wheel INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 2834 of 4171

PARKING BRAKE SHOEPB-9

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

PB

N

O P

PARKING BRAKE SHOE

Removal and InstallationINFOID:0000000003772473

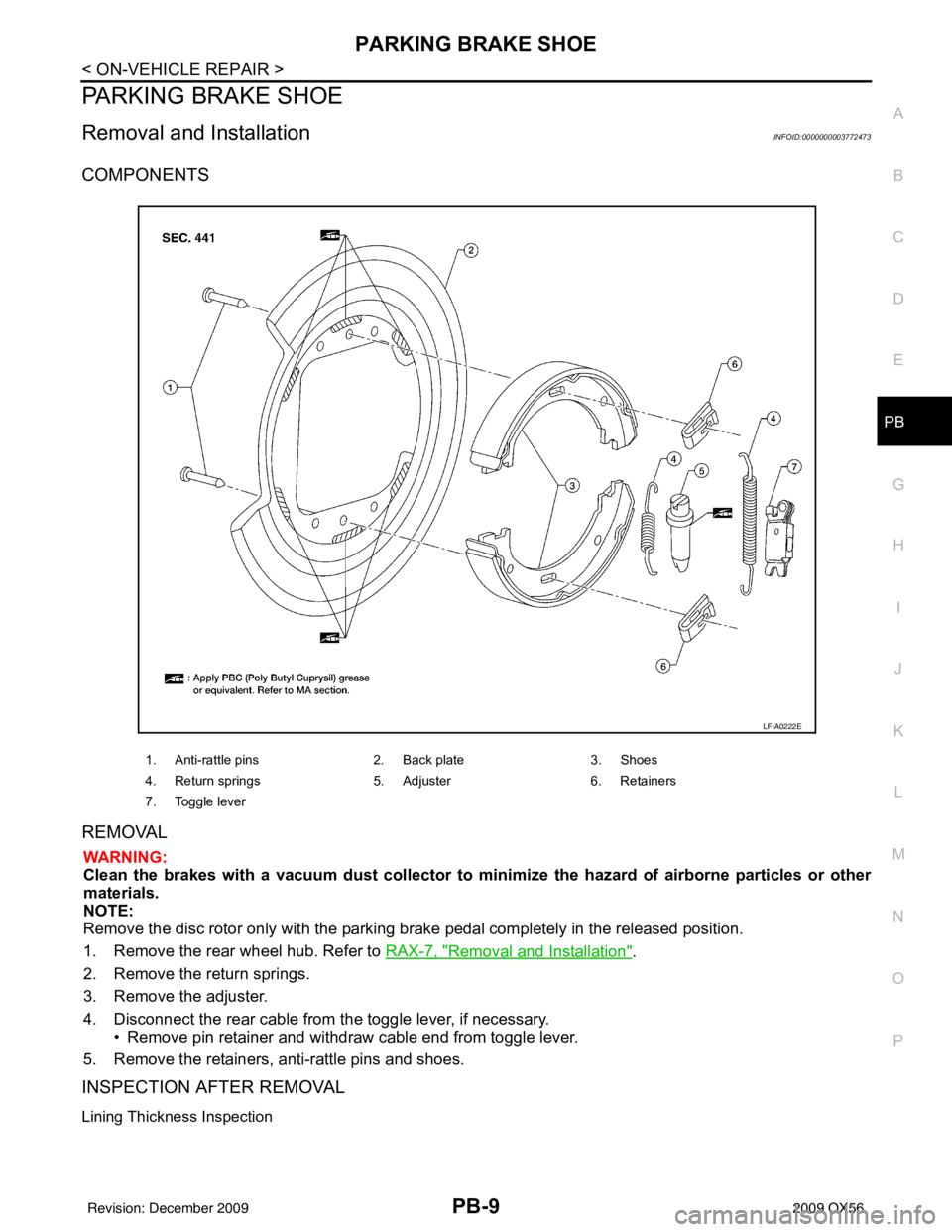

COMPONENTS

REMOVAL

WARNING:

Clean the brakes with a vacuum dust co llector to minimize the hazard of airborne particles or other

materials.

NOTE:

Remove the disc rotor only with the parking brake pedal completely in the released position.

1. Remove the rear wheel hub. Refer to RAX-7, "

Removal and Installation".

2. Remove the return springs.

3. Remove the adjuster.

4. Disconnect the rear cable from the toggle lever, if necessary.

• Remove pin retainer and withdraw cable end from toggle lever.

5. Remove the retainers, anti-rattle pins and shoes.

INSPECTION AFTER REMOVAL

Lining Thickness Inspection

1. Anti-rattle pins 2. Back plate3. Shoes

4. Return springs 5. Adjuster6. Retainers

7. Toggle lever

LFIA0222E

Revision: December 20092009 QX56

Page 2838 of 4171

PCS

PCS-1

ELECTRICAL & POWER CONTROL

C

DE

F

G H

I

J

K L

B

SECTION PCS

A

O P

N

CONTENTS

POWER CONTROL SYSTEM

IPDM E/R

BASIC INSPECTION ....... .............................

2

DIAGNOSIS AND REPAIR WORKFLOW ..... .....2

Work Flow ........................................................... ......2

FUNCTION DIAGNOSIS ...............................5

RELAY CONTROL SYSTEM ......................... .....5

System Diagram .................................................. ......5

System Description ...................................................6

Component Parts Location ........................................7

POWER CONTROL SYSTEM .............................8

System Diagram .................................................. ......8

System Description ...................................................8

SIGNAL BUFFER SYSTEM ................................9

System Diagram .................................................. ......9

System Description ...................................................9

POWER CONSUMPTION CONTROL SYS-

TEM ....................................................................

10

System Diagram .................................................. ....10

System Description .................................................10

Component Parts Location ......................................11

DIAGNOSIS SYSTEM (IPDM E/R) .....................12

Diagnosis Description ......................................... ....12

CONSULT - III Function (IPDM E/R) .......................14

COMPONENT DIAGNOSIS .........................17

U1000 CAN COMM CIRCUIT ...........................17

Description ........................................................... ....17

DTC Logic ................................................................17

Diagnosis Procedure ...............................................17

POWER SUPPLY AND GROUND CIRCUIT ....18

Diagnosis Procedure ...............................................18

ECU DIAGNOSIS .........................................19

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) ................

19

Reference Value .................................................. ....19

Terminal Layout .......................................................21

Physical Values ................................................... ....21

Wiring Diagram ........................................................26

Fail Safe ..................................................................29

DTC Index ...............................................................31

PRECAUTION ..............................................32

PRECAUTIONS .................................................32

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

32

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ...................................

32

REMOVAL AND INSTALLATION ...............34

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) ................

34

Removal and Installation of IPDM E/R ................ ....34

Revision: December 20092009 QX56

Page 2869 of 4171

![INFINITI QX56 2009 Factory Service Manual PCS-32

< PRECAUTION >[IPDM E/R]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005851897

The Supplemental INFINITI QX56 2009 Factory Service Manual PCS-32

< PRECAUTION >[IPDM E/R]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005851897

The Supplemental](/img/42/57031/w960_57031-2868.png)

PCS-32

< PRECAUTION >[IPDM E/R]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005851897

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005851898

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: December 20092009 QX56

Page 2872 of 4171

PG

PG-1

ELECTRICAL & POWER CONTROL

C

DE

F

G H

I

J

K L

B

SECTION PG

A

O P

N

CONTENTS

POWER SUPPLY, GROUND & CIRCUIT ELEMENTS

PRECAUTION .......

........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution for Power Generation Variable Voltage

Control System ..........................................................

3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

BASIC INSPECTION ....................................5

BATTERY ....................................................... .....5

How to Handle Battery ........................................ ......5

Work Flow ........................................................... ......7

INSPECTION AND ADJUSTMENT .....................8

ADDITIONAL SERVICE WHEN REMOVING BAT-

TERY NEGATIVE TERMINAL ............................... ......

8

ADDITIONAL SERVICE WHEN REMOVING

BATTERY NEGATIVE TERMINAL : Special Re-

pair Requirement ................................................. ......

8

COMPONENT DIAGNOSIS ..........................9

POWER SUPPLY ROUTING CIRCUIT .......... .....9

Wiring Diagram — Battery Power Supply — ....... ......9

Wiring Diagram — Accessory Power Supply — .....18

Wiring Diagram — Ignition Power Supply — ..........22

Fuse ........................................................................30

Fusible Link ......................................................... ....30

GROUND ...........................................................31

Ground Distribution ..................................................31

HARNESS .........................................................41

Harness Layout ................................................... ....41

ELECTRICAL UNITS LOCATION ....................64

Electrical Units Location ..........................................64

HARNESS CONNECTOR .................................67

Description ...............................................................67

STANDARDIZED RELAY .................................70

Description ...............................................................70

FUSE BLOCK - JUNCTION BOX (J/B) ............72

Terminal Arrangement .............................................72

FUSE, FUSIBLE LINK AND RELAY BOX ........73

Terminal Arrangement .............................................73

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) ................

75

IPDM E/R Terminal Arrangement ............................75

ON-VEHICLE REPAIR .................................76

BATTERY ..........................................................76

Removal and Installation ..................................... ....76

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

77

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

77

Battery ................................................................. ....77

Revision: December 20092009 QX56

Page 2873 of 4171

PG-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005852239

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005852240

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: December 20092009 QX56

Page 2916 of 4171

PG

HARNESSPG-45

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

B A

O P

N

D2 M55 W/4 : Hazard switch

D4 M203 W/12 : A/T shift selector

D4 M56 W/16 : To M201 D5 M205 W/32 : DVD player

A3 M57 — : Body ground D5 M207 B/3 : Console power socket

F2 M58 B/6 : Intake door motor C4 M208 BR/20 : To M69

F3 M59 BR/2 : Glove box lamp C5 M209 W/2: Inside key antenna 2 (rear of center

console)

G3 M60 W/6 : Fuse block (J/B) C4 M210 GR/2: Inside key antenna 3 (front of center

console)

C3 M61 — : Body ground C4 M212 W/6 : Rear heated seat switch LH

F4 M62 B/2 : Front blower motor C4 M213 BR/6 : Rear heated seat switch RH

D4 M63 BR/20 : To M251 Console switch sub-harness

D4 M64 BR/24 : To M202 D4 M251 BR/20 : To M63

F2 M65 W/4 : To M301 D4 M252 BR/6 : Front heated seat switch RH

G3 M66 B/1 : To E33 C4 M253 GR/6 : VDC OFF switch

C3 M69 BR/20 : To M208 C3 M255 W/6 : Front heated seat switch LH

A2 M70 W/40 : Intelligent key unit C4 M256 B/2 : A/T shift selector

A2 M71 L/4 : Heated steering relay C4 M260 W/6 : Heated steering wheel switch

D3 M73 BR/6 : Back-up lamp relay Optical sensor sub-harness

G3 M74 BR/24 : To D102 F1 M301 W/4 : To M65

G3 M75 W/10 : To D101 D1 M302 B/4 : Optical sensor

A3 M76 W/6 : Electric brake (pre-wiring)

E2 M77 Y/4 : Front passenger air bag module

(service replacement)

Revision: December 20092009 QX56

Page 2917 of 4171

PG-46

< COMPONENT DIAGNOSIS >

HARNESS

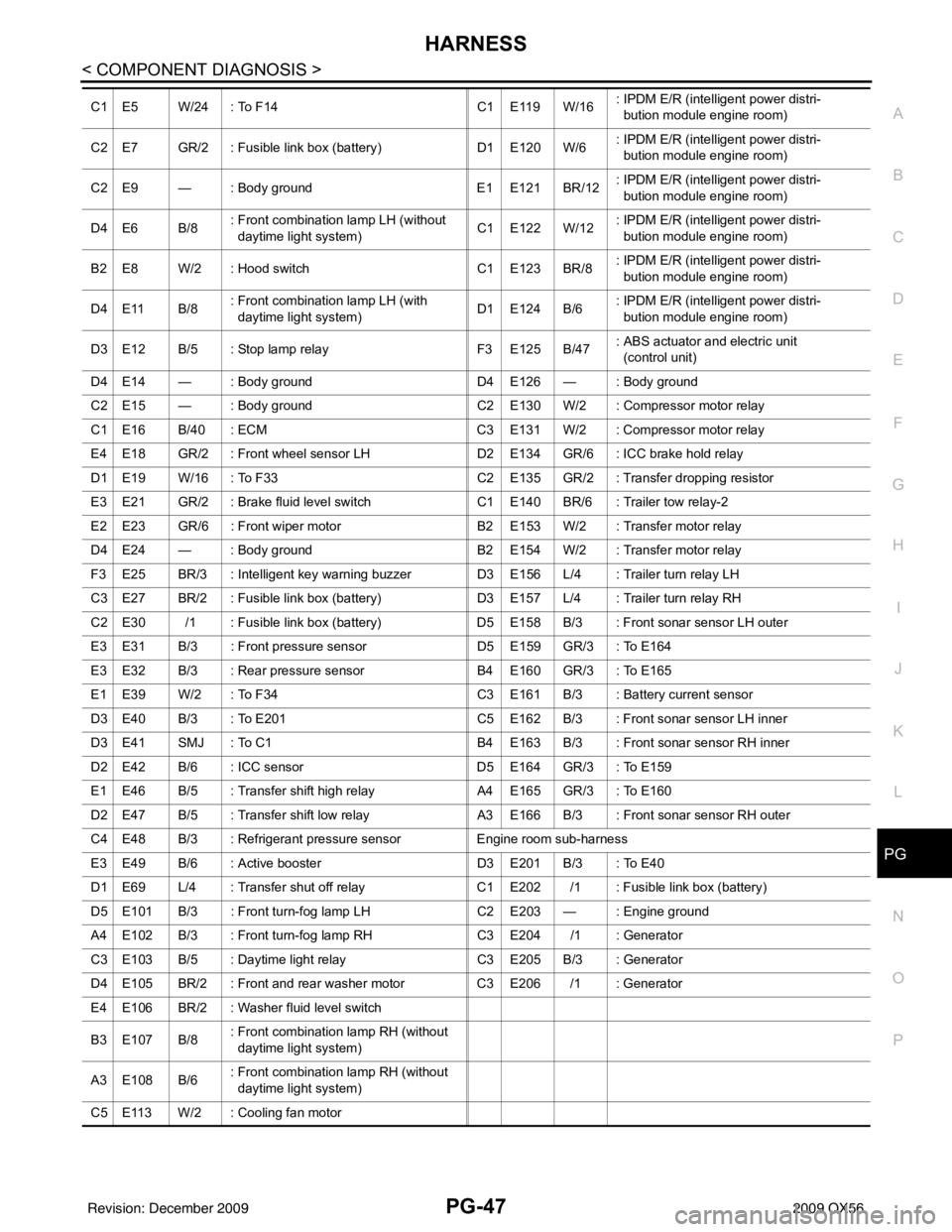

ENGINE ROOM HARNESS

AAMIA0451GB

C4 E1 GR/2 : Ambient sensorE3 E114 B/6 : Delta stroke motor

D3 E2 W/16 : To F32 D1 E116 W/2 : Condenser-2

C3 E3 B/2 : Horn D3 E117 GR/2 : Front wheel sensor RH

C3 E4 Y/2 : Crash zone sensor D3 E118 B/2: IPDM E/R (intelligent power distri-

bution module engine room)

Revision: December 20092009 QX56

Page 2918 of 4171

PG

HARNESSPG-47

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

B A

O P

N

C1 E5 W/24 : To F14

C1 E119 W/16: IPDM E/R (intelligent power distri-

bution module engine room)

C2 E7 GR/2 : Fusible link box (battery) D1 E120 W/6: IPDM E/R (intelligent power distri-

bution module engine room)

C2 E9 — : Body ground E1 E121 BR/12: IPDM E/R (intelligent power distri-

bution module engine room)

D4 E6 B/8 : Front combination lamp LH (without

daytime light system) C1 E122 W/12: IPDM E/R (intelligent power distri-

bution module engine room)

B2 E8 W/2 : Hood switch C1 E123 BR/8: IPDM E/R (intelligent power distri-

bution module engine room)

D4 E11 B/8 : Front combination lamp LH (with

daytime light system) D1 E124 B/6

: IPDM E/R (intelligent power distri-

bution module engine room)

D3 E12 B/5 : Stop lamp relay F3 E125 B/47: ABS actuator and electric unit

(control unit)

D4 E14 — : Body ground D4 E126 — : Body ground

C2 E15 — : Body ground C2 E130 W/2 : Compressor motor relay

C1 E16 B/40 : ECM C3 E131 W/2 : Compressor motor relay

E4 E18 GR/2 : Front wheel sensor LH D2 E134 GR/6 : ICC brake hold relay

D1 E19 W/16 : To F33 C2 E135 GR/2 : Transfer dropping resistor

E3 E21 GR/2 : Brake fluid level swit chC1 E140 BR/6 : Trailer tow relay-2

E2 E23 GR/6 : Front wiper motor B2 E153 W/2 : Transfer motor relay

D4 E24 — : Body ground B2 E154 W/2 : Transfer motor relay

F3 E25 BR/3 : Intelligent key warning buzzer D3 E156 L/4 : Trailer turn relay LH

C3 E27 BR/2 : Fusible link box (battery) D3 E157 L/4 : Trailer turn relay RH

C2 E30 /1 : Fusible link box (battery) D5 E158 B/3 : Front sonar sensor LH outer

E3 E31 B/3 : Front pressure sensor D5 E159 GR/3 : To E164

E3 E32 B/3 : Rear pressure sensor B4 E160 GR/3 : To E165

E1 E39 W/2 : To F34 C3 E161 B/3 : Battery current sensor

D3 E40 B/3 : To E201 C5 E162 B/3 : Front sonar sensor LH inner

D3 E41 SMJ : To C1 B4 E163 B/3 : Front sonar sensor RH inner

D2 E42 B/6 : ICC sensor D5 E164 GR/3 : To E159

E1 E46 B/5 : Transfer shift high relay A4 E165 GR/3 : To E160

D2 E47 B/5 : Transfer shift low relay A3 E166 B/3 : Front sonar sensor RH outer

C4 E48 B/3 : Refrigerant pressure sensor Engine room sub-harness

E3 E49 B/6 : Active booster D3 E201 B/3 : To E40

D1 E69 L/4 : Transfer shut off relay C1 E202 /1 : Fusible link box (battery)

D5 E101 B/3 : Front turn-fog lamp LH C2 E203 — : Engine ground

A4 E102 B/3 : Front turn-fog lamp RH C3 E204 /1 : Generator

C3 E103 B/5 : Daytime light relay C3 E205 B/3 : Generator

D4 E105 BR/2 : Front and rear washer motor C3 E206 /1 : Generator

E4 E106 BR/2 : Washer fluid level switch

B3 E107 B/8 : Front combination lamp RH (without

daytime light system)

A3 E108 B/6 : Front combination lamp RH (without

daytime light system)

C5 E113 W/2 : Cooling fan motor

Revision: December 20092009 QX56

Page 2924 of 4171

PG

HARNESSPG-53

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

B A

O P

N

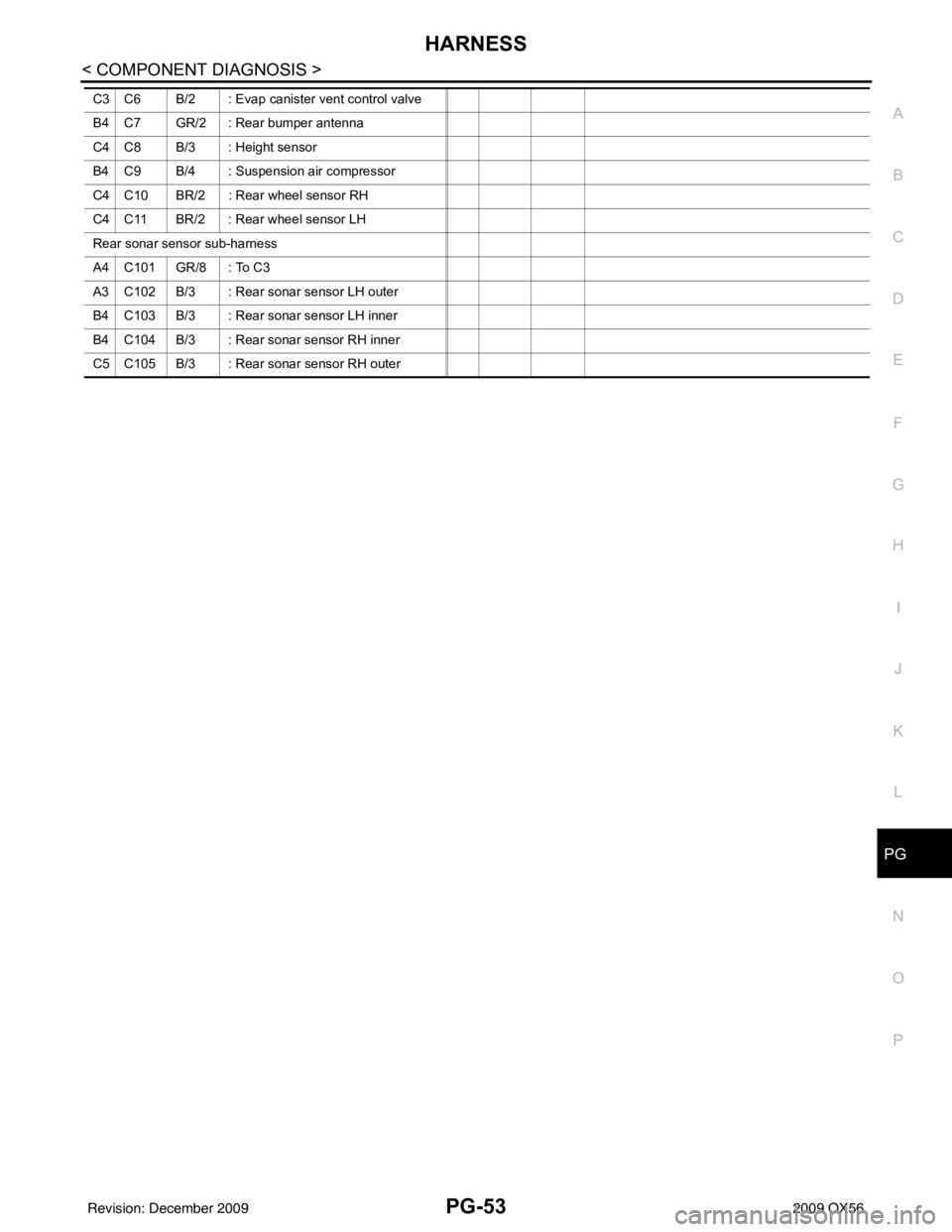

C3 C6 B/2 : Evap canister vent control valve

B4 C7 GR/2 : Rear bumper antenna

C4 C8 B/3 : Height sensor

B4 C9 B/4 : Suspension air compressor

C4 C10 BR/2 : Rear wheel sensor RH

C4 C11 BR/2 : Rear wheel sensor LH

Rear sonar sensor sub-harness

A4 C101 GR/8 : To C3

A3 C102 B/3 : Rear sonar sensor LH outer

B4 C103 B/3 : Rear sonar sensor LH inner

B4 C104 B/3 : Rear sonar sensor RH inner

C5 C105 B/3 : Rear sonar sensor RH outer

Revision: December 20092009 QX56

Page 2951 of 4171

PWC-3

C

DE

F

G H

I

J

L

M A

B

PWC

N

O P

ANTI-PINCH SYSTEM DOES NOT OPERATE

NORMALLY (PASSENGER SIDE) ................ ..

103

Diagnosis Procedure ........................................... ..103

ANTI-PINCH SYSTEM DOES NOT OPERATE

NORMALLY (REAR LH SIDE) .........................

104

Diagnosis Procedure ........................................... ..104

ANTI-PINCH SYSTEM DOES NOT OPERATE

NORMALLY (REAR RH SIDE) ........................

105

Diagnosis Procedure ........................................... ..105

AUTO OPERATION DOES NOT OPERATE

BUT MANUAL OPERATES NORMALLY

(DRIVER SIDE) .................................................

106

Diagnosis Procedure ........................................... ..106

AUTO OPERATION DOES NOT OPERATE

BUT MANUAL OPERATES NORMALLY

(PASSENGER SIDE) ...................................... ..

107

Diagnosis Procedure ........................................... ..107

AUTO OPERATION DOES NOT OPERATE

BUT MANUAL OPERATES NORMALLY

(REAR LH SIDE) ..............................................

108

Diagnosis Procedure ........................................... ..108

AUTO OPERATION DOES NOT OPERATE

BUT MANUAL OPERATES NORMALLY

(REAR RH SIDE) ..............................................

109

Diagnosis Procedure ........................................... ..109

POWER WINDOW RETAINED POWER OP-

ERATION DOES NOT OPERATE PROPERLY

..

110

Diagnosis Procedure ........................................... ..110

DOES NOT OPERATE BY KEY CYLINDER

SWITCH ...........................................................

111

Diagnosis Procedure ........................................... ..111

KEYLESS POWER WINDOW DOWN DOES

NOT OPERATE ...............................................

112

Diagnosis Procedure .............................................112

POWER WINDOW LOCK SWITCH DOES

NOT FUNCTION ..............................................

113

Diagnosis Procedure .............................................113

REAR POWER VENT WINDOWS DO NOT

OPERATE .......................................................

114

Diagnosis Procedure .............................................114

PRECAUTION ............................................115

PRECAUTIONS ...............................................115

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

115

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .................................

115

ON-VEHICLE REPAIR ...............................117

POWER WINDOW MAIN SWITCH .................117

Removal and Installation ..................................... ..117

FRONT POWER WINDOW SWITCH ..............118

Removal and Installation .......................................118

REAR POWER WINDOW SWITCH ................119

Removal and Installation .......................................119

REAR POWER VENT WINDOW SWITCH .....120

Removal and Installation .......................................120

Revision: December 20092009 QX56