sensor INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 2621 of 4171

![INFINITI QX56 2009 Factory Service Manual LAN-52

< COMPONENT DIAGNOSIS >[CAN]

CAN COMMUNICATION SYSTEM

COMPONENT DIAGNOSIS

CAN COMMUNICATION SYSTEM

Component Parts LocationINFOID:0000000003776457

1. ECM E16

2. IPDM E/R E122 3. ICC sensor E42

INFINITI QX56 2009 Factory Service Manual LAN-52

< COMPONENT DIAGNOSIS >[CAN]

CAN COMMUNICATION SYSTEM

COMPONENT DIAGNOSIS

CAN COMMUNICATION SYSTEM

Component Parts LocationINFOID:0000000003776457

1. ECM E16

2. IPDM E/R E122 3. ICC sensor E42](/img/42/57031/w960_57031-2620.png)

LAN-52

< COMPONENT DIAGNOSIS >[CAN]

CAN COMMUNICATION SYSTEM

COMPONENT DIAGNOSIS

CAN COMMUNICATION SYSTEM

Component Parts LocationINFOID:0000000003776457

1. ECM E16

2. IPDM E/R E122 3. ICC sensor E42

4. AV control unit M45 5. Combination meter M246. ABS actuator and electric unit (con-

trol unit) E125

7. Intelligent Key unit M70 8. BCM M189. Data link connector M22

10. Steering angle sensor M17 11. Driver seat control unit B202 12. ICC unit B13

13. Air bag diagnosis sensor unit M35 14. A/T assembly F9 15. A/C auto amp. M50

16. Transfer control unit E142

AWMIA0011ZZ

Revision: December 20092009 QX56

Page 2629 of 4171

![INFINITI QX56 2009 Factory Service Manual LAN-60

< COMPONENT DIAGNOSIS >[CAN]

MALFUNCTION AREA CHART

MALFUNCTION AREA CHART

Main LineINFOID:0000000003776459

Branch LineINFOID:0000000003776460

Short CircuitINFOID:0000000003776461

Malfunction A INFINITI QX56 2009 Factory Service Manual LAN-60

< COMPONENT DIAGNOSIS >[CAN]

MALFUNCTION AREA CHART

MALFUNCTION AREA CHART

Main LineINFOID:0000000003776459

Branch LineINFOID:0000000003776460

Short CircuitINFOID:0000000003776461

Malfunction A](/img/42/57031/w960_57031-2628.png)

LAN-60

< COMPONENT DIAGNOSIS >[CAN]

MALFUNCTION AREA CHART

MALFUNCTION AREA CHART

Main LineINFOID:0000000003776459

Branch LineINFOID:0000000003776460

Short CircuitINFOID:0000000003776461

Malfunction Area

Reference

Main line between TCM and driver seat control unit LAN-61, "

Diagnosis Procedure"

Main line between TCM and ICC sensorLAN-63, "Diagnosis Procedure"

Main line between ICC sensor and ICC unitLAN-64, "Diagnosis Procedure"

Main line between ICC unit and driver seat control unitLAN-65, "Diagnosis Procedure"

Main line between driver seat control unit and AV control unitLAN-66, "Diagnosis Procedure"

Main line between AV control unit and data link connectorLAN-67, "Diagnosis Procedure"

Main line between data link connector and combination meterLAN-68, "Diagnosis Procedure"

Main line between combination meter and ABS actuator and

electric unit (control unit)LAN-69, "Diagnosis Procedure"

Malfunction Area

Reference

ECM branch line circuit LAN-70, "

Diagnosis Procedure"

TCM branch line circuitLAN-71, "Diagnosis Procedure"

ICC sensor branch line circuitLAN-72, "Diagnosis Procedure"

ICC unit branch line circuitLAN-73, "Diagnosis Procedure"

Driver seat control unit branch line circuitLAN-74, "Diagnosis Procedure"

AV control unit branch line circuitLAN-75, "Diagnosis Procedure"

BCM branch line circuit LAN-76, "Diagnosis Procedure"

Data link connector branch line circuit LAN-77, "Diagnosis Procedure"

A/C auto amp. branch line circuitLAN-78, "Diagnosis Procedure"

Intelligent Key unit branch line circuitLAN-79, "Diagnosis Procedure"

Combination meter branch line circuit LAN-80, "Diagnosis Procedure"

Steering angle sensor branch line circuit LAN-81, "Diagnosis Procedure"

Transfer control unit branch line circuit LAN-82, "Diagnosis Procedure"

ABS actuator and electric unit (control unit) branch line circuit LAN-83, "Diagnosis Procedure"

IPDM E/R branch line circuit LAN-84, "Diagnosis Procedure"

Malfunction Area Reference

CAN communication circuit LAN-85, "

Diagnosis Procedure"

Revision: December 20092009 QX56

Page 2632 of 4171

![INFINITI QX56 2009 Factory Service Manual LAN

MAIN LINE BETWEEN TCM AND LASER CIRCUITLAN-63

< COMPONENT DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

MAIN LINE BETWEEN TC

M AND LASER CIRCUIT

Diagnosis ProcedureINFOID:0000000003776463

INSPEC INFINITI QX56 2009 Factory Service Manual LAN

MAIN LINE BETWEEN TCM AND LASER CIRCUITLAN-63

< COMPONENT DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

MAIN LINE BETWEEN TC

M AND LASER CIRCUIT

Diagnosis ProcedureINFOID:0000000003776463

INSPEC](/img/42/57031/w960_57031-2631.png)

LAN

MAIN LINE BETWEEN TCM AND LASER CIRCUITLAN-63

< COMPONENT DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

MAIN LINE BETWEEN TC

M AND LASER CIRCUIT

Diagnosis ProcedureINFOID:0000000003776463

INSPECTION PROCEDURE

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cabl e from the negative terminal.

3. Check the following terminals and connectors for damage, bend and loose connection (connector side

and harness side).

- Harness connector F14

- Harness connector E5

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS CONTI NUITY (OPEN CIRCUIT)

1. Disconnect the following harness connectors.

- A/T assembly

- Harness connectors F14 and E5

2. Check the continuity between the A/T asse mbly harness connector and the harness connector.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair the main line between the A/T assembly and the harness connector F14.

3.CHECK HARNESS CONTI NUITY (OPEN CIRCUIT)

1. Disconnect the connector of ICC sensor.

2. Check the continuity between the harness connector and the ICC sensor harness connector.

Is the inspection result normal?

YES (Present error)>>Check the following items again. • Decision of CAN system type.

• Not received CONSULT-III data [SELF-DIAG RESULTS, CAN DIAG SUPPORT MNTR (“ECU

list” included)].

• Procedure for detecting root cause.

YES (Past error)>>Error was detected in the main line between the A/T assembly and the ICC sensor.

NO >> Repair the main line between the harness connector E5 and the ICC sensor.

A/T assembly harness connector Harness connector

Continuity

Connector No. Terminal No.Connector No. Terminal No.

F9 3

F14 5

Existed

8 15Existed

Harness connector ICC sensor harness connector

Continuity

Connector No. Terminal No.Connector No. Terminal No.

E5 5

E42 2

Existed

15 3Existed

Revision: December 20092009 QX56

Page 2633 of 4171

![INFINITI QX56 2009 Factory Service Manual LAN-64

< COMPONENT DIAGNOSIS >[CAN]

MAIN LINE BETWEEN LASER AND ICC CIRCUIT

MAIN LINE BETWEEN LA

SER AND ICC CIRCUIT

Diagnosis ProcedureINFOID:0000000003776464

INSPECTION PROCEDURE

1.CHECK CONNECTOR

1 INFINITI QX56 2009 Factory Service Manual LAN-64

< COMPONENT DIAGNOSIS >[CAN]

MAIN LINE BETWEEN LASER AND ICC CIRCUIT

MAIN LINE BETWEEN LA

SER AND ICC CIRCUIT

Diagnosis ProcedureINFOID:0000000003776464

INSPECTION PROCEDURE

1.CHECK CONNECTOR

1](/img/42/57031/w960_57031-2632.png)

LAN-64

< COMPONENT DIAGNOSIS >[CAN]

MAIN LINE BETWEEN LASER AND ICC CIRCUIT

MAIN LINE BETWEEN LA

SER AND ICC CIRCUIT

Diagnosis ProcedureINFOID:0000000003776464

INSPECTION PROCEDURE

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the following terminals and connectors for damage, bend and loose connection (connector side and harness side).

- Harness connector E34

- Harness connector B40

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS CONTI NUITY (OPEN CIRCUIT)

1. Disconnect the following harness connectors.

- ICC sensor

- Harness connectors E34 and B40

2. Check the continuity between the ICC sens or harness connector and the harness connector.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair the main line between the ICC sensor and the harness connector E34.

3.CHECK HARNESS CONTI NUITY (OPEN CIRCUIT)

1. Disconnect the connector of ICC unit.

2. Check the continuity between the harness connector and the ICC unit harness connector.

Is the inspection result normal?

YES (Present error)>>Check the following items again. • Decision of CAN system type.

• Not received CONSULT-III data [SELF-DIAG RESULTS, CAN DIAG SUPPORT MNTR (“ECUlist” included)].

• Procedure for detecting root cause.

YES (Past error)>>Error was detected in the ma in line between the ICC sensor and the ICC unit.

NO >> Repair the main line between the harness connector B40 and the ICC unit.

ICC sensor harness connector Harness connector

Continuity

Connector No. Terminal No.Connector No. Terminal No.

E42 2

E34 24

Existed

3 23Existed

Harness connector ICC unit harness connector

Continuity

Connector No. Terminal No.Connector No. Terminal No.

B40 24

B13 14

Existed

23 5Existed

Revision: December 20092009 QX56

Page 2640 of 4171

![INFINITI QX56 2009 Factory Service Manual LAN

TCM BRANCH LINE CIRCUITLAN-71

< COMPONENT DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

TCM BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003776471

1.CHECK CONNECTOR

1. Turn the ignition INFINITI QX56 2009 Factory Service Manual LAN

TCM BRANCH LINE CIRCUITLAN-71

< COMPONENT DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

TCM BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003776471

1.CHECK CONNECTOR

1. Turn the ignition](/img/42/57031/w960_57031-2639.png)

LAN

TCM BRANCH LINE CIRCUITLAN-71

< COMPONENT DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

TCM BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003776471

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cabl e from the negative terminal.

3. Check the terminals and connectors of the A/T assembly for damage, bend and loose connection (unit

side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of A/T assembly.

2. Check the resistance between the A/T assembly harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the TCM branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the TCM. Refer to TM-92, "

Diagnosis Procedure".

Is the inspection result normal?

YES (Present error)>>Replace the control valve with TCM. Refer to TM-203, "Control Valve with TCM and A/

T Fluid Temperature Sensor 2".

YES (Past error)>>Error was detected in the TCM branch line.

NO >> Repair the power supply and the ground circuit.

A/T assembly harness connector Resistance (Ω)

Connector No. Terminal No.

F9 3 8 Approx. 54 – 66

Revision: December 20092009 QX56

Page 2641 of 4171

![INFINITI QX56 2009 Factory Service Manual LAN-72

< COMPONENT DIAGNOSIS >[CAN]

LASER BRANCH LINE CIRCUIT

LASER BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003776472

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the INFINITI QX56 2009 Factory Service Manual LAN-72

< COMPONENT DIAGNOSIS >[CAN]

LASER BRANCH LINE CIRCUIT

LASER BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003776472

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the](/img/42/57031/w960_57031-2640.png)

LAN-72

< COMPONENT DIAGNOSIS >[CAN]

LASER BRANCH LINE CIRCUIT

LASER BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003776472

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the ICC s ensor for damage, bend and loose connection (unit side

and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of ICC sensor.

2. Check the resistance between the ICC sensor harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the ICC sensor branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the ICC sensor. Refer to CCS-47, "

Wiring Diagram".

Is the inspection result normal?

YES (Present error)>>Replace the ICC sensor. Refer to CCS-71, "ICC Sensor".

YES (Past error)>>Error was detect ed in the ICC sensor branch line.

NO >> Repair the power supply and the ground circuit.

ICC sensor harness connector Resistance (Ω)

Connector No. Terminal No.

E42 23Approx. 54 – 66

Revision: December 20092009 QX56

Page 2650 of 4171

![INFINITI QX56 2009 Factory Service Manual LAN

STRG BRANCH LINE CIRCUITLAN-81

< COMPONENT DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

STRG BRANCH

LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003776481

INSPECTION PROCEDURE

1.CHECK CONNECT INFINITI QX56 2009 Factory Service Manual LAN

STRG BRANCH LINE CIRCUITLAN-81

< COMPONENT DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

STRG BRANCH

LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003776481

INSPECTION PROCEDURE

1.CHECK CONNECT](/img/42/57031/w960_57031-2649.png)

LAN

STRG BRANCH LINE CIRCUITLAN-81

< COMPONENT DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

STRG BRANCH

LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003776481

INSPECTION PROCEDURE

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cabl e from the negative terminal.

3. Check the terminals and connectors of the steer ing angle sensor for damage, bend and loose connection

(unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of steering angle sensor.

2. Check the resistance between the steering angle sensor harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the steering angle sensor branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the steering angle sensor. Refer to BRC-92, "

Wiring Dia-

gram".

Is the inspection result normal?

YES (Present error)>>Replace the steering angle sensor. Refer to BRC-118, "Removal and Installation".

YES (Past error)>>Error was detected in the steering angle sensor branch line.

NO >> Repair the power supply and the ground circuit.

Steering angle sensor harness connector Resistance (Ω)

Connector No. Terminal No.

M17 4 5 Approx. 54 – 66

Revision: December 20092009 QX56

Page 2657 of 4171

LU-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005851889

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005851890

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: December 20092009 QX56

Page 2675 of 4171

MA-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005867447

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005867448

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: December 20092009 QX56

Page 2679 of 4171

MA-6

< ON-VEHICLE MAINTENANCE >

GENERAL MAINTENANCE

ON-VEHICLE MAINTENANCE

GENERAL MAINTENANCE

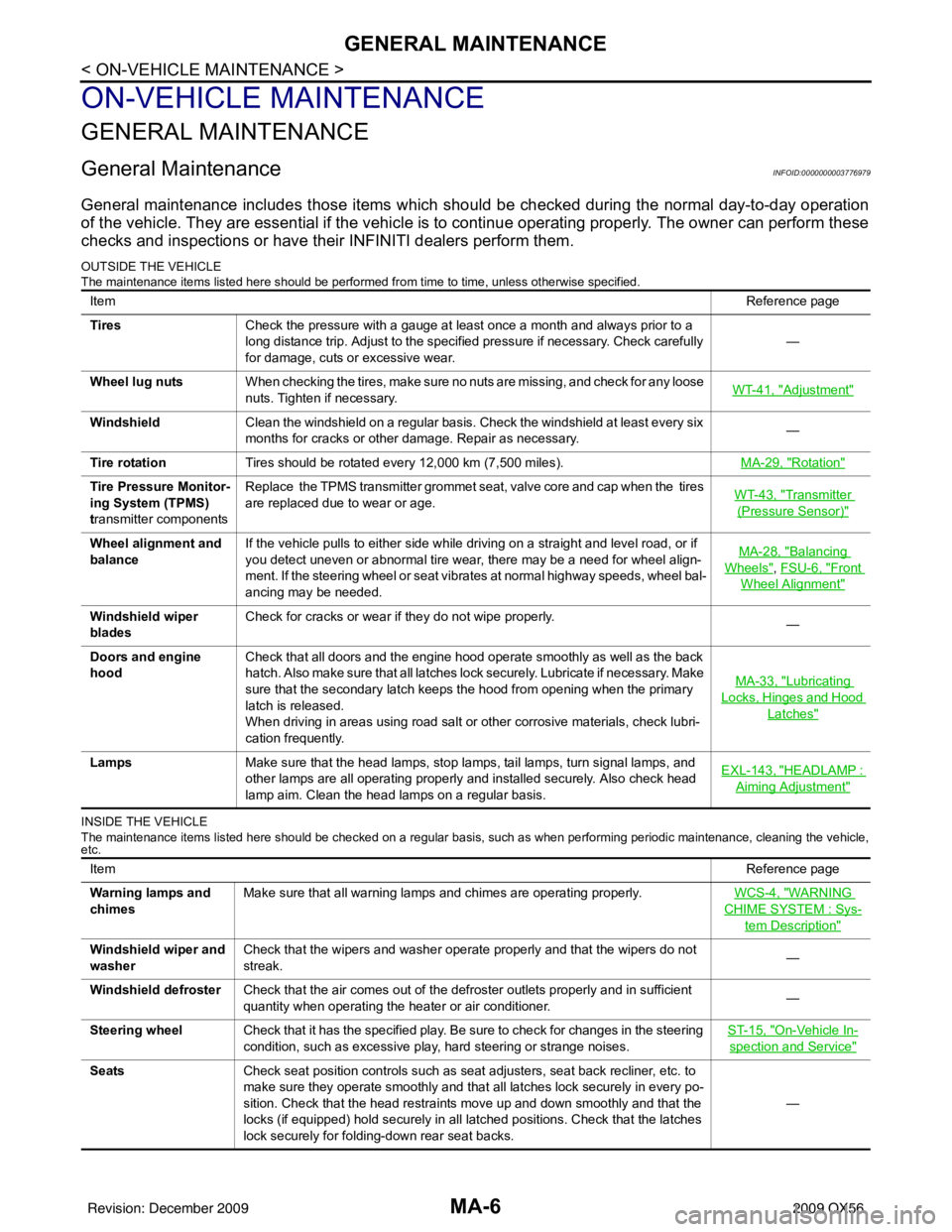

General MaintenanceINFOID:0000000003776979

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owner can perform these

checks and inspections or have thei r INFINITI dealers perform them.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed fr om time to time, unless otherwise specified.

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the vehicle,

etc.

Item Reference page

Tires Check the pressure with a gauge at least once a month and always prior to a

long distance trip. Adjust to the specified pressure if necessary. Check carefully

for damage, cuts or excessive wear. —

Wheel lug nuts When checking the tires, make sure no nuts are missing, and check for any loose

nuts. Tighten if necessary. WT-41, "

Adjustment"

Windshield

Clean the windshield on a regular basis. Check the windshield at least every six

months for cracks or other damage. Repair as necessary. —

Tire rotation Tires should be rotated every 12,000 km (7,500 miles). MA-29, "

Rotation"

Tire Pressure Monitor-

ing System (TPMS)

transmitter componentsReplace the TPMS transmitter grommet seat, valve core and cap when the tires

are replaced due to wear or age.

WT-43, "Transmitter

(Pressure Sensor)"

Wheel alignment and

balanceIf the vehicle pulls to either side while driving on a straight and level road, or if

you detect uneven or abnormal tire wear, there may be a need for wheel align-

ment. If the steering wheel or seat vibrates at normal highway speeds, wheel bal-

ancing may be needed. MA-28, "Balancing

Wheels", FSU-6, "Front

Wheel Alignment"

Windshield wiper

blades

Check for cracks or wear if they do not wipe properly.

—

Doors and engine

hood Check that all doors and the engine hood operate smoothly as well as the back

hatch. Also make sure that all latches lock securely. Lubricate if necessary. Make

sure that the secondary latch keeps the hood from opening when the primary

latch is released.

When driving in areas using road salt or other corrosive materials, check lubri-

cation frequently. MA-33, "

Lubricating

Locks, Hinges and Hood

Latches"

Lamps

Make sure that the head lamps, stop lamps, tail lamps, turn signal lamps, and

other lamps are all operating properly and installed securely. Also check head

lamp aim. Clean the head lamps on a regular basis. EXL-143, "HEADLAMP :

Aiming Adjustment"

Item

Reference page

Warning lamps and

chimes Make sure that all warning lamps and chimes are operating properly.

WCS-4, "

WARNING

CHIME SYSTEM : Sys-

tem Description"

Windshield wiper and

washerCheck that the wipers and washer operate properly and that the wipers do not

streak.

—

Windshield defroster Check that the air comes out of the defroster outlets properly and in sufficient

quantity when operating the heater or air conditioner. —

Steering wheel Check that it has the specified play. Be sure to check for changes in the steering

condition, such as excessive play, hard steering or strange noises. ST-15, "

On-Vehicle In-

spection and Service"

Seats

Check seat position controls such as seat adjusters, seat back recliner, etc. to

make sure they operate smoothly and that all latches lock securely in every po-

sition. Check that the head restraints move up and down smoothly and that the

locks (if equipped) hold securely in all latched positions. Check that the latches

lock securely for folding-down rear seat backs. —

Revision: December 20092009 QX56