INFINITI QX56 2009 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 3741 of 4171

MAIN POWER SUPPLY AND GROUND CIRCUITTM-93

< COMPONENT DIAGNOSIS >

CEF

G H

I

J

K L

M A

B

TM

N

O P

5.DETECT MALFUNCTIONING ITEM

Check the following items:

The A/T assembly harness connector terminals for damage or loose connection with harness connector.

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

6.PERFORM SELF-DIAGNOSIS

Perform self-diagnosis. Refer to TM-32, "CONSULT-III Function (TRANSMISSION)"

.

OK or NG

OK >> INSPECTION END

NG-1 >> Self-diagnosis does not activate: GO TO 7.

NG-2 >> DTC is displayed: Check t he malfunctioning system. Refer to TM-32, "CONSULT-III Function

(TRANSMISSION)".

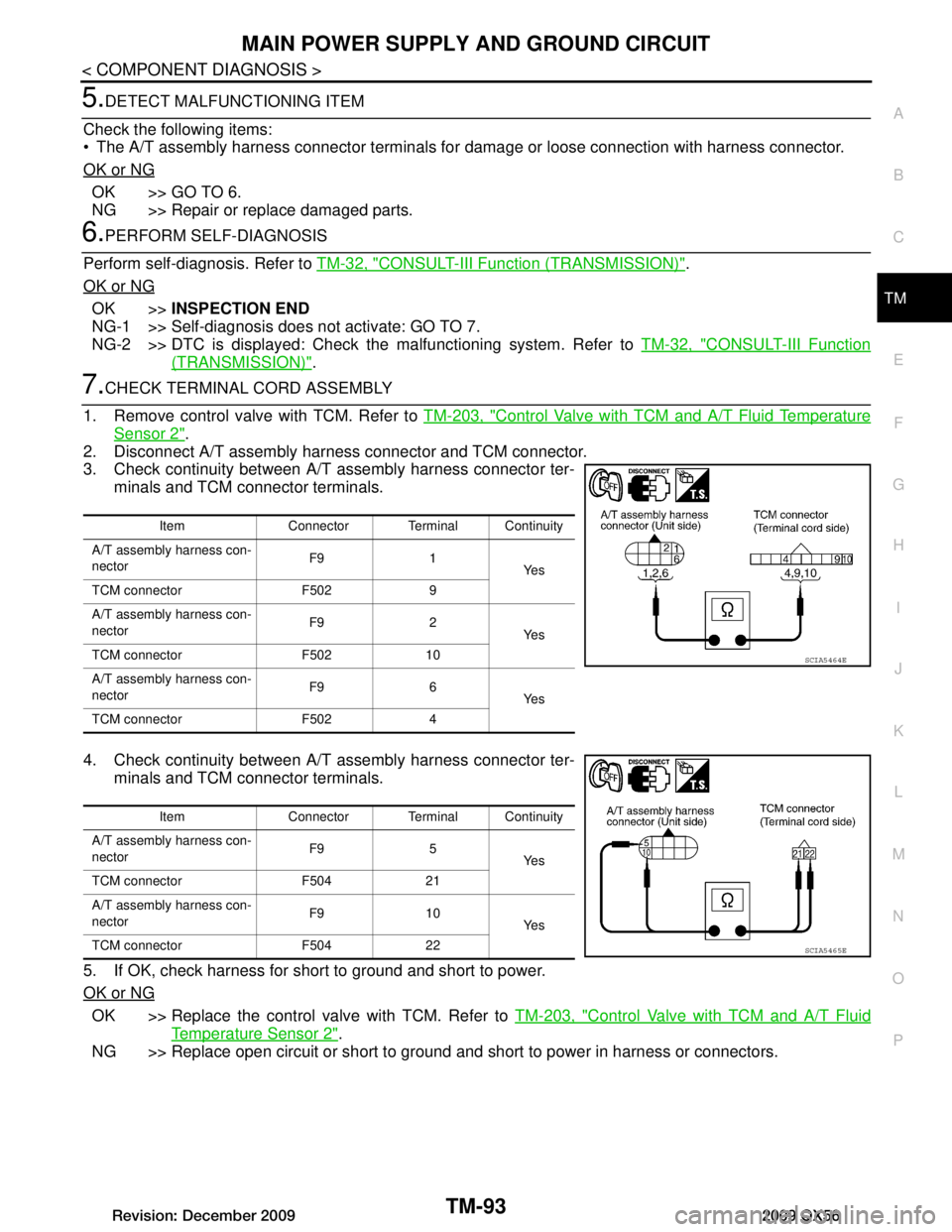

7.CHECK TERMINAL CORD ASSEMBLY

1. Remove control valve with TCM. Refer to TM-203, "Control Valve with TCM and A/T Fluid Temperature

Sensor 2".

2. Disconnect A/T assembly harness connector and TCM connector.

3. Check continuity between A/T assembly harness connector ter- minals and TCM connector terminals.

4. Check continuity between A/T assembly harness connector ter- minals and TCM connector terminals.

5. If OK, check harness for short to ground and short to power.

OK or NG

OK >> Replace the control valve with TCM. Refer to TM-203, "Control Valve with TCM and A/T Fluid

Temperature Sensor 2".

NG >> Replace open circuit or short to ground and short to power in harness or connectors.

Item Connector Terminal Continuity

A/T assembly harness con-

nector F9 1

Ye s

TCM connector F502 9

A/T assembly harness con-

nector F9 2

Ye s

TCM connector F502 10

A/T assembly harness con-

nector F9 6

Ye s

TCM connector F502 4

SCIA5464E

Item Connector Terminal Continuity

A/T assembly harness con-

nector F9 5

Ye s

TCM connector F504 21

A/T assembly harness con-

nector F9 10

Ye s

TCM connector F504 22

SCIA5465E

Revision: December 20092009 QX56

Page 3742 of 4171

TM-94

< COMPONENT DIAGNOSIS >

CLOSED THROTTLE POSITION AND WIDE OPEN THROTTLE POSITION CIR-

CUIT

CLOSED THROTTLE POSITION AND WIDE OPEN THROTTLE POSITION

CIRCUIT

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000003771976

Diagnosis ProcedureINFOID:0000000003771977

1.CHECK CAN COMMUNICATION LINE

Perform the self-diagnosis. Refer to TM-32, "CONSULT-III Function (TRANSMISSION)"

.

Is a malfunction in the CAN communication indicated in the results?

YES >> Check CAN communication line. Refer to TM-39.

NO >> GO TO 2.

2.CHECK THROTTLE POSI TION SIGNAL CIRCUIT

With CONSULT-III

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “ECU INPUT SIGNALS” in “DATA MONI TOR” mode for “TRANSMISSION” with CONSULT-III.

3. Depress accelerator pedal and read out the value of “CLSD THL POS” and “W/O THL POS”.

OK or NG

OK >> INSPECTION END

NG >> Check the following items. If NG, repair or replace damaged parts. Perform the self-diagnosis for “ENGINE” with CONSULT-III.

Open circuit or short to ground or shor t to power in harness or connectors.

Pin terminals for damage or loos e connection with harness connector.

Item name Condition Display value

CLSD THL POSReleased accelerator pedal. ON

Fully depressed accelerator pedal. OFF

W/O THL POS Fully depressed accelerator pedal. ON

Released accelerator pedal. OFF

Accelerator Pedal Operation Monitor Item

CLSD THL POS W/O THL POS

Released ON OFF

Fully depressed OFF ON

Revision: December 20092009 QX56

Page 3743 of 4171

BRAKE SIGNAL CIRCUITTM-95

< COMPONENT DIAGNOSIS >

CEF

G H

I

J

K L

M A

B

TM

N

O P

BRAKE SIGNAL CIRCUIT

CONSULT-III Reference Val ue in Data Monitor ModeINFOID:0000000003771978

Diagnosis ProcedureINFOID:0000000003771979

1.CHECK CAN COMMUNICATION LINE

Perform the self-diagnosis. Refer to TM-32, "CONSULT-III Function (TRANSMISSION)"

.

Is a malfunction in the CAN communication indicated in the results?

YES >> Check CAN communication line. Refer to TM-39, "Diagnosis Procedure".

NO >> GO TO 2.

2.CHECK STOP LAMP SWITCH CIRCUIT

With CONSULT-III

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “ECU INPUT SIGNALS” in “DATA MONITO R” mode for “TRANSMISSION” with CONSULT-III.

3. Read out ON/OFF switching action of the “BRAKE SW”.

OK or NG

OK >> INSPECTION END

NG >> GO TO 3.

3.CHECK STOP LAMP SWITCH

Check continuity between stop lamp switch terminals 1 and 2.

Check stop lamp switch after adjusting brake pedal — refer to

BR-15, "Inspection and Adjustment"

.

OK or NG

OK >> Check stop lamp switch circuit.

NG >> Repair or replace stop lamp switch.

Item name Condition Display value

BRAKE SW Depressed brake pedal. ON

Released brake pedal. OFF

Condition Continuity

When brake pedal is depressed Yes

When brake pedal is released No

AWDIA0165ZZ

Revision: December 20092009 QX56

Page 3744 of 4171

TM-96

< COMPONENT DIAGNOSIS >

TOW MODE SWITCH

TOW MODE SWITCH

DescriptionINFOID:0000000003771980

When tow mode switch is “ON”, tow mode switch signals are sent to TCM from combination meter by CAN

communication line.Then it`s a tow mode condition.

Diagnosis ProcedureINFOID:0000000003771981

1.CHECK CAN COMMUNICATION LINE

Perform the self-diagnosis. Refer to TM-32, "CONSULT-III Function (TRANSMISSION)"

.

Is any malfunction in the CAN communication indicated in the results?

YES >> Check CAN communication line. Refer to TM-39.

NO >> GO TO 2.

2.CHECK POWER SOURCE

1. Turn ignition switch “ON”. (Do not start engine.)

2. Check the voltage between tow mode switch connector M258 terminal 1 and ground.

OK or NG

OK >> INSPECTION END

NG >> GO TO 3.

3.CHECK TOW MODE SWITCH

1. Turn ignition switch “OFF”.

2. Disconnect tow mode switch connector.

3. Check continuity between tow mode switch terminals 1 and 2.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace tow mode switch.

4.DETECT MALFUNCTIONING ITEM

Check the following items. If any items are damaged, repair or replace damaged parts.

Harness for short or open between combination meter connector terminal 35 and tow mode switch connec- tor terminal 1.

Harness for short or open between tow mode switch connector terminal 2 and ground.

OK or NG

OK >> GO TO 5.

NG >> Repair or replace damaged parts.

5.CHECK COMBINATION METER

Check the combination meter. Refer to MWI-4, "Work Flow"

.

OK or NG

OK >> INSPECTION END

NO >> Repair or replace damaged parts.

Condition To w m o d e

switch Data (Approx.)

When ignition switch is turned to “ON” ON 0V

OFF Battery voltage

SCIA5156E

Condition Continuity

Tow mode switch “ON” Yes

Tow mode switch “OFF” No

SCIA5584E

Revision: December 20092009 QX56

Page 3745 of 4171

A/T SHIFT LOCK SYSTEMTM-97

< COMPONENT DIAGNOSIS >

CEF

G H

I

J

K L

M A

B

TM

N

O P

A/T SHIFT LOCK SYSTEM

Wiring Diagram - A/ T Shift Lock SystemINFOID:0000000003771982

AADWA0090GB

Revision: December 20092009 QX56

Page 3746 of 4171

TM-98

< COMPONENT DIAGNOSIS >

A/T SHIFT LOCK SYSTEM

AADIA0061GB

Revision: December 20092009 QX56

Page 3747 of 4171

A/T SHIFT LOCK SYSTEMTM-99

< COMPONENT DIAGNOSIS >

CEF

G H

I

J

K L

M A

B

TM

N

O P

AADIA0141GB

Revision: December 20092009 QX56

Page 3748 of 4171

TM-100

< COMPONENT DIAGNOSIS >

A/T SHIFT LOCK SYSTEM

ABDIA0045GB

Revision: December 20092009 QX56

Page 3749 of 4171

A/T SHIFT LOCK SYSTEMTM-101

< COMPONENT DIAGNOSIS >

CEF

G H

I

J

K L

M A

B

TM

N

O P

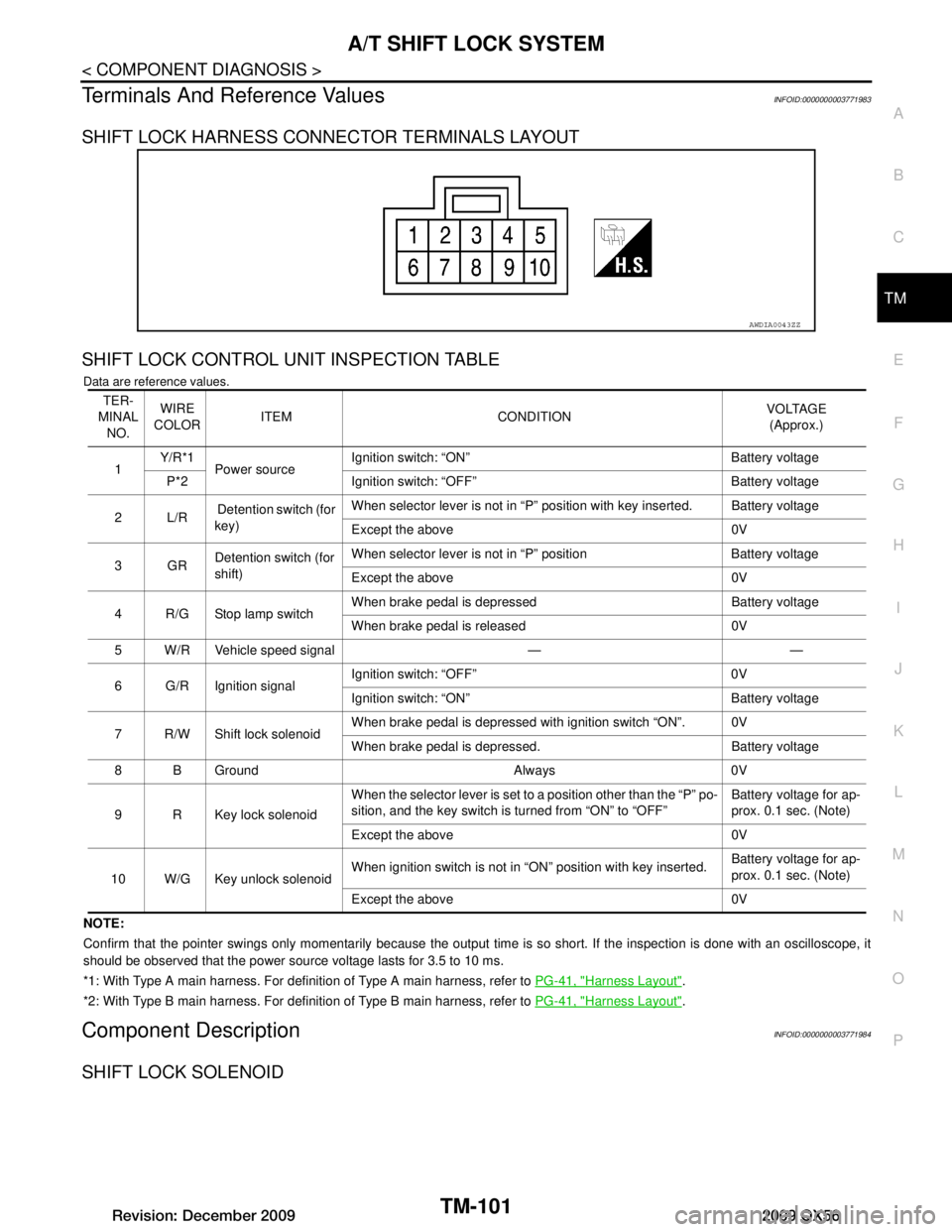

Terminals And Reference ValuesINFOID:0000000003771983

SHIFT LOCK HARNESS CONNECTOR TERMINALS LAYOUT

SHIFT LOCK CONTROL UNIT INSPECTION TABLE

Data are reference values.

NOTE:

Confirm that the pointer swings only momentarily because the output time is so short. If the inspection is done with an oscillo scope, it

should be observed that the power source voltage lasts for 3.5 to 10 ms.

*1: With Type A main harness. For definition of Type A main harness, refer to PG-41, "Harness Layout"

.

*2: With Type B main harness. For definition of Type B main harness, refer to PG-41, "Harness Layout"

.

Component DescriptionINFOID:0000000003771984

SHIFT LOCK SOLENOID

AWDIA0043ZZ

TER-

MINAL NO. WIRE

COLOR ITEM CONDITION VOLTAGE

(Approx.)

1 Y/R*1

Power source Ignition switch: “ON” Battery voltage

P*2 Ignition switch: “OFF” Battery voltage

2L/R Detention switch (for

key) When selector lever is not in “P” position with key inserted. Battery voltage

Except the above 0V

3GR Detention switch (for

shift) When selector lever is not in “P” position Battery voltage

Except the above 0V

4 R/G Stop lamp switch When brake pedal is depressed Battery voltage

When brake pedal is released 0V

5 W/R Vehicle speed signal — —

6 G/R Ignition signal Ignition switch: “OFF” 0V

Ignition switch: “ON” Battery voltage

7 R/W Shift lock solenoid When brake pedal is depressed with ignition switch “ON”. 0V

When brake pedal is depressed. Battery voltage

8 B Ground Always 0V

9 R Key lock solenoid When the selector lever is set to a position other than the “P” po-

sition, and the key switch is turned from “ON” to “OFF”

Battery voltage for ap-

prox. 0.1 sec. (Note)

Except the above 0V

10 W/G Key unlock solenoid When ignition switch is not in “ON” position with key inserted.

Battery voltage for ap-

prox. 0.1 sec. (Note)

Except the above 0V

Revision: December 20092009 QX56

Page 3750 of 4171

TM-102

< COMPONENT DIAGNOSIS >

A/T SHIFT LOCK SYSTEM

Check operation by applying battery voltage to A/T shift selectorterminal 9 and ground to terminal 10.

CAUTION:

Be sure to apply the voltage of the correct polarity to the

respective terminals. Otherwise, the part may be damaged.

PARK POSITION SWITCH

Check continuity between terminals of the A/T shift selector.

DETENT SWITCH

Check continuity between terminals of the A/T shift selector.

KEY LOCK SOLENOID

Key lock

Check operation by applying battery voltage to key switch and key lock solenoid terminal 6 and ground to terminal 5.

CAUTION:

Be careful not to cause burnout of the harness.

Key unlock

AWDIA0700ZZ

Condition Terminal No. Continuity

When selector lever is “P” position. 5 - 6No

When selector lever is not “P” position. Yes

AWDIA0567ZZ

Condition Terminal No. Continuity

When selector lever is “P” position. 3 - 4No

When selector lever is not “P” position. Yes

AWDIA0568ZZ

AWDIA0544ZZ

Revision: December 20092009 QX56