key INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 1666 of 5598

DLK-130

< DTC/CIRCUIT DIAGNOSIS >

UNLOCK SENSOR

UNLOCK SENSOR

Component Function CheckINFOID:0000000006225941

1.CHECK FUNCTION

1. Select “INTELLIGE NT KEY” of “BCM” using CONSULT-III.

2. Select “UNLK SEN-DR” in “DATA MONITOR” mode.

3. Check that the function operates normall y according to the following conditions.

Is the inspection result normal?

YES >> Unlock sensor is OK.

NO >> Refer to DLK-130, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000006225942

1.CHECK UNLOCK SENSOR INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect front door lock assembly (driver side) connector.

3. Check signal between front door lock assembly (d river side) harness connector and ground with oscillo-

scope.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK UNLOCK SENSOR CIRCUIT

1. Disconnect BCM connector.

2. Check continuity between BCM harness connector and front door lock assembly (driver side) harness connector.

3. Check continuity between BCM harness connector and ground.

Is the inspection result normal?

YES >> Replace BCM. Refer to BCS-81, "Removal and Installation".

Monitor item Condition Status

UNLK SEN -DR Driver side door Lock OFF

Unlock ON

(+)

(–)Signal

(Reference value)

Front door lock assembly (driver side)

Connector Terminal

D9 3 Ground

PKIB4960J

BCM Front door lock assembly (driver side) Continuity

Connector Terminal Connector Terminal

M68 31 D9 3 Existed

BCM GroundContinuity

Connector Terminal

M68 31 Not existed

Revision: 2010 May2011 QX56

Page 1668 of 5598

DLK-132

< DTC/CIRCUIT DIAGNOSIS >

DOOR KEY CYLINDER SWITCH

DOOR KEY CYLINDER SWITCH

Component Function CheckINFOID:0000000006225944

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “KEY CYL LK-SW”, “KEY CY L UN-SW” in “DATA MONITOR” mode.

3. Check that the function operates normall y according to the following conditions.

Is the inspection result normal?

YES >> Door key cylinder switch is OK.

NO >> Refer to DLK-132, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000006225945

1.CHECK DOOR KEY CYLINDER SWITCH INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect front door lock assembly (driver side) connector.

3. Check voltage between front door lock assembly (driver side) harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK DOOR KEY CYLINDER SWITCH SIGNAL CIRCUIT

1. Disconnect power window main switch connector.

2. Check continuity between power window main s witch harness connector and front door lock assembly

(driver side) harness connector.

3. Check continuity between power window main switch harness connector and ground.

Is the inspection result normal?

YES >> Replace power window main switch. Refer to PWC-74, "Removal and Installation".

Monitor item Condition Status

KEY CYL LK-SW Driver side door key cylinder Lock ON

Neutral / Unlock OFF

KEY CYL UN-SW Unlock ON

Neutral / Lock OFF

(+)

(–)Vo l ta g e

(Approx.)

Front door lock assembly (driver side)

Connector Terminal

D9 5

Ground 5 V

6

Power window main switch Front do or lock assembly (driver side)

Continuity

Connector Terminal Connector Terminal

D5 4

D9 6

Existed

65

Power window main switch GroundContinuity

Connector Terminal

D5 4

Not existed

6

Revision: 2010 May2011 QX56

Page 1669 of 5598

DOOR KEY CYLINDER SWITCHDLK-133

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

DLK

N

O P

NO >> Repair or replace harness.

3.CHECK DOOR KEY CYLINDER SWITCH GROUND CIRCUIT

Check continuity between front door lock assembly (driver side) harness connector and ground.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace harness.

4.CHECK DOOR KEY CYLINDER SWITCH

Refer to DLK-133, "

Component Inspection".

Is the inspection result normal?

YES >> GO TO 5.

NO >> Replace front door lock assembly (driver side).

5.CHECK INTERMITTENT INCIDENT

Refer to GI-40, "

Intermittent Incident".

>> INSPECTION END

Component InspectionINFOID:0000000006225946

1.CHECK DOOR KEY CYLINDER SWITCH

1. Turn ignition switch OFF.

2. Disconnect front door lock assembly (driver side) connector.

3. Check continuity between front door lock assembly (driver side) terminals.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace front door lock assembly (driver side).

Front door lock assembly (driver side)

GroundContinuity

Connector Terminal

D9 4 Existed

Front door lock assembly (driver side) Condition Continuity

Te r m i n a l

5 4 Driver side door key cylinder Unlock Existed

Neutral / Lock Not existed

6 Lock Existed

Neutral / Unlock Not existed

Revision: 2010 May2011 QX56

Page 1670 of 5598

DLK-134

< DTC/CIRCUIT DIAGNOSIS >

REMOTE KEYLESS ENTRY RECEIVER

REMOTE KEYLESS ENTRY RECEIVER

Component Function CheckINFOID:0000000006225947

1.CHECK FUNCTION

1. Select “INTELLIGE NT KEY” of “BCM” using CONSULT-III.

2. Select “RKE OPE COUN1” in “DATA MONITOR” mode.

3. Check that the function operates normall y according to the following conditions.

Is the inspection result normal?

YES >> Remote keyless entry receiver is OK.

NO >> Refer to DLK-134, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000006225948

1.CHECK REMOTE KEYLESS ENTRY RECEIVER OUTPUT SIGNAL

1. Turn ignition switch OFF.

2. Check signal between remote keyless entry receiver harness connector and ground using oscilloscope.

Is the inspection result normal?

YES >> GO TO 2.

NO >> GO TO 3.

2.CHECK REMOTE K EYLESS ENTRY RECEIVER CIRCUIT 1

1. Disconnect BCM and remote keyless entry receiver connector

2. Check continuity between BCM harness connector and remote keyless entry receiver harness connector.

Is the inspection result normal?

YES >> GO TO 8.

NO >> Repair or replace harness.

Monitor item Condition

RKE OPE COUN1 Checks whether value changes when operating Intelligent Key

(+) (–) Condition Signal

(Reference value)

Remote keyless entry receiver

Connector Terminal

B21 2 Ground Waiting

Signal receiving

JMKIA3838GB

JMKIA3841GB

BCM Remote keyless entry receiver

Continuity

Connector Terminal Connector Terminal

M68 20 B21 2 Existed

Revision: 2010 May2011 QX56

Page 1671 of 5598

REMOTE KEYLESS ENTRY RECEIVERDLK-135

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

DLK

N

O P

3.CHECK REMOTE KEYLESS EN TRY RECEIVER CIRCUIT 2

1. Disconnect BCM connector.

2. Check continuity between BCM harness connector and ground.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace harness.

4.CHECK REMOTE KEYLESS ENTRY RECEIVER POWER SUPPLY

1. Disconnect remote keyless entry receiver.

2. Check signal between remote keyless entry rece iver harness connector and ground using oscilloscope.

Is the inspection result normal?

YES >> GO TO 6.

NO >> GO TO 5.

5.CHECK REMOTE KEYLESS EN TRY RECEIVER CIRCUIT 3

1. Disconnect BCM connector.

2. Check continuity between BCM harness connector and remote keyless entry receiver harness connector.

3. Check continuity between BCM harness connector and ground.

Is the inspection result normal?

YES >> Replace BCM. Refer to BCS-81, "Removal and Installation".

NO >> Repair or replace harness.

6.CHECK REMOTE KEYLESS ENTR Y RECEIVER GROUND CIRCUIT 1

1. Disconnect BCM connector.

2. Check continuity between BCM harness connector and remote keyless entry receiver harness connector.

BCM

GroundContinuity

Connector Terminal

M68 20 Not existed

(+)

(–)Signal

(Reference value)

Remote keyless entry receiver

Connector Terminal

B21 4 Ground

JMKIA3838GB

BCM Remote keyless entry receiver Continuity

Connector Terminal Connector Terminal

M68 19 B21 4 Existed

BCM GroundContinuity

Connector Terminal

M68 19 Not existed

BCM Remote keyless entry receiver Continuity

Connector Terminal Connector Terminal

M68 18 B21 1 Existed

Revision: 2010 May2011 QX56

Page 1672 of 5598

DLK-136

< DTC/CIRCUIT DIAGNOSIS >

REMOTE KEYLESS ENTRY RECEIVER

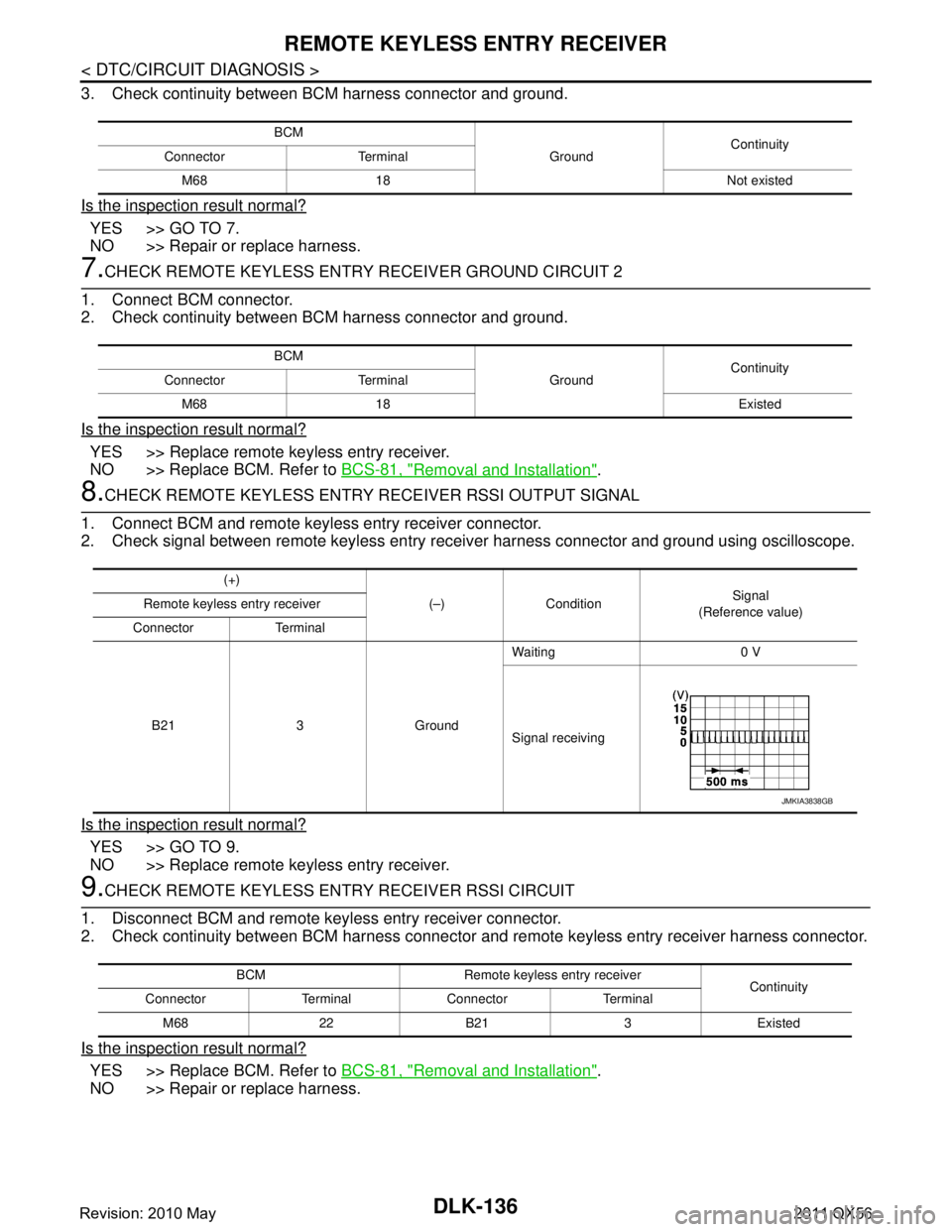

3. Check continuity between BCM harness connector and ground.

Is the inspection result normal?

YES >> GO TO 7.

NO >> Repair or replace harness.

7.CHECK REMOTE KEYLESS ENTRY RECEIVER GROUND CIRCUIT 2

1. Connect BCM connector.

2. Check continuity between BCM harness connector and ground.

Is the inspection result normal?

YES >> Replace remote keyless entry receiver.

NO >> Replace BCM. Refer to BCS-81, "

Removal and Installation".

8.CHECK REMOTE KEYLESS ENTRY RE CEIVER RSSI OUTPUT SIGNAL

1. Connect BCM and remote keyless entry receiver connector.

2. Check signal between remote keyless entry receiver harness connector and ground using oscilloscope.

Is the inspection result normal?

YES >> GO TO 9.

NO >> Replace remote keyless entry receiver.

9.CHECK REMOTE KEYL ESS ENTRY RECEIVER RSSI CIRCUIT

1. Disconnect BCM and remote keyless entry receiver connector.

2. Check continuity between BCM harness connector and remote keyless entry receiver harness connector.

Is the inspection result normal?

YES >> Replace BCM. Refer to BCS-81, "Removal and Installation".

NO >> Repair or replace harness.

BCM

GroundContinuity

Connector Terminal

M68 18 Not existed

BCM GroundContinuity

Connector Terminal

M68 18 Existed

(+) (–) Condition Signal

(Reference value)

Remote keyless entry receiver

Connector Terminal

B21 3 Ground Waiting 0 V

Signal receiving

JMKIA3838GB

BCM Remote keyless entry receiver

Continuity

Connector Terminal Connector Terminal

M68 22 B21 3 Existed

Revision: 2010 May2011 QX56

Page 1673 of 5598

DOOR REQUEST SWITCHDLK-137

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

DLK

N

O P

DOOR REQUEST SWITCH

Component Function CheckINFOID:0000000006225949

1.CHECK FUNCTION

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “REQ SW-DR”, “REQ SW-AS” in “DATA MONITOR” mode.

3. Check that the function operates normall y according to the following conditions.

Is the inspection result normal?

YES >> Front door request switch is OK.

NO >> Refer to DLK-137, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000006225950

1.CHECK DOOR REQUEST SWITCH INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect malfunctioning front door request switch connector.

3. Check voltage between malfunctioning front door request switch harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK DOOR REQUEST SWITCH CIRCUIT

1. Disconnect BCM connector.

2. Check continuity between malfunctioning front door request switch harness connector and BCM harness

connector.

3. Check continuity between malfunctioning front door request switch harness connector and ground.

Is the inspection result normal?

YES >> Replace BCM. Refer to BCS-81, "Removal and Installation".

NO >> Repair or replace harness.

Monitor item Condition Status

REQ SW -DR Driver side door request switchPressed ON

Released OFF

REQ SW -AS Passenger side door request switch Pressed ON

Released OFF

(+)

(–)Vo l ta g e

(Approx.)

Front door request switch

Connector Terminal

Driver side D11 1 Ground 12 V

Passenger side D31

Front door request switch BCM Continuity

Connector Terminal Connector Terminal

Driver side D11 1M7175

Existed

Passenger side D31 76

Front door request switch GroundContinuity

Connector Terminal

Driver side D11 1 Not existed

Passenger side D31

Revision: 2010 May2011 QX56

Page 1675 of 5598

BACK DOOR REQUEST SWITCHDLK-139

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

DLK

N

O P

BACK DOOR REQUEST SWITCH

Component Function CheckINFOID:0000000006225952

1.CHECK FUNCTION

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “REQ SW-BD/TR” in “DATA MONITOR” mode.

3. Check that the function operates normall y according to the following conditions.

Is the inspection result normal?

YES >> Back door request switch is OK.

NO >> Refer to DLK-139, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000006225953

1.CHECK BACK DOOR REQUEST SWITCH INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect back door opener switch assembly connector.

3. Check voltage between back door opener switch assembly harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK BACK DOOR REQUEST SWITCH CIRCUIT

1. Disconnect BCM connector.

2. Check continuity between BCM harness connector and back door opener switch assembly harness con-

nector.

3. Check continuity between BCM harness connector and ground.

Is the inspection result normal?

YES >> Replace BCM. Refer to BCS-81, "Removal and Installation".

NO >> Repair or replace harness.

3.CHECK BACK DOOR REQUEST SWITCH GROUND CIRCUIT

Check continuity between back door opener s witch assembly harness connector and ground.

Monitor item Condition Status

REQ SW-BD/TR Back door request switch Pressed On

Released Off

(+)

(–)Vol tag e

(Approx.)

Back door opener switch assembly

Connector Terminal D154 4 Ground 12 V

BCM Back door opener switch assembly Continuity

Connector Terminal Connector Terminal

M69 51 D154 4 Existed

BCM GroundContinuity

Connector Terminal

M69 51 Not existed

Revision: 2010 May2011 QX56

Page 1679 of 5598

INTELLIGENT KEY WARNING BUZZERDLK-143

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

DLK

N

O P

INTELLIGENT KEY WARNING BUZZER

Component Function CheckINFOID:0000000006225958

1.CHECK FUNCTION

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “OUTSIDE BUZZER ” in “ACTIVE TEST” mode.

3. Touch “On” or “Off” to check that it works normally.

Is the inspection result normal?

YES >> Intelligent Key warning buzzer is OK.

NO >> Refer to DLK-143, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000006225959

1.CHECK FUSE

1. Turn ignition switch OFF.

2. Check 10 A fuse, [No. 6, located in fuse block (J/B)].

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace the blown fuse after repairing the affected circuit if a fuse is blown.

2.CHECK INTELLIGENT KEY WARNING BUZZER POWER SUPPLY CIRCUIT

1. Disconnect Intelligent Key warning buzzer connector.

2. Check voltage between Intelligent Key warning buzzer harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace harness.

3.CHECK INTELLIGENT KEY WARNING BUZZER CIRCUIT

1. Disconnect BCM connector.

2. Check continuity between BCM harness connector and Intelligent Key warning buzzer harness connector.

3. Check continuity between BCM harness connector and ground.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace harness.

4.CHECK INTELLIGENT KEY WARNING BUZZER

Refer to DLK-144, "

Component Inspection".

Is the inspection result normal?

YES >> Replace BCM. Refer to BCS-81, "Removal and Installation".

NO >> Replace Intelligent Key warning buzzer.

(+)

(–)Vo l ta g e

(Approx.)

Intelligent Key warning buzzer

Connector Terminal E25 1 Ground Battery voltage

BCM Intelligent Key warning buzzer Continuity

Connector Terminal Connector Terminal

M71 93 E25 3 Existed

BCM GroundContinuity

Connector Terminal

M71 93 Not existed

Revision: 2010 May2011 QX56

Page 1680 of 5598

DLK-144

< DTC/CIRCUIT DIAGNOSIS >

INTELLIGENT KEY WARNING BUZZER

Component Inspection

INFOID:0000000006225960

1.CHECK INTELLIGENT KEY WARNING BUZZER

1. Turn ignition switch OFF.

2. Disconnect Intelligent Key warning buzzer connector.

3. Connect battery power supply directly to Intelli gent Key warning buzzer terminals and check the opera-

tion.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace Intelligent Key warning buzzer.

Intelligent Key warning buzzer Operation

Te r m i n a l

(+) ( −)

1 3 Buzzer sounds

Revision: 2010 May2011 QX56