light INFINITI QX56 2007 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 698 of 3061

BCM (BODY CONTROL MODULE)

BCS-11

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

BCS

N

O

P

Terminal and Reference Value for BCMINFOID:0000000003533600

Te r m i n a lWire

colorSignal nameSignal

input/

outputMeasuring condition

Reference value or waveform

(Approx.) Ignition

switchOperation or condition

1BR/WIgnition keyhole illumi-

nationOutput OFFDoor is locked (SW OFF) Battery voltage

Door is unlocked (SW ON) 0V

2SBCombination switch

input 5Input ONLighting, turn, wiper OFF

Wiper dial position 4

3G/YCombination switch

input 4Input ONLighting, turn, wiper OFF

Wiper dial position 4

4YCombination switch

input 3Input ONLighting, turn, wiper OFF

Wiper dial position 4

5G/BCombination switch

input 2

Input ONLighting, turn, wiper OFF

Wiper dial position 4

6VCombination switch

input 1

9Y/BRear window defogger

switchInput ONRear window defogger switch

ON0V

Rear window defogger switch

OFF5V

10 G Hazard lamp flash Input OFFON (opening or closing) 0V

OFF (other than above) Battery voltage

11 OIgnition switch (ACC

or ON)InputACC or

ONIgnition switch ACC or ON Battery voltage

12 R/L Front door switch RH Input OFFON (open) 0V

OFF (closed) Battery voltage

13 GR Rear door switch RH Input OFFON (open) 0V

OFF (closed) Battery voltage

15 L/WTire pressure warning

check connectorInput OFF — 5V

SKIA5291E

SKIA5292E

SKIA5291E

SKIA5292E

Page 700 of 3061

BCM (BODY CONTROL MODULE)

BCS-13

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

BCS

N

O

P

27 W/RCompressor ON sig-

nalInput ONA/C switch OFF 5V

A/C switch ON 0V

28 L/R Front blower monitor Input ONFront blower motor OFF Battery voltage

Front blower motor ON 0V

29 W/B Hazard switch Input OFFON 0V

OFF 5V

30 Y/BR Glass hatch switch Input OFFGlass hatch switch released

→ Glass hatch switch pressedBattery voltage → 0V

32 R/GCombination switch

output 5Output ONLighting, turn, wiper OFF

Wiper dial position 4

33 R/YCombination switch

output 4Output ONLighting, turn, wiper OFF

Wiper dial position 4

34 LCombination switch

output 3Output ONLighting, turn, wiper OFF

Wiper dial position 4

35 O/BCombination switch

output 2

Output ONLighting, turn, wiper OFF

Wiper dial position 4

36 R/WCombination switch

output 1

37 B/RKey switch and key

lock solenoidInput OFFKey inserted Battery voltage

Key removed 0V

38 W/L Ignition switch (ON) Input ON — Battery voltage

39 L CAN-H — — — —

40 P CAN-L — — — —

42 GRGlass hatch ajar

switchInput ONGlass hatch open 0

Glass hatch closed Battery

43 R/BBack door latch (door

ajar switch)Input OFFON (open) 0V

OFF (closed) Battery voltage Te r m i n a lWire

colorSignal nameSignal

input/

outputMeasuring condition

Reference value or waveform

(Approx.) Ignition

switchOperation or condition

SKIA5291E

SKIA5292E

SKIA5291E

SKIA5292E

Page 716 of 3061

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

BL-5

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

Work FlowINFOID:0000000003532888

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document the facts and conditions when the noise occurs and any

customer's comments; refer to BL-9, "

Diagnostic Worksheet". This information is necessary to duplicate the

conditions that exist when the noise occurs.

• The customer may not be able to provide a detailed description or the location of the noise. Attempt to obtain

all the facts and conditions that exist when the noise occurs (or does not occur).

• If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by test driving the vehicle with the customer.

• After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

• Squeak —(Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

• Creak—(Like walking on an old wooden floor)

Creak characteristics include firm contact/slow movement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

• Rattle—(Like shaking a baby rattle)

Rattle characteristics include the fast repeated contact/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

• Knock —(Like a knock on a door)

Knock characteristics include hollow sounding/sometimes repeating/often brought on by driver action.

• Tick—(Like a clock second hand)

Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver

action or road conditions.

• Thump—(Heavy, muffled knock noise)

Thump characteristics include softer knock/dead sound often brought on by activity.

• Buzz—(Like a bumble bee)

Buzz characteristics include high frequency rattle/firm contact.

• Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge

as acceptable may be very irritating to the customer.

• Weather conditions, especially humidity and temperature, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or location of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

SBT842

Page 717 of 3061

BL-6

< SERVICE INFORMATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on A/T model).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

• Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

• If it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, check ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area.To help pinpoint the source of the noise, use a listening tool

(Chassis Ear: J-39570, Engine Ear: J-39565 and mechanic's stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

• removing the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fasteners can be broken

or lost during the repair, resulting in the creation of new noise.

• tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only tem-

porarily.

• feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

• placing a piece of paper between components that you suspect are causing the noise.

• looking for loose components and contact marks.

Refer to BL-7, "

Generic Squeak and Rattle Troubleshooting".

REPAIR THE CAUSE

• If the cause is a loose component, tighten the component securely.

• If the cause is insufficient clearance between components:

- separate components by repositioning or loosening and retightening the component, if possible.

- insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or urethane

tape. A NISSAN Squeak and Rattle Kit (J-43980) is available through your authorized NISSAN Parts Depart-

ment.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

Always check with the Parts Department for the latest parts information.

The following materials are contained in the NISSAN Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100×135 mm (3.94×5.31 in)/76884-71L01: 60×85 mm (2.36×3.35 in)/76884-71L02: 15×25

mm (0.59×0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50×50 mm (1.97×1.97 in)/73982-50Y00: 10 mm (0.39 in) thick,

50×50 mm (1.97×1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30×50 mm (1.18×1.97 in)

FELT CLOTH TAPE

Used to insulate where movement does not occur. Ideal for instrument panel applications.

68370-4B000: 15×25 mm (0.59×0.98 in) pad/68239-13E00: 5 mm (0.20 in) wide tape roll. The following

materials not found in the kit can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

Page 719 of 3061

BL-8

< SERVICE INFORMATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the console panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the console at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lense loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 723 of 3061

BL-12

< SERVICE INFORMATION >

HOOD

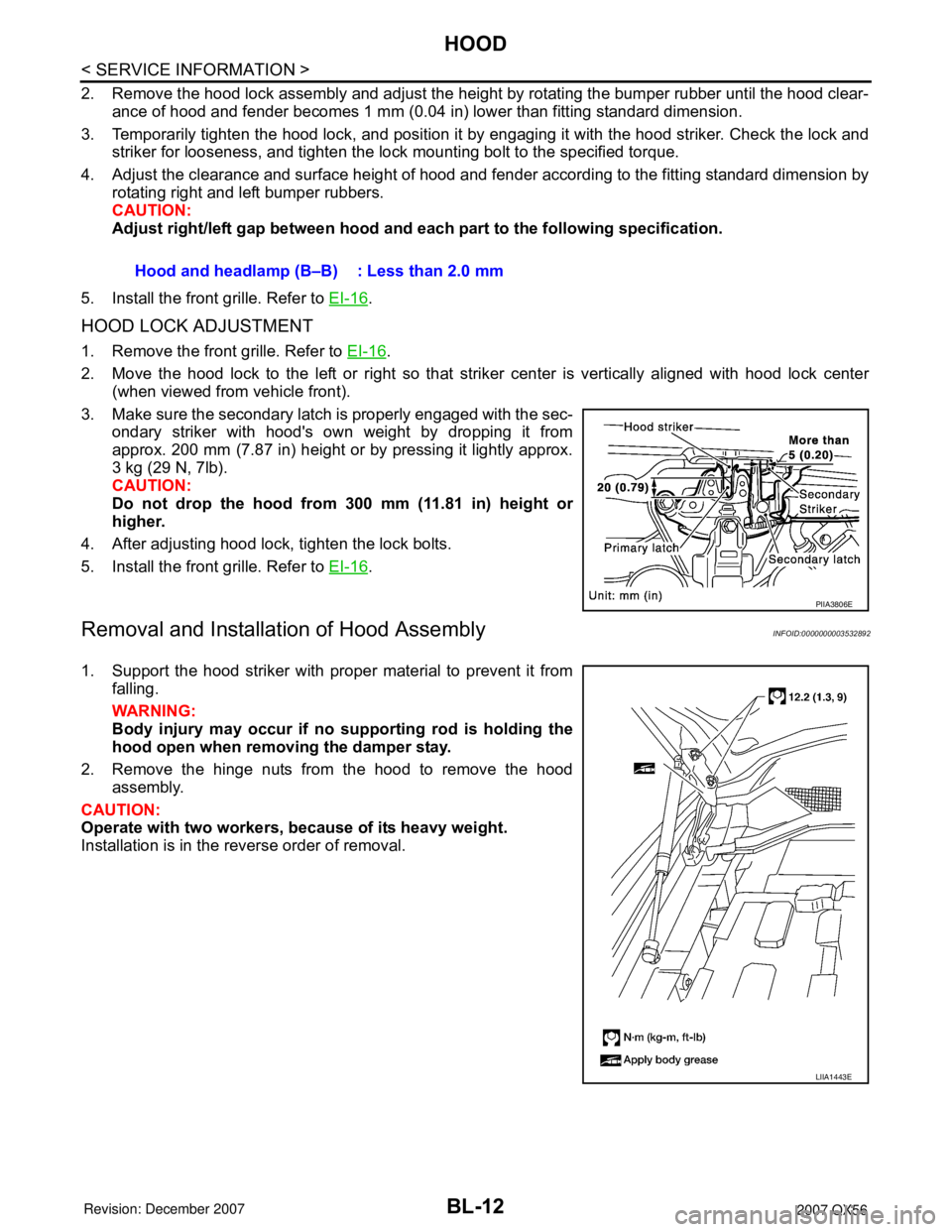

2. Remove the hood lock assembly and adjust the height by rotating the bumper rubber until the hood clear-

ance of hood and fender becomes 1 mm (0.04 in) lower than fitting standard dimension.

3. Temporarily tighten the hood lock, and position it by engaging it with the hood striker. Check the lock and

striker for looseness, and tighten the lock mounting bolt to the specified torque.

4. Adjust the clearance and surface height of hood and fender according to the fitting standard dimension by

rotating right and left bumper rubbers.

CAUTION:

Adjust right/left gap between hood and each part to the following specification.

5. Install the front grille. Refer to EI-16

.

HOOD LOCK ADJUSTMENT

1. Remove the front grille. Refer to EI-16.

2. Move the hood lock to the left or right so that striker center is vertically aligned with hood lock center

(when viewed from vehicle front).

3. Make sure the secondary latch is properly engaged with the sec-

ondary striker with hood's own weight by dropping it from

approx. 200 mm (7.87 in) height or by pressing it lightly approx.

3 kg (29 N, 7lb).

CAUTION:

Do not drop the hood from 300 mm (11.81 in) height or

higher.

4. After adjusting hood lock, tighten the lock bolts.

5. Install the front grille. Refer to EI-16

.

Removal and Installation of Hood AssemblyINFOID:0000000003532892

1. Support the hood striker with proper material to prevent it from

falling.

WARNING:

Body injury may occur if no supporting rod is holding the

hood open when removing the damper stay.

2. Remove the hinge nuts from the hood to remove the hood

assembly.

CAUTION:

Operate with two workers, because of its heavy weight.

Installation is in the reverse order of removal.Hood and headlamp (B–B) : Less than 2.0 mm

PIIA3806E

LIIA1443E

Page 766 of 3061

REMOTE KEYLESS ENTRY SYSTEM

BL-55

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

Check voltage between IPDM E/R connector E122 terminal 45 and

ground.

OK or NG

OK >> Replace IPDM E/R.

NG >> GO TO 2.

2.CHECK IPDM E/R INPUT VOLTAGE

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R and horn relay.

3. Check continuity between IPDM E/R connector E122 terminal

45 and horn relay connector H-1 terminal 1.

4. Check continuity between IPDM E/R connector E122 terminal

45 and ground.

OK or NG

OK >> Further inspection is necessary. Refer to BL-47, "Trou-

ble Diagnosis".

NG >> Repair or replace harness

Check Hazard FunctionINFOID:0000000003532932

1.CHECK HAZARD WARNING LAMP

Does hazard indicator flash with hazard switch?

Ye s o r N o

Yes >> Hazard warning lamp circuit is OK.

No >> Check hazard indicator. Refer to LT- 5 7

.

Check Horn FunctionINFOID:0000000003532933

First, perform the "SELF-DIAG RESULTS" in "BCM" with CONSULT-II, then perform the trouble diagnosis of

malfunction system indicated in "SELF-DIAG RESULTS" of "BCM".

1.CHECK HORN FUNCTION

Does horn sound with horn switch?

Ye s o r N o

Yes >> Horn circuit is OK.

No >> Check horn circuit. Refer to WW-43

.

Check Headlamp FunctionINFOID:0000000003532934

First, perform the "SELF-DIAG RESULTS" in "BCM" with CONSULT-II, then perform the trouble diagnosis of

malfunction system indicated in "SELF-DIAG RESULTS" of "BCM".

1.CHECK HEADLAMP OPERATION

Does headlamp come on when turning lighting switch ON?

Ye s o r N o

Yes >> Headlamp operation circuit is OK.

No >> Check headlamp circuit. Refer to LT- 5

.

ConnectorTe r m i n a l s

Voltage (V)

(Approx.)

(+) (–)

E122 45 Ground Battery voltage

LIIA1053E

45 - 1 : Continuity should exist.

45 - Ground : Continuity should not exist.

WIIA0679E

Page 790 of 3061

VEHICLE SECURITY (THEFT WARNING) SYSTEM

BL-79

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

Check continuity between main power window and door lock/unlock

switch connector (A) D7 terminals 4, 6 and front door lock assembly

LH (key cylinder switch) connector (B) D14 terminals 1, 6 and body

ground.

OK or NG

OK >> Replace main power window and door lock/unlock switch.

NG >> Repair or replace harness.

Vehicle Security Horn Alarm CheckINFOID:0000000003532953

1.CHECK HORN OPERATION

Check if horn sounds with horn switch.

Does horn operate?

YES >> Check harness for open or short between IPDM E/R and horn relay.

NO >> Check horn circuit. Refer to WW-43

.

Vehicle Security Headlamp Alarm CheckINFOID:0000000003532954

1.CHECK VEHICLE SECURITY HEADLAMP ALARM OPERATION

Check if headlamps operate with lighting switch.

Do headlamps come on when turning switch ON?

YES >> Headlamp alarm is OK.

NO >> Check headlamp system. Refer to LT- 5

or LT- 2 4.

Door Lock/Unlock Switch CheckINFOID:0000000003532955

1.CHECK DOOR LOCK/UNLOCK SWITCH INPUT SIGNAL

Check if power door lock operates with door lock/unlock switch.

Do doors lock/unlock when using each door lock/unlock switch?

YES >> Door lock/unlock switch is OK.

NO >> Refer to "Door Lock/Unlock Switch Check ".

Connector Terminals Connector Terminals Continuity

A: Main

power win-

dow and

door lock/

unlock

switch4 B: Front

door lock

assembly

LH (key

cylinder

switch)1Yes

66Yes

4, 6 Ground No

WIIA0756E

Page 828 of 3061

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)

BL-117

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

• Since only IVIS (NATS) ignition keys, whose IDs have been registered into the ECM and BCM, allow the

engine to run, operation of a stolen vehicle without a IVIS (NATS) registered key is prevented by IVIS

(NATS).

IVIS (NATS) will immobilize the engine if someone tries to start it without the registered key of IVIS (NATS).

• All of the originally supplied ignition key IDs have been IVIS (NATS) registered.

If requested by the vehicle owner, a maximum of five key IDs can be registered into the IVIS (NATS) compo-

nents.

• The security indicator blinks when the ignition switch is in OFF or ACC position. IVIS (NATS) warns outsiders

that the vehicle is equipped with the anti-theft system.

• When IVIS (NATS) detects a malfunction, the security indicator lamp lights up while ignition key is in the ON

position.

• IVIS (NATS) trouble diagnoses, system initialization and additional registration of other IVIS (NATS) ignition

key IDs must be carried out using CONSULT-II hardware and CONSULT-II IVIS (NATS) software.

When IVIS (NATS) initialization has been completed, the ID of the inserted ignition key is automatically IVIS

(NATS) registered. Then, if necessary, additional registration of other IVIS (NATS) ignition key IDs can be

carried out.

Regarding the procedures of IVIS (NATS) initialization and IVIS (NATS) ignition key ID registration, refer to

CONSULT-II Operation Manual NATS-IVIS/NVIS.

•When servicing a malfunction of the IVIS (NATS) (indicated by lighting up of Security Indicator

Lamp) or registering another IVIS (NATS) ignition key ID, it may be necessary to re-register original

key identification. Therefore, be sure to receive ALL KEYS from vehicle owner.

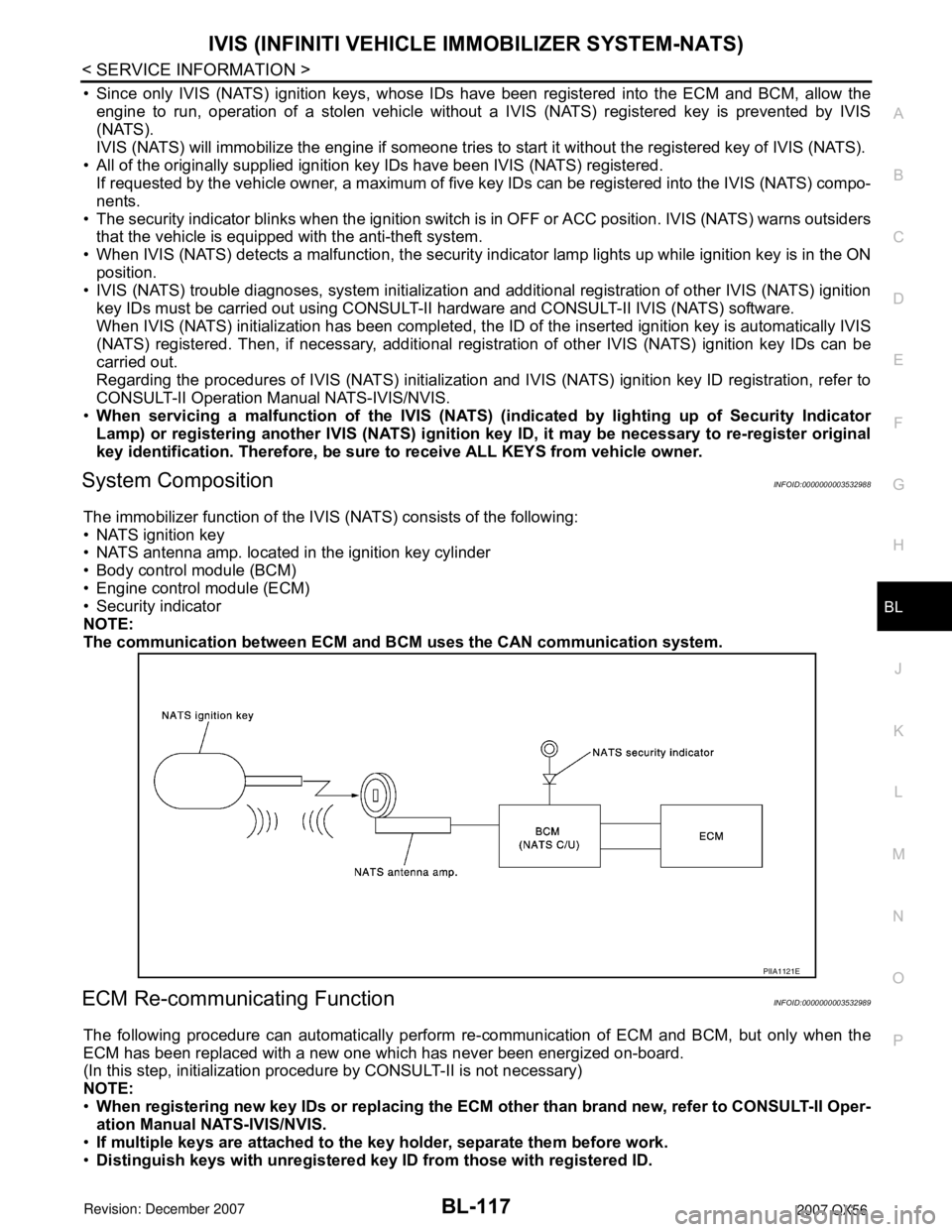

System CompositionINFOID:0000000003532988

The immobilizer function of the IVIS (NATS) consists of the following:

• NATS ignition key

• NATS antenna amp. located in the ignition key cylinder

• Body control module (BCM)

• Engine control module (ECM)

• Security indicator

NOTE:

The communication between ECM and BCM uses the CAN communication system.

ECM Re-communicating FunctionINFOID:0000000003532989

The following procedure can automatically perform re-communication of ECM and BCM, but only when the

ECM has been replaced with a new one which has never been energized on-board.

(In this step, initialization procedure by CONSULT-II is not necessary)

NOTE:

•When registering new key IDs or replacing the ECM other than brand new, refer to CONSULT-II Oper-

ation Manual NATS-IVIS/NVIS.

•If multiple keys are attached to the key holder, separate them before work.

•Distinguish keys with unregistered key ID from those with registered ID.

PIIA1121E

Page 835 of 3061

BL-124

< SERVICE INFORMATION >

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)

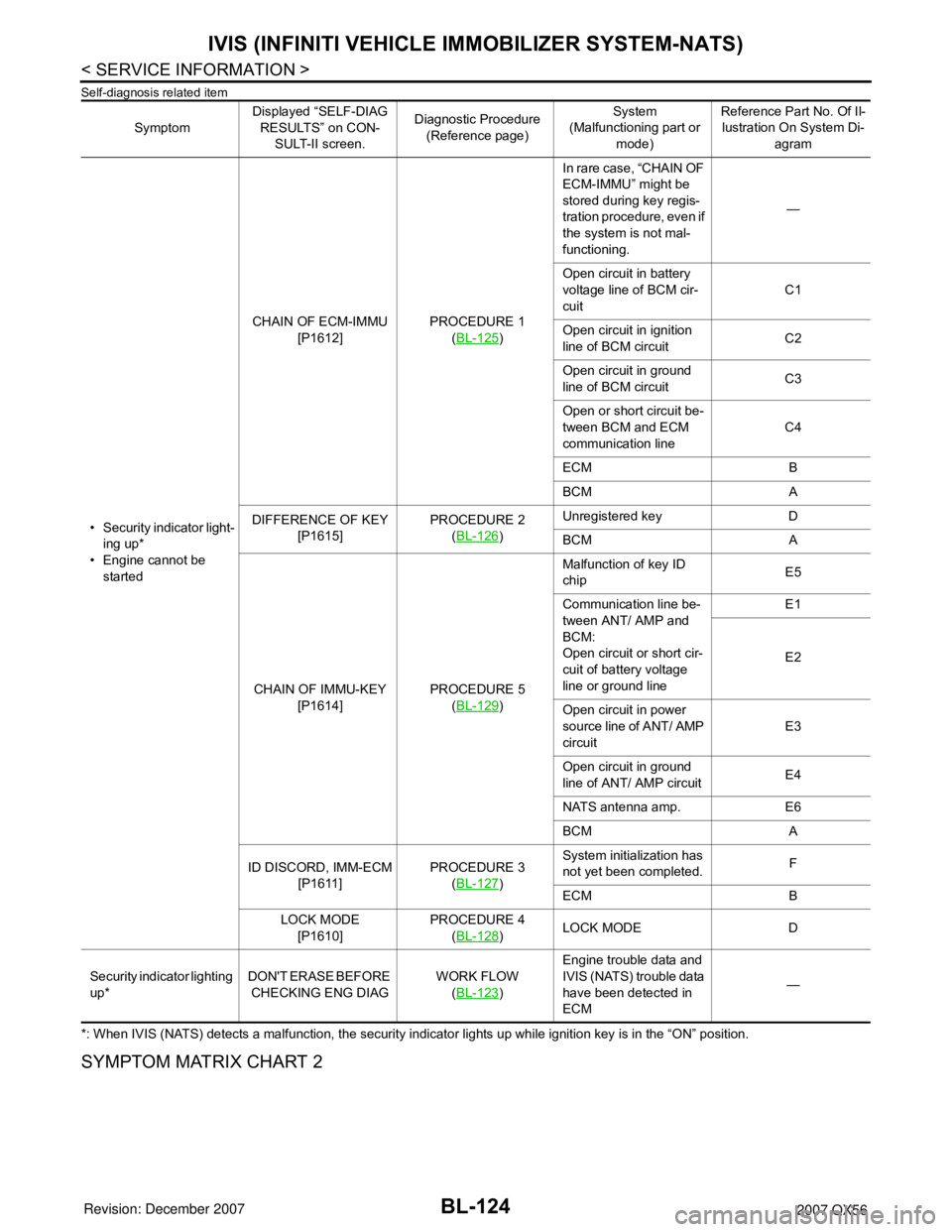

Self-diagnosis related item

*: When IVIS (NATS) detects a malfunction, the security indicator lights up while ignition key is in the “ON” position.

SYMPTOM MATRIX CHART 2

SymptomDisplayed “SELF-DIAG

RESULTS” on CON-

SULT-II screen.Diagnostic Procedure

(Reference page)System

(Malfunctioning part or

mode)Reference Part No. Of Il-

lustration On System Di-

agram

• Security indicator light-

ing up*

• Engine cannot be

startedCHAIN OF ECM-IMMU

[P1612]PROCEDURE 1

(BL-125

)In rare case, “CHAIN OF

ECM-IMMU” might be

stored during key regis-

tration procedure, even if

the system is not mal-

functioning.—

Open circuit in battery

voltage line of BCM cir-

cuitC1

Open circuit in ignition

line of BCM circuitC2

Open circuit in ground

line of BCM circuitC3

Open or short circuit be-

tween BCM and ECM

communication lineC4

ECM B

BCM A

DIFFERENCE OF KEY

[P1615]PROCEDURE 2

(BL-126

)Unregistered key D

BCM A

CHAIN OF IMMU-KEY

[P1614]PROCEDURE 5

(BL-129

)Malfunction of key ID

chipE5

Communication line be-

tween ANT/ AMP and

BCM:

Open circuit or short cir-

cuit of battery voltage

line or ground lineE1

E2

Open circuit in power

source line of ANT/ AMP

circuitE3

Open circuit in ground

line of ANT/ AMP circuitE4

NATS antenna amp. E6

BCM A

ID DISCORD, IMM-ECM

[P1611]PROCEDURE 3

(BL-127

)System initialization has

not yet been completed.F

ECM B

LOCK MODE

[P1610]PROCEDURE 4

(BL-128

)LOCK MODE D

Security indicator lighting

up*DON'T ERASE BEFORE

CHECKING ENG DIAGWORK FLOW

(BL-123

)Engine trouble data and

IVIS (NATS) trouble data

have been detected in

ECM—