turn signal INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1719 of 3061

EC-636

< SERVICE INFORMATION >

IGNITION SIGNAL

Do the following procedure in the place where ventilation is good without the combustible.

1. Turn ignition switch OFF.

2. Disconnect ignition coil harness connector.

3. Check resistance between ignition coil terminals as follows.

4. If NG, replace ignition coil with power transistor.

If OK, go to next step.

5. Turn ignition switch OFF.

6. Reconnect all harness connectors disconnected.

7. Remove fuel pump fuse in fuse block No. 1 to release fuel pres-

sure.

NOTE:

Do not use CONSULT-II to release fuel pressure, or fuel pres-

sure applies again during the following procedure.

8. Start engine.

9. After engine stalls, crank it two or three times to release all fuel

pressure.

10. Turn ignition switch OFF.

11. Remove all ignition coil harness connectors to avoid the electri-

cal discharge from the ignition coils.

12. Remove ignition coil and spark plug of the cylinder to be

checked.

13. Crank engine for 5 seconds or more to remove combustion gas in the cylinder.

14. Connect spark plug and harness connector to ignition coil.

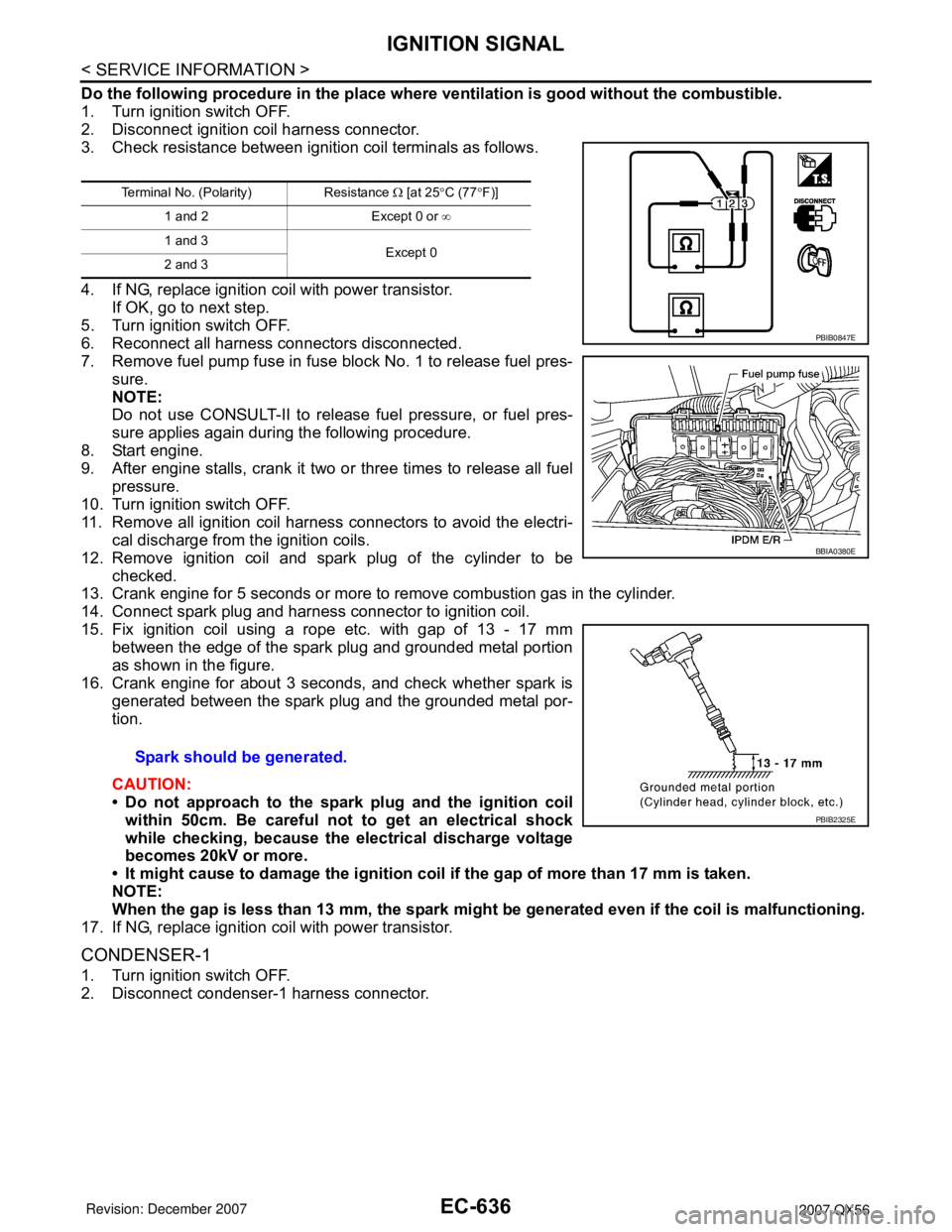

15. Fix ignition coil using a rope etc. with gap of 13 - 17 mm

between the edge of the spark plug and grounded metal portion

as shown in the figure.

16. Crank engine for about 3 seconds, and check whether spark is

generated between the spark plug and the grounded metal por-

tion.

CAUTION:

• Do not approach to the spark plug and the ignition coil

within 50cm. Be careful not to get an electrical shock

while checking, because the electrical discharge voltage

becomes 20kV or more.

• It might cause to damage the ignition coil if the gap of more than 17 mm is taken.

NOTE:

When the gap is less than 13 mm, the spark might be generated even if the coil is malfunctioning.

17. If NG, replace ignition coil with power transistor.

CONDENSER-1

1. Turn ignition switch OFF.

2. Disconnect condenser-1 harness connector.

Terminal No. (Polarity) Resistance Ω [at 25°C (77°F)]

1 and 2 Except 0 or ∞

1 and 3

Except 0

2 and 3

Spark should be generated.

PBIB0847E

BBIA0380E

PBIB2325E

Page 1724 of 3061

REFRIGERANT PRESSURE SENSOR

EC-641

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1. Disconnect refrigerant pressure sensor harness connector.

2. Turn ignition switch ON.

3. Check voltage between refrigerant pressure sensor terminal 1

and ground with CONSULT-II or tester.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E5, F14

• Harness for open or short between ECM and refrigerant pressure sensor

>> Repair harness or connectors.

5.CHECK REFRIGERANT PRESSURE SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between refrigerant pressure sensor terminal 3 and ECM terminal 67.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 7.

NG >> GO TO 6.

6.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E5, F14

• Harness for open or short between ECM and refrigerant pressure sensor

>> Repair open circuit or short to ground or short to power in harness or connectors.

7.CHECK REFRIGERANT PRESSURE SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between ECM terminal 70 and refrigerant pressure sensor terminal 2.

Refer to Wiring Diagram.

2. Also check harness for short to ground and short to power.

OK or NG

BBIA0445E

Voltage: Approximately 5V

PBIB0188E

Continuity should exist.

Continuity should exist.

Page 1846 of 3061

EM-76

< SERVICE INFORMATION >

ENGINE ASSEMBLY

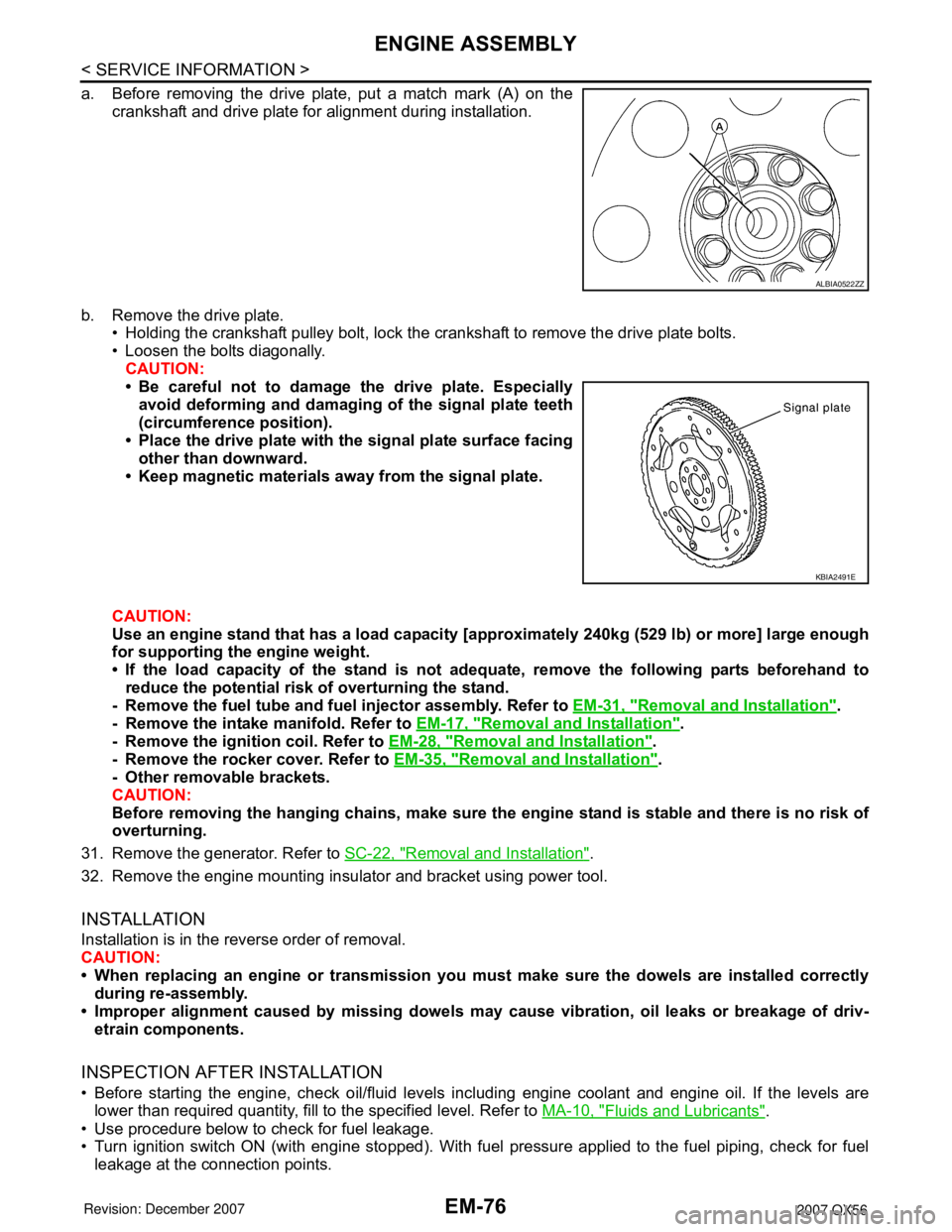

a. Before removing the drive plate, put a match mark (A) on the

crankshaft and drive plate for alignment during installation.

b. Remove the drive plate.

• Holding the crankshaft pulley bolt, lock the crankshaft to remove the drive plate bolts.

• Loosen the bolts diagonally.

CAUTION:

• Be careful not to damage the drive plate. Especially

avoid deforming and damaging of the signal plate teeth

(circumference position).

• Place the drive plate with the signal plate surface facing

other than downward.

• Keep magnetic materials away from the signal plate.

CAUTION:

Use an engine stand that has a load capacity [approximately 240kg (529 lb) or more] large enough

for supporting the engine weight.

• If the load capacity of the stand is not adequate, remove the following parts beforehand to

reduce the potential risk of overturning the stand.

- Remove the fuel tube and fuel injector assembly. Refer to EM-31, "

Removal and Installation".

- Remove the intake manifold. Refer to EM-17, "

Removal and Installation".

- Remove the ignition coil. Refer to EM-28, "

Removal and Installation".

- Remove the rocker cover. Refer to EM-35, "

Removal and Installation".

- Other removable brackets.

CAUTION:

Before removing the hanging chains, make sure the engine stand is stable and there is no risk of

overturning.

31. Remove the generator. Refer to SC-22, "

Removal and Installation".

32. Remove the engine mounting insulator and bracket using power tool.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• When replacing an engine or transmission you must make sure the dowels are installed correctly

during re-assembly.

• Improper alignment caused by missing dowels may cause vibration, oil leaks or breakage of driv-

etrain components.

INSPECTION AFTER INSTALLATION

• Before starting the engine, check oil/fluid levels including engine coolant and engine oil. If the levels are

lower than required quantity, fill to the specified level. Refer to MA-10, "

Fluids and Lubricants".

• Use procedure below to check for fuel leakage.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to the fuel piping, check for fuel

leakage at the connection points.

ALBIA0522ZZ

KBIA2491E

Page 2037 of 3061

GW-18

< SERVICE INFORMATION >

POWER WINDOW SYSTEM

The signal is transmitted from main power window and door lock/unlock switch to power window and door

lock/unlock switch RH

• Front door window RH operation signal.

• Power window control by front door lock assembly LH (key cylinder switch) signal.

• Power window lock signal.

• Retained power operation signal.

• Rear power window operation.

POWER WINDOW LOCK

The power window lock is designed to lock operation of all windows except for front door window LH.

When in the lock position, the power window lock signal is transmitted to power window and door lock/unlock

switch RH by power window serial link. This prevents the power window motor from operating.

RETAINED POWER OPERATION

When the ignition switch is turned to the OFF position from ON or START position, power is supplied for 45

seconds

• to main power window and door lock/unlock switch terminal 10

• from BCM terminal 68.

When power and ground are supplied, the BCM continues to be energized, and the power window can be

operated.

The retained power operation is canceled when the front LH or front RH door is opened.

Retained power operation period can be changed by CONSULT-II. Refer to GW-31, "

CONSULT-II Function

(BCM)" .

ANTI-PINCH SYSTEM

Main power window and door lock/unlock switch, power window and door lock/unlock switch RH and rear

power window control unit LH and RH monitors the power window motor operation and the power window

position (full closed or other) for each power window by the signals from encoder and limit switch in power win-

dow motor.

When a window switch detects interruption during the following close operation,

• automatic close operation when ignition switch is in the ON position

• automatic close operation during retained power operation

Main power window and door lock/unlock switch, power window and door lock/unlock switch RH and rear

power window control unit LH and RH controls each power window motor for open and the power window will

be lowered about 150 mm (5.91 in).

POWER WINDOW CONTROL BY THE FRONT DOOR LOCK ASSEMBLY LH (KEY CYLINDER

SWITCH)

When ignition key switch is OFF, front power window LH and RH can be opened or closed by turning the front

door lock assembly LH (key cylinder switch) to the UNLOCK/LOCK position for more than 1 second.

• Front power windows can be opened as the front door lock assembly LH (key cylinder switch) is kept fully

turned to the UNLOCK position.

• Front power windows can be closed as the front door lock assembly LH (key cylinder switch) is kept fully

turned to the LOCK position.

• While performing open/close operation for the windows, power window is stopped when the front door lock

assembly LH (key cylinder switch) is placed in the NEUTRAL position.

• When the ignition switch is turned ON while the power window opening operation is performed, the power

window opening stops.

CAN Communication System DescriptionINFOID:0000000003533026

Refer to LAN-4.

Page 2048 of 3061

POWER WINDOW SYSTEM

GW-29

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

GW

N

O

P

outINFOID:0000000003533029

Terminal and Reference Value for Main Power Window and Door Lock/Unlock Switch

INFOID:0000000003533030

LIIA2455E

Terminal Wire Color Item ConditionVoltage (V)

(Approx.)

2 W/B Limit switch and encoder ground — 0

4LFront door key cylinder switch LH

lock signalKey position

(Neutral → Unlocked)5 → 0

6RFront door key cylinder LH switch

unlock signalKey position

(Neutral → Locked)5 → 0

8G/RFront power window motor LH UP

signalWhen power window motor is op-

erated UP Battery voltage

9 O Limit switch signalFront power window LH is be-

tween fully-open and just before

fully-closed position (ON)0

Front power window LH is be-

tween just before fully-closed po-

sition and fully-closed position

(OFF)5

10 W/L RAP signalWhen ignition switch ON Battery voltage

Within 45 seconds after ignition

switch is turned to OFFBattery voltage

More than 45 seconds after igni-

tion switch is turned to OFF0

When front door LH or RH open

or power window timer operates0

11 G / WFront power window motor LH

DOWN signalWhen power window motor is op-

erated DOWN Battery voltage

13 G/Y Encoder pulse signalWhen power window motor oper-

ates

14 LG/W Power window serial linkWhen ignition switch ON or power

window timer operates

OCC3383D

PIIA2344J

Page 2051 of 3061

GW-32

< SERVICE INFORMATION >

POWER WINDOW SYSTEM

WORK SUPPORT

DATA MONITOR

Trouble Diagnosis Symptom ChartINFOID:0000000003533036

• Check that other systems using the signal of the following systems operate normally.

Te s t I t e m D e s c r i p t i o n

RETAINED PWRThis test is able to supply RAP signal (power) from BCM (body control module) to power window

system and power sunroof system (if equipped). Those systems can be operated when turning on

“RETAINED PWR” on CONSULT-II screen even if the ignition switch is turned OFF.

NOTE:

During this test, CONSULT-II can be operated with ignition switch in OFF position. “RETAINED

P W R ” s h o u l d b e t u r n e d “ O N ” o r “ O F F ” o n C O N S U LT- I I s c r e e n w h e n i g n i t i o n s w i t c h i s O N . T h e n t u r n

ignition switch OFF to check retained power operation. CONSULT-II might be stuck if “RETAINED

PWR” is turned “ON” or “OFF” on CONSULT-II screen when ignition switch is OFF.

Work item Description

RETAINED PWRRAP signal’s power supply period can be changed by mode setting. Selects RAP signal’s power

supply period between three steps

• MODE1 (45 sec.) / MODE2 (OFF) / MODE 3 (2 min.).

Work item Description

IGN ON SW Indicates (ON/OFF) condition of ignition switch

DOOR SW-DR Indicates (ON/OFF) condition of front door switch driver side

DOOR SW-AS Indicates (ON/OFF) condition of front door switch passenger side

Symptom Repair order Refer to page

None of the power windows can be operated using any switch1. BCM power supply and ground circuit checkBCS-15

2. Main power window and door lock/unlock

power supply and ground circuit checkGW-34

3. Power window serial link check front LH and

RHGW-46

Front power window LH alone does not operate1. Main power window and door lock/unlock

power supply and ground circuit checkGW-342. Front power window motor LH circuit checkGW-36

3. Replace main power window and door lock/

unlock switchEI-31

Front power window RH alone does not operate1. Power window and door lock/unlock switch

RH power supply and ground circuit checkGW-352. Power window serial link check front LH and

RHGW-46

3. Front power window motor RH circuit checkGW-37

4. Replace BCMBCS-24

Rear power window LH alone does not operate1. Rear power window control unit LH or RH

power supply and ground circuit checkGW-48

2. Rear power window switch LH or RH power

supply and ground circuit checkGW-49

3. Rear power window motor LH circuit checkGW-50

4. Power window serial link check rear LH and

RHGW-54

5. Replace BCMBCS-24

Page 2054 of 3061

POWER WINDOW SYSTEM

GW-35

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

GW

N

O

P

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness.

4.CHECK BCM OUTPUT SIGNAL

1. Connect BCM.

2. Turn ignition switch ON.

3. Check voltage between BCM connector M20 terminals 68, 69

and ground.

OK or NG

OK >> Check the condition of the harness and the connector.

NG >> Replace BCM. Refer to BCS-24, "

BCM".

Power Window and Door Lock/Unlock Switch RH Power Supply and Ground Circuit In-

spection

INFOID:0000000003533039

1.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch ON.

2. Check voltage between power window and door lock/unlock

switch RH connector D105 terminal 10 and ground.

OK or NG

OK >> GO TO 2.

NG >> GO TO 3.

2.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect power window and door lock/unlock switch RH.

3. Check continuity between power window and door lock/unlock

switch RH connector D105 terminal 11 and ground.

OK or NG

OK >> Power supply and ground circuit are OK.

NG >> Repair or replace harness.

3.CHECK POWER WINDOW AND DOOR LOCK/UNLOCK SWITCH RH POWER SUPPLY CIRCUIT

Connector

Te r m i n a l

GroundContinuity

A

BCM: M2068 No

69 No

68 - Ground : Battery voltage

69 - Ground : Battery voltage

LIIA0917E

10 - Ground : Battery voltage

LIIA1257E

11 - Ground : Continuity should exist.

LIIA1258E

Page 2055 of 3061

GW-36

< SERVICE INFORMATION >

POWER WINDOW SYSTEM

1. Turn ignition switch OFF.

2. Disconnect BCM.

3. Check continuity between BCM connector M20 (A) terminal 69

and power window and door lock/unlock switch RH connector

D105 (B) terminal 10.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness.

4.CHECK BCM OUTPUT SIGNAL

1. Connect BCM.

2. Turn ignition switch ON.

3. Check voltage between BCM connector M20 terminal 69 and

ground.

OK or NG

OK >> Check the condition of the harness and the connector.

NG >> Replace BCM. Refer to BCS-24, "

BCM" .

Front Power Window Motor LH Circuit InspectionINFOID:0000000003533040

1.CHECK MAIN POWER WINDOW AND DOOR LOCK/UNLOCK SWITCH OUTPUT SIGNAL

1. Turn ignition switch ON.

2. Check voltage between main power window and door lock/

unlock switch connector D7 terminals 8, 11 and ground.

OK or NG

OK >> GO TO 2.

NG >> Replace main power window and door lock/unlock switch. Refer to EI-31, "

Removal and Installa-

tion".

2.CHECK POWER WINDOW MOTOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect main power window and door lock/unlock switch and

front power window motor LH.

3. Check continuity between main power window and door lock/

unlock switch connector D7 terminals 8, 11 and front power win-

dow motor LH connector D9 terminals 1, 2.

OK or NG

OK >> Replace front power window motor LH. Refer to GW-59.

NG >> Repair or replace harness.69 - 10 : Continuity should exist.

LIIA2298E

69 - Ground : Battery voltage

WIIA0508E

ConnectorTe r m i n a l s

ConditionVoltage (V)

(Approx.)

(+) (-)

D78

GroundUP Battery voltage

DOWN 0

11UP 0

DOWN Battery voltage

LIIA0317E

8 - 2 : Continuity should exist.

11 - 1 : Continuity should exist.

LIIA1260E

Page 2056 of 3061

POWER WINDOW SYSTEM

GW-37

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

GW

N

O

P

Front Power Window Motor RH Circuit InspectionINFOID:0000000003533041

1.CHECK POWER WINDOW AND DOOR LOCK/UNLOCK SWITCH RH OUTPUT SIGNAL

1. Connect power window and door lock/unlock switch RH.

2. Turn ignition switch ON.

3. Check voltage between power window and door lock/unlock

switch RH connector D105 terminals 8, 9 and ground.

OK or NG

OK >> GO TO 2.

NG >> Replace power window and door lock/unlock switch RH. Refer to EI-31, "

Removal and Installa-

tion".

2.CHECK FRONT POWER WINDOW MOTOR RH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect front power window motor RH and power window

and door lock/unlock switch RH.

3. Check continuity between power window and door lock/unlock

switch RH connector D105 terminals 8, 9 and front power win-

dow motor RH connector D104 terminals 1, 2.

OK or NG

OK >> Replace front power window motor RH. Refer to GW-59

.

NG >> Repair or replace harness.

Limit Switch Circuit Inspection Front LHINFOID:0000000003533042

1.CHECK MAIN POWER WINDOW AND DOOR LOCK/UNLOCK SWITCH LIMIT SIGNAL

1. Turn ignition switch ON.

2. Check voltage between main power window and door lock/

unlock switch connector D7 termimal 9 and ground.

OK or NG

OK >> Limit switch circuit is OK.

NG >> GO TO 2.

ConnectorTe r m i n a l s

ConditionVoltage (V)

(Approx.)

(+) (-)

D1059

GroundUP 0

DOWN Battery voltage

8UP Battery voltage

DOWN 0

LIIA1261E

8 - 2 : Continuity should exist.

9 - 1 : Continuity should exist.

LIIA1262E

ConnectorTe r m i n a l

Condition Voltage (V)

(Approx.)

(+) (-)

D7 9 GroundFront power window LH is

between fully-open and just

before fully-closed position

(ON)0

Front power window LH is

between just before fully-

closed position and fully-

closed position (OFF)5

LIIA0339E

Page 2057 of 3061

GW-38

< SERVICE INFORMATION >

POWER WINDOW SYSTEM

2.CHECK FRONT POWER WINDOW MOTOR LH LIMIT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect front power window motor LH.

3. Turn ignition switch ON.

4. Check voltage between front power window motor LH connector

D9 terminal 5 and ground.

OK or NG

OK >> GO TO 3.

NG >> GO TO 5.

3.CHECK LIMIT SWITCH GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between front power window motor LH connec-

tor D9 terminal 6 and ground.

OK or NG

OK >> Replace front power window motor LH. Refer to GW-59.

NG >> GO TO 4.

4.CHECK HARNESS CONTINUITY

1. Disconnect main power window and door lock/unlock switch.

2. Check continuity between front power window motor LH connec-

tor D9 terminal 6 and main power window and door lock/unlock

switch connector D7 terminal 2.

OK or NG

OK >> Replace main power window and door lock/unlock

switch. Refer to EI-31, "

Removal and Installation".

NG >> Repair or replace harness.

5.CHECK HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect main power window and door lock/unlock switch.

3. Check continuity between front power window motor LH connec-

tor D9 terminal 5 and main power window and door lock/unlock

switch connector D7 terminal 9.

OK or NG

OK >> Replace main power window and door lock/unlock

switch. Refer to EI-31, "

Removal and Installation".

NG >> Repair or replace harness.

Limit Switch Circuit Inspection Front RHINFOID:0000000003533043

1.CHECK POWER WINDOW AND DOOR LOCK/UNLOCK SWITCH RH LIMIT SIGNAL 5 - Ground : Approx. 5V

LIIA0922E

6 - Ground : Continuity should exist.

LIIA0923E

6 - 2 : Continuity should exist.

LIIA0924E

5 - 9 : Continuity should exist.

LIIA0925E