height INFINITI QX56 2007 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2014 of 3061

GI-48

< SERVICE INFORMATION >

IDENTIFICATION INFORMATION

ENGINE SERIAL NUMBER

TRANSFER SERIAL NUMBER

AUTOMATIC TRANSMISSION NUMBER

DimensionsINFOID:0000000003531505

Unit: mm (in)

Wheels & TiresINFOID:0000000003531506

LAIA0044E

LAIA0048E

PAIA0054E

Drive type2WD 4WD

Overall length 5255 (206.9) 5255 (206.9)

Overall width 2001 (78.8) 2001 (78.8)

Overall height (with roof rack) 1976.8 (77.0) 1997.7 (77.8)

Front tread width 1725 (67.9) 1725 (67.9)

Rear tread width 1725 (67.9) 1725 (67.9)

Wheelbase 3130 (123.2) 3130 (123.2)

Minimum Running Ground Clearance (at front suspen-

sion)With standard

undercover254.8 (10.03) 273.7 (10.77)

With oil pan skid

plate250.5 (9.86) 269.5 (10.61)

Page 2109 of 3061

IDX-5

A

C

D

E

F

G

H

I

J

K

L B

IDX

ALPHABETICAL INDEX

Grease .............................................................. MA-11

Ground distribution ............................................ PG-31

H

H/AIM - Wiring diagram ...................................... LT-51

H/LAMP - Wiring diagram .................................... LT-9

Handling precautions for plastics ..................... BL-179

Harness connector ............................................ PG-68

Harness layout .................................................. PG-41

Hazard warning lamp ......................................... LT-63

Headlamp ............................................................. LT-5

Headlamp aiming control ................................... LT-51

Headlamp leveler - See Headlamp aiming control . LT-

51

Headlamp removal and installation .................... LT-25

Heated oxygen sensor 2 (bank 1) .... EC-276, EC-287,

EC-300

Heated oxygen sensor 2 (bank 2) .... EC-276, EC-287,

EC-300

Heated oxygen sensor 2 heater (bank 1) ........ EC-181

Heated oxygen sensor 2 heater (bank 2) ........ EC-181

Heated seat ....................................................... SE-82

Heater and cooling unit (Heater core) . ATC-157, ATC-

160

Heater unit (heater core) ............... ATC-157, ATC-160

Height (Dimensions) ........................................... GI-51

HFC134a (R134a) system identification ........... ATC-6

HFC134a (R134a) system precaution ............... ATC-5

HFC134a (R134a) system service procedure ATC-175

HFC134a (R134a) system service tools ......... ATC-14

HFC134a system service equipment precaution ATC-

11

High and low reverse clutch solenoid valve .... AT-147,

AT-149

Homelink universal transceiver ........................ BL-146

Horn ................................................................ WW-48

HORN - Wiring diagram .................................. WW-48

How to erase DTC for OBD system .................. EC-63

HSEAT - Wiring diagram ................................... SE-84

I

IATS - Wiring diagram ..................................... EC-215

ICC - Wiring diagram ....................................... ACS-20

ICC/BS - Wiring diagram ................................. EC-565

ICC/SW - Wiring diagram ................................ EC-550

ICCBOF - Wiring diagram ............................... EC-672

Identification plate .............................................. GI-49

Idle air volume learning ..................................... EC-80

Idle speed .............................................. EC-73, EC-78

Idle speed control (ISC) .................... EC-466, EC-468

Ignition coil .......................................... EM-28, EC-679

Ignition control system .................................... EC-679

Ignition key hole illumination ............................ LT-110

Ignition timing ........................................ EC-73, EC-78

IGNSYS - Wiring diagram ............................... EC-680

ILL - Wiring diagram ......................................... LT-136

Illumination ....................................................... LT-130

In vehicle sensor ........................... ATC-141, ATC-150

In-cabin Microfilter ............................................. MA-21

INJECT - Wiring diagram ................................. EC-660

Injector ............................................................. EC-659

Input clutch solenoid valve ................. AT-135, AT-137

Instrument panel .................................................. IP-10

Intake air temperature sensor ............ EC-214, EC-234

Intake door control linkage adjustment . ATC-85, ATC-

88

Intake door motor ........................... ATC-83, ATC-164

Intake manifold .................................................. EM-17

Intake sensor ................................ ATC-146, ATC-152

Intake valve timing control (Bank 1) ................ EC-161

Intake valve timing control (Bank 2) ................ EC-161

Intake valve timing control position sensor (Bank 1) ....

EC-492

Intake valve timing control position sensor (Bank 2) ....

EC-492

Intake valve timing control solenoid valve (Bank 1) EC-

189

Intake valve timing control solenoid valve (Bank 2) EC-

189

Integrated homelink transmitter - See Homelink univer-

sal tranceiver .................................................... BL-146

Intelligent cruise control (ICC) system ............... ACS-6

Interior ................................................................. EI-35

Interior lamp ...................................................... LT-110

Interior lamp on-off control ................................ LT-111

Internal gear (Transfer) ....................... TF-149, TF-176

IPDM (Intelligent power distribution module engine

room) ................................................................. PG-18

IVCB1 - Wiring diagram ................................... EC-190

IVCB2 - Wiring diagram ................................... EC-192

IVCSB1 - Wiring diagram ................................ EC-493

IVCSB2 - Wiring diagram ................................ EC-495

IVIS (Infiniti vehicle immobilizer system) .......... BL-127

IVIS (Infiniti vehicle immobilizer system) precautions ...

GI-3

IVTB1 - Wiring diagram ................................... EC-164

IVTB2 - Wiring diagram ................................... EC-166

J

Jacking points ..................................................... GI-42

Junction box (J/B) .............................................. PG-76

K

Key illumination ................................................ LT-111

KEYLES - Wiring diagram .................................. BL-45

Knock sensor (KS) ........................................... EC-357

KS - Wiring diagram ........................................ EC-358

L

Laser beam aiming adjustment ....................... ACS-12

Length (Dimensions) .......................................... GI-51

License lamp ...................................................... LT-89

Lifting points ....................................................... GI-43

Page 2262 of 3061

FRONT FOG LAMP

LT-55

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

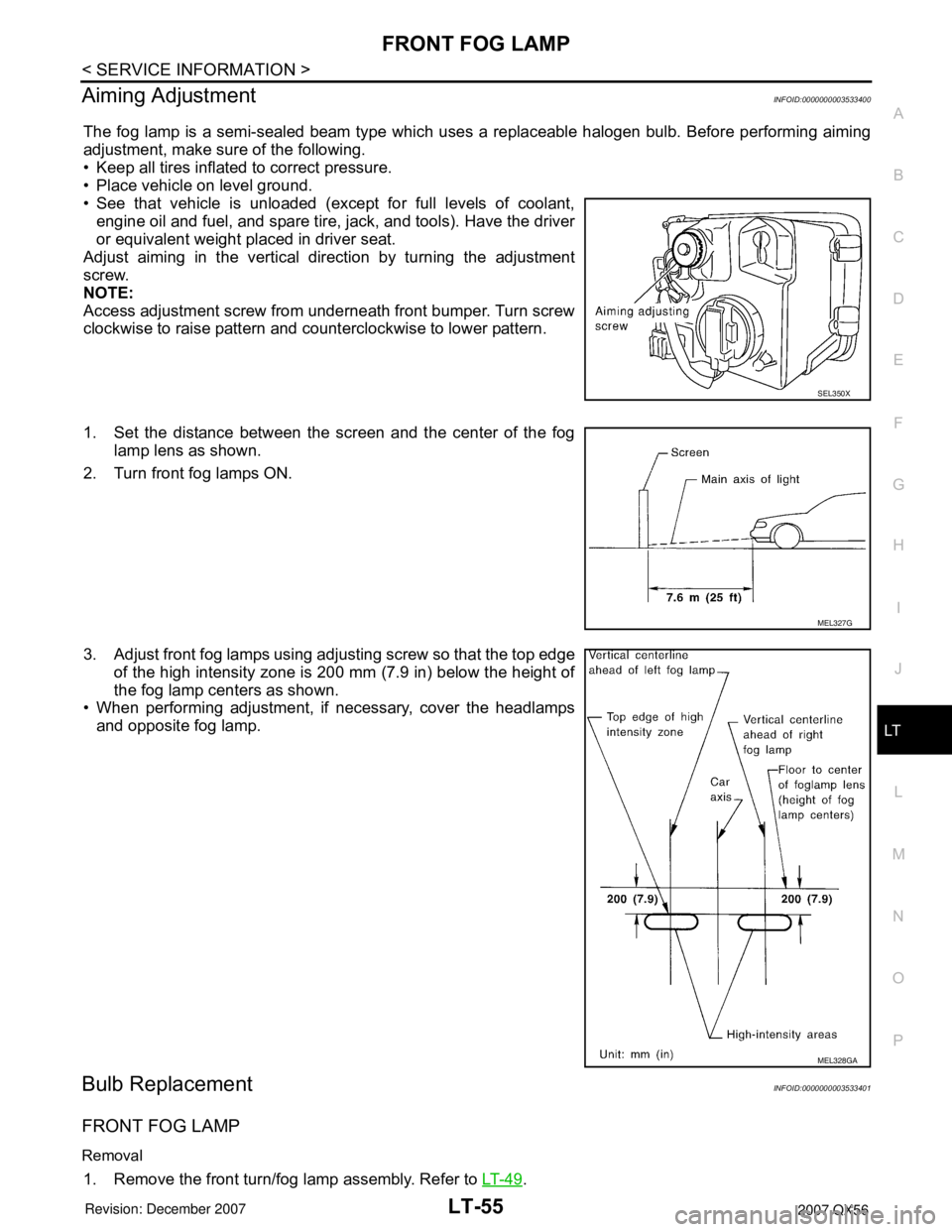

Aiming AdjustmentINFOID:0000000003533400

The fog lamp is a semi-sealed beam type which uses a replaceable halogen bulb. Before performing aiming

adjustment, make sure of the following.

• Keep all tires inflated to correct pressure.

• Place vehicle on level ground.

• See that vehicle is unloaded (except for full levels of coolant,

engine oil and fuel, and spare tire, jack, and tools). Have the driver

or equivalent weight placed in driver seat.

Adjust aiming in the vertical direction by turning the adjustment

screw.

NOTE:

Access adjustment screw from underneath front bumper. Turn screw

clockwise to raise pattern and counterclockwise to lower pattern.

1. Set the distance between the screen and the center of the fog

lamp lens as shown.

2. Turn front fog lamps ON.

3. Adjust front fog lamps using adjusting screw so that the top edge

of the high intensity zone is 200 mm (7.9 in) below the height of

the fog lamp centers as shown.

• When performing adjustment, if necessary, cover the headlamps

and opposite fog lamp.

Bulb ReplacementINFOID:0000000003533401

FRONT FOG LAMP

Removal

1. Remove the front turn/fog lamp assembly. Refer to LT- 4 9.

SEL350X

MEL327G

MEL328GA

Page 2552 of 3061

RF-20

< SERVICE INFORMATION >

SUNROOF

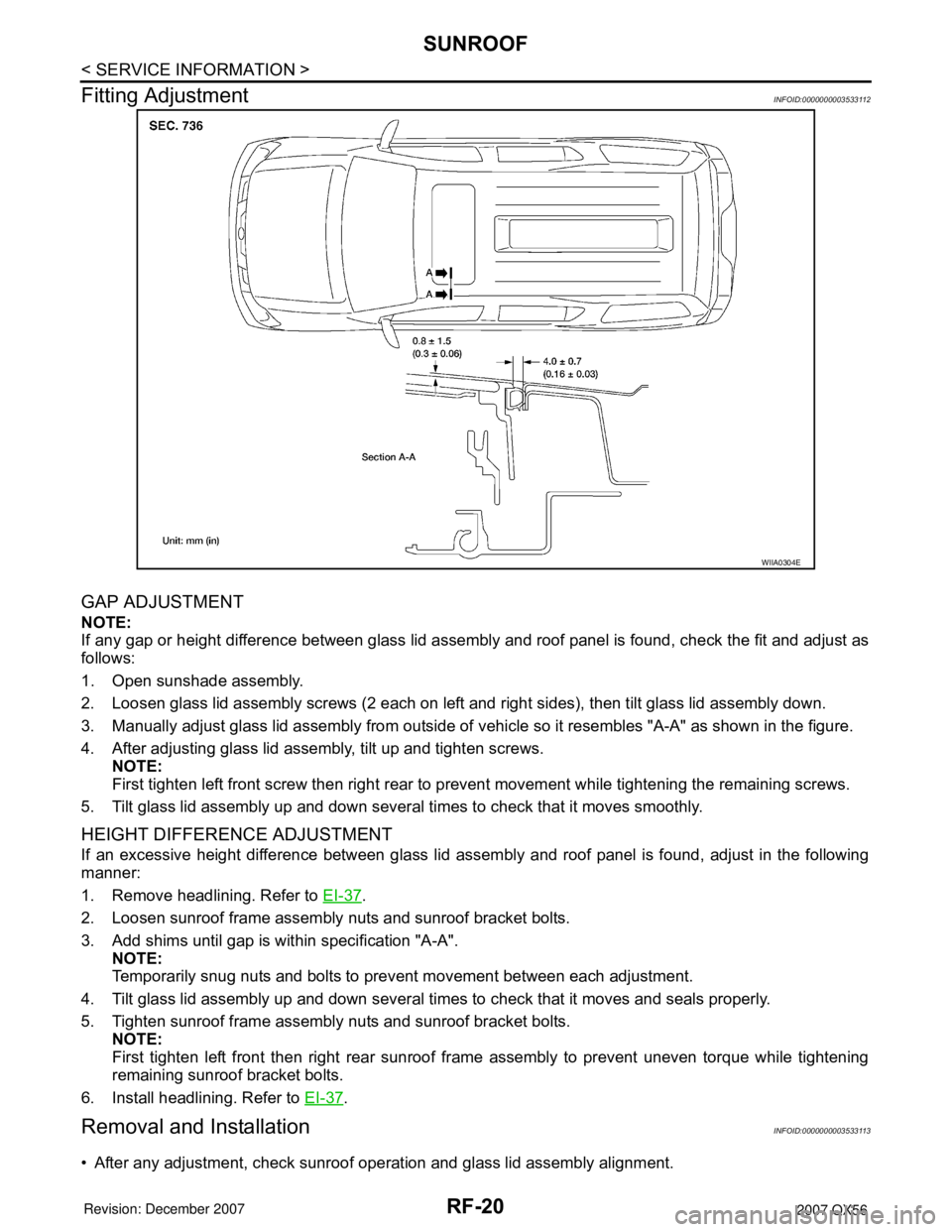

Fitting Adjustment

INFOID:0000000003533112

GAP ADJUSTMENT

NOTE:

If any gap or height difference between glass lid assembly and roof panel is found, check the fit and adjust as

follows:

1. Open sunshade assembly.

2. Loosen glass lid assembly screws (2 each on left and right sides), then tilt glass lid assembly down.

3. Manually adjust glass lid assembly from outside of vehicle so it resembles "A-A" as shown in the figure.

4. After adjusting glass lid assembly, tilt up and tighten screws.

NOTE:

First tighten left front screw then right rear to prevent movement while tightening the remaining screws.

5. Tilt glass lid assembly up and down several times to check that it moves smoothly.

HEIGHT DIFFERENCE ADJUSTMENT

If an excessive height difference between glass lid assembly and roof panel is found, adjust in the following

manner:

1. Remove headlining. Refer to EI-37

.

2. Loosen sunroof frame assembly nuts and sunroof bracket bolts.

3. Add shims until gap is within specification "A-A".

NOTE:

Temporarily snug nuts and bolts to prevent movement between each adjustment.

4. Tilt glass lid assembly up and down several times to check that it moves and seals properly.

5. Tighten sunroof frame assembly nuts and sunroof bracket bolts.

NOTE:

First tighten left front then right rear sunroof frame assembly to prevent uneven torque while tightening

remaining sunroof bracket bolts.

6. Install headlining. Refer to EI-37

.

Removal and InstallationINFOID:0000000003533113

• After any adjustment, check sunroof operation and glass lid assembly alignment.

WIIA0304E

Page 2554 of 3061

RF-22

< SERVICE INFORMATION >

SUNROOF

SUNROOF UNIT

Removal

CAUTION:

• Always work with a helper.

• When taking sunroof unit out, use shop cloths to protect the seats and trim from damage.

• After installing the sunroof unit and glass lid assembly, check gap adjustment to make sure there is

no malfunction.

1. Remove headlining. Refer to EI-37

.

2. Remove the sunroof glass lid assembly. Refer to "GLASS LID ASSEMBLY".

3. Remove overhead console bracket.

4. Disconnect front and rear drain hoses.

5. Remove front sunroof frame assembly bolts.

6. Remove rear sunroof bracket bolts.

7. Remove the sunroof frame assembly side bolts, then the sunroof unit.

Installation

1. Position the sunroof frame assembly and install the side bolts.

2. Install the sunroof brackets and bolts.

3. Install the front sunroof frame assembly bolts.

4. Connect front and rear drain hoses.

5. Install the overhead console bracket.

6. Install the sunroof glass lid assembly. Refer to "GLASS LID ASSEMBLY".

NOTE:

Adjust sunroof glass lid assembly gap and height, refer to RF-20, "

Fitting Adjustment".

7. Install headlining. Refer to EI-37

.

GLASS LID ASSEMBLY

Removal

1. Open sunshade assembly.

NOTE:

Be sure glass lid assembly is fully closed.

2. Remove side cover LH and RH.

3. Remove the glass lid assembly screws at the sunroof frame

assembly.

4. Remove the glass lid assembly.

Installation

1. Position glass lid assembly to sunroof frame assembly.

2. Install glass lid assembly screws.

NOTE:

First tighten left front screw, then right rear to prevent movement while tightening the remaining screws.

1. Glass lid assembly 2. Wind deflector 3. Rear drain hoses

4. Shade stoppers 5. Sunroof bracket 6. Sunshade assembly

7. Front drain hoses 8. Sunroof motor assembly 9. Sunroof frame assembly

10. Overhead console bracket 11. Side cover LH 12. Side cover RH

WIIA0252E

Page 2573 of 3061

RFD-16

< SERVICE INFORMATION >

REAR FINAL DRIVE ASSEMBLY

1. Drive pinion lock nut 2. Companion flange 3. Front oil seal

4. Drive pinion front bearing 5. Collapsible spacer 6. Drive pinion rear bearing

7. Drive pinion height adjusting washer 8. Drive pinion 9. Gear carrier

10. Drive gear 11. Pinion mate shaft 12. Lock pin

13. Pinion mate gear 14. Pinion mate thrust washer 15. Side gear

16. Side gear thrust washer 17. Differential case 18. Side bearing

WDIA0191E

Page 2575 of 3061

RFD-18

< SERVICE INFORMATION >

REAR FINAL DRIVE ASSEMBLY

1. Apply red lead to the drive gear.

NOTE:

Apply red lead to both faces of three to four gears, at four loca-

tions evenly spaced on the drive gear.

2. Rotate the drive gear back and forth several times. Then check

for correct drive pinion to drive gear tooth contact as shown.

CAUTION:

Check tooth contact on drive side and reverse side.

3. If the tooth contact is improperly adjusted, follow the procedure

below to adjust the pinion height (dimension X).

• If the tooth contact is near the face (face contact), or near the heel

(heel contact), use a thicker drive pinion height adjusting washers

to move the drive pinion closer to the drive gear.

Refer to RFD-32, "

Inspection and Adjustment".

• If the tooth contact is near the flank (flank contact), or near the toe

(toe contact), use a thinner drive pinion height adjusting washers to

move the drive pinion farther from the drive gear.

Refer to RFD-32, "

Inspection and Adjustment".

SPD357

SDIA0570E

SDIA0517E

PDIA0440E

PDIA0441E

Page 2580 of 3061

REAR FINAL DRIVE ASSEMBLY

RFD-23

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

RFD

N

O

P

5. Press the drive pinion assembly (with rear inner bearing race

and collapsible spacer) out of the gear carrier.

CAUTION:

Do not drop drive pinion assembly.

6. Remove the front oil seal.

CAUTION:

Do not damage gear carrier.

7. Remove the drive pinion front bearing inner race.

8. Remove the drive pinion rear bearing inner race and drive pinion

height adjusting washer using Tool.

9. Remove the drive pinion front and rear bearing outer races by

tapping them uniformly using suitable tool.

CAUTION:

Do not damage gear carrier.

INSPECTION AFTER DISASSEMBLY

Clean the disassembled parts. Then inspect the parts for wear or damage. If wear or damage are found, follow

the measures below.

Drive Pinion and Drive Gear

• If the drive pinion and drive gear teeth do not mesh or line-up correctly, determine the cause and adjust,

repair, or replace as necessary.

• If the drive pinion or drive gear are worn, cracked, damaged, pitted or chipped (by friction) noticeably,

replace with new drive pinion and drive gear.

• Drive pinion and drive gear are supplied in matched sets only. Matching numbers on both drive pinion and

drive gear are etched for verification. If a new drive pinion and drive gear set are being used, verify the num-

bers of each drive pinion and drive gear before proceeding with assembly.

Bearing

• If bearings are chipped (by friction), pitted, worn, rusted, scratched, or unusual noise is coming from bearing,

replace with new bearing assembly (as a new set).

• Bearing must be replaced with a new one whenever disassembled.

Side Gear and Pinion Mate Gear

• If any cracks or damage are found on the surface of the teeth, replace with new one.

• If any worn or chipped marks are found on the side of the side gear and pinion mate gear which contact the

thrust washer, replace with new one.

• Replace both side gear and pinion mate gear as a set when replacing side gear or pinion mate gear.

Side Gear Thrust Washer and Pinion Mate Thrust Washer

• If any chips (by friction), damage, or unusual wear are found, replace with new one.

SPD892

Tool number: : ST30021000 ( — )

S-PD179

SDIA0817E

Page 2583 of 3061

RFD-26

< SERVICE INFORMATION >

REAR FINAL DRIVE ASSEMBLY

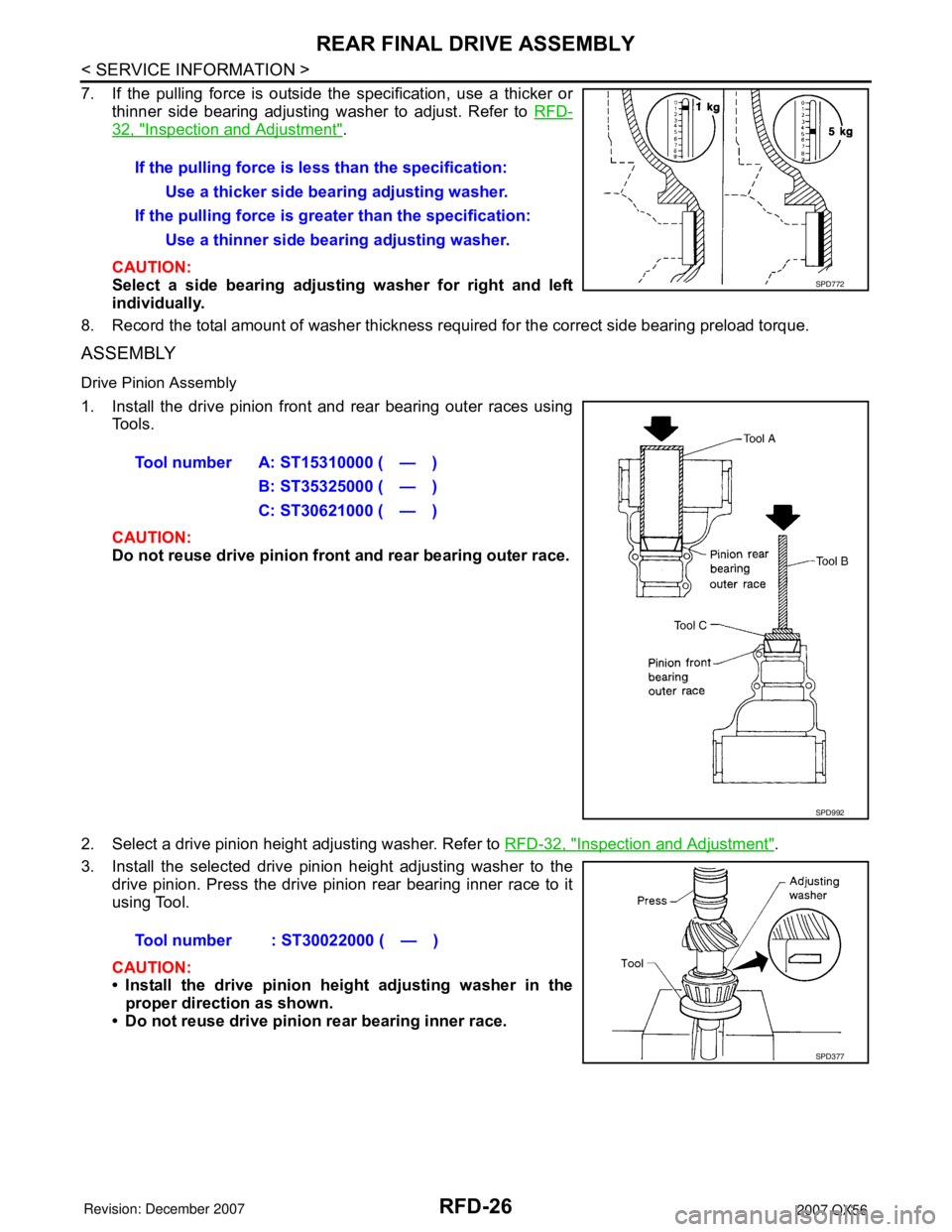

7. If the pulling force is outside the specification, use a thicker or

thinner side bearing adjusting washer to adjust. Refer to RFD-

32, "Inspection and Adjustment".

CAUTION:

Select a side bearing adjusting washer for right and left

individually.

8. Record the total amount of washer thickness required for the correct side bearing preload torque.

ASSEMBLY

Drive Pinion Assembly

1. Install the drive pinion front and rear bearing outer races using

Tools.

CAUTION:

Do not reuse drive pinion front and rear bearing outer race.

2. Select a drive pinion height adjusting washer. Refer to RFD-32, "

Inspection and Adjustment".

3. Install the selected drive pinion height adjusting washer to the

drive pinion. Press the drive pinion rear bearing inner race to it

using Tool.

CAUTION:

• Install the drive pinion height adjusting washer in the

proper direction as shown.

• Do not reuse drive pinion rear bearing inner race.If the pulling force is less than the specification:

Use a thicker side bearing adjusting washer.

If the pulling force is greater than the specification:

Use a thinner side bearing adjusting washer.

SPD772

Tool number A: ST15310000 ( — )

B: ST35325000 ( — )

C: ST30621000 ( — )

SPD992

Tool number : ST30022000 ( — )

SPD377

Page 2590 of 3061

SERVICE DATA AND SPECIFICATIONS (SDS)

RFD-33

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

RFD

N

O

P

Unit: mm (in)

*: Always check with the Parts Department for the latest parts information.

Drive Pinion Height Adjusting Washer

Unit: mm (in)

*: Always check with the Parts Department for the latest parts information.

Side Bearing Adjusting Washer

Unit: mm (in)

*: Always check with the Parts Department for the latest parts information.Thickness Part number*

1.75 (0.0688)

1.80 (0.0708)

1.85 (0.0728)38424 7S000

38424 7S001

38424 7S002

Thickness Part number* Thickness Part number*

2.59 (0.1020)

2.61 (0.1028)

2.63 (0.1035)

2.65 (0.1043)

2.67 (0.1051)

2.69 (0.1059)

2.71 (0.1067)

2.73 (0.1075)

2.75 (0.1083)

2.77 (0.1091)38154 40P00

38154 40P01

38154 40P02

38154 40P03

38154 40P04

38154 40P05

38154 40P06

38154 40P07

38154 40P08

38154 40P092.79 (0.1098)

2.81 (0.1106)

2.83 (0.1114)

2.85 (0.1122)

2.87 (0.1130)

2.89 (0.1138)

2.91 (0.1146)

2.93 (0.1154)

2.95 (0.1161)

2.97 (0.1169)38154 40P10

38154 40P11

38154 40P12

38154 40P13

38154 40P14

38154 40P15

38154 40P16

38154 40P17

38154 40P18

38154 40P19

Thickness Part number* Thickness Part number*

2.00 (0.0787)

2.05 (0.0807)

2.10 (0.0827)

2.15 (0.0846)

2.20 (0.0866)

2.25 (0.0886)

2.30 (0.0906)38453 40P00

38453 40P01

38453 40P02

38453 40P03

38453 40P04

38453 40P05

38453 40P062.35 (0.0925)

2.40 (0.0945)

2.45 (0.0965)

2.50 (0.0984)

2.55 (0.1004)

2.60 (0.1024)38453 40P07

38453 40P08

38453 40P09

38453 40P10

38453 40P11

38453 40P12