wheel INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 2703 of 4171

MA-30

< ON-VEHICLE MAINTENANCE >

CHASSIS AND BODY MAINTENANCE

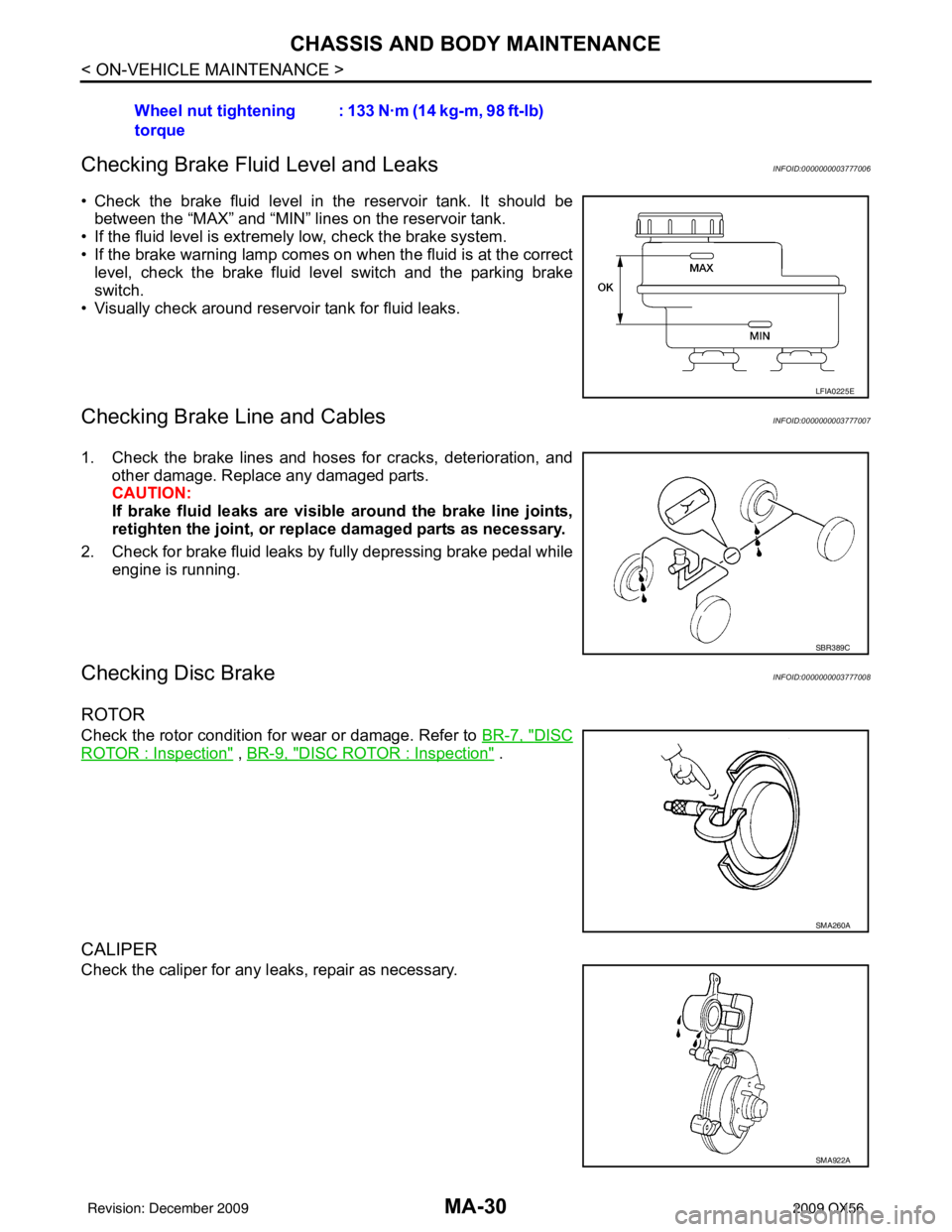

Checking Brake Fluid Level and Leaks

INFOID:0000000003777006

• Check the brake fluid level in the reservoir tank. It should be between the “MAX” and “MIN” lines on the reservoir tank.

• If the fluid level is extremely low, check the brake system.

• If the brake warning lamp comes on when the fluid is at the correct level, check the brake fluid level switch and the parking brake

switch.

• Visually check around reservoir tank for fluid leaks.

Checking Brake Line and CablesINFOID:0000000003777007

1. Check the brake lines and hoses for cracks, deterioration, and other damage. Replace any damaged parts.

CAUTION:

If brake fluid leaks are visible around the brake line joints,

retighten the joint, or replace damaged parts as necessary.

2. Check for brake fluid leaks by fully depressing brake pedal while engine is running.

Checking Disc BrakeINFOID:0000000003777008

ROTOR

Check the rotor condition for wear or damage. Refer to BR-7, "DISC

ROTOR : Inspection" , BR-9, "DISC ROTOR : Inspection" .

CALIPER

Check the caliper for any l eaks, repair as necessary.

Wheel nut tightening

torque

: 133 N·m (14 kg-m, 98 ft-lb)

LFIA0225E

SBR389C

SMA260A

SMA922A

Revision: December 20092009 QX56

Page 2705 of 4171

MA-32

< ON-VEHICLE MAINTENANCE >

CHASSIS AND BODY MAINTENANCE

Checking Axle and Suspension Parts

INFOID:0000000003777011

FRONT AND REAR AXLE AND SUSPENSION PARTS

Check front and rear axle and suspension parts for excessive play, cracks, wear or other damage.

• Shake each wheel to check for excessive play.

• Rotate each wheel to check for abnormal noise.

• Check the axle and suspension nuts and bolts for looseness.

• Check the strut and shock absorber for oil leakage or other damage.

• Check the suspension ball joints for grease leakage and ball joint dust cover for cracks or other damage.

DRIVE SHAFT

Check the boots and drive shaft for cracks, wear, damage, and

grease leakage.

SMA525A

SFA901

Revision: December 20092009 QX56

Page 2708 of 4171

MIR-1

DRIVER CONTROLS

C

DE

F

G H

I

J

K

M

SECTION MIR

A

B

MIR

N

O P

CONTENTS

MIRRORS

COMPONENT DIAGNOSIS ..........................2

DOOR MIRROR .............................................. .....2

Wiring Diagram ................................................... ......2

INSIDE MIRROR .................................................5

Wiring Diagram ................................................... ......5

PRECAUTION ...............................................8

PRECAUTIONS .............................................. .....8

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

8

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

8

Handling for Adhesive and Primer ............................9

PREPARATION ...........................................10

PREPARATION .............................................. ....10

Special Service Tool ............................................ ....10

Commercial Service Tool ........................................10

REMOVAL AND INSTALLATION ...............11

INSIDE MIRROR ...............................................11

Removal and Installation ..................................... ....11

DOOR MIRROR ................................................12

Door Mirror Assembly ..............................................12

Door Mirror Glass ....................................................12

DISASSEMBLY AND ASSEMBLY ..............14

DOOR MIRROR ................................................14

Exploded View ..................................................... ....14

Mirror Actuator .........................................................14

DOOR MIRROR COVER ....................................... ....15

DOOR MIRROR COVER : Disassembly .................15

DOOR MIRROR COVER : Assembly ......................15

Revision: December 20092009 QX56

Page 2715 of 4171

MIR-8

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005867736

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005867737

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: December 20092009 QX56

Page 2725 of 4171

MWI

MWI-3

C

DE

F

G H

I

J

K L

M B

A

O P

Diagnosis Procedure ...........................................

....

96

THE LOW WASHER FLUID WARNING CON-

TINUES DISPLAYING, or DOES NOT DIS-

PLAY ..................................................................

97

Description .......................................................... ....97

Diagnosis Procedure ...............................................97

THE DOOR OPEN WARNING CONTINUES

DISPLAYING, OR DOES NOT DISPLAY ..........

98

Description .......................................................... ....98

Diagnosis Procedure ...............................................98

NORMAL OPERATING CONDITION .................99

COMPASS ............................................................. ....99

COMPASS : Description (Early Production) ...........99

PRECAUTION ............................................100

PRECAUTIONS ...............................................100

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

100

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .................................

100

ON-VEHICLE REPAIR ...............................102

COMBINATION METER .................................102

Removal and Installation ..................................... ..102

CLOCK ............................................................103

Removal and Installation .......................................103

Revision: December 20092009 QX56

Page 2822 of 4171

MWI-100

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005867495

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005867496

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: December 20092009 QX56

Page 2826 of 4171

PB-1

BRAKES

C

DE

G H

I

J

K L

M

SECTION PB

A

B

PB

N

O P

CONTENTS

PARKING BRAKE SYSTEM

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

PREPARATION ............................................4

PREPARATION .............................................. .....4

Commercial Service Tool .................................... ......4

ON-VEHICLE MAINTENANCE .....................5

PARKING BRAKE SYSTEM .......................... .....5

On-Vehicle Service ............................................. ......5

ON-VEHICLE REPAIR ..................................7

PARKING BRAKE CONTROL ...........................7

Component .......................................................... .....7

Removal and Installation ..........................................7

PARKING BRAKE SHOE ..................................9

Removal and Installation ..........................................9

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

12

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

12

Parking Brake ...................................................... ....12

Parking Brake Control .............................................12

Revision: December 20092009 QX56

Page 2827 of 4171

PB-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005867887

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005867888

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: December 20092009 QX56

Page 2830 of 4171

PARKING BRAKE SYSTEMPB-5

< ON-VEHICLE MAINTENANCE >

C

DE

G H

I

J

K L

M A

B

PB

N

O P

ON-VEHICLE MAINTENANCE

PARKING BRAKE SYSTEM

On-Vehicle ServiceINFOID:0000000003772470

PEDAL STROKE

• When parking brake pedal is operated with the specified forc e, make sure the stroke is within the specified

number of notches. Check by listening and counting the ratchet clicks.

INSPECTION

• Make sure the components are attached pr operly, checking for looseness or backlash.

• Check parking brake pedal assembly for bends, damage and cracks, and replace if necessary.

• Check cable for wear and damage, and replace if necessary.

• Check parking brake warning lamp switch for malfunction, and replace if necessary. Refer to BCS-36, "

Diag-

nosis Procedure".

ADJUSTMENT

1. Remove the lower instrument panel LH. Refer to IP-15, "Exploded View".

2. Partially engage parking brake pedal to access adjusting nut.

3. Insert a deep socket wrench to rotate adjusting nut and loosen cable sufficiently. Then, disengage the parking brake pedal.

4. Remove the wheel and tire using power tool.

5. Remove the disc rotor and measure inner diameter at widest point using suitable tool.

6. Transfer measurement less 0.6 mm (0.024 in) to the parking brake shoes and adjust accordingly.

7. Using wheel nuts, secure the disc rotor to the hub to prevent it from tilting.

8. Rotate the disc rotor to make sure there is no drag.

9. Adjust cable as follows:

a. Operate pedal 10 or more times with a force of 490 N (50 kg-f, 110 lb-f).

b. Rotate adjusting nut with deep socket to adjust pedal stroke to specification.

c. With parking brake pedal completely disengaged, make sure there is no drag on the parking brake.

10. Install the disc rotor.

11. Install the wheel and tire using power tool. Pedal stroke : Refer to

PB-12, "

Parking Brake Control".

WFIA0165E

Tool number : — (J-21177-A)

Pedal stroke : Refer to PB-12, "

Parking Brake

Control".

WFIA0166E

Revision: December 20092009 QX56

Page 2832 of 4171

PARKING BRAKE CONTROLPB-7

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

PB

N

O P

ON-VEHICLE REPAIR

PARKING BRAKE CONTROL

ComponentINFOID:0000000003772471

Removal and InstallationINFOID:0000000003772472

REMOVAL

1. Remove lower instrument panel LH. Refer to IP-17, "Removal and Installation".

2. Remove center console. Refer to IP-20, "

Removal and Installation".

3. Remove floor trim. Refer to INT-16, "

Removal and Installation".

4. Remove adjusting nut and discard. CAUTION:

Do not reuse adjusting nut after removing it.

5. Remove the lock plate from the front cable.

6. Remove front cable retaining bolts and nut.

7. Disconnect return spring from equalizer.

8. Disconnect right and left rear cables from equalizer.

9. Remove rear wheel hub. Refer to RAX-7, "

Removal and Installa-

tion".

1. Pedal assembly 2. Front cable3. Right rear cable

4. Left rear cable 5. Return spring6. Equalizer

7. Adjusting nut 8. Lock plate

WFIA0218E

WFIA0165E

Revision: December 20092009 QX56