wheel INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 2267 of 4171

PRECAUTIONSHA-3

< PRECAUTION >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005856236

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wh eel Rotation After Battery Disconnect

INFOID:0000000005856237

NOTE:

This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: December 20092009 QX56

Page 2295 of 4171

COMPRESSORHA-31

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

COMPRESSOR

Removal and Installation for CompressorINFOID:0000000003775309

A/C Compressor Mounting

REMOVAL

1. Discharge the refrigerant. Refer to HA-20, "HFC-134a (R-134a) Service Procedure".

2. Remove the front left wheel and tire assembly. Refer to WT-41, "Adjustment"

.

3. Remove the engine under cover.

4. Remove front fender protector. Refer to EXT-23, "Removal and Installation"

.

5. Remove the engine air cleaner and air ducts. Refer to EM-25, "Removal and Installation"

.

6. Remove the drive belt. Refer to EM-13, "Removal and Installation"

.

7. Disconnect the compressor electrical connector.

8. Disconnect the high-pressure flexible hose and low-pressure flexible hose from the compressor. CAUTION:

Cap or wrap the joint of the pipe with suitable mate rial such as vinyl tape to avoid the entry of air.

9. Remove the compressor bolts and nut using power tools.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

AWIIA1291GB

Revision: December 20092009 QX56

Page 2303 of 4171

LOW-PRESSURE PIPEHA-39

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

5. Remove the front and rear bumper fascia. Refer to EXT-13, "Removal and Installation" (front), EXT-15,

"Removal and Installation" (rear).

6. Reposition the front fender protec tor out of the way. Refer to EXT-23, "Removal and Installation"

.

7. Disconnect the chassis harness connector.

8. Remove the spare wheel and tire.

9. Remove the tailpipe and tailpipe hanger bracket. Refer to EX-6, "Removal and Installation"

.

10. Remove the seatbelt latch anchor. Refer to EX-6, "Removal and Installation"

.

11. Remove the front floor heat shield.

12. Disconnect each end of the underfloor rear high- and low-pressure A/C and heater core pipes. Refer to

HA-29, "Component"

.

CAUTION:

Cap or wrap the joint of the pipes with suitable material such as viny l tape to avoid the entry of air.

13. Set two suitable jacks at the RH body mount points to support the vehicle body when it is separated from the RH side of the frame.

14. Remove the RH body mount bolts. Refer to BRM-6, "Body Mounting"

.

15. Use the vehicle hoist to lower the RH side of the frame from the RH side of the body [approximately 305

mm (12 in)] until there is suffici ent clearance to remove the underfloor rear high- and low-pressure A/C

and heater core pipes from between the body and the frame.

16. Remove the underfloor rear high- and low-pressure A/ C and heater core pipes from the back of the vehi-

cle.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Replace the O-rings of the underfloor rear high - and low-pressure A/C and heater core pipes with

new ones, then apply compressor oil to them for installation.

After charging refrigerant, check for leaks.

Revision: December 20092009 QX56

Page 2305 of 4171

HIGH-PRESSURE PIPEHA-41

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

HIGH-PRESSURE PIPE

Removal and Installation for High-Pressure PipeINFOID:0000000003775316

REMOVAL

1. Remove the cowl top extension. Refer to EXT-18, "Removal and Installation".

2. Disconnect the battery negative termi nal and positive battery terminal.

3. Reposition the IPDM E/R aside.

4. Remove the front left wheel and tire assembly. Refer to MA-29, "Rotation"

.

5. Position aside the front floor insulator.

6. Discharge the refrigerant. Refer to HA-20, "HFC-134a (R-134a) Service Procedure"

.

7. Remove the low pressure pipe. Refer to HA-37, "Removal and Installation for Low-Pressure Pipe"

.

8. Remove the high-pressure pipe. CAUTION:

Cap or wrap the joint of the pipe with suitable mate rial such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

Refer to HA-29, "Component"

.

CAUTION:

Replace the O-ring of the high-pressure pipe with a new one, then apply compressor oil to it when

installing it.

After charging refrigerant, check for leaks.

Removal and Installation for Rear High- and Low-Pressure A/C and Heater Core Pipes

INFOID:0000000003775317

REMOVAL

1. Discharge the refrigerant from the A/C system. Refer to HA-20, "HFC-134a (R-134a) Service Procedure".

2. Drain the coolant from the engine cooling system. Refer to CO-11, "Changing Engine Coolant"

.

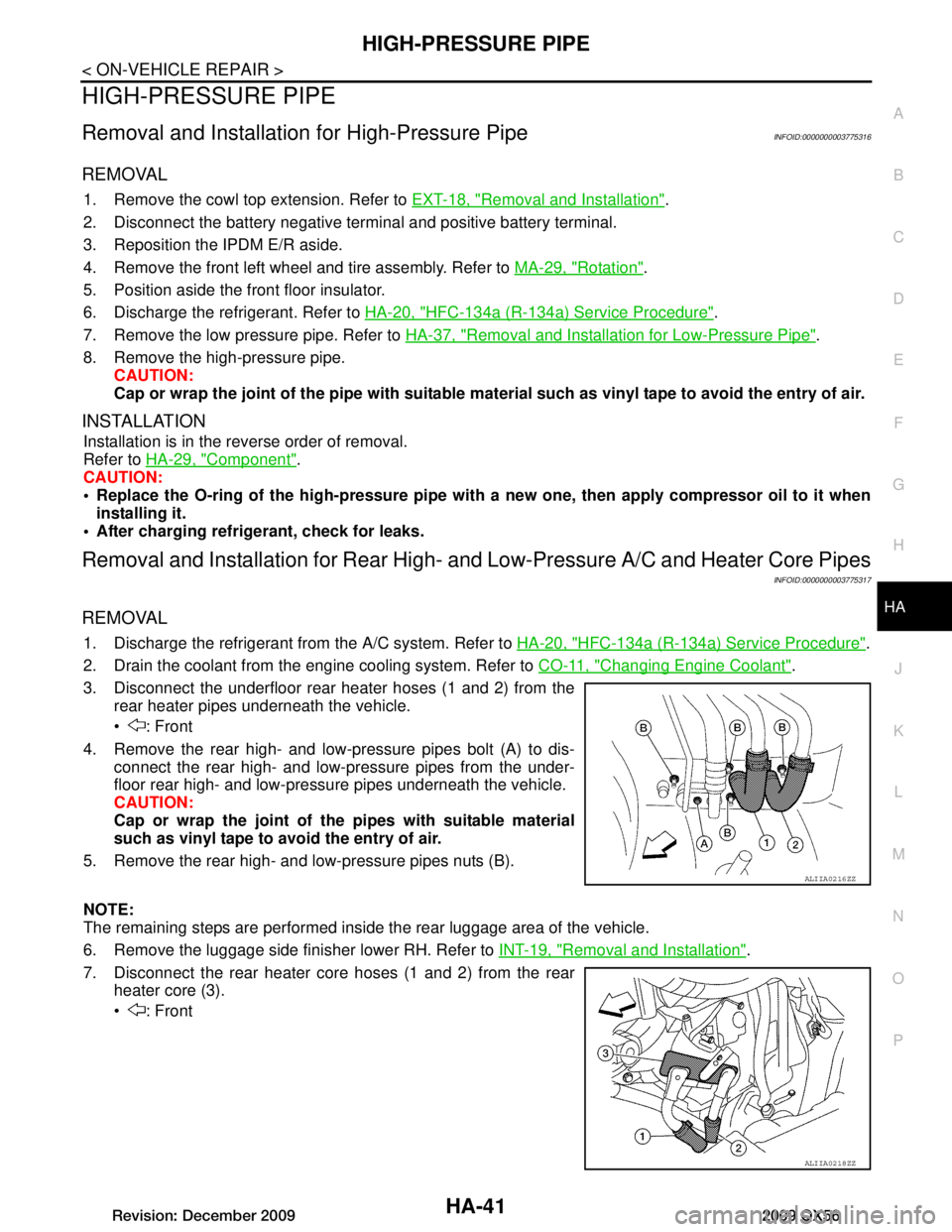

3. Disconnect the underfloor rear heater hoses (1 and 2) from the rear heater pipes underneath the vehicle.

: Front

4. Remove the rear high- and low-pressure pipes bolt (A) to dis- connect the rear high- and low-pressure pipes from the under-

floor rear high- and low-pressu re pipes underneath the vehicle.

CAUTION:

Cap or wrap the joint of the pipes with suitable material

such as vinyl tape to avoid the entry of air.

5. Remove the rear high- and low-pressure pipes nuts (B).

NOTE:

The remaining steps are performed inside the rear luggage area of the vehicle.

6. Remove the luggage side finisher lower RH. Refer to INT-19, "Removal and Installation"

.

7. Disconnect the rear heater core hoses (1 and 2) from the rear heater core (3).

: Front

ALIIA0216ZZ

ALIIA0218ZZ

Revision: December 20092009 QX56

Page 2307 of 4171

HIGH-PRESSURE PIPEHA-43

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

5. Remove the front and rear bumper fascia. Refer to EXT-13, "Removal and Installation" (front), EXT-15,

"Removal and Installation" (rear).

6. Reposition the front fender protec tor out of the way. Refer to EXT-23, "Removal and Installation"

.

7. Disconnect the chassis harness connector.

8. Remove the spare wheel and tire.

9. Remove the tailpipe and tailpipe hanger bracket. Refer to EX-6, "Removal and Installation"

.

10. Remove the seatbelt latch anchor. Refer to EX-6, "Removal and Installation"

.

11. Remove the front floor heat shield.

12. Disconnect each end of the underfloor rear high- and low-pressure A/C and heater core pipes. Refer to

HA-29, "Component"

.

CAUTION:

Cap or wrap the joint of the pipes with suitable material such as viny l tape to avoid the entry of air.

13. Set two suitable jacks at the RH body mount points to support the vehicle body when it is separated from the RH side of the frame.

14. Remove the RH body mount bolts. Refer to BRM-6, "Body Mounting"

.

15. Use the vehicle hoist to lower the RH side of the frame from the RH side of the body [approximately 305

mm (12 in)] until there is suffici ent clearance to remove the underfloor rear high- and low-pressure A/C

and heater core pipes from between the body and the frame.

16. Remove the underfloor rear high- and low-pressure A/ C and heater core pipes from the back of the vehi-

cle.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Replace the O-rings of the underfloor rear high - and low-pressure A/C and heater core pipes with

new ones, then apply compressor oil to them for installation.

After charging refrigerant, check for leaks.

Revision: December 20092009 QX56

Page 2438 of 4171

HRN-1

DRIVER CONTROLS

C

DE

F

G H

I

J

K

M

SECTION HRN

A

B

HRN

N

O P

CONTENTS

HORN

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

COMPONENT DIAGNOSIS ..........................4

HORN .................................................................4

Wiring Diagram .................................................... .....4

REMOVAL AND INSTALLATION ................7

HORN .................................................................7

Removal and Installation ..................................... .....7

Revision: December 20092009 QX56

Page 2439 of 4171

HRN-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005856032

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005887777

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: December 20092009 QX56

Page 2446 of 4171

INL-2

DTC Index ..............................................................68

SYMPTOM DIAGNOSIS .............................70

INTERIOR LIGHTING SYSTEM SYMPTOMS ...70

Symptom Table ................................................... ...70

PRECAUTION .............................................71

PRECAUTIONS .............................................. ...71

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. ...

71

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ..................................

71

General precautions for service operations ......... ...72

ON-VEHICLE REPAIR ...............................73

INTERIOR ROOM LAMP ................................ ...73

Removal and Installation .........................................73

ILLUMINATION .............................................. ...77

Removal and Installation .........................................77

SERVICE DATA AND SPECIFICATIONS

(SDS) .......... ................................. ...............

79

BULB SPECIFICATIONS ............................... ...79

Interior Lamp/Illumination ........................................79

Revision: December 20092009 QX56

Page 2515 of 4171

PRECAUTIONSINL-71

< PRECAUTION >

C

DE

F

G H

I

J

K

M A

B

INL

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005867732

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000005867733

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: December 20092009 QX56

Page 2524 of 4171

INT-1

BODY INTERIOR

C

DE

F

G H

I

K L

M

SECTION INT

A

B

INT

N

O P

CONTENTS

INTERIOR

SYMPTOM DIAGNOSIS ..... ..........................2

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ........................ ........................................

2

Work Flow ........................................................... ......2

Generic Squeak and Rattle Troubleshooting ............4

Diagnostic Worksheet ...............................................6

PRECAUTION ...............................................8

PRECAUTIONS .............................................. .....8

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

8

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

8

Service Notice ...........................................................9

PREPARATION ...........................................10

PREPARATION .............................................. ....10

Special Service Tool ............................................ ....10

Commercial Service Tool ........................................10

ON-VEHICLE REPAIR .................................11

DOOR FINISHER ..............................................11

Removal and Installation ..................................... ....11

BODY SIDE TRIM .............................................14

Removal and Installation .........................................14

FLOOR TRIM ....................................................16

Removal and Installation .........................................16

HEADLINING ....................................................17

Removal and Installation .........................................17

LUGGAGE FLOOR TRIM .................................19

Removal and Installation .........................................19

BACK DOOR TRIM ...........................................21

Removal and Installation ..................................... ....21

Revision: December 20092009 QX56