaft pulley. Refer to EM-38, "

Removal and Installation".

Tool number : KV10116200 (J-26336-A)

: KV10115900 (J-26336-20)

: KV10109220 ( — )

WBIA0578E

Tool number : KV10107902 (J-38959)

WBIA0478E

Tool number : KV10115600 (J-38958)

Height "H" (without valve spring installed)Intake and exhaust : 14.3 - 14.9 mm (0.563 - 0.587 in)

WBIA0490E

Page 1832 of 3061

EM-62

< SERVICE INFORMATION >

OIL SEAL

3. Remove the front oil seal using suitable tool.CAUTION:

Do not damage front cover and oil pump drive spacer.

INSTALLATION

1. Apply new engine oil to both the oil seal lip and dust seal lip of the new front oil seal.

2. Install the front oil seal.• Install the front oil seal so that each seal lip is oriented as

shown.

• Press-fit until the height of the front oil seal is level with the mounting surface using suitable tool.

CAUTION:

• Do not damage front timing chain case and crankshaft.

• Press-fit straight and avoid causing burrs or tilting oil

seal.

3. Installation of the remaining components is in the reverse order of removal.

Removal and Installation of Rear Oil SealINFOID:0000000003531539

REMOVAL

1. Remove the transmission assembly. Refer to AT-223, "Removal and Installation (2WD)" or AT-225,

"Removal and Installation (4WD)".

2. Lock the drive plate using Tool A.

CAUTION:

Do not damage the drive plat e. Especially, avoid deforming

and damaging the signal plat e teeth (circumference posi-

tion).

Keep magnetic materials away from signal plate.

NOTE:

Remove the bolts diagonally.

SBIA0359E

SEM715A

PBIC2931E

Tool number : — (J-47245)

LBIA0455E

Page 1838 of 3061

EM-68

< SERVICE INFORMATION >

CYLINDER HEAD

7. Remove the valve oil seal using Tool.

8. Replace the valve seat if necessary. Refer to EM-69, "

Inspection After Disassembly".

9. Replace the valve guide if necessary. Refer to EM-69, "

Inspection After Disassembly".

10. Remove the spark plug tube, as necessary.

• Remove the spark plug tube out of the cylinder head using suitable tool.

CAUTION:

• Do not damage the cylinder head.

• Do not remove the spark plug tube unless absolutely necessary. Once removed, the spark plug

tube will be deformed and cannot be reused.

ASSEMBLY

1. Install the valve guide if necessary. Refer to EM-69, "Inspection After Disassembly".

2. Install the valve seat if necessary. Refer to EM-69, "

Inspection After Disassembly".

3. Install the valve oil seal using Tool.

• Apply new engine oil on the new valve oil seal joint and seal

lip.

• Install the valve oil seal to the specified height "H".

4. Install the valves in their original position.

5. Install the valve spring seats.

6. Install the valve springs.

• Install the narrow pitch end (paint mark side) to the cylinder

head side.

7. Install the valve spring retainers.Tool number : KV10107902 (J-38959)

WBIA0478E

Tool number : KV10115600 (J-38958)

Height "H" (without valve spring installed)

Intake and exhaust : 14.3 - 14.9 mm (0.563 - 0.587 in)

WBIA0490E

SEM085D