INFINITI QX56 2008 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 1891 of 4083

EM-88

< DISASSEMBLY AND ASSEMBLY >

ENGINE UNIT

• Tap until flattened with the front edge of the rear oil sealretainer using suitable tool.

• Fit the rear oil seal until it is level with the rear end surface of

rear oil seal retainer.

9. Install rear oil seal retainer. • Apply liquid gasket thoroughly to rear oil seal retainer as

shown.

Use Genuine RTV Silicone Seal ant or equivalent. Refer to

GI-15, "

Recommended Chemical Products and Sealants".

• Apply new engine oil on the lips of rear oil seal. Do not touch.

10. Install the piston to the connecting rod.

a. Install the snap ring to the gr ooves of the piston rear side.

• Insert it fully into the groove to install.

b. Install the piston to the connecting rod. • Heat piston until piston pin can be pushed in by hand without excess force [approx. 60° to 70 C ° (140° to

158 °F)]. From the front to the rear, insert t he piston pin into the piston and the connecting rod.

• Assemble so that the front mark on the piston crown and the

oil holes and cylinder No. on the connecting rod are positioned

as shown.

c. Install the snap ring to the gr ooves of the piston front side.

• Insert it fully into the groove to install.

• After installing, make sure connecting rod moves smoothly.

11. Install piston rings. CAUTION:

Do not damage piston.

• Position each ring with the gap as shown, referring to the pis-ton front mark.

• Install the second ring with the stamped surface facing

upward.

PBIC0097E

SBIA0391E

KBIA2534E

Stamped mark Second ring : 2N

PBIC0100E

Revision: March 2010 2008 QX56

Page 1892 of 4083

ENGINE UNITEM-89

< DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

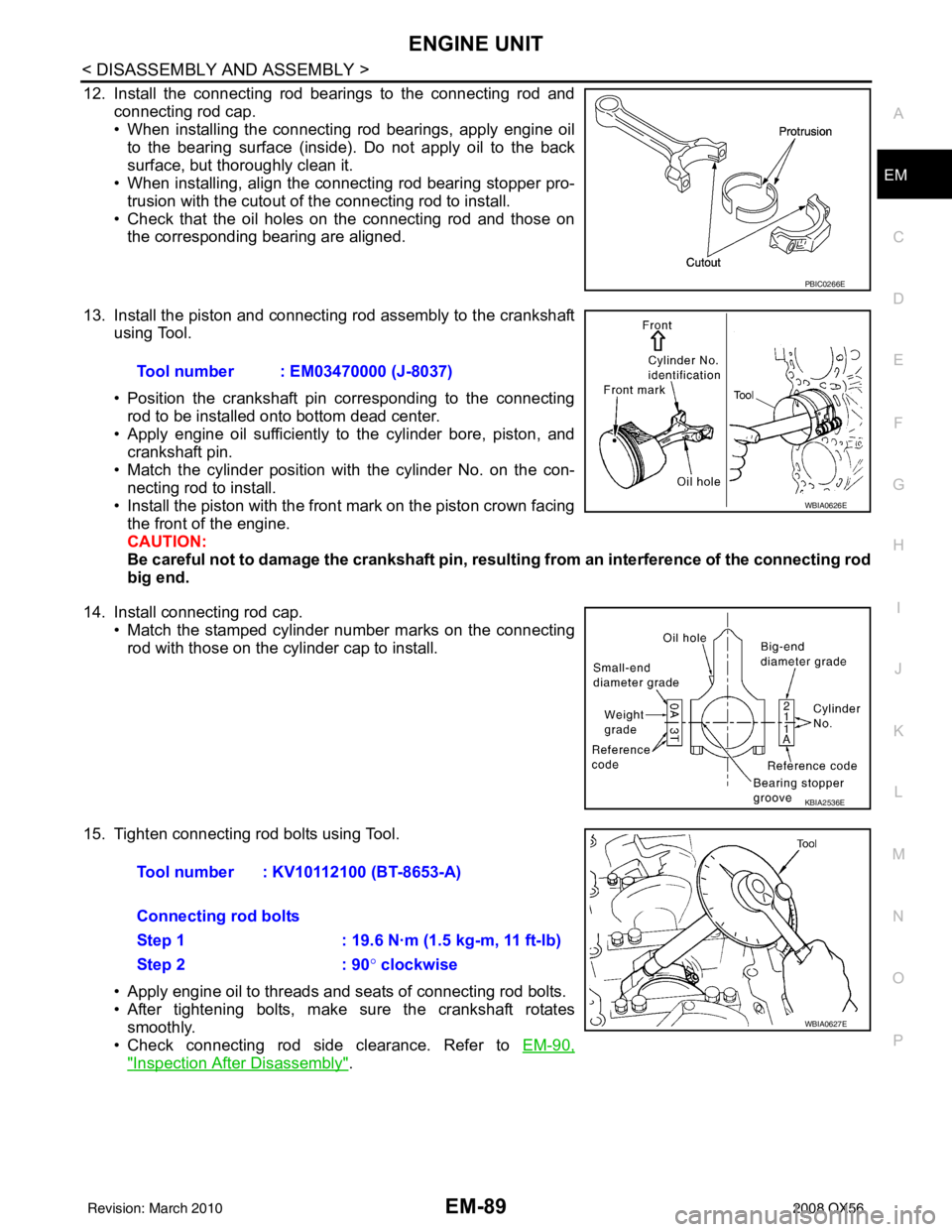

12. Install the connecting rod bearings to the connecting rod and

connecting rod cap.

• When installing the connecting rod bearings, apply engine oilto the bearing surface (inside). Do not apply oil to the back

surface, but thoroughly clean it.

• When installing, align the connecting rod bearing stopper pro-

trusion with the cutout of the connecting rod to install.

• Check that the oil holes on the connecting rod and those on the corresponding bearing are aligned.

13. Install the piston and connecting rod assembly to the crankshaft using Tool.

• Position the crankshaft pin corresponding to the connecting

rod to be installed onto bottom dead center.

• Apply engine oil sufficiently to the cylinder bore, piston, and

crankshaft pin.

• Match the cylinder position with the cylinder No. on the con- necting rod to install.

• Install the piston with the front mark on the piston crown facing the front of the engine.

CAUTION:

Be careful not to damage the crankshaft pin, resu lting from an interference of the connecting rod

big end.

14. Install connecting rod cap. • Match the stamped cylinder number marks on the connectingrod with those on the cylinder cap to install.

15. Tighten connecting rod bolts using Tool. • Apply engine oil to threads and seats of connecting rod bolts.

• After tightening bolts, make sure the crankshaft rotatessmoothly.

• Check connecting rod side clearance. Refer to EM-90,

"Inspection After Disassembly".

PBIC0266E

Tool number : EM03470000 (J-8037)

WBIA0626E

KBIA2536E

Tool number : KV10112100 (BT-8653-A)

Connecting rod bolts

Step 1 : 19.6 N·m (1.5 kg-m, 11 ft-lb)

Step 2: 90° clockwise

WBIA0627E

Revision: March 2010 2008 QX56

Page 1893 of 4083

EM-90

< DISASSEMBLY AND ASSEMBLY >

ENGINE UNIT

16. Install knock sensors.CAUTION:

If knock sensor is dropped, replace it with a new one.

• Make sure that there is no foreign material on the cylinderblock mating surface and the back surface of knock sensor.

• Install it with its connector facing the center of the cylinder

block side.

• Do not tighten knock sensor bolts while holding connector.

• Make sure knock sensor does not interfere with other parts.

• Position the sub-harness as shown before installing intake manifold.

17. Installation of the remaining components is in the reverse order of removal.

18. Remove engine assembly from engine stand.

19. Install drive plate. • Align dowel pin of crankshaft rear end with pin holes of eachpart to install.

• Install drive plate, reinforcement plate and pilot converter (if not installed in step 4) as shown.

• Face the chamfered or rounded edge side to the crankshaft.

Inspection After DisassemblyINFOID:0000000001538833

CRANKSHAFT END PLAY

KBIA2493E

KBIA2549E

KBIA2494E

KBIA2537E

Revision: March 2010 2008 QX56

Page 1894 of 4083

ENGINE UNITEM-91

< DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

• Move the crankshaft fully forward and backward and measure the

clearance between the thrust bear ings and crankshaft arm using

suitable tool.

• If measured value exceeds the repair limit, replace the thrust bear- ings, and measure again. If it still exceeds the repair limit, replace

crankshaft also.

CONNECTING ROD SIDE CLEARANCE

• Measure side clearance between the connecting rod and crank-shaft arm using suitable tool.

• If measured value exceeds the repair limit, replace the connecting rod bearings, and measure again. If it still exceeds the repair limit,

replace the crankshaft also.

PISTON AND PISTON PIN CLEARANCE

Piston Pin Hole Diameter

• Measure diameter of piston pin hole using suitable tool.

Piston Pin Diameter

• Measure diameter of piston pin using suitable tool.

Piston and Piston Pin Clearance

Standard : 0.10 - 0.26 mm (0.0039 - 0.0102 in)

Limit : 0.30 mm (0.0118 in)

PBIC0114E

Standard : 0.20 - 0.40 mm (0.0079 - 0.0157 in)

Limit : 0.40 mm (0.0157 in)

PBIC0115E

Standard : 21.993 - 21.999 mm (0.8659 - 0.8661 in)

PBIC0116E

Standard : 21.989 - 21.995 mm (0.8657 - 0.8659 in)

PBIC0117E

Revision: March 2010 2008 QX56

Page 1895 of 4083

EM-92

< DISASSEMBLY AND ASSEMBLY >

ENGINE UNIT

(Piston pin clearance) = (Piston pin hole diameter) – (Piston pin

diameter)

• If clearance exceeds specification, replace either or both the pis-

ton/piston pin assembly and the connecting rod assembly with ref-

erence to the specification of each part.

• Use the piston selection table to replace piston/piston pin assem-

bly. Refer to EM-101, "

How to Select Piston and Bearing".

• Use the connecting rod bearing selection table to replace connect- ing rod. Refer to EM-101, "

How to Select Piston and Bearing".

NOTE:

The connecting rod small end grade and piston pin hole (piston

pin) grade are provided only for the parts installed at the plant. For

service parts, no grades can be selected (only 0 grade is avail-

able).

• Follow the "Connecting Rod Bushing Oil Clearance (Small End)" procedure for the values for each grade at the plant.

PISTON RING SIDE CLEARANCE

• Measure side clearance of the piston ring and piston ring grooveusing suitable tool.

• If out of specification, replac e piston and/or piston ring assembly.

PISTON RING END GAP

• Check if the diameter of the cyli nder bore is within specification.

Follow the "Piston to Cylinder Bore Clearance" procedure.

• Insert the piston ring into the middle of the cylinder using the pis- ton, and measure the gap.

• If out of specification, replace pi ston ring. If the gap still exceeds the li mit even with a new ring, re-bore the

cylinder and use oversized piston and piston ring. Standard : 0.002 - 0.006 mm (0.0001 - 0.0002 in)

KBIA2496E

KBIA2536E

Standard:

Top ring : 0.035 - 0.085 mm (0.0014 - 0.0033 in)

2nd ring : 0.030 - 0.070 mm (0.0012 - 0.0028 in)

Oil ring : 0.015 - 0.050 mm (0.0006 - 0.0020 in)

Limit: Top ring : 0.11 mm (0.0043 in)

2nd ring : 0.10 mm (0.0039 in)

SEM024AA

Standard Top ring : 0.23 - 0.33 mm (0.0091 - 0.0130 in)

2nd ring : 0.25 - 0.40 mm (0.0098 - 0.0157 in)

Oil ring : 0.20 - 0.60 mm (0.0079 - 0.0236 in)

Limit: Top ring : 0.56 mm (0.0220 in)

2nd ring : 0.52 mm (0.0205 in)

Oil ring : 0.96 mm (0.0378 in)

PBIC0118E

Revision: March 2010 2008 QX56

Page 1896 of 4083

ENGINE UNITEM-93

< DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

CONNECTING ROD BEND AND TORSION

• Check connecting rod alignment using suitable tool.

• If measurement exceeds the limi

t, replace connecting rod assem-

bly.

CONNECTING ROD BEARING (BIG END)

• Install the connecting rod cap without the connecting rod bearing installed. After tightening the connecting rod bolt to the specified

torque, measure the connecting rod large end inside diameter.

Refer to EM-82, "

Disassembly and Assembly".

• If measurement exceeds the standard, replace connecting rod.

CONNECTING ROD BUSHING OIL CLEARANCE (SMALL END)

Connecting Rod Inside Diameter (Small End)

• Measure inside diameter of bushing using suitable tool.

Piston Pin Diameter

Limit: Bend: 0.15 mm (0.0059 in) per 100 mm (3.94 in) length

To r s i o n : 0.30 mm (0.0118 in) per 100 mm (3.94 in) length

SEM003F

SEM038F

Standard : 57.000 - 57.013 mm (2.2441 - 2.2446 in)

PBIC1641E

Standard : 22.000 - 22.006 mm (0.8661 - 0.8664 in)

PBIC0120E

Revision: March 2010 2008 QX56

Page 1897 of 4083

EM-94

< DISASSEMBLY AND ASSEMBLY >

ENGINE UNIT

• Measure diameter of piston pin using suitable tool.

Connecting Rod Bushing Oil Clearance (Small End)

(Connecting rod small end oil clearance) = (Inside diameter of con-

necting rod small end) – (Piston pin diameter)

• If measured value exceeds the standard, replace the connectingrod assembly and/or piston and piston pin assembly.

• If replacing the piston and piston pin assembly, use the Table for

Selective Fitting for Piston to select the piston corresponding to the

applicable bore grade of the cylinder block to be used. Refer to

EM-101, "

How to Select Piston and Bearing".

Factory installed parts grading:

• Only grade 0 is available.

Unit: mm (in)

CYLINDER BLOCK DISTORTION

• Remove any oil, scale, gasket, sealant and carbon deposits from the cylinder block surface.

CAUTION:

Do not allow any debris to en ter the oil or coolant passages.

• Measure block upper face for distortion in six directions as shown.

• If measurement exceeds the limit, replace cylinder block.

MAIN BEARING HOUSING INSIDE DIAMETER

Standard : 21.989 - 21.995 mm (0.8657 - 0.8659 in)

PBIC0117E

Standard : 0.005 - 0.017 mm (0.0002 - 0.0007 in)

KBIA2536E

Grade 0

Connecting rod bushing inside diameter 22.000 - 22.006

(0.8661 - 0.8664)

Piston pin diameter 21.989 - 21.995

(0.8657 - 0.8659)

Piston pin hole diameter 21.993 - 21.999

(0.8659 - 0.8661)

KBIA2496E

Standard : 0.03 mm (0.0012 in)

Limit : 0.1 mm (0.004 in)

SEM123C

Revision: March 2010 2008 QX56

Page 1898 of 4083

ENGINE UNITEM-95

< DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

• Install the main bearing caps with the main bearings removed, and

tighten the bolts to the specified torque. Refer to EM-82, "

Disas-

sembly and Assembly".

• Measure inside diameter of main bearing housing.

• If out of the standard, replace cylinder block and main bearing caps as an assembly.

NOTE:

These components must be replaced as a single unit, because

they were processed together.

PISTON TO CYLINDER BORE CLEARANCE

Cylinder Bore Diameter

• Measure the cylinder bore for wear, out-of-round and taper at six

different points on each cylinder ( ″X″ and ″Y″ directions at ″A″ , ″B″

and ″C ″).

NOTE:

When determining cylinder bore grade, measure cylinder bore at

"B" position.

• If measured value exceeds the repair limit, or if ther e are scratches and/or seizure on the cylinder inner wall,

hone or bore the inner wall.

Piston Skirt Diameter

• Measure piston skirt diameter using suitable tool. Standard : 68.944 - 68.968 mm (2.7143 - 2.7153 in)

PBIC1643E

PBIC0123E

Standard diameter:

98.000 - 98.030 mm (3.8583 - 3.8594 in)

Wear limit: 0.20 mm (0.0079 in)

Out-of-round (Difference between ″X″ and ″Y″ ):

Limit: 0.015 mm (0.0006 in)

Taper limit (Difference between ″A ″ and ″C ″):

Limit: 0.010 mm (0.0004 in)

PBIC0124E

Standard : 97. 980 - 98. 010 mm (3.8575 - 3.8587 in)

PBIC0125E

Revision: March 2010 2008 QX56

Page 1899 of 4083

EM-96

< DISASSEMBLY AND ASSEMBLY >

ENGINE UNIT

• Measure point ″H″.

Piston to Cylinde r Bore Clearance

• Calculate by using diameter of the piston skirt and the cylinder bore diameter (direction X, position B).

(Clearance) = (Cylinder bore diameter) – (piston skirt diameter)

• If calculation exceeds the limit, replace piston/piston pin assembly.

Reboring Cylinder Bore

1. Cylinder bore size is determined by adding pi ston-to-bore clearance to piston diameter “A”.

2. Install main bearing caps, and tighten them to the specified torque. Otherwise, cylinder bores may be dis-

torted in final assembly.

3. Cut the cylinder bores. NOTE:

• When any cylinder needs boring, all other cylinders must also be bored.

• Do not cut too much out of cylinder bore at one time. Cut only 0.05 mm (0.0020 in) or so in diameter at atime.

4. Hone cylinders to obtain the specified piston-to-bore clearance.

5. Measure finished cylinder bore for out-of-round and taper. NOTE:

Measurement should be done after cylinder bore cools down.

CRANKSHAFT JOURNAL DIAMETER

• Measure diameter of crankshaft journals.

• If measurement is out of standard, measure the ma in bearing oil clearance. Then use the undersize bearing.

Follow the "MAIN BEARING OIL CLEARANCE" procedure.

CRANKSHAFT PIN DIAMETER

Distance from the top : 39 mm (1.54 in)

KBIA2545E

Standard : 0.010 - 0.030 mm (0.0004 - 0.0012 in)

Limit : 0.08 mm (0.0031 in)

Rebored size calculation: D = A +B - C

where,

D: Bored diameter

A: Piston diameter as measured

B: Piston - to - bore clearance (standard value)

C: Honing allowance 0.02 mm (0.0008 in)

Standard : 63.940 - 63.964 mm (2.5173 - 2.5183 in)

Revision: March 2010 2008 QX56

Page 1900 of 4083

ENGINE UNITEM-97

< DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

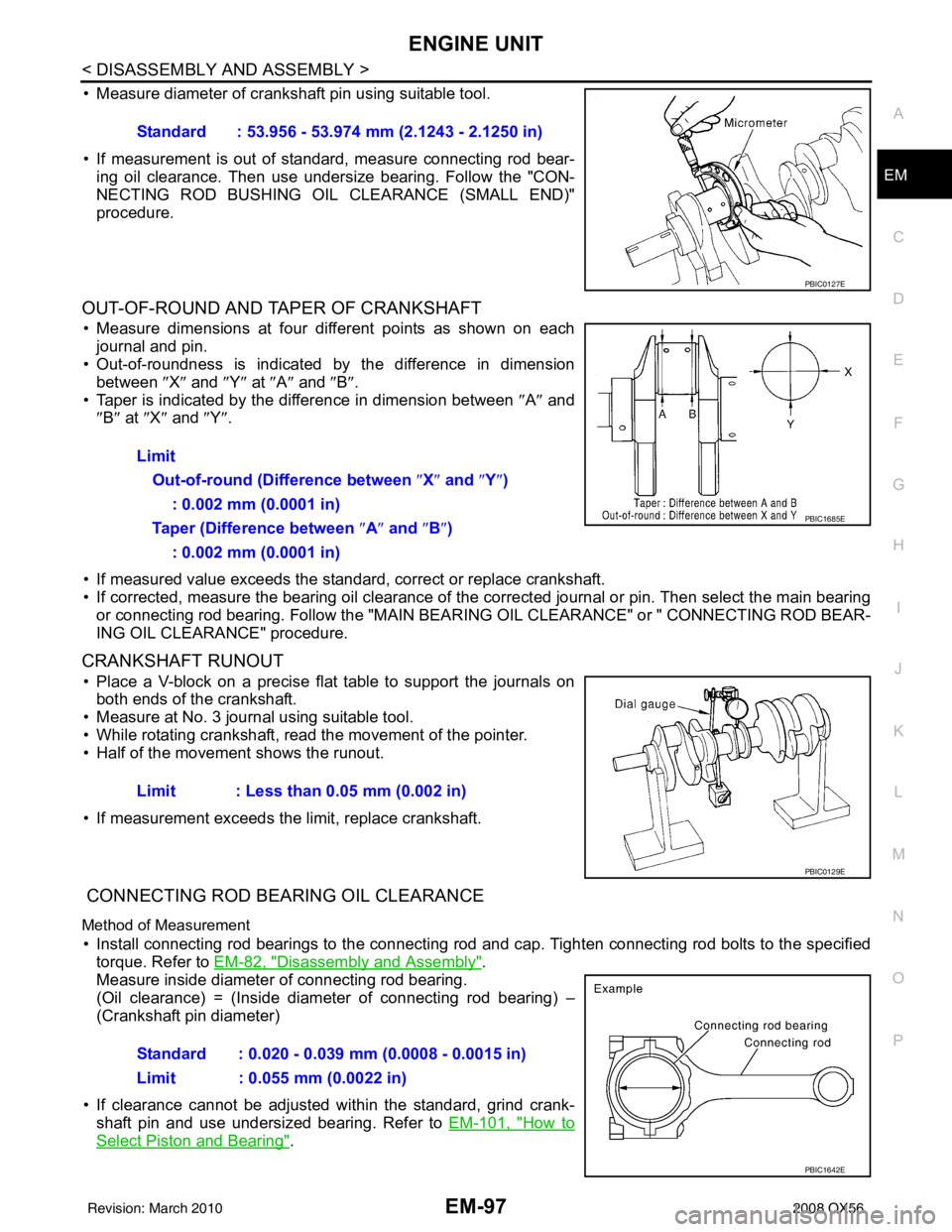

• Measure diameter of crankshaft pin using suitable tool.

• If measurement is out of standard, measure connecting rod bear-

ing oil clearance. Then use undersize bearing. Follow the "CON-

NECTING ROD BUSHING OIL CLEARANCE (SMALL END)"

procedure.

OUT-OF-ROUND AND TAPER OF CRANKSHAFT

• Measure dimensions at four di fferent points as shown on each

journal and pin.

• Out-of-roundness is indicated by the difference in dimension

between ″X″ and ″Y″ at ″A″ and ″B″ .

• Taper is indicated by the difference in dimension between ″A ″ and

″ B″ at ″X ″ and ″Y″ .

• If measured value exceeds the standard, correct or replace crankshaft.

• If corrected, measure the bearing oil clearance of the corrected journal or pin. Then select the main bearing or connecting rod bearing. Follow the "MAIN BEA RING OIL CLEARANCE" or " CONNECTING ROD BEAR-

ING OIL CLEARANCE" procedure.

CRANKSHAFT RUNOUT

• Place a V-block on a precise flat table to support the journals on both ends of the crankshaft.

• Measure at No. 3 journal using suitable tool.

• While rotating crankshaft, read the movement of the pointer.

• Half of the movement shows the runout.

• If measurement exceeds the limit, replace crankshaft.

CONNECTING ROD BEARING OIL CLEARANCE

Method of Measurement

• Install connecting rod bearings to the connecting rod and cap. Tighten connecting rod bolts to the specified

torque. Refer to EM-82, "

Disassembly and Assembly".

Measure inside diameter of connecting rod bearing.

(Oil clearance) = (Inside diameter of connecting rod bearing) –

(Crankshaft pin diameter)

• If clearance cannot be adjusted wit hin the standard, grind crank-

shaft pin and use undersized bearing. Refer to EM-101, "

How to

Select Piston and Bearing".

Standard : 53.956 - 53.974 mm (2.1243 - 2.1250 in)

PBIC0127E

Limit

Out-of-round (Difference between ″X ″ and ″ Y″)

: 0.002 mm (0.0001 in)

Taper (Difference between ″ A″ and ″B ″)

: 0.002 mm (0.0001 in)

PBIC1685E

Limit : Less than 0.05 mm (0.002 in)

PBIC0129E

Standard : 0.020 - 0.039 mm (0.0008 - 0.0015 in)

Limit : 0.055 mm (0.0022 in)

PBIC1642E

Revision: March 2010 2008 QX56