turn signal INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1696 of 3061

FUEL PUMP

EC-613

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

FUEL PUMP

DescriptionINFOID:0000000003532166

SYSTEM DESCRIPTION

*: ECM determines the start signal status by the signals of engine speed and battery voltage.

The ECM activates the fuel pump for several seconds after the ignition switch is turned ON to improve engine

startability. If the ECM receives a engine speed signal from the camshaft position sensor (PHASE), it knows

that the engine is rotating, and causes the pump to operate. If the engine speed signal is not received when

the ignition switch is ON, the engine stalls. The ECM stops pump operation and prevents battery discharging,

thereby improving safety. The ECM does not directly drive the fuel pump. It controls the ON/OFF fuel pump

relay, which in turn controls the fuel pump.

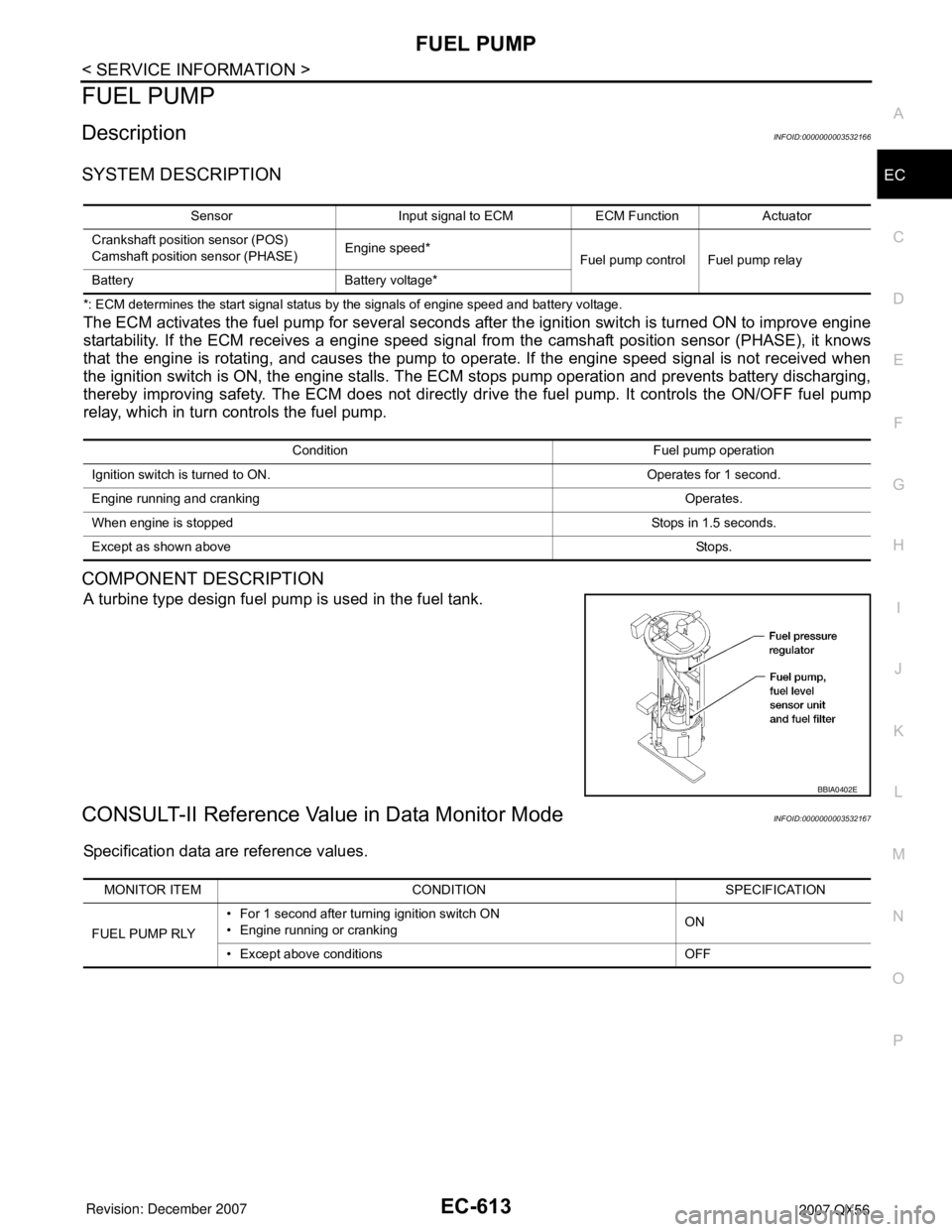

COMPONENT DESCRIPTION

A turbine type design fuel pump is used in the fuel tank.

CONSULT-II Reference Value in Data Monitor ModeINFOID:0000000003532167

Specification data are reference values.

Sensor Input signal to ECM ECM Function Actuator

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE)Engine speed*

Fuel pump control Fuel pump relay

Battery Battery voltage*

Condition Fuel pump operation

Ignition switch is turned to ON. Operates for 1 second.

Engine running and crankingOperates.

When engine is stopped Stops in 1.5 seconds.

Except as shown aboveSto ps .

BBIA0402E

MONITOR ITEM CONDITION SPECIFICATION

FUEL PUMP RLY• For 1 second after turning ignition switch ON

• Engine running or crankingON

• Except above conditions OFF

Page 1702 of 3061

ICC BRAKE SWITCH

EC-619

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

ICC BRAKE SWITCH

Component DescriptionINFOID:0000000003532172

When depress on the brake pedal, ICC brake switch is turned OFF

and stop lamp switch is turned ON. ECM detects the state of the

brake pedal by this input of two kinds (ON/OFF signal)

Refer to ACS-6

for the ICC function.

CONSULT-II Reference Value in Data Monitor ModeINFOID:0000000003532173

Specification data are reference values.

BBIA0470E

MONITOR ITEM CONDITION SPECIFICATION

BRAKE SW 1

(ICC brake switch)• Ignition switch: ONBrake pedal: Fully released ON

Brake pedal: Slightly depressed OFF

BRAKE SW 2

(Stop lamp switch)• Ignition switch: ONBrake pedal: Fully released OFF

Brake pedal: Slightly depressed ON

Page 1706 of 3061

ICC BRAKE SWITCH

EC-623

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

6.CHECK ICC BRAKE SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ICC brake switch harness connector.

3. Check harness continuity between ICC brake hold relay terminal

3 and ICC brake switch terminal 1.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 7.

NG >> Repair open circuit or short to ground or short to power

in harness or connectors.

7.CHECK ICC BRAKE SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ICC brake switch terminal 2 and ECM terminal 108.

Refer Wiring Diagram.

3. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 8.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

8.CHECK ICC BRAKE HOLD RELAY

Refer to EC-624, "

Component Inspection" .

OK >> GO TO 9.

NG >> Replace ICC brake hold relay.

9.CHECK ICC BRAKE SWITCH

Refer to EC-624, "

Component Inspection" .

OK or NG

OK >> GO TO 14.

NG >> Replace ICC brake switch.

10.CHECK STOP LAMP SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect stop lamp switch harness connector.Continuity should exist.

BBIA0470E

Continuity should exist.

BBIA0470E

Page 1707 of 3061

EC-624

< SERVICE INFORMATION >

ICC BRAKE SWITCH

3. Check voltage between stop lamp switch terminal 3 and ground

with CONSULT -II or tester.

OK or NG

OK >> GO TO 12.

NG >> GO TO 11.

11 .DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors M31, E152

• Fuse block (J/B) No. 1 connector M60

• 10A fuse

• Harness for open or short between stop lamp switch and battery

>> Repair open circuit or short to ground or short to power in harness or connectors.

12.CHECK STOP LAMP SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 101 and stop lamp switch terminal 4.

Refer to Wiring Diagram.

3. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 13.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

13.CHECK STOP LAMP SWITCH

Refer to EC-624, "

Component Inspection" .

OK or NG

OK >> GO TO 14.

NG >> Replace stop lamp switch.

14.CHECK INTERMITTENT INCIDENT

Refer to EC-138

.

>>INSPECTION END

Component InspectionINFOID:0000000003532176

ICC BRAKE SWITCH

1. Turn ignition switch OFF.

2. Disconnect ICC brake switch harness connector.Voltage: Battery voltage

PBIB2102E

Continuity should exist.

Page 1709 of 3061

EC-626

< SERVICE INFORMATION >

IGNITION SIGNAL

IGNITION SIGNAL

Component DescriptionINFOID:0000000003532177

IGNITION COIL & POWER TRANSISTOR

The ignition signal from the ECM is sent to and amplified by the power transistor. The power transistor turns

ON and OFF the ignition coil primary circuit. This ON/OFF operation induces the proper high voltage in the coil

secondary circuit.

1. Ignition coils (with power transistor)

(bank 2)2. Ignition coils (with power transistor)

(bank 1)

BBIA0777E

Page 1711 of 3061

![INFINITI QX56 2007 Factory Service Manual EC-628

< SERVICE INFORMATION >

IGNITION SIGNAL

TER-

MI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

111 W / BECM relay

(Self shut-off)[Engine is running]

[Ignition switch: OFF]

• For a few s INFINITI QX56 2007 Factory Service Manual EC-628

< SERVICE INFORMATION >

IGNITION SIGNAL

TER-

MI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

111 W / BECM relay

(Self shut-off)[Engine is running]

[Ignition switch: OFF]

• For a few s](/img/42/57029/w960_57029-1710.png)

EC-628

< SERVICE INFORMATION >

IGNITION SIGNAL

TER-

MI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

111 W / BECM relay

(Self shut-off)[Engine is running]

[Ignition switch: OFF]

• For a few seconds after turning ignition

switch OFF0 - 1.5V

[Ignition switch: OFF]

• More than a few seconds after turning igni-

tion switch OFFBATTERY VOLTAGE

(11 - 14V)

11 9

120BR

BRPower supply for ECM[Ignition switch: ON]BATTERY VOLTAGE

(11 - 14V)

Page 1715 of 3061

EC-632

< SERVICE INFORMATION >

IGNITION SIGNAL

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

Diagnosis ProcedureINFOID:0000000003532179

1.CHECK ENGINE START

Turn ignition switch OFF, and restart engine.

Is engine running?

Ye s o r N o

Yes (With CONSULT-II)>>GO TO 2.

Yes (Without CONSULT-II)>>GO TO 3.

No >> GO TO 4.

2.CHECK OVERALL FUNCTION

With CONSULT-II

1. Perform “POWER BALANCE” in “ACTIVE TEST” mode with

CONSULT-II.

2. Make sure that each circuit produces a momentary engine

speed drop.

OK or NG

OK >>INSPECTION END

NG >> GO TO 10.

3.CHECK OVERALL FUNCTION

Without CONSULT-II

1. Let engine idle.

TER-

MI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

65

79

80

81G/R

V/W

W/R

W/GIgnition signal No. 8

Ignition signal No. 6

Ignition signal No. 4

Ignition signal No. 2[Engine is running]

•Warm-up condition

• Idle speed

NOTE:

The pulse cycle changes depending on rpm at

idle.0 - 0.2V

[Engine is running]

•Warm-up condition

• Engine speed: 2,000 rpm.0.1 - 0.4V

PBIB0044E

PBIB0045E

PBIB0133E

Page 1716 of 3061

IGNITION SIGNAL

EC-633

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

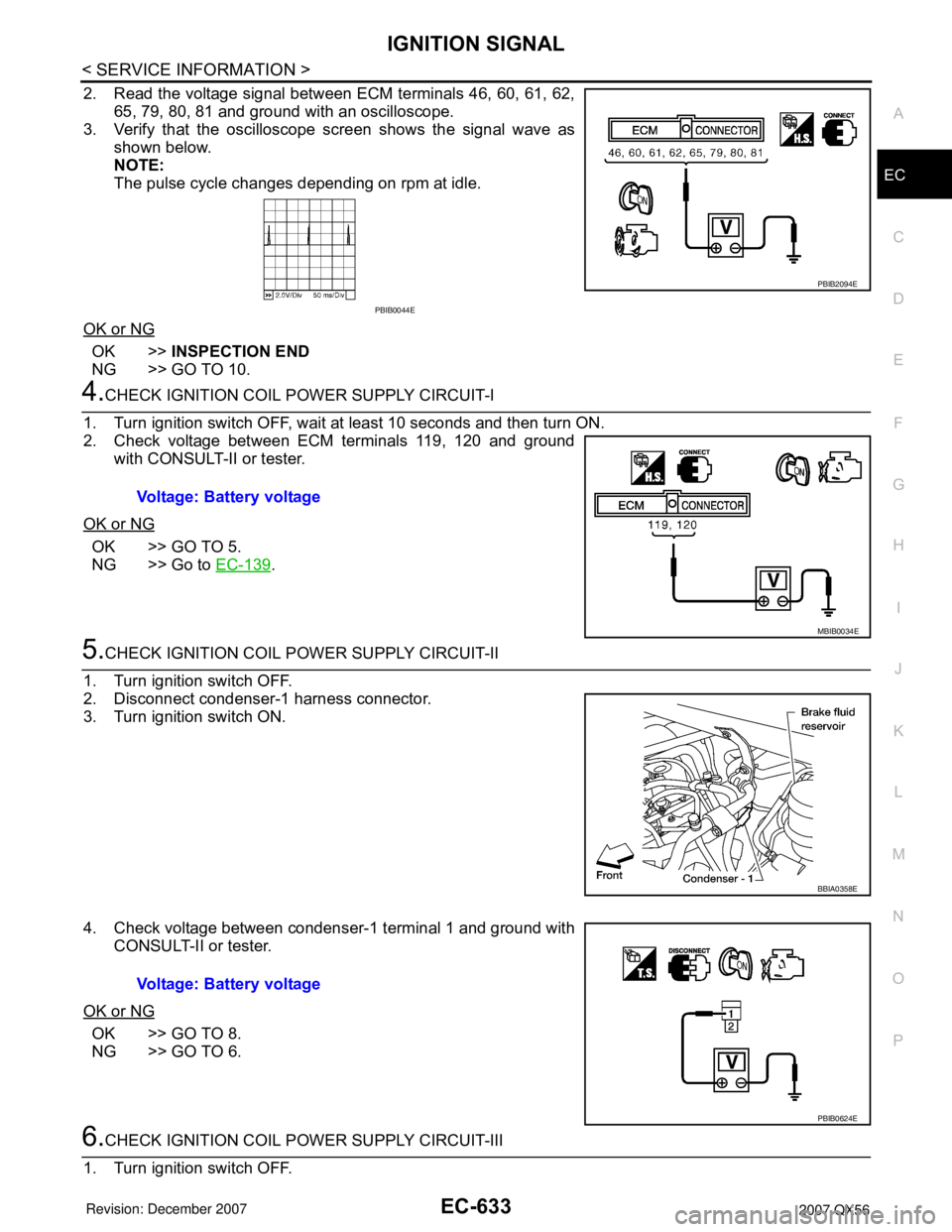

2. Read the voltage signal between ECM terminals 46, 60, 61, 62,

65, 79, 80, 81 and ground with an oscilloscope.

3. Verify that the oscilloscope screen shows the signal wave as

shown below.

NOTE:

The pulse cycle changes depending on rpm at idle.

OK or NG

OK >>INSPECTION END

NG >> GO TO 10.

4.CHECK IGNITION COIL POWER SUPPLY CIRCUIT-I

1. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

2. Check voltage between ECM terminals 119, 120 and ground

with CONSULT-II or tester.

OK or NG

OK >> GO TO 5.

NG >> Go to EC-139

.

5.CHECK IGNITION COIL POWER SUPPLY CIRCUIT-II

1. Turn ignition switch OFF.

2. Disconnect condenser-1 harness connector.

3. Turn ignition switch ON.

4. Check voltage between condenser-1 terminal 1 and ground with

CONSULT-II or tester.

OK or NG

OK >> GO TO 8.

NG >> GO TO 6.

6.CHECK IGNITION COIL POWER SUPPLY CIRCUIT-III

1. Turn ignition switch OFF.

PBIB2094E

PBIB0044E

Voltage: Battery voltage

MBIB0034E

BBIA0358E

Voltage: Battery voltage

PBIB0624E

Page 1717 of 3061

EC-634

< SERVICE INFORMATION >

IGNITION SIGNAL

2. Disconnect IPDM E/R connector E119.

3. Check harness continuity between IPDM E/R terminal 4 and condenser-1 terminal 1.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> Go to EC-139.

NG >> GO TO 7.

7.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E2, F32

• Harness for open or short between condenser-1 and IPDM E/R

>> Repair open circuit or short to ground or short to power in harness or connectors.

8.CHECK CONDENSER-1 GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Check harness continuity between condenser-1 terminal 2 and ground.

Refer to Wiring Diagram.

3. Also check harness for short to power.

OK or NG

OK >> GO TO 9.

NG >> Repair open circuit or short to power in harness or connectors.

9.CHECK CONDENSER-1

Refer to EC-635, "

Component Inspection".

OK or NG

OK >> GO TO 10.

NG >> Replace condenser-1.

10.CHECK IGNITION COIL POWER SUPPLY CIRCUIT-IV

1. Turn ignition switch OFF.

2. Reconnect all harness connectors disconnected.

3. Disconnect ignition coil harness connector.

4. Turn ignition switch ON.Continuity should exist.

Continuity should exist.

1. Ignition coils (with power transistor)

(bank 2)2. Ignition coils (with power transistor)

(bank 1)

BBIA0777E

Page 1718 of 3061

IGNITION SIGNAL

EC-635

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

5. Check voltage between ignition coil terminal 3 and ground with

CONSULT-II or tester.

OK or NG

OK >> GO TO 12.

NG >> GO TO 11.

11 .DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E2, F32

• Harness for open or short between ignition coil and harness connector F32

>> Repair or replace harness or connectors.

12.CHECK IGNITION COIL GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Check harness continuity between ignition coil terminal 2 and ground.

Refer to Wiring Diagram.

3. Also check harness for short to power.

OK or NG

OK >> GO TO 13.

NG >> Repair open circuit or short to power in harness or connectors.

13.CHECK IGNITION COIL OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminals 46, 60, 61, 62, 65, 79, 80, 81 and ignition coil terminal

1.

Refer to Wiring Diagram.

3. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 14.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

14.CHECK IGNITION COIL WITH POWER TRANSISTOR

Refer to EC-635, "

Component Inspection".

OK or NG

OK >> GO TO 15.

NG >> Replace ignition coil with power transistor.

15.CHECK INTERMITTENT INCIDENT

Refer to EC-138

.

>>INSPECTION END

Component InspectionINFOID:0000000003532180

IGNITION COIL WITH POWER TRANSISTOR

CAUTION:Voltage: Battery voltage

PBIB0138E

Continuity should exist.

Continuity should exist.