engine coolant INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 3806 of 5598

MWI

B2268 WATER TEMPMWI-63

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

K L

M B A

O P

B2268 WATER TEMP

DescriptionINFOID:0000000006221740

The engine coolant temperature signal is transmitted from ECM to the combination meter via CAN communi-

cation.

DTC LogicINFOID:0000000006221741

DTC DETECTION LOGIC

Diagnosis ProcedureINFOID:0000000006221742

1.PERFORM SELF-DIAGNOSIS OF ECM

Perform “Self Diagnosis Result” of ECM, and repair or replace malfunctioning parts.

>> Refer to EC-98, "

DTC Index".

DTCDisplay contents of

CONSULT-III Diagnostic item is detected when... Probable malfunction location

B2268 WATER TEMP ECM continuously transmits abnormal engine

coolant temperature signals for 60 seconds or

more Engine coolant temperature sensor

ECM

Revision: 2010 May2011 QX56

Page 3856 of 5598

![INFINITI QX56 2011 Factory Service Manual

PCS

IPDM E/RPCS-15

< ECU DIAGNOSIS INFORMATION > [IPDM E/R]

C

D

E

F

G H

I

J

K L

B A

O P

N

ECU DIAGNOSIS INFORMATION

IPDM E/R

Reference ValueINFOID:0000000006220172

VALUES ON THE DIAGNOSIS TOOL

Monito INFINITI QX56 2011 Factory Service Manual

PCS

IPDM E/RPCS-15

< ECU DIAGNOSIS INFORMATION > [IPDM E/R]

C

D

E

F

G H

I

J

K L

B A

O P

N

ECU DIAGNOSIS INFORMATION

IPDM E/R

Reference ValueINFOID:0000000006220172

VALUES ON THE DIAGNOSIS TOOL

Monito](/img/42/57033/w960_57033-3855.png)

PCS

IPDM E/RPCS-15

< ECU DIAGNOSIS INFORMATION > [IPDM E/R]

C

D

E

F

G H

I

J

K L

B A

O P

N

ECU DIAGNOSIS INFORMATION

IPDM E/R

Reference ValueINFOID:0000000006220172

VALUES ON THE DIAGNOSIS TOOL

Monitor Item Condition Value/Status

RAD FAN REQ Engine idle speed Changes depending on engine

coolant temperature, air condition-

er operation status, vehicle speed,

etc.0 – 100 %

AC COMP REQ Engine running A/C switch OFF Off

A/C switch ON

(Compressor is operating)

On

TAIL&CLR REQ Lighting switch OFF Off

Lighting switch 1ST, 2ND or AUTO (Light is illuminated) On

HL LO REQ Lighting switch OFF Off

Lighting switch 2ND or AUTO (Light is illuminated) On

HL HI REQ Lighting switch 2ND or

AUTO (Light is illuminated) Lighting switch other than HI and

PA S S

Off

Lighting switch HI or PASS On

FR FOG REQ Lighting switch 2ND or

AUTO (Light is illuminated) Front fog lamp switch OFF Off

Front fog lamp switch ON On

FR WIP REQ Ignition switch ON Front wiper switch OFF Stop

Front wiper switch INT 1LOW

Front wiper switch LO Low

Front wiper switch HI Hi

WIP AUTO STOP Ignition switch ON Front wiper stop position STOP P

Any position other than front wiper

stop position

ACT P

WIP PROT Ignition switch ON Front wiper operates normally. Off

Front wiper stops at fail-safe opera-

tion.

BLOCK

IGN RLY1 -REQ Ignition switch OFF or ACC Off

Ignition switch ON On

IGN RLY Ignition switch OFF or ACC Off

Ignition switch ON On

PUSH SW Release the push-button ignition switch Off

Press the push-button ignition switch On

INTER/NP SW Ignition switch ON Selector lever in any position other

than P or N

Off

Selector lever in P or N position On

ST RLY CONT Ignition switch ON Off

At engine cranking On

IHBT RLY -REQ Ignition switch ON Off

At engine cranking On

Revision: 2010 May2011 QX56

Page 4257 of 5598

RSU-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precautions for SuspensionINFOID:0000000006225656

• When installing rubber bushings, the final tightening must be carried out under unladen conditions with tires

on ground. Spilled oil might shorten the life of rubber bushings. Be sure to wipe off any spilled oil.

- Unladen conditions mean that fuel, engine coolant and l ubricant are full. Spare tire, jack, hand tools and

mats are in designated positions.

After servicing suspension parts, be sure to check wheel alignment.

Self-lock nuts are not reusable. Always use new ones when installing. Since new self-lock nuts are pre-oiled,

tighten as they are.

Revision: 2010 May2011 QX56

Page 4261 of 5598

RSU-6

< PERIODIC MAINTENANCE >

WHEEL ALIGNMENT

WHEEL ALIGNMENT

InspectionINFOID:0000000006225661

DESCRIPTION

Measure wheel alignment under unladen conditions.

NOTE:

“Unladen conditions” means that fuel, engine coolant, and lubricant are full. Spare tire, jack, hand tools and

mats are in designated positions.

PRELIMINARY CHECK

Check the following:

Tires for improper air pressure and wear

Road wheels for runout. Refer to WT-64, "

Inspection".

Wheel bearing axial end play. Refer to RAX-5, "

Inspection".

Ball joint axial end play of suspension arm and front lower link. Refer to RSU-20, "

Ball Joint".

Shock absorber operation

Each mounting point of axle and suspension for looseness and deformation

Each of front lower link, rear lower link, rear suspension member, suspension arm and shock absorber for

cracks, deformation, and other damage

Vehicle height (posture)

GENERAL INFORMATION AND RECOMMENDATIONS

A four-wheel thrust alignment should be performed.

- This type of alignment is recomm ended for any NISSAN/INFINITI vehicle.

- The four-wheel “thrust” process helps ensure that t he vehicle is properly aligned and the steering wheel is

centered.

- The alignment rack itself should be capable of accepting any NISSAN/INFINITI vehicle.

- The rack should be checked to ensure that it is level.

Make sure the machine is properly calibrated.

- Your alignment equipment should be regularly calib rated in order to give correct information.

- Check with the manufacturer of your specific equi pment for their recommended Service/Calibration Sched-

ule.

ALIGNMENT PROCESS

IMPORTANT:

Use only the alignment specifications listed in this Service Manual.

When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or

minus, Go/No Go). Never use these indicators.

- The alignment specifications programmed into your machine that operate these indicators may not be cor-

rect.

- This may result in an ERROR.

Some newer alignment machines are equipped with an optional “Rolling Compensation” method to “com- pensate” the sensors (alignment targets or head units). Never use this “Rolling Compensation” method.

- Use the “Jacking Compensation Method”. After installi ng the alignment targets or head units, raise the vehi-

cle and rotate the wheels 1/2 turn both ways.

- See Instructions in the alignment machine you're using for more information on this.

AdjustmentINFOID:0000000006225662

CAMBER

Revision: 2010 May2011 QX56

Page 4275 of 5598

RSU-20

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

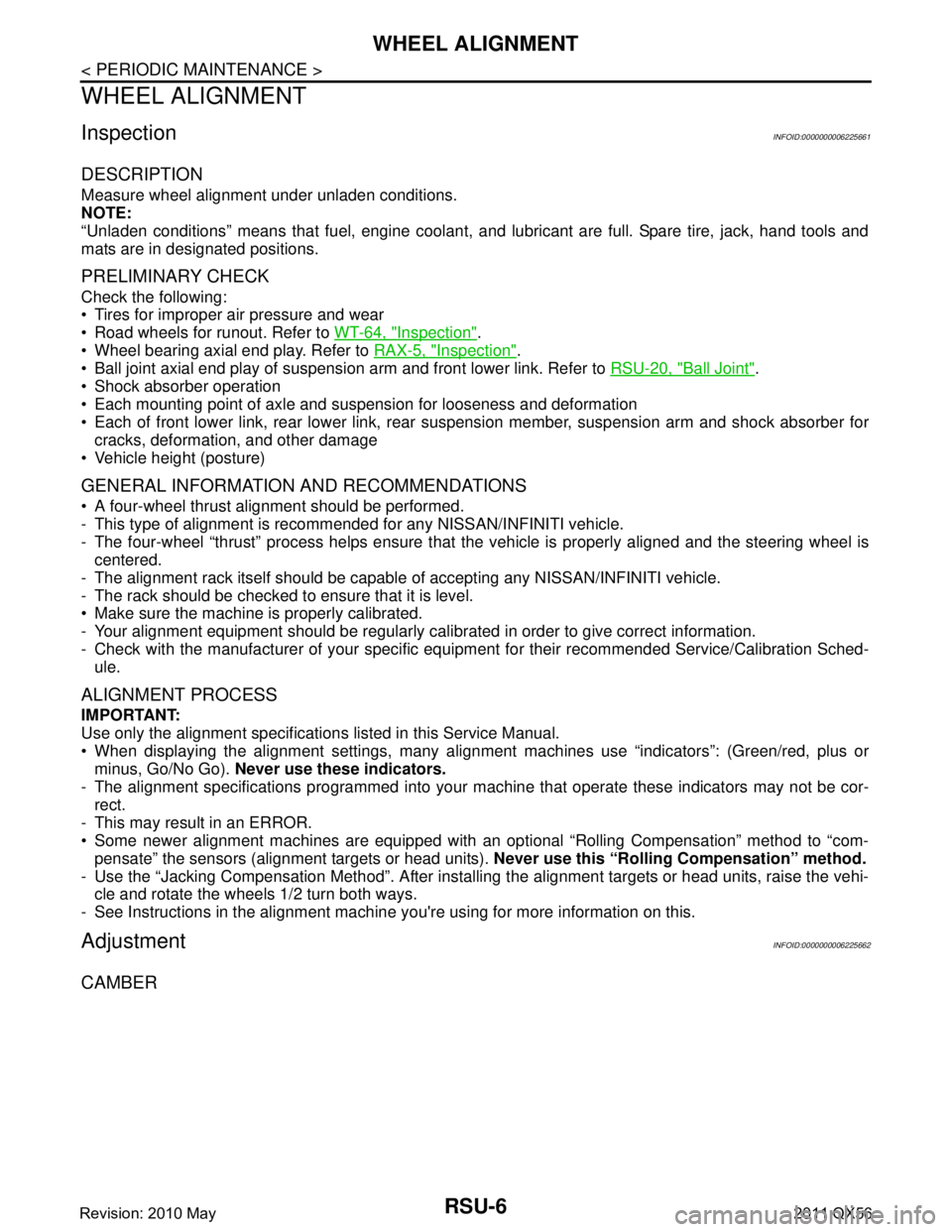

Wheel AlignmentINFOID:0000000006225679

Measure value under unladen* conditions.

*: Fuel, engine coolant and lubricant are full. Spare tire, jack, hand tools and mats are in designated positions.

Ball JointINFOID:0000000006225680

Wheel HeightINFOID:0000000006225681

Measure value under unladen* conditions.

*: Fuel, engine coolant and lubricant are full. Spare tire, jack, hand tools and mats are in designated positions.Item Standard

Camber

Degree minute (Decimal degree) Minimum –1

° 00 ′ (–1.00 °)

Nominal –0 ° 30 ′ (–0.50 °)

Maximum 0 ° 00 ′ (0.00 °)

Left and right difference 0 ° 45 ′ (0.75 °) or less

To e - i n Total toe-in

Distance

Minimum 0 mm (0 in)

Nominal In 3.4 mm (0.134 in)

Maximum In 6.8 mm (0.268 in)

Toe angle (left wheel or right wheel)

Degree minute (Decimal degree) Minimum 0

° 00 ′ (0.00 °)

Nominal In 0 ° 07 ′ (0.12 °)

Maximum In 0 ° 14 ′ (0.23 °)

Item Standard

Swing torque 0.5 – 6.4 N·m (0.06 – 0.65 kg-m, 5 – 56 in-lb)

Measurement on spring balance (groove position) Suspension arm 11.4 – 145.4 N (1.17 – 14.83 kg, 2.57 – 32.68 lb)

Front lower link 11.0 – 140.6 N (1.13 – 14.34 kg, 2.48 – 31.60 lb)

Rotating torque 0.5 – 6.4 N·m (0.06 – 0.65 kg-m, 5 – 56 in-lb)

Axial end play 0 mm (0 in)

Item Standard

Front (Hf) 903 mm (35.55 in)

Rear (Hr) 890 mm (35.04 in)

SFA746B

Revision: 2010 May2011 QX56

Page 5080 of 5598

STR-12

< BASIC INSPECTION >

DIAGNOSIS AND REPAIR WORKFLOW

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter motor and alternator test segments must be

done as a set from start to finish.

1.DIAGNOSIS WITH STARTING /CHARGING SYSTEM TESTER

Perform the starting system test with Starting/Char ging System Tester (SST: J-44373). For details and operat-

ing instructions, refer to Technical Service Bulletin.

Te s t r e s u l t

CRANKING VOLTAGE NORMAL>>GO TO 2.

CRANKING VOLTAGE LOW>>GO TO 5.

CHARGE BATTERY>>Perform the slow battery charging procedure. (Initial rate of charge is 10A for 12

hours.) Perform battery test again. Re fer to Technical Service Bulletin.

REPLACE BATTERY>>Before replacing battery, clean t he battery cable clamps and battery posts. Perform

battery test again. Refer to Technical Service Bu lletin. If second test result is “REPLACE BAT-

TERY”, then do so. Perform battery test again to confirm repair.

2.CRANKING CHECK

Check that the starter motor operates correctly.

Does the engine crank normally?

YES >> GO TO 3.

NO >> GO TO 4.

3.ENGINE START CHECK

Check that the engine starts.

Does the engine start?

YES >> Starter motor is OK. INSPECTION END

NO >> Perform further diagnosis of engine mechanical or engine control system. Refer EM and EC sec-

tions. Once resolved, perform battery test again.

4.STARTER MOTOR ACTIVATION

Check that the starter motor operates.

Does the starter motor turn?

YES >> Check ring gear and starter motor drive pinion. Once resolved, perform battery test again.

NO >> GO TO 7.

5.COMPARISON BETWEEN ENGINE COOLANT AND CRANKING VOLTAGE

Compare the engine coolant temperature and the cranking voltage with the specifications.

Minimum Specification of Cranking Voltage Referencing Coolant Temperature

Is the voltage less than the specified value?

YES >> GO TO 7.

NO >> GO TO 6.

6.STARTER OPERATION

Check the starter operation status.

Does the starter motor turn smoothly?

YES >> Starter motor is OK. INSPECTION END

NO >> GO TO 7.

7.“B” TERMINAL CIRCUIT INSPECTION

Check “B” terminal circuit. Refer to STR-14, "

Diagnosis Procedure".

Is

“B” terminal circuit normal?

Engine coolant temperature [ °C ( °F)] Voltage [V]

− 30 to −20 ( −22 to −4) 8.6

− 19 to −10 ( −2 to 14) 9.1

− 9 to 0 (16 to 32) 9.5

More than 1 (More than 34) 9.9

Revision: 2010 May2011 QX56

Page 5130 of 5598

![INFINITI QX56 2011 Factory Service Manual

TM-42

< SYSTEM DESCRIPTION >[7AT: RE7R01B]

STRUCTURE AND OPERATION

A/T FLUID COOLER SCHEMATIC

COMPONENT DESCRIPTION

A/T fluid warmer

The A/T fluid warmer (1) is installed on the front part of cylin INFINITI QX56 2011 Factory Service Manual

TM-42

< SYSTEM DESCRIPTION >[7AT: RE7R01B]

STRUCTURE AND OPERATION

A/T FLUID COOLER SCHEMATIC

COMPONENT DESCRIPTION

A/T fluid warmer

The A/T fluid warmer (1) is installed on the front part of cylin](/img/42/57033/w960_57033-5129.png)

TM-42

< SYSTEM DESCRIPTION >[7AT: RE7R01B]

STRUCTURE AND OPERATION

A/T FLUID COOLER SCHEMATIC

COMPONENT DESCRIPTION

A/T fluid warmer

The A/T fluid warmer (1) is installed on the front part of cylinder

block of engine.

When engine is started while engine and A/T are cold, engine cool-

ant temperature rises more quickly than A/T fluid temperature. A/T

fluid warmer is provided with two circuits for ATF and engine cool-

ant respectively so that warmed engine coolant warms ATF

quickly. This helps shorten A/T warming up time, improving fuel

economy.

A cooling effect is obtained when A/T fluid temperature is high.

A/T fluid cooler (with bypass valve)

A/T fluid cooler (1) is installed in the front of radiator (2) and con- denser (3).

A/T fluid cooler is provided with a bypass valve that controls ATF

flow. Bypass valve operates by thermo wax and a return spring.

Bypass valve fully opens when A/T fluid temperature is approxi-

mately 90 °C (194 °F) and fully closes when A/T fluid temperature is

approximately 100 °C (212 °F).

When A/T fluid temperature is low, the bypass valve is open. Most of ATF therefore returns to the transmission without flowing into the

cooler core that has larger flow resistance.

JSDIA1803GB

JSDIA1811ZZ

JSDIA1814ZZ

JSDIA1815GB

Revision: 2010 May2011 QX56

Page 5411 of 5598

WCS

SYSTEMWCS-7

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K L

M B A

O P

WARNING CHIME SYSTEM : Fail-SafeINFOID:0000000006369726

FA I L - S A F E

The combination meter activates the fail-safe contro l if CAN communication with each unit is malfunctioning.

Seat belt warning chimeThe warning chime sounds when the driver

seat belt is unfastened with the ignition switch

in ON position. BCMWCS-11,

"SEAT BELT

WARNING

CHIME : Sys-

tem Descrip-

tion"

Parking brake release warning chime

The warning chime sounds when the ignition

switch is in ON position with the parking brake

in operation and the vehicle speed 7 km/h (4.3

MPH) or more. Combination meterWCS-12,

"PA R K I N G

BRAKE RE-

LEASE WARN-

ING CHIME :

System De-

scription"

Warning functions Out line Warning judgment unit Refer to

Function Specifications

Speedometer

Reset to zero by suspending communication.

Tachometer

Engine coolant temperature gauge

Engine oil pressure gauge

Illumination control When suspending communication, changes to nighttime mode.

Information display Odo/trip meter An indicated value is maintained at communications blackout.

Shift position indicator The display turns OFF by suspending communication.

Door open warning The display turns OFF by suspending communication.

Buzzer The buzzer turns OFF by suspending communication.

Revision: 2010 May2011 QX56

Page 5418 of 5598

WCS-14

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (COMBINATION METER)

DIAGNOSIS SYSTEM (COMBINATION METER)

CONSULT-III FunctionINFOID:0000000006222742

CONSULT-III APPLICATION ITEMS

CONSULT-III can perform the following diagnosis modes via CAN communication and the combination meter.

SELF DIAG RESULT

Refer to MWI-43, "DTC Index".

DATA MONITOR

Display Item List

X: Applicable

System Diagnosis mode Description

METER/M&A Self Diagnostic Result The combination meter checks the conditions and displays memorized errors.

Data Monitor Displays the combination meter input/output data in real time.

Special function Lighting history of the warning lamp and indicator lamp can be checked.

Display item [Unit]

MAIN

SIGNALS Description

SPEED METER

[km/h] XValue of vehicle speed

signal received from ABS actuator and el ectric unit (control

unit) via CAN communication.

NOTE:

655.35 is displayed when the malfunction signal is received.

SPEED OUTPUT

[km/h] XVehicle speed signal value transmitted to other units via CAN communication.

NOTE:

655.35 is displayed when the malfunction signal is received.

ODO OUTPUT

[km/h or mph] Odometer signal value transmitted to other units via CAN communication.

TACHO METER

[rpm] XValue of the engine speed signal received from ECM via CAN communication.

NOTE:

8191.875 is displayed when the malfunction signal is received.

FUEL METER

[L] X Fuel level indicated on combination meter.

W TEMP METER

[ ° C] XValue of engine coolant temperature signal is received from ECM via CAN com-

munication.

NOTE:

215 is displayed when the malfunction signal is input.

ABS W/L

[On/Off] Status of ABS warning lamp

detected from ABS warning lamp signal is received

from ABS actuator and electric unit (control unit) via CAN communication.

VDC/TCS IND

[On/Off] Status of VDC OFF indicator lamp detected from VDC OFF indicator lamp signal

is received from ABS actuator and electric

unit (control unit) via CAN communica-

tion.

SLIP IND

[On/Off] Status of VDC warning lamp detected from VDC warning lamp signal received

from ABS actuator and electric unit (control unit) via CAN communication.

BRAKE W/L

[On/Off] Status of brake warning lamp detected from brake warning lamp signal is received

from ABS actuator and electric unit (control unit) via CAN communication.

NOTE:

Displays “Off” if the brake warning lamp is illuminated when the valve check starts,

the parking brake switch is turned ON or the brake fluid level switch is turned ON.

DOOR W/L

[On/Off] Status of door open warning detected from door switch signal received from BCM

via CAN communication.

HI-BEAM IND

[On/Off] Status of high beam indicator lamp detected from high beam request signal is re-

ceived from BCM via CAN communication.

TURN IND

[On/Off] Status of turn indicator lamp detected from turn indicator signal is received from

BCM via CAN communication.

Revision: 2010 May2011 QX56

Page 5426 of 5598

WCS-22

< ECU DIAGNOSIS INFORMATION >

COMBINATION METER

ECU DIAGNOSIS INFORMATION

COMBINATION METER

Reference ValueINFOID:0000000006222688

VALUES ON THE DIAGNOSIS TOOL

Monitor Item Condition Value/Status

SPEED METER

[km/h] Ignition switch

ON

While driving Input value of vehicle speed signal

(CAN communication signal)

NOTE:

655.35 is displayed when the malfunc-

tion signal is received

SPEED OUTPUT

[km/h] Ignition switch

ON

While driving Output value of vehicle speed signal

(CAN communication signal)

NOTE:

655.35 is displayed when the malfunc-

tion signal is received

ODO OUTPUT

[km/h or mph] Ignition switch

ON

—Output value of odometer signal (CAN

communication signal)

TACHO METER

[rpm] Ignition switch

ON

Engine running Input value of engine speed signal

(CAN communication signal)

NOTE:

8191.875 is displayed when the mal-

function signal is received

FUEL METER

[L] Ignition switch

ON

— Input value of fuel level sensor signal

W TEMP METER

[ ° C] Ignition switch

ON

—Input value of engine coolant tempera-

ture signal (CAN communication sig-

nal)

NOTE:

215 is displayed when the malfunction

signal is input

ABS W/L Ignition switch

ONABS warning lamp ON On

ABS warning lamp OFF Off

VDC/TCS IND Ignition switch

ONVDC OFF indicator lamp ON On

VDC OFF indicator lamp OFF Off

SLIP IND Ignition switch

ONVDC warning lamp ON On

VDC warning lamp OFF Off

BRAKE W/L Ignition switch

ONBrake warning lamp ON On

Brake warning lamp OFF Off

DOOR W/L Ignition switch

ONDoor open warning ON On

Other than the above Off

HI-BEAM IND Ignition switch

ONHigh-beam indicator lamp ON On

High-beam indicator lamp OFF Off

TURN IND Ignition switch

ONTurn signal indicator lamp ON On

Turn signal indicator lamp OFF Off

FR FOG IND Ignition switch

ONNOTE:

This item is displayed, but cannot be moni-

tored.

Off

RR FOG IND Ignition switch

ONNOTE:

This item is displayed, but cannot be moni-

tored.

Off

Revision: 2010 May2011 QX56