check oil INFINITI QX56 2010 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 767 of 4210

PRECAUTIONSCO-3

< PRECAUTION >

C

DE

F

G H

I

J

K L

M A

CO

NP

O

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Precaution for Liquid GasketINFOID:0000000005149035

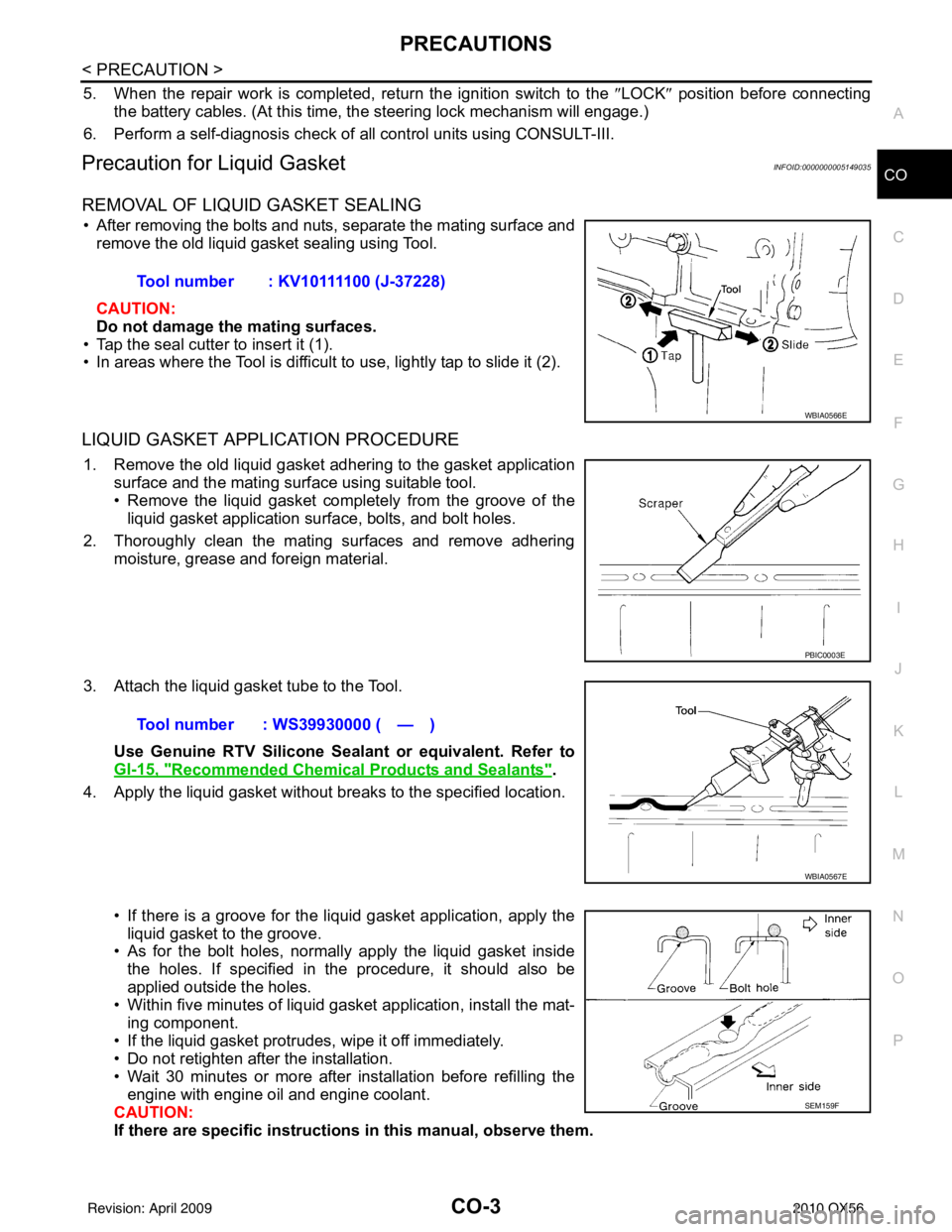

REMOVAL OF LIQUID GASKET SEALING

• After removing the bolts and nuts, separate the mating surface and

remove the old liquid gasket sealing using Tool.

CAUTION:

Do not damage the mating surfaces.

• Tap the seal cutter to insert it (1).

• In areas where the Tool is difficult to use, lightly tap to slide it (2).

LIQUID GASKET APPLICATION PROCEDURE

1. Remove the old liquid gasket adhering to the gasket application surface and the mating surface using suitable tool.

• Remove the liquid gasket completely from the groove of the

liquid gasket application surface, bolts, and bolt holes.

2. Thoroughly clean the mating surfaces and remove adhering moisture, grease and foreign material.

3. Attach the liquid gasket tube to the Tool. Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-15, "

Recommended Chemical Products and Sealants".

4. Apply the liquid gasket without breaks to the specified location.

• If there is a groove for the liquid gasket application, apply theliquid gasket to the groove.

• As for the bolt holes, normally apply the liquid gasket inside

the holes. If specified in the procedure, it should also be

applied outside the holes.

• Within five minutes of liquid gasket application, install the mat-

ing component.

• If the liquid gasket protrudes, wipe it off immediately.

• Do not retighten after the installation.

• Wait 30 minutes or more after installation before refilling the engine with engine oil and engine coolant.

CAUTION:

If there are specific instructions in this manual, observe them.

Tool number : KV10111100 (J-37228)

WBIA0566E

PBIC0003E

Tool number : WS39930000 ( — )

WBIA0567E

SEM159F

Revision: April 20092010 QX56

Page 768 of 4210

CO-4

< PREPARATION >

PREPARATION

PREPARATION

PREPARATION

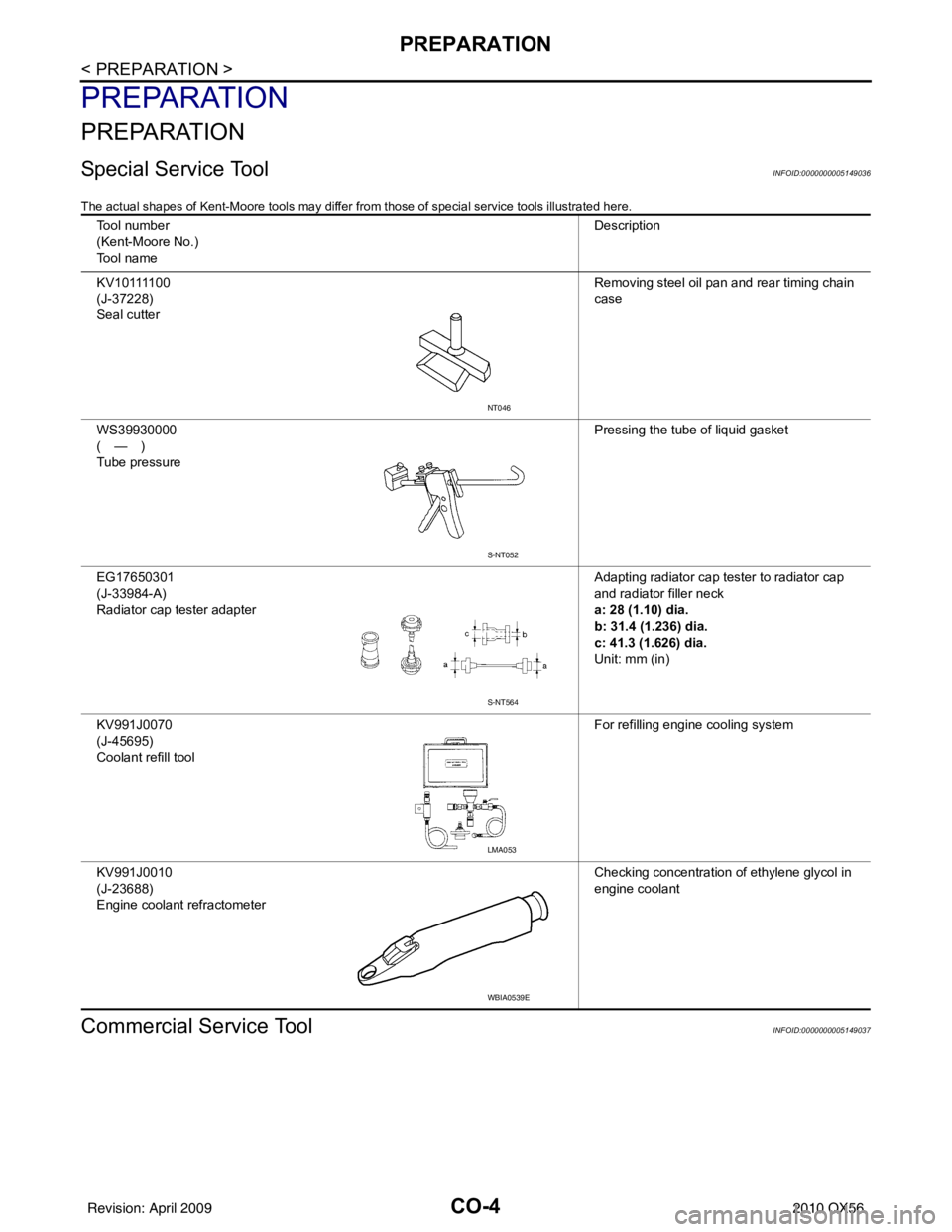

Special Service ToolINFOID:0000000005149036

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolINFOID:0000000005149037

Tool number

(Kent-Moore No.)

Tool name Description

K V 1 0 1111 0 0

(J-37228)

Seal cutter Removing steel oil pan and rear timing chain

case

WS39930000

(—)

Tube pressure Pressing the tube of liquid gasket

EG17650301

(J-33984-A)

Radiator cap tester adapter Adapting radiator cap tester to radiator cap

and radiator filler neck

a: 28 (1.10) dia.

b: 31.4 (1.236) dia.

c: 41.3 (1.626) dia.

Unit: mm (in)

KV991J0070

(J-45695)

Coolant refill tool For refilling engine cooling system

KV991J0010

(J-23688)

Engine coolant refractometer Checking concentration of ethylene glycol in

engine coolant

NT046

S-NT052

S-NT564

LMA053

WBIA0539E

Revision: April 20092010 QX56

Page 776 of 4210

CO-12

< ON-VEHICLE MAINTENANCE >

ENGINE COOLANT

5. Remove the reservoir tank to drain the engine coolant, then clean the reservoir tank before installing it.

6. Check the drained coolant for contaminants such as rust, corrosion or discoloration.

If the coolant is contaminated, flus h the engine cooling system. Refer to CO-11, "

Changing Engine Cool-

ant".

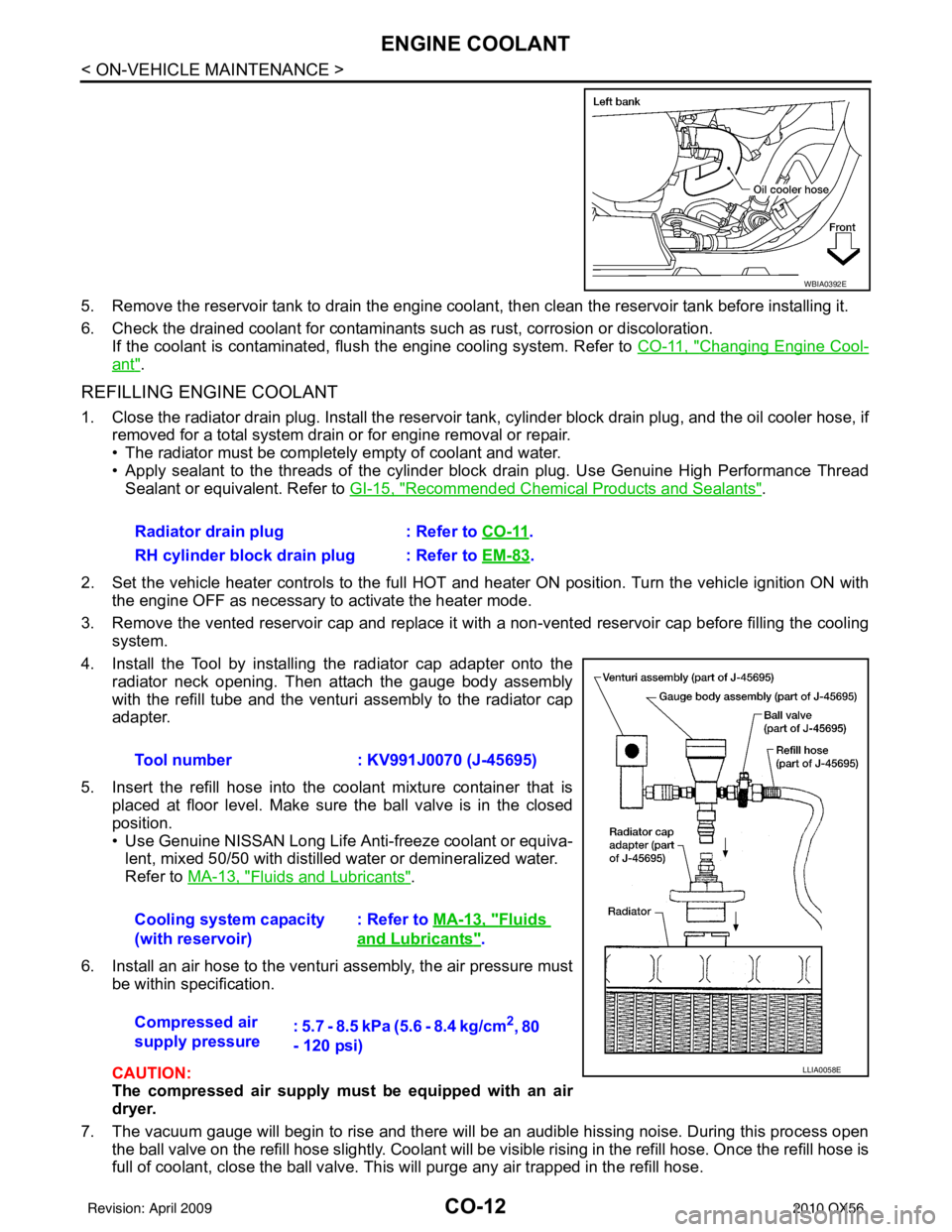

REFILLING ENGINE COOLANT

1. Close the radiator drain plug. Install the reservoir t ank, cylinder block drain plug, and the oil cooler hose, if

removed for a total system drain or for engine removal or repair.

• The radiator must be completely empty of coolant and water.

• Apply sealant to the threads of the cylinder bl ock drain plug. Use Genuine High Performance Thread

Sealant or equivalent. Refer to GI-15, "

Recommended Chemical Products and Sealants".

2. Set the vehicle heater controls to the full HOT and heat er ON position. Turn the vehicle ignition ON with

the engine OFF as necessary to activate the heater mode.

3. Remove the vented reservoir cap and replace it with a non-vented reservoir cap before filling the cooling

system.

4. Install the Tool by installing the radiator cap adapter onto the radiator neck opening. Then attach the gauge body assembly

with the refill tube and the venturi assembly to the radiator cap

adapter.

5. Insert the refill hose into the coolant mixture container that is placed at floor level. Make sure the ball valve is in the closed

position.

• Use Genuine NISSAN Long Life Anti-freeze coolant or equiva-lent, mixed 50/50 with distilled water or demineralized water.

Refer to MA-13, "

Fluids and Lubricants".

6. Install an air hose to the venturi assembly, the air pressure must be within specification.

CAUTION:

The compressed air supply must be equipped with an air

dryer.

7. The vacuum gauge will begin to rise and there will be an audible hissing noise. During this process open the ball valve on the refill hose slightly. Coolant will be vi sible rising in the refill hose. Once the refill hose is

full of coolant, close the ball valve. This will purge any air trapped in the refill hose.

WBIA0392E

Radiator drain plug : Refer to CO-11.

RH cylinder block drain plug : Refer to EM-83

.

Tool number : KV991J0070 (J-45695)

Cooling system capacity

(with reservoir) : Refer to

MA-13, "

Fluids

and Lubricants".

Compressed air

supply pressure : 5.7 - 8.5 kPa (5.6 - 8.4 kg/cm

2, 80

- 120 psi)

LLIA0058E

Revision: April 20092010 QX56

Page 781 of 4210

RADIATORCO-17

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

M A

CO

NP

O

12. Lift up and remove the radiator.

CAUTION:

Do not damage or scratch air conditioner condenser, A/T oil

cooler or radiator core when removing.

INSTALLATION

Installation is in the reverse order of removal.

INSPECTION AFTER INSTALLATION

• Check for leaks of engine coolant. Refer to CO-10, "Inspection".

• Start and warm up the engine. Visually check for leaks of the engine coolant and A/T fluid.

PBIC1536E

Revision: April 20092010 QX56

Page 782 of 4210

CO-18

< ON-VEHICLE REPAIR >

ENGINE COOLING FAN

ENGINE COOLING FAN

Exploded ViewINFOID:0000000005149046

Crankshaft Driven Type

Removal and Installation (Crankshaft Driven Type)INFOID:0000000005149047

REMOVAL

1. Partially drain engine coolant from the radiator. Refer to CO-11, "Changing Engine Coolant".

2. Remove the lower and upper radiator shrouds. Refer to CO-15, "

Exploded View".

3. Remove the drive belt. Refer to EM-13, "

Removal and Installation".

4. Remove the cooling fan.

5. Remove the fan bracket, if necessary.

INSPECTION AFTER REMOVAL

Fan Coupling

• Inspect fan coupling for oil leakage and bimetal conditions.

• If there are any unusual concerns, replace the fan coupling.

Fan Bracket

• Visually check that there is no significant looseness in the fan bracket shaft, and that it turns smoothly by hand.

• If there are any unusual concerns, replace the fan bracket.

Cooling Fan Pulley

• Inspect cooling fan pulley.

• If there are any unusual concerns, replace the cooling fan pulley.

AWBIA0812GB

1. Cooling fan 2. Fan coupling3. Fan bracket

4. Cooling fan pulley A. Front mark Engine front

SLC072

WBIA0418E

Revision: April 20092010 QX56

Page 833 of 4210

REAR WINDOW DEFOGGERDEF-45

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

ON-VEHICLE REPAIR

REAR WINDOW DEFOGGER

Filament CheckINFOID:0000000005146857

1. When measuring voltage, wrap tin foil around the top of the neg- ative probe.Then press the foil against the wire with your finger.

2. Attach probe circuit tester (in Volt range) to middle portion of each filament.

3. If a filament is burned out, circuit tester registers 0 or battery voltage.

4. To locate burned out point, move probe to left and right along fil- ament. Test needle will swing abruptly when probe passes the

point.

Filament RepairINFOID:0000000005146858

REPAIR EQUIPMENT

• Conductive silver composition (DuPont No. 4817 or equivalent)

• Ruler 30 cm (11.8 in) long

SEL122R

SEL263

SEL265

Revision: April 20092010 QX56

Page 1070 of 4210

![INFINITI QX56 2010 Factory User Guide DLK-236

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

HOOD

4. Install the primary and secondary cables securely to the hood

lock assembly.

5. Install the hood lock and the secondary hood lock rel INFINITI QX56 2010 Factory User Guide DLK-236

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

HOOD

4. Install the primary and secondary cables securely to the hood

lock assembly.

5. Install the hood lock and the secondary hood lock rel](/img/42/57032/w960_57032-1069.png)

DLK-236

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

HOOD

4. Install the primary and secondary cables securely to the hood

lock assembly.

5. Install the hood lock and the secondary hood lock release assemblies.

6. Check the hood lock adjustment and hood opener operation. Refer to DLK-233, "

Fitting Adjustment".

7. Install the remaining components in the reverse order of removal.

Hood Lock Control InspectionINFOID:0000000005147053

CAUTION:

If the hood lock cable is bent or deformed, replace it.

1. Remove the front grille. Refer to EXT-17, "

Removal and Installation".

2. Make sure the secondary latch is properly engaged with the sec- ondary striker with hood's own weight by dropping it from

approx. 200 mm (7.87 in) height.

3. While operating the hood opener, carefully make sure the front end of the hood is raised by approx. 20 mm (0.79 in). Also make

sure the hood opener returns to the original position.

4. Check the hood lock lubrication condition. If necessary, apply “body grease” to the points shown in the figure.

5. Install the front grille. Refer to EXT-17, "

Removal and Installa-

tion".

Hood Stay DisposalINFOID:0000000005356855

1. Fix hood stay (1) using a vise (C).

2. Using hacksaw (A) slowly make 2 holes in the hood stay, in numerical order as shown in the figure.

CAUTION:

• When cutting a hole on hood stay, always cover a hack-saw using a shop cloth (B) to avoid scattering metal frag-

ments or oil.

• Wear eye protection (safety glasses).

• Wear gloves.

PIIA0174E

PIIA1086E

PIIA0176E

JMKIA3336ZZ

Revision: April 20092010 QX56

Page 1086 of 4210

DLN-4

Commercial Service Tool ......................................193

SYMPTOM DIAGNOSIS ............................194

NOISE, VIBRATION, AND HARSHNESS

(NVH) TROUBLESHOOTING ......................... .

194

NVH Troubleshooting Chart ................................ ..194

ON-VEHICLE REPAIR ...............................195

PROPELLER SHAFT ..................................... .195

On-Vehicle Service .............................................. ..195

REMOVAL AND INSTALLATION ..............196

PROPELLER SHAFT ..................................... .196

Removal and Installation ..................................... ..196

DISASSEMBLY AND ASSEMBLY ............199

PROPELLER SHAFT ..................................... .199

Disassembly and Assembly ................................. ..199

SERVICE DATA AND SPECIFICATIONS

(SDS) ........................................................ ..

201

SERVICE DATA AND SPECIFICATIONS

(SDS) ............................................................... .

201

General Specification .......................................... ..201

Snap Ring ..............................................................201

FRONT FINAL DRIVE: M205

PRECAUTION .............. ..............................

203

PRECAUTIONS .............................................. .203

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. ..

203

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .................................

203

Precaution for Servicing Front Final Drive .............204

PREPARATION ..........................................205

PREPARATION .............................................. .205

Special Service Tool ............................................ ..205

Commercial Service Tool ......................................207

SYMPTOM DIAGNOSIS ............................208

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ......................... .

208

NVH Troubleshooting Chart ................................ ..208

ON-VEHICLE MAINTENANCE ..................209

DIFFERENTIAL GEAR OIL ............................ .209

Changing Front Differential Gear Oil .....................209

Checking Front Differential Gear Oil .................... ..209

ON-VEHICLE REPAIR ...............................210

SIDE OIL SEAL .............................................. ..210

Removal and Installation .......................................210

FRONT OIL SEAL ............................................211

Removal and Installation .......................................211

CARRIER COVER .......................................... ..214

Removal and Installation .......................................214

REMOVAL AND INSTALLA TION .............215

FRONT FINAL DRIVE .................................... ..215

Removal and Installation .......................................215

DISASSEMBLY AND ASSEMBLY ...........217

FRONT FINAL DRIVE .................................... ..217

Disassembly and Assembly ................................. .217

SERVICE DATA AND SPECIFICATIONS

(SDS) ........ .................................................

234

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ..

234

General Specification ........................................... .234

Inspection and Adjustment ....................................234

REAR FINAL DRIVE: R230

PRECAUTION ............... ............................

236

PRECAUTIONS .............................................. ..236

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. .

236

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ................................

236

Precaution for Servicing Rear Final Drive .............237

PREPARATION .........................................238

PREPARATION .............................................. ..238

Special Service Tool ............................................ .238

Commercial Service Tool ......................................240

SYMPTOM DIAGNOSIS ...........................242

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ......................... ..

242

NVH Troubleshooting Chart ..................................242

DESCRIPTION ................................................ ..243

Cross-Sectional View ........................................... .243

ON-VEHICLE MAINTENANCE .................244

DIFFERENTIAL GEAR OIL ..............................244

Changing Rear Differential Gear Oil .................... .244

Checking Rear Differential Gear Oil ......................244

ON-VEHICLE REPAIR ..............................245

FRONT OIL SEAL ............................................245

Revision: April 20092010 QX56

Page 1096 of 4210

![INFINITI QX56 2010 Factory User Guide DLN-14

< FUNCTION DIAGNOSIS >[ATX14B]

4WD SYSTEM

• Displays 4LO condition while engine is running. 4LO indicator lamp flashes if transfer gear does not shift

completely under 2WD, AUTO, 4H ⇔4LO. ( INFINITI QX56 2010 Factory User Guide DLN-14

< FUNCTION DIAGNOSIS >[ATX14B]

4WD SYSTEM

• Displays 4LO condition while engine is running. 4LO indicator lamp flashes if transfer gear does not shift

completely under 2WD, AUTO, 4H ⇔4LO. (](/img/42/57032/w960_57032-1095.png)

DLN-14

< FUNCTION DIAGNOSIS >[ATX14B]

4WD SYSTEM

• Displays 4LO condition while engine is running. 4LO indicator lamp flashes if transfer gear does not shift

completely under 2WD, AUTO, 4H ⇔4LO. (When 4WD warning lamp is turned on, 4LO indicator lamp is

turned off.)

• Turns ON for approximately 1 second when ignition switch is turned ON, for purpose of lamp check.

4WD WARNING LAMP

Turns on or flashes when there is a malfunction in 4WD system.

Also turns on when ignition switch is turned ON, for purpose of lamp che\

ck. Turns OFF approximately 1 sec-

ond after the engine starts if system is normal.

4WD Warning Lamp Indication

ATP WARNING LAMP

When the A/T selector lever is in P position, the vehicle may move if the transfer case is in neutral. ATP warn-

ing lamp is turned on to indicate this condition to the driver.

LINE PRESSURE SWITCH

• With the transfer system design, control of the oil pressure provides the transmission of drive torque to the

front wheels. The main pressure to control the oil pressure is referred to as the line pressure.

• The line pressure switch determines whether or not adequate line pressure has built up under different oper- ating conditions.

• The line pressure switch closes when line pressure is produced.

• The line pressure switch senses line pressure abnormalities and turns the 4WD warning lamp ON.

CLUTCH PRESSURE SWITCH

• The clutch pressure switch determines whether or not adequate clutch pressure has built up under different

operating conditions.

• The clutch pressure switch closes when clutch pressure is produced.

• The clutch pressure switch senses clutch pressure abnormalities and turns the 4WD warning lamp ON.

WAIT DETECTION SWITCH

• The wait detection switch operates when there is circulating torque produced in the propeller shaft (L→H) or

when there is a phase difference between 2-4 sleeve and clutch drum (H →L). After the release of the circu-

lating torque, the wait detection switch helps provi de the 4WD lock gear (clutch drum) shifts. A difference

may occur between the operation of the 4WD shift swit ch and actual drive mode. At this point, the wait

detection switch senses an actual drive mode.

• The wait detection switch operates as follows.

- 4WD lock gear (clutch drum) locked: ON

- 4WD lock gear (clutch drum) released: OFF

• The wait detection switch senses an actual drive mode and the 4WD shift indicator lamp indicates the vehi-

cle drive mode.

ATP SWITCH

ATP switch detects if transfer case is in neutral by the position of the L-H shift fork.

NOTE:

Transfer case may be in neutral when shifting between 4H-4LO.

NEUTRAL-4LO SWITCH

The neutral-4LO switch detects that transfer gear is in neutral or 4LO (or shifting from neutral to 4LO) condi-

tion by L-H shift fork position.

Condition 4WD warning lamp

System normal OFF

Lamp check Turns ON when ignition switch is turned ON.

Turns OFF after engine start.

4WD system malfunction ON

During self-diagnosis Flashes malfunction mode.

Large difference in diameter of front/

rear tires Flashes slow (1 flash / 2 seconds)

(Continues to flash until the ignition switch is turned OFF)

High fluid temperature in transfer case Flashes rapidly (2 flashes / 1 second)

(Continues to flash until fluid temperature returns to normal)

Revision: April 20092010 QX56

Page 1150 of 4210

![INFINITI QX56 2010 Factory User Guide DLN-68

< COMPONENT DIAGNOSIS >[ATX14B]

P1826 TRANSFER FLUID TEMPERATURE

P1826 TRANSFER FLUID TEMPERATURE

DescriptionINFOID:0000000005148829

Signal voltage from the transfer fluid temperature sensor is INFINITI QX56 2010 Factory User Guide DLN-68

< COMPONENT DIAGNOSIS >[ATX14B]

P1826 TRANSFER FLUID TEMPERATURE

P1826 TRANSFER FLUID TEMPERATURE

DescriptionINFOID:0000000005148829

Signal voltage from the transfer fluid temperature sensor is](/img/42/57032/w960_57032-1149.png)

DLN-68

< COMPONENT DIAGNOSIS >[ATX14B]

P1826 TRANSFER FLUID TEMPERATURE

P1826 TRANSFER FLUID TEMPERATURE

DescriptionINFOID:0000000005148829

Signal voltage from the transfer fluid temperature sensor is abnormally high (Transfer fluid temperature is

abnormally low) while driving.

DTC LogicINFOID:0000000005148830

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Perform self-diagnosis.

Is DTC P1826 displayed?

YES >> Perform diagnosis procedure. Refer to DLN-68, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000005148831

Regarding Wiring Diagram information, refer to DLN-89, "Wiring Diagram - ALL-MODE 4WD SYSTEM -".

1.CHECK TRANSFER FLUID TEMPERATURE SENSOR SIGNAL

With CONSULT-III

1. Start engine.

2. Select DATA MONITOR mode for ALL MODE AWD/4WD with CONSULT-III.

3. Read out the value of FLUID TEMP SE.

Without CONSULT-III

1. Start engine.

2. Check voltage between transfer control unit harness connector

terminals and ground.

Are inspection results normal?

DTC CONSULT-III Diagnostic item is detected when... Reference

[P1826] OIL TEMP SEN Signal voltage from transfer fluid temper-

ature sensor is abnormally high (Trans-

fer fluid temperature is abnormally low)

while driving.Refer to

DLN-68

.

Condition Display value

(Approx.)

Transfer fluid temperature approx. 20 - 80 °C (68 - 176 °F) 1.1 - 0.3V

Connector Terminal ConditionData

(Approx.)

E143 28 -

Ground Always

0V

31 -

Ground Ignition switch:

ON Transfer fluid temperature

approx. 20

°C (68 °F) 1.1V

Transfer fluid temperature

approx. 80 °C (176 °F) 0.3V

SDIA2742E

Revision: April 20092010 QX56