INFINITI QX56 2008 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 2161 of 4083

TERMINOLOGYGI-19

< HOW TO USE THIS MANUAL >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

***: Not applicable Transmission control module TCM A/T control unit

Turbocharger TC Turbocharger

Vehicle speed sensor VSS Vehicle speed sensor

Volume air flow sensor VAFS Air flow meter

Warm up oxidation catalyst WU-OC Catalyst

Warm up oxidation catalytic converter sys-

tem

WU-OC system ***

Warm up three way catalyst WU-TWC Catalyst

Warm up three way catalytic converter sys-

tem WU-TWC system

***

Wide open throttle position switch WOTP switchFull switch

NEW TERM

NEW ACRONYM /

ABBREVIATION OLD TERM

Revision: March 2010

2008 QX56

Page 2162 of 4083

GI-20

< FEATURES OF NEW MODEL >

IDENTIFICATION INFORMATION

FEATURES OF NEW MODEL

IDENTIFICATION INFORMATION

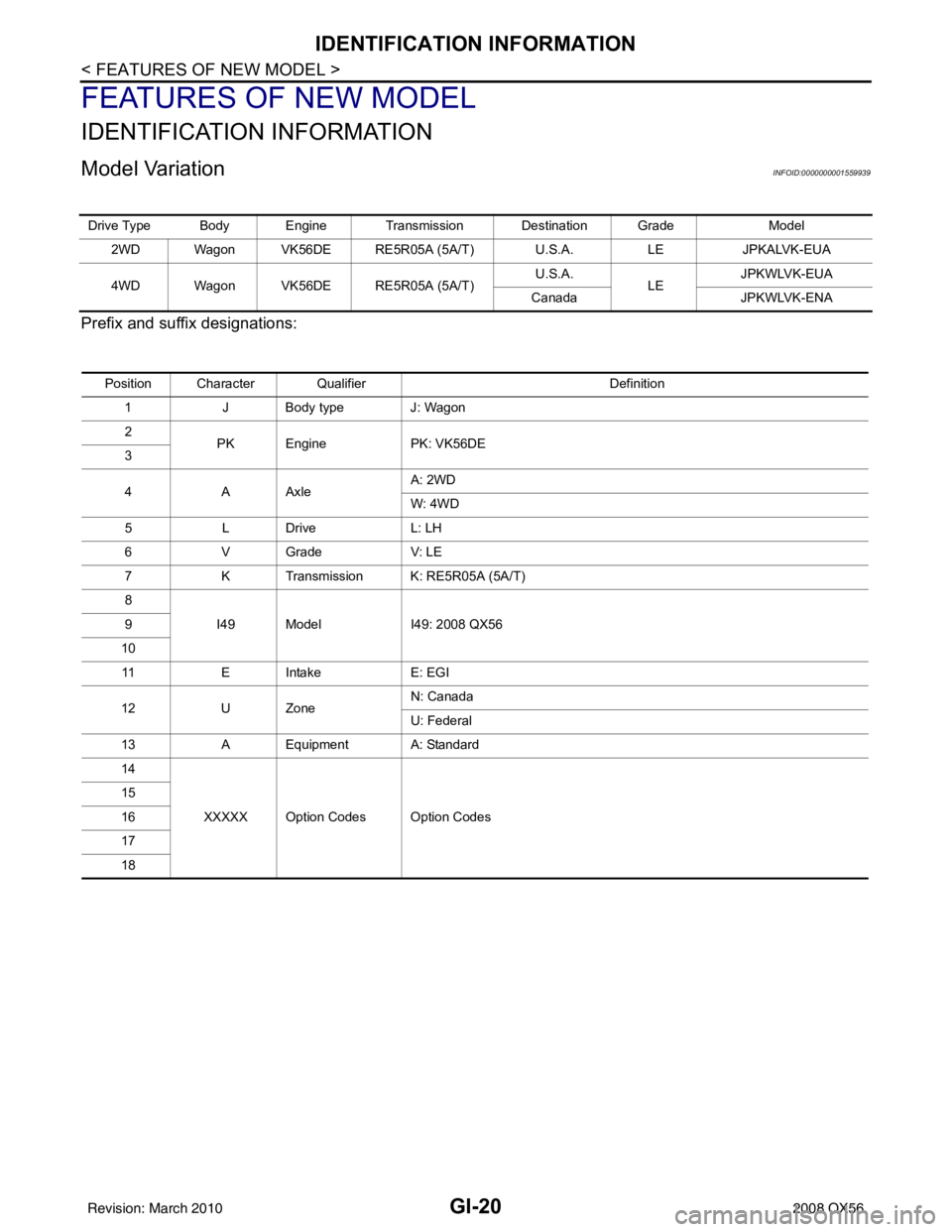

Model VariationINFOID:0000000001559939

Prefix and suffix designations:

Drive Type Body Engine Transmission Destination GradeModel

2WD Wagon VK56DE RE5R05A (5A/T) U.S.A. LEJPKALVK-EUA

4WD Wagon VK56DE RE5R05A (5A/T) U.S.A.

LEJPKWLVK-EUA

Canada JPKWLVK-ENA

Position Character Qualifier Definition

1 J Body type J: Wagon

2 PK Engine PK: VK56DE

3

4AA xle A: 2WD

W: 4WD

5LD riv e L : L H

6 V Grade V: LE

7 K Transmission K: RE5R05A (5A/T)

8 I49 Model I49: 2008 QX56

9

10 11 E I n t a k e E : E G I

12 U Zone N: Canada

U: Federal

13 A Equipment A: Standard

14

XXXXX Option Codes Option Codes

15

16

17

18

Revision: March 2010

2008 QX56

Page 2163 of 4083

IDENTIFICATION INFORMATIONGI-21

< FEATURES OF NEW MODEL >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

Identification NumberINFOID:0000000001559940

VEHICLE IDENTIFICATION NUMBER ARRANGEMENT

1. Emission control information label/ vacuum hose diagram 2. Tire placard 3. F.M.V.S.S./C.M.V.S.S. certification

label

4. Vehicle identification number plate 5. Air conditioner specification label

AWAIA0026GB

Position Character Qualifier Definition

1 5N3 Manufacturer 5N3: USA produced multi-purpose vehicle

2

3

4 A Engine type A: VK56DE

5 A0 Model code A0: Infiniti QX56

6

7 8 Body type 8: 4 door wagon

8D Gross vehicle

weight ratingD: 2WD, 4-wheel ABS, Class F

C: 4WD, 4-wheel ABS, Class F

9 * Check digit (0 to 9 or X) The code for the check digit is determined by a mathematical com-

putation.

10 8 Model year 2008

11 NManufacturing

plant

N: Canton Mississippi

12

XXXXXX Vehicle serial num-

ber Chassis number

13

14

15

16

17

Revision: March 2010

2008 QX56

Page 2164 of 4083

GI-22

< FEATURES OF NEW MODEL >

IDENTIFICATION INFORMATION

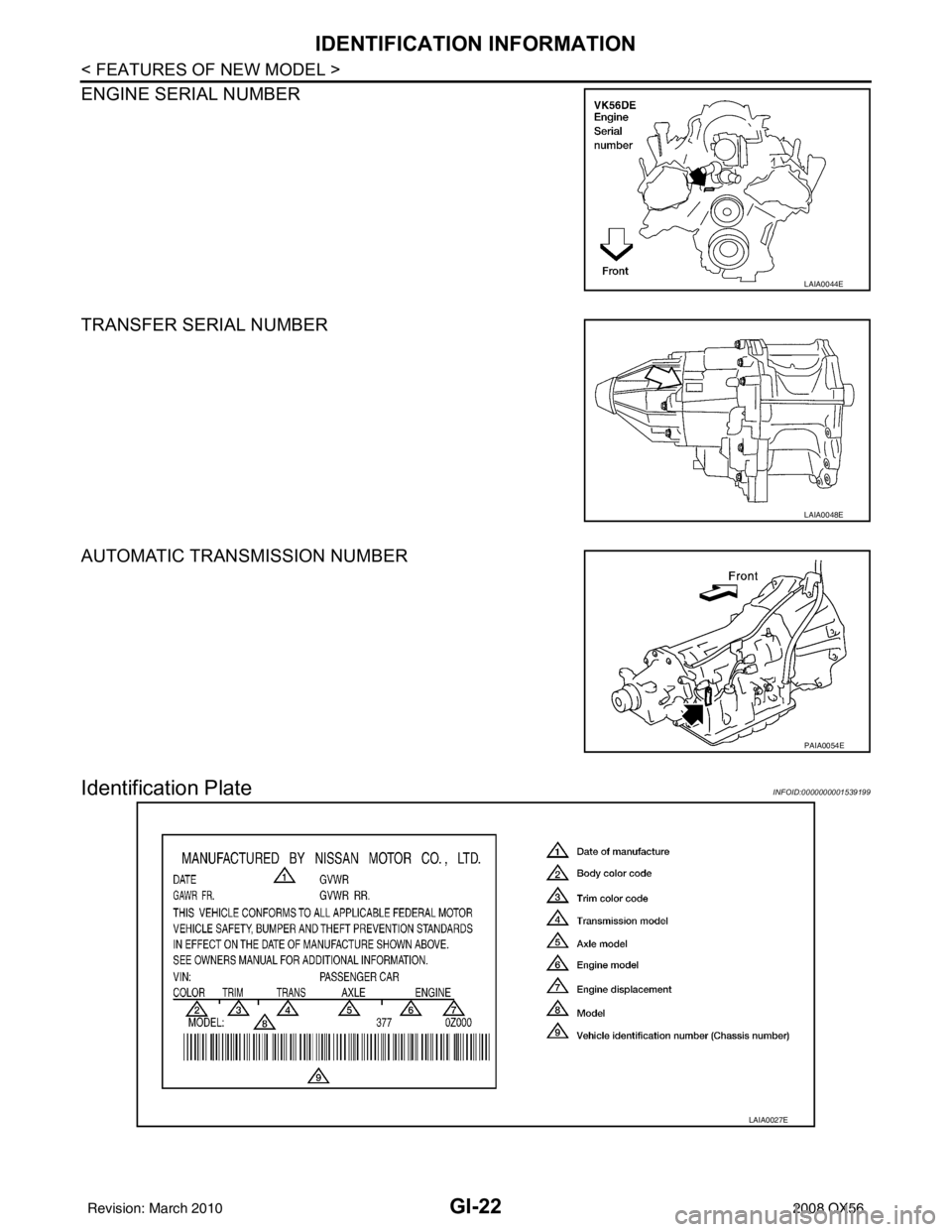

ENGINE SERIAL NUMBER

TRANSFER SERIAL NUMBER

AUTOMATIC TRANSMISSION NUMBER

Identification PlateINFOID:0000000001539199

LAIA0044E

LAIA0048E

PAIA0054E

LAIA0027E

Revision: March 20102008 QX56

Page 2165 of 4083

IDENTIFICATION INFORMATIONGI-23

< FEATURES OF NEW MODEL >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

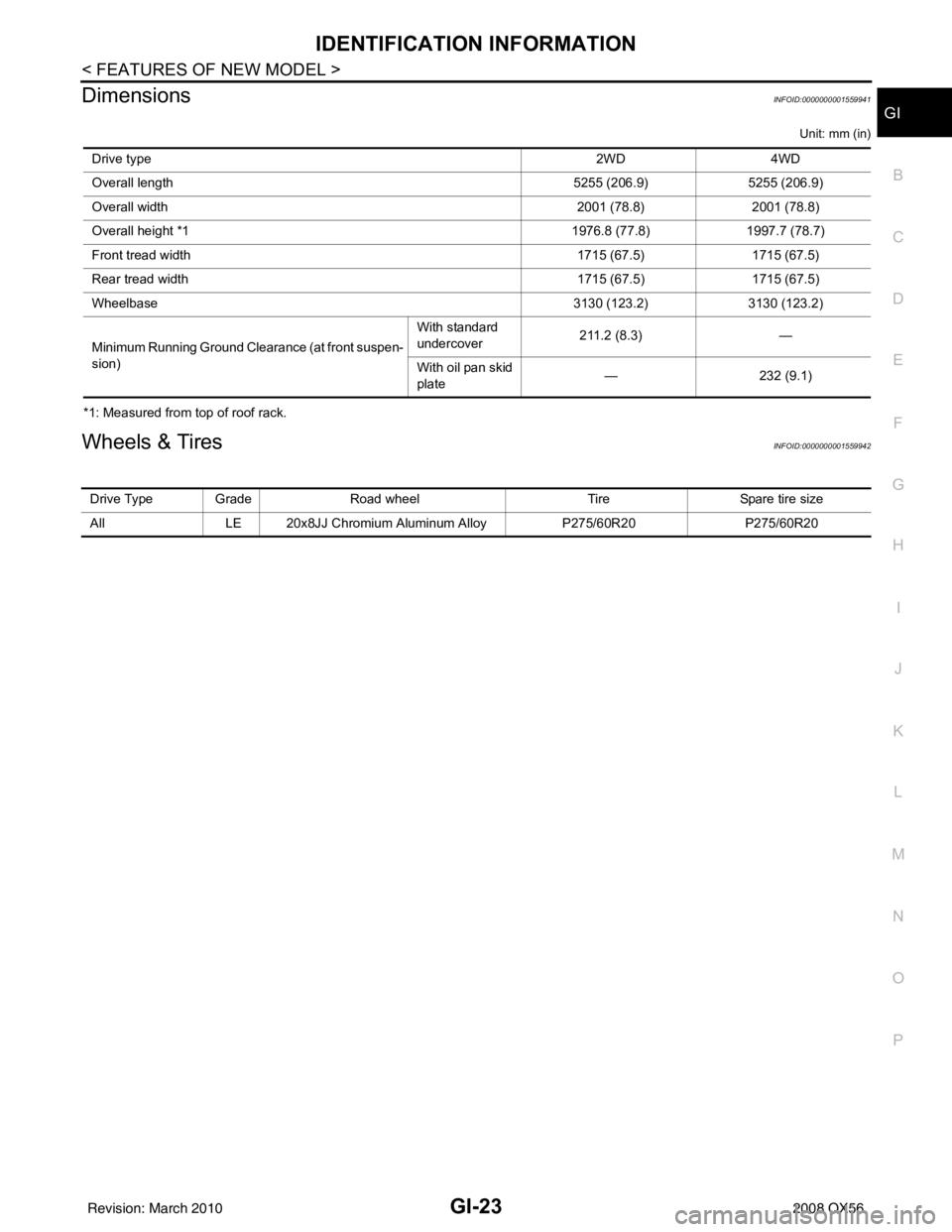

DimensionsINFOID:0000000001559941

Unit: mm (in)

*1: Measured from top of roof rack.

Wheels & TiresINFOID:0000000001559942

Drive type 2WD 4WD

Overall length 5255 (206.9)5255 (206.9)

Overall width 2001 (78.8)2001 (78.8)

Overall height *1 1976.8 (77.8)1997.7 (78.7)

Front tread width 1715 (67.5)1715 (67.5)

Rear tread width 1715 (67.5)1715 (67.5)

Wheelbase 3130 (123.2)3130 (123.2)

Minimum Running Ground Clearance (at front suspen-

sion) With standard

undercover

211.2 (8.3)

—

With oil pan skid

plate —2

32 ( 9.1 )

Drive Type Grade Road wheelTireSpare tire size

All LE 20x8JJ Chromium Aluminum Alloy P275/60R20P275/60R20

Revision: March 2010 2008 QX56

Page 2166 of 4083

GI-24

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

DescriptionINFOID:0000000001539205

Observe the following precautions to ensure safe and proper servicing. These precautions are not

described in each individual section.

Precaution for Supplemental Restraint Syst em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006054104

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000004900859

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

Revision: March 2010 2008 QX56

Page 2167 of 4083

PRECAUTIONSGI-25

< PRECAUTION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Procedures without Cowl Top CoverINFOID:0000000001539208

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

General PrecautionsINFOID:0000000001539209

• Do not operate the engine for an extended period of time without

proper exhaust ventilation.

Keep the work area well ventilated and free of any inflammable

materials. Special care should be taken when handling any inflam-

mable or poisonous materials, such as gasoline, refrigerant gas,

etc. When working in a pit or ot her enclosed area, be sure to prop-

erly ventilate the area before working with hazardous materials.

Do not smoke while working on the vehicle.

• Before jacking up the vehicle, apply wheel chocks or other tire blocks to the wheels to prevent t he vehicle from moving. After jack-

ing up the vehicle, support the vehicle weight with safety stands at

the points designated for proper lifting before working on the vehi-

cle.

These operations should be done on a level surface.

• When removing a heavy component such as the engine or tran-

saxle/transmission, be careful not to lose your balance and drop

them. Also, do not allow them to strike adjacent parts, especially

the brake tubes and master cylinder.

PIIB3706J

SGI285

SGI231

Revision: March 2010 2008 QX56

Page 2168 of 4083

GI-26

< PRECAUTION >

PRECAUTIONS

• Before starting repairs which do not require battery power:Turn off ignition switch.

Disconnect the negative battery terminal.

• If the battery terminals are disconnected, recorded memory of radio and each control unit is erased.

• To prevent serious burns: Avoid contact with hot metal parts.

Do not remove the radiator cap when the engine is hot.

• Dispose of drained oil or the solvent used for cleaning parts in an appropriate manner.

• Do not attempt to top off the fuel tank after the fuel pump nozzle

shuts off automatically.

Continued refueling may cause fuel overflow, resulting in fuel spray

and possibly a fire.

• Clean all disassembled parts in the designated liquid or solvent prior to inspection or assembly.

• Replace oil seals, gaskets, packings, O-rings, locking washers,

cotter pins, self-locking nuts, etc. with new ones.

• Replace inner and outer races of tapered roller bearings and needle bearings as a set.

• Arrange the disassembled parts in accordance with their assembled locations and sequence.

• Do not touch the terminals of electrical com ponents which use microcomputers (such as ECM).

Static electricity may damage internal electronic components.

• After disconnecting vacuum or air hoses, atta ch a tag to indicate the proper connection.

• Use only the fluids and lubricants specified in this manual.

• Use approved bonding agent, sealants or their equivalents when required.

• Use hand tools, power tools (disassembly only) and recommended special tools where specified for safe and efficient service repairs.

• When repairing the fuel, oil, water, vacuum or exhaust systems, check all affected lines for leaks.

• Before servicing the vehicle: Protect fenders, upholstery and carpeting with appropriate covers.

Take caution that keys, buckles or buttons do not scratch paint.

WARNING:

To prevent ECM from storing the diagnostic tro uble codes, do not carelessly disconnect the harness

connectors which are related to the engine control system and TCM (transmission control module)

SEF289H

SGI233

PBIC0190E

SGI234

Revision: March 2010 2008 QX56

Page 2169 of 4083

PRECAUTIONSGI-27

< PRECAUTION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

system. The connectors should be disconnected only when working according to the WORK FLOW of

TROUBLE DIAGNOSES in EC and TM sections.

Three Way CatalystINFOID:0000000001539210

If a large amount of unburned fuel flows into the catalyst, the catalyst temperature will be excessively high. To

prevent this, follow the instructions.

• Use unleaded gasoline only. Leaded gasoline will seriously damage the three way catalyst.

• When checking for ignition spark or measuring engine compression, make tests quickly and only when nec-

essary.

• Do not run engine when the fuel tank level is low, otherwise the engine may misfire, causing damage to the

catalyst.

Do not place the vehicle on flammable material. Keep flammable material off the exhaust pipe and the three

way catalyst.

Precaution for Fuel (Unlead ed Premium Gasoline Recommended)INFOID:0000000006211825

INFINITI recommends the use of unleaded premium gasoline with an octane rating of at least 91 AKI (Anti-

Knock Index) number (Research octane number 96).

If unleaded premium gasoline is not available, unleaded regular gasoline with an octane rating of at least 87

AKI number (Research octane number 91) can be us ed, but only under the following precautions:

• have the fuel tank filled only partially with unleaded regular gasoline, and fill up with unleaded premium gas- oline as soon as possible.

• avoid full throttle driving and abrupt acceleration.

However, for maximum vehicle performance, the u se of unleaded premium gasoline is recommended.

CAUTION:

Do not use leaded gasoline. Usin g leaded gasoline will damage the three way catalyst. Using a fuel

other than that specified could adversely affect the emission cont rol devices and systems, and could

also affect the warranty coverage validity.

Multiport Fuel Inje ction System or Engine Control SystemINFOID:0000000001539213

• Before connecting or disconnecting any harness connector for the

multiport fuel injection system or ECM:

Turn ignition switch to “OFF” position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

• Before disconnecting pressurized fuel line from fuel pump to injec- tors, be sure to release fuel pressure.

• Be careful not to jar components such as ECM and mass air flow

sensor.

HosesINFOID:0000000001539214

HOSE REMOVAL AND INSTALLATION

• To prevent damage to rubber hose, do not pry off rubber hose withtapered tool or screwdriver.

SGI787

SMA019D

Revision: March 2010 2008 QX56

Page 2170 of 4083

GI-28

< PRECAUTION >

PRECAUTIONS

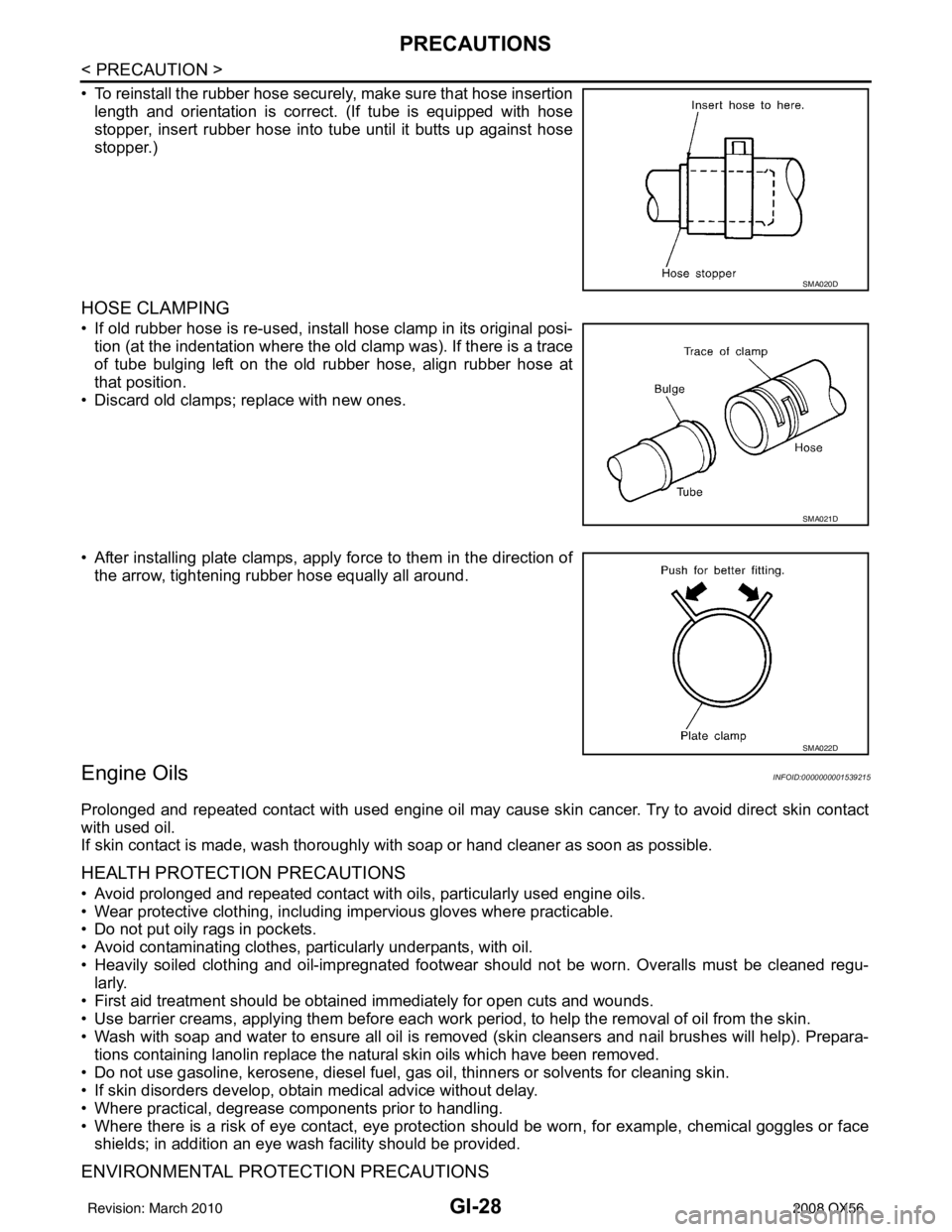

• To reinstall the rubber hose securely, make sure that hose insertionlength and orientation is correct. (If tube is equipped with hose

stopper, insert rubber hose into tube until it butts up against hose

stopper.)

HOSE CLAMPING

• If old rubber hose is re-used, install hose clamp in its original posi-tion (at the indentation where the old clamp was). If there is a trace

of tube bulging left on the old rubber hose, align rubber hose at

that position.

• Discard old clamps; replace with new ones.

• After installing plate clamps, apply force to them in the direction of the arrow, tightening rubber hose equally all around.

Engine OilsINFOID:0000000001539215

Prolonged and repeated contact with used engine oil may cause skin cancer. Try to avoid direct skin contact

with used oil.

If skin contact is made, wash thoroughly with soap or hand cleaner as soon as possible.

HEALTH PROTECTION PRECAUTIONS

• Avoid prolonged and repeated contact with oils, particularly used engine oils.

• Wear protective clothing, including impervious gloves where practicable.

• Do not put oily rags in pockets.

• Avoid contaminating clothes, pa rticularly underpants, with oil.

• Heavily soiled clothing and oil-impregnated footwear should not be worn. Overalls must be cleaned regu- larly.

• First aid treatment should be obtained immediately for open cuts and wounds.

• Use barrier creams, applying them before each work period, to help the removal of oil from the skin.

• Wash with soap and water to ensure all oil is removed (skin cleansers and nail brushes will help). Prepara-

tions containing lanolin replace the natural skin oils which have been removed.

• Do not use gasoline, kerosene, diesel fuel, gas oil, thinners or solvents for cleaning skin.

• If skin disorders develop, obtain medical advice without delay.

• Where practical, degrease components prior to handling.

• Where there is a risk of eye contact, eye protection should be worn, for example, chemical goggles or face

shields; in addition an eye wash facility should be provided.

ENVIRONMENTAL PROTECTION PRECAUTIONS

SMA020D

SMA021D

SMA022D

Revision: March 2010 2008 QX56