radiator INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 676 of 5598

BRM-1

BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITY

C

D

E

F

G H

I

J

L

M

SECTION BRM

A

B

BRM

N

O P

CONTENTS

BODY REPAIR

VEHICLE INFORMATION ... ..........................2

BODY EXTERIOR PAINT COLOR ................ .....2

Body Exterior Paint Color ................................. ......2

PRECAUTION ...............................................4

REPAIRING HIGH STRENGTH STEEL ......... .....4

High Strength Steel (HSS) ................................ ......4

Handling of Ultra High Strength Steel Plate Parts ......6

PREPARATION ............................................7

REPAIRING MATERIAL ................................ .....7

Foam Repair ....................................................... ......7

BODY COMPONENT PARTS .............................9

Underbody Component Parts ............................ ......9

Body Component Parts ...........................................11

Frame Component Parts .........................................13

REMOVAL AND INSTALLATION ...............15

CORROSION PROTECTION ......................... ....15

Description .......................................................... ....15

Anti-corrosive Wax ..................................................15

Undercoating ...........................................................16

Stone Guard Coat ...................................................17

Body Sealing ...........................................................18

BODY CONSTRUCTION ....................................22

Body Construction ............................................... ....22

REPLACEMENT OPERATIONS .......................24

Description ...............................................................24

Radiator Core Support .............................................26

Hoodledge ...............................................................26

Hoodledge (Partial Replacement) ...........................27

Front Pillar ...............................................................29

Center Pillar .............................................................32

Outer Sill .................................................................35

Rear Fender ............................................................39

Rear Fender Extension ............................................42

Rear Panel and Rear End Crossmember ................42

Rear Floor Rear .....................................................45

Crush Horn ..............................................................46

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .............................................

48

BODY ALIGNMENT ..........................................48

Body Center Marks ............................................ ....48

Description ...............................................................48

Engine Compartment ..............................................49

Underbody ...............................................................52

Passenger Compartment .........................................54

Rear Body ...............................................................56

LOCATION OF PLASTIC PARTS ....................58

Precautions for Plastics ...........................................58

Location of Plastic Parts ..........................................59

Revision: 2010 May2011 QX56

Page 679 of 5598

BRM-4

< PRECAUTION >

REPAIRING HIGH STRENGTH STEEL

PRECAUTION

REPAIRING HIGH STRENGTH STEEL

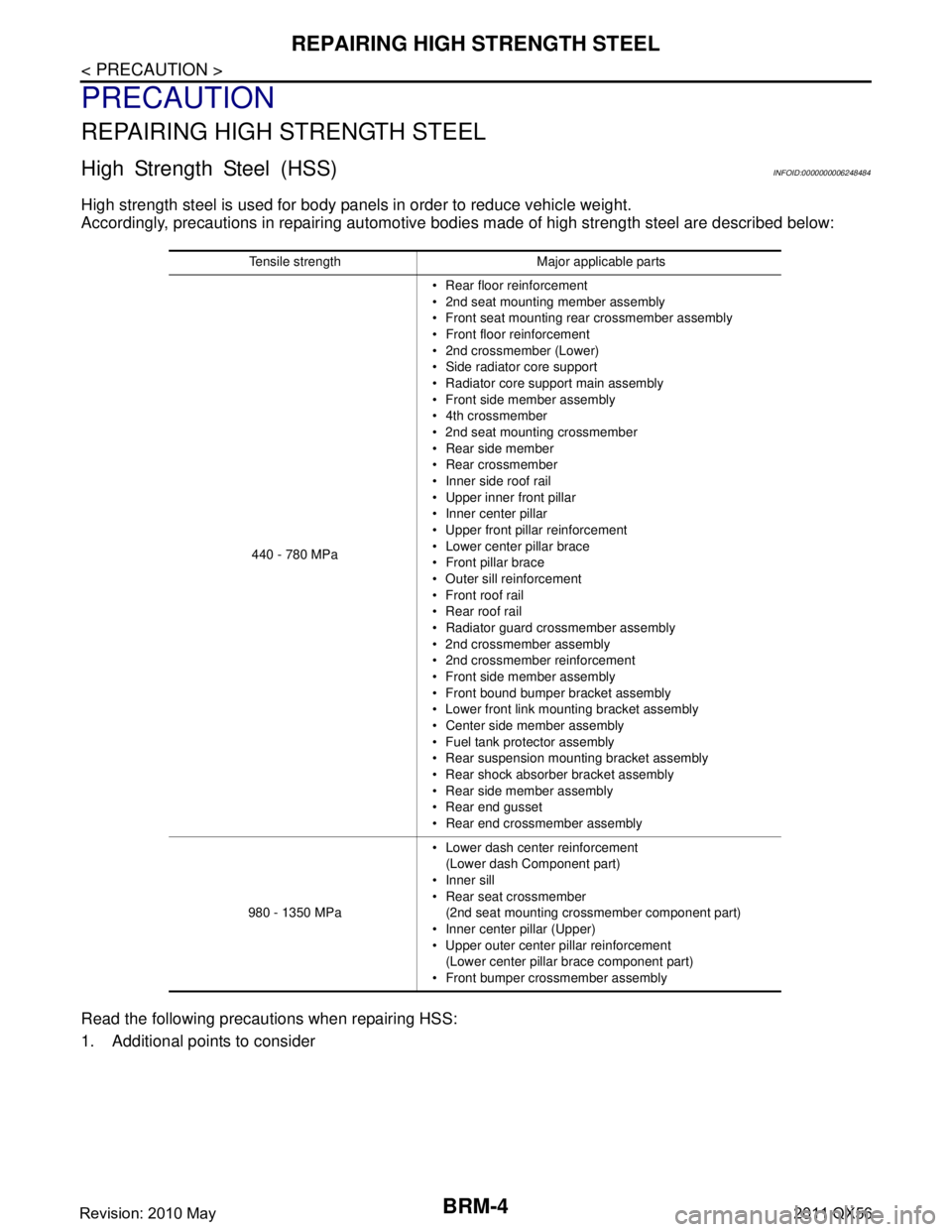

High Strength Steel (HSS)INFOID:0000000006248484

High strength steel is used for body panels in order to reduce vehicle weight.

Accordingly, precautions in repairing automotive bodies made of high strength steel are described below:

Read the following precautions when repairing HSS:

1. Additional points to consider

Tensile strength Major applicable parts 440 - 780 MPa Rear floor reinforcement

2nd seat mounting member assembly

Front seat mounting rear crossmember assembly

Front floor reinforcement

2nd crossmember (Lower)

Side radiator core support

Radiator core support main assembly

Front side member assembly

4th crossmember

2nd seat mounting crossmember

Rear side member

Rear crossmember

Inner side roof rail

Upper inner front pillar

Inner center pillar

Upper front pillar reinforcement

Lower center pillar brace

Front pillar brace

Outer sill reinforcement

Front roof rail

Rear roof rail

Radiator guard crossmember assembly

2nd crossmember assembly

2nd crossmember reinforcement

Front side member assembly

Front bound bumper bracket assembly

Lower front link mounting bracket assembly

Center side member assembly

Fuel tank protector assembly

Rear suspension mounting bracket assembly

Rear shock absorber bracket assembly

Rear side member assembly

Rear end gusset

Rear end crossmember assembly

980 - 1350 MPa Lower dash center reinforcement

(Lower dash Component part)

Inner sill

Rear seat crossmember

(2nd seat mounting crossmember component part)

Inner center pillar (Upper)

Upper outer center pillar reinforcement

(Lower center pillar brace component part)

Front bumper crossmember assembly

Revision: 2010 May2011 QX56

Page 685 of 5598

BRM-10

< PREPARATION >

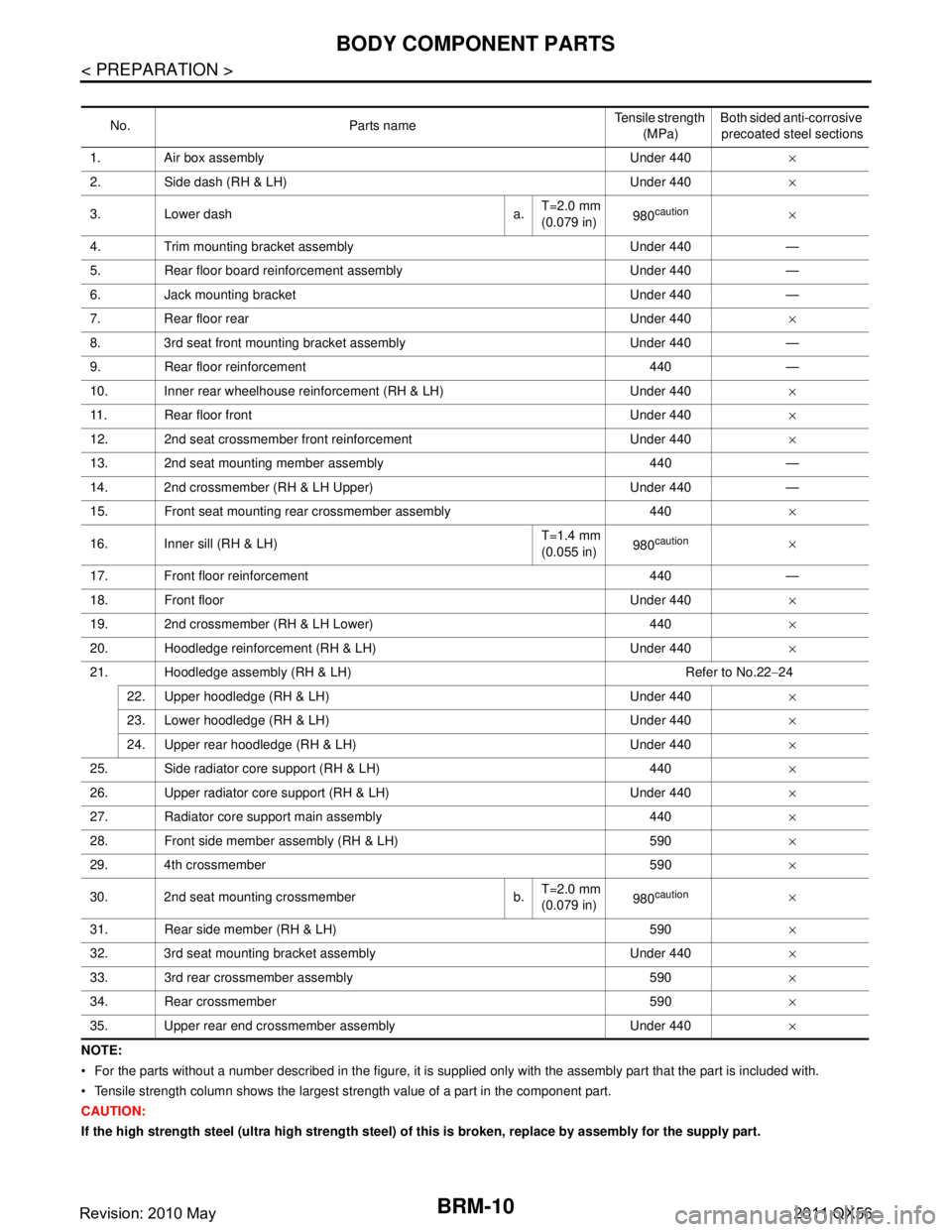

BODY COMPONENT PARTS

NOTE:

For the parts without a number described in the figure, it is supplied only with the assembly part that the part is included with.

Tensile strength column shows the largest strength value of a part in the component part.

CAUTION:

If the high strength steel (ultra high strength steel) of this is broken, replace by assembly for the supply part. No. Parts name

Tensile strength

(MPa) Both sided anti-corrosive

precoated steel sections

1. Air box assembly Under 440 ×

2. Side dash (RH & LH) Under 440 ×

3. Lower dash a. T=2.0 mm

(0.079 in)

980

caution×

4. Trim mounting bracket assembly Under 440 —

5. Rear floor board reinforcement assembly Under 440 —

6. Jack mounting bracket Under 440 —

7. Rear floor rear Under 440 ×

8. 3rd seat front mounting bracket assembly Under 440 —

9. Rear floor reinforcement 440 —

10. Inner rear wheelhouse reinforcement (RH & LH) Under 440 ×

11. Rear floor front Under 440 ×

12. 2nd seat crossmember front reinforcement Under 440 ×

13. 2nd seat mounting member assembly 440 —

14. 2nd crossmember (RH & LH Upper) Under 440 —

15. Front seat mounting rear crossmember assembly 440 ×

16. Inner sill (RH & LH) T=1.4 mm

(0.055 in)

980

caution×

17. Front floor reinforcement 440 —

18. Front floor Under 440 ×

19. 2nd crossmember (RH & LH Lower) 440 ×

20. Hoodledge reinforcement (RH & LH) Under 440 ×

21. Hoodledge assembly (RH & LH) Refer to No.22 −24

22. Upper hoodledge (RH & LH) Under 440 ×

23. Lower hoodledge (RH & LH) Under 440 ×

24. Upper rear hoodledge (RH & LH) Under 440 ×

25. Side radiator core support (RH & LH) 440 ×

26. Upper radiator core support (RH & LH) Under 440 ×

27. Radiator core support main assembly 440 ×

28. Front side member assembly (RH & LH) 590 ×

29. 4th crossmember 590 ×

30. 2nd seat mounting crossmember b. T=2.0 mm

(0.079 in)

980

caution×

31. Rear side member (RH & LH) 590 ×

32. 3rd seat mounting bracket assembly Under 440 ×

33. 3rd rear crossmember assembly 590 ×

34. Rear crossmember 590 ×

35. Upper rear end crossmember assembly Under 440 ×

Revision: 2010 May2011 QX56

Page 701 of 5598

BRM-26

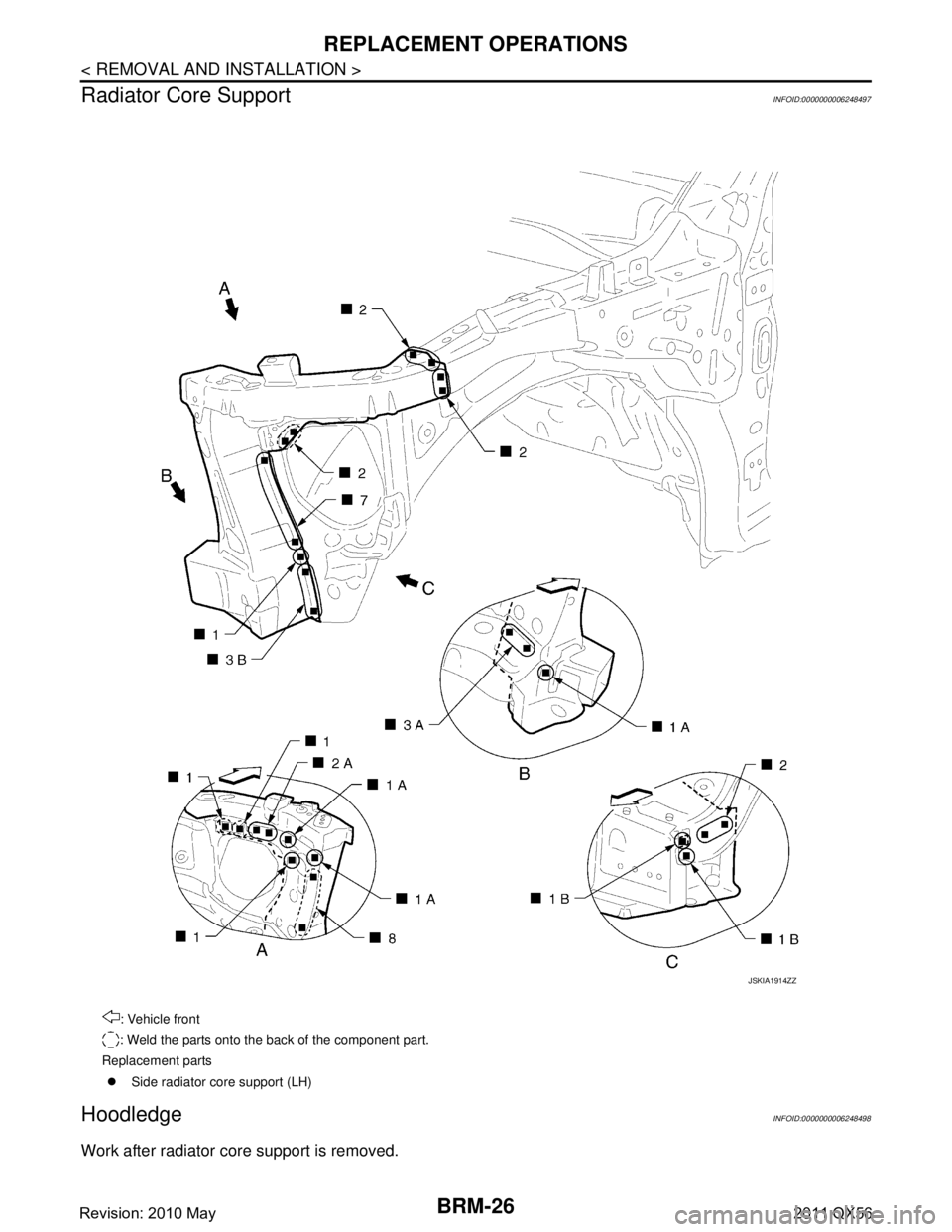

< REMOVAL AND INSTALLATION >

REPLACEMENT OPERATIONS

Radiator Core Support

INFOID:0000000006248497

HoodledgeINFOID:0000000006248498

Work after radiator core support is removed.

: Vehicle front

: Weld the parts onto the back of the component part.

Replacement parts �z Side radiator core support (LH)

JSKIA1914ZZ

Revision: 2010 May2011 QX56

Page 702 of 5598

REPLACEMENT OPERATIONSBRM-27

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

BRM

N

O P

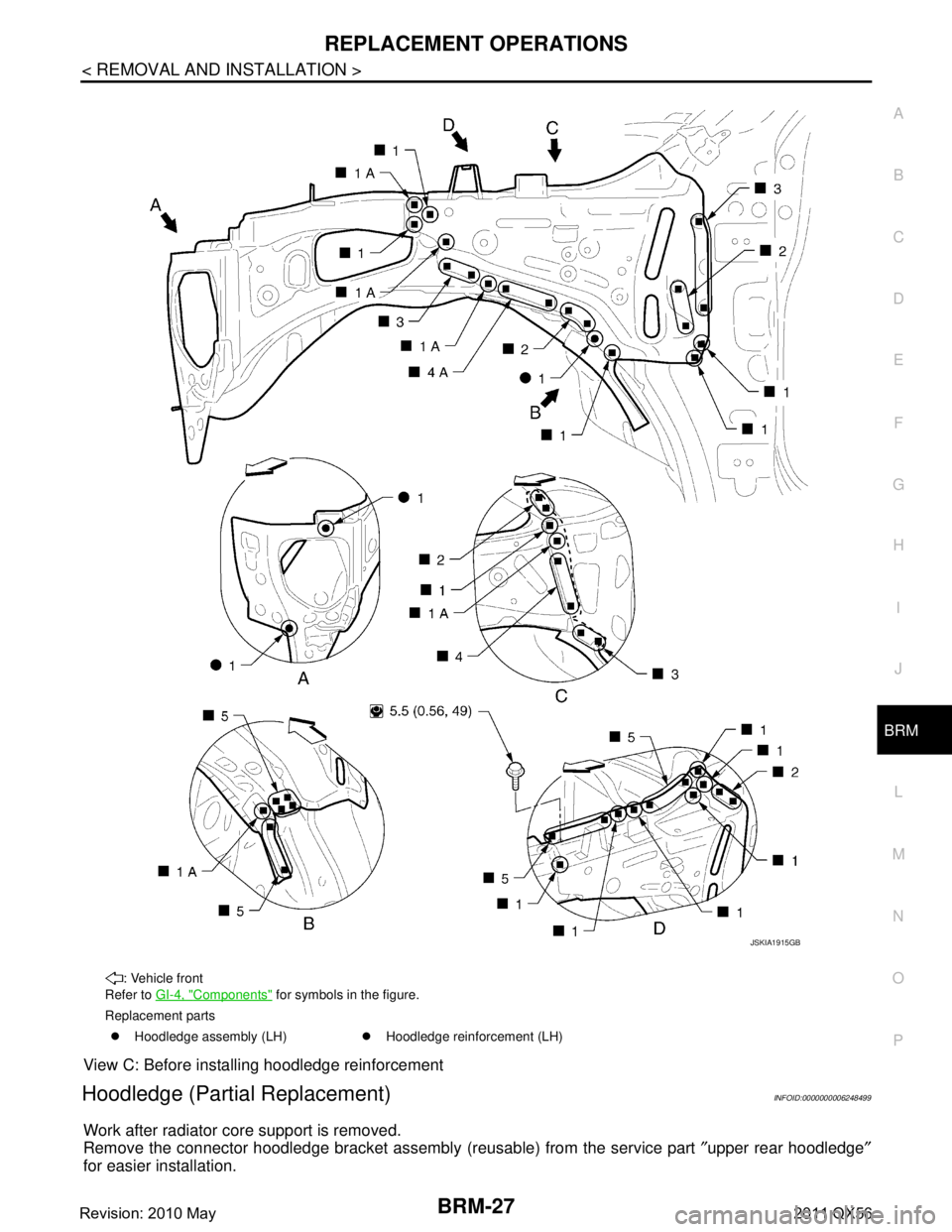

View C: Before installing hoodledge reinforcement

Hoodledge (Partial Replacement)INFOID:0000000006248499

Work after radiator core support is removed.

Remove the connector hoodledge bracket assembly (reusable) from the se\

rvice part ″upper rear hoodledge ″

for easier installation.

: Vehicle front

Refer to GI-4, "

Components" for symbols in the figure.

Replacement parts �z Hoodledge assembly (LH) �zHoodledge reinforcement (LH)

JSKIA1915GB

Revision: 2010 May2011 QX56

Page 726 of 5598

BODY ALIGNMENTBRM-51

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

DE

F

G H

I

J

L

M A

B

BRM

N

O P

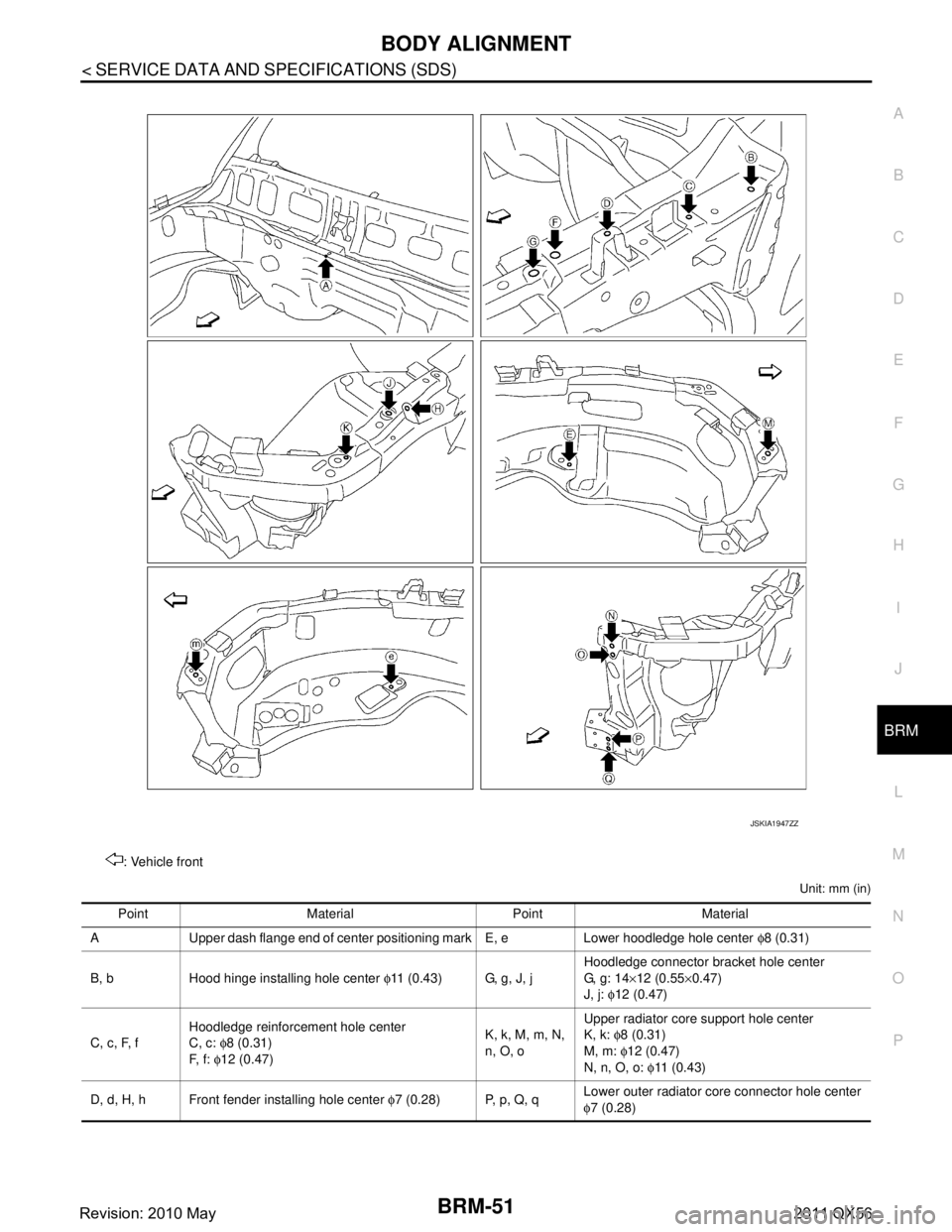

Unit: mm (in)

: Vehicle front

JSKIA1947ZZ

Point Material Point Material

A Upper dash flange end of center positioning mark E, e Lower hoodledge hole center φ8 (0.31)

B, b Hood hinge installing hole center φ11 (0.43) G, g, J, j Hoodledge connector bracket hole center

G, g: 14

×12 (0.55 ×0.47)

J, j: φ12 (0.47)

C, c, F, f Hoodledge reinforcement hole center

C, c:

φ8 (0.31)

F, f: φ12 (0.47) K, k, M, m, N,

n, O, oUpper radiator core support hole center

K, k:

φ8 (0.31)

M, m: φ12 (0.47)

N, n, O, o: φ11 ( 0 . 4 3 )

D, d, H, h Front fender installing hole center φ7 (0.28) P, p, Q, q Lower outer radiator core connector hole center

φ

7 (0.28)

Revision: 2010 May2011 QX56

Page 943 of 5598

CO-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION CO

A

CO

N

O P

CONTENTS

ENGINE COOLING SYSTEM

PRECAUTION ................ ...............................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

PREPARATION ............................................3

PREPARATION .............................................. .....3

Commercial Service Tools ................................. ......3

SYSTEM DESCRIPTION ..............................4

DESCRIPTION ............................................... .....4

Engine Cooling System ..................................... ......4

Engine Cooling System Schematic .........................5

SYMPTOM DIAGNOSIS ...............................6

OVERHEATING CAUSE ANALYSIS ............. .....6

Troubleshooting Chart ........................................ ......6

PERIODIC MAINTENANCE ..........................8

ENGINE COOLANT ....................................... .....8

Inspection ............................................................ ......8

Draining .....................................................................8

Refilling .....................................................................9

Flushing ...................................................................10

RADIATOR .........................................................11

RESERVOIR TANK CAP ..........................................11

RESERVOIR TANK CAP : Inspection ................. ....11

RADIATOR ............................................................. ....11

RADIATOR : Inspection ...........................................11

REMOVAL AND INSTALLATION ...............13

RADIATOR ....................................... .................13

Exploded View ..................................................... ....13

Removal and Installation .........................................13

Inspection ................................................................15

COOLING FAN ..................................................16

Exploded View .........................................................16

Removal and Installation .........................................16

Inspection ................................................................17

WATER PUMP ..................................................18

Exploded View .........................................................18

Removal and Installation .........................................18

Inspection ................................................................19

WATER INLET AND THERMOSTAT ASSEM-

BLY ....................................................................

20

Exploded View .........................................................20

Removal and Installation .........................................20

Inspection ................................................................21

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .............................................

23

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

23

Periodical Maintenance Specification ................ ....23

Radiator ...................................................................23

Thermostat ..............................................................23

Revision: 2010 May2011 QX56

Page 945 of 5598

PREPARATIONCO-3

< PREPARATION >

C

DE

F

G H

I

J

K L

M A

CO

NP

O

PREPARATION

PREPARATION

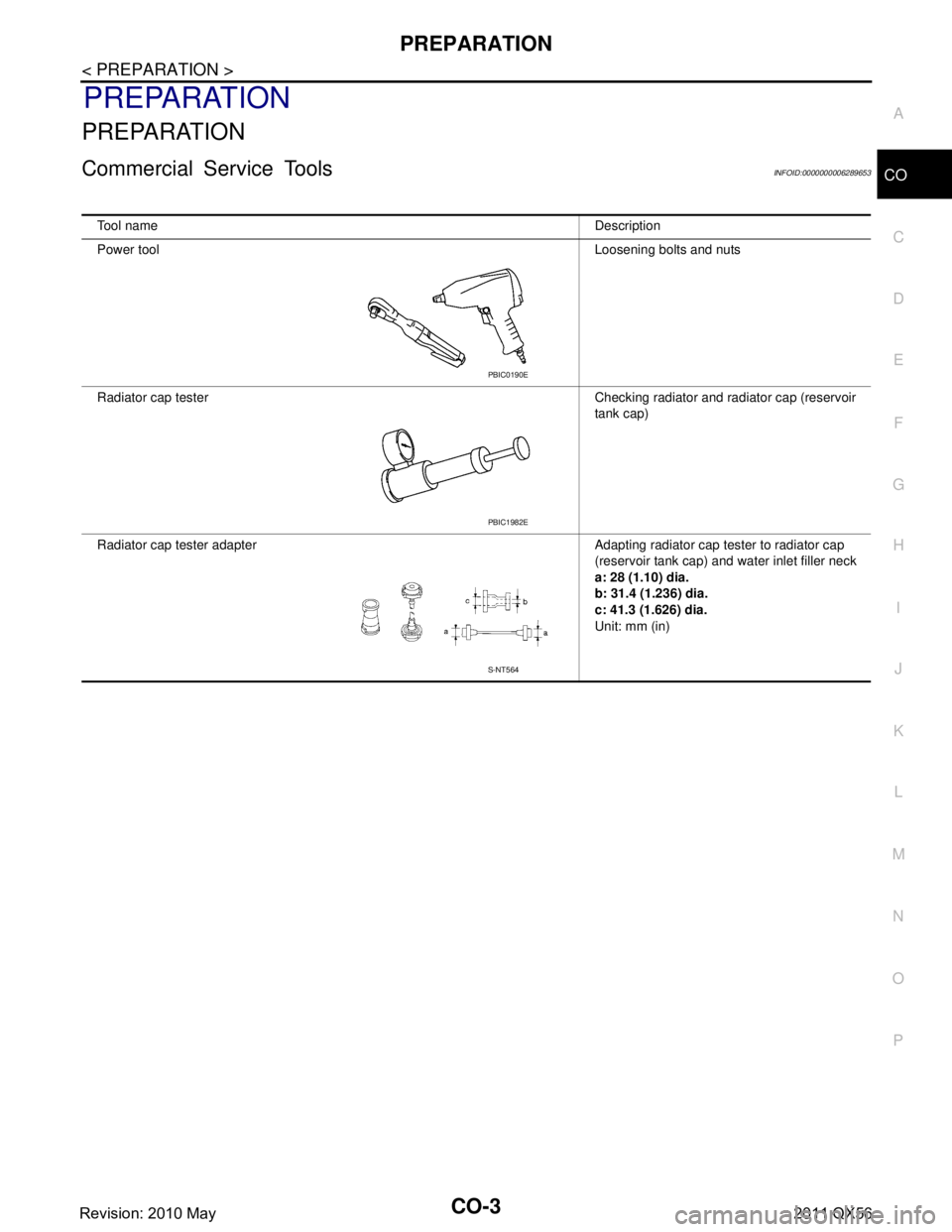

Commercial Service ToolsINFOID:0000000006289653

Tool name

Description

Power tool Loosening bolts and nuts

Radiator cap tester Checking radiator and radiator cap (reservoir tank cap)

Radiator cap tester adapter Adapting radiator cap tester to radiator cap (reservoir tank cap) and water inlet filler neck

a: 28 (1.10) dia.

b: 31.4 (1.236) dia.

c: 41.3 (1.626) dia.

Unit: mm (in)

PBIC0190E

PBIC1982E

S-NT564

Revision: 2010 May2011 QX56

Page 948 of 5598

CO-6

< SYMPTOM DIAGNOSIS >

OVERHEATING CAUSE ANALYSIS

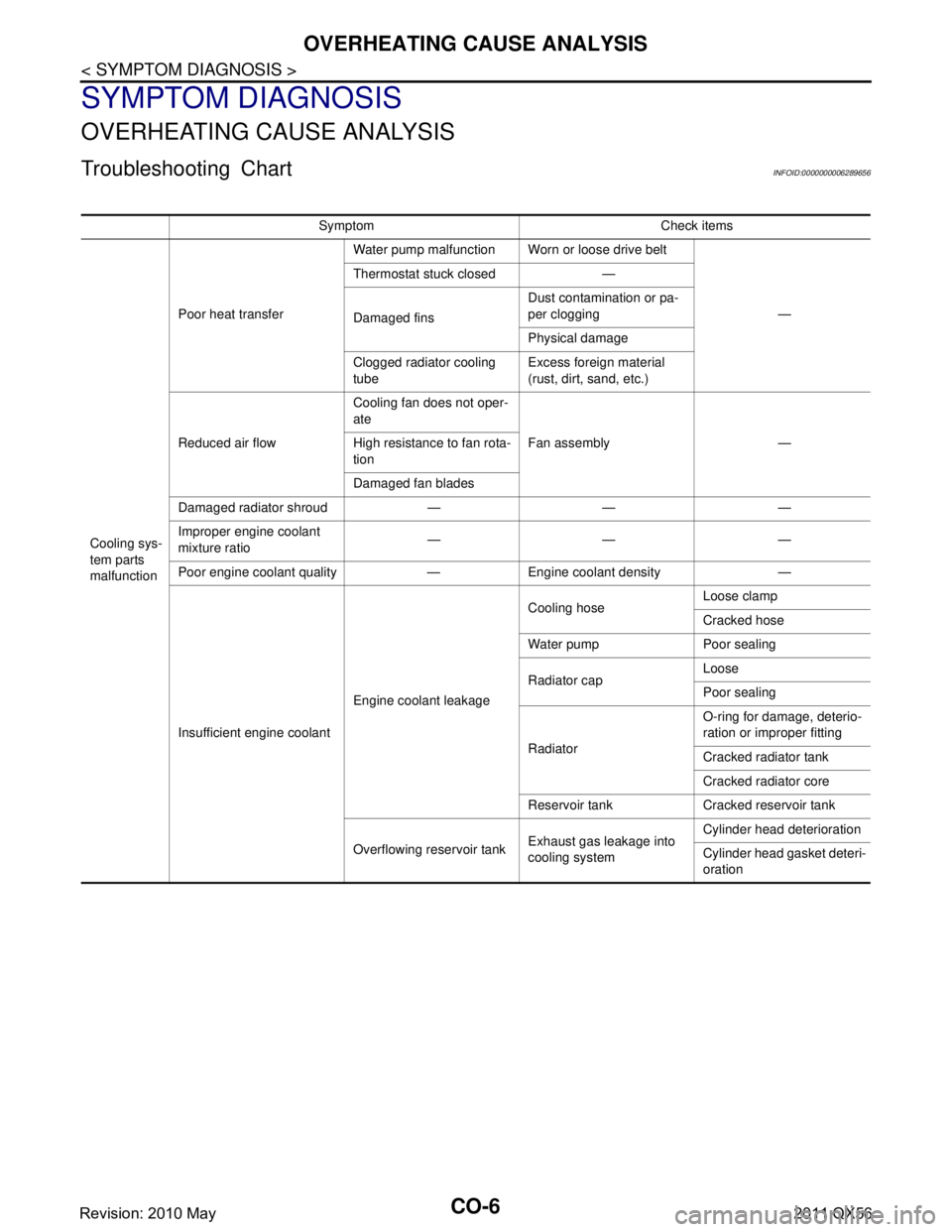

SYMPTOM DIAGNOSIS

OVERHEATING CAUSE ANALYSIS

Troubleshooting ChartINFOID:0000000006289656

Symptom Check items

Cooling sys-

tem parts

malfunction Poor heat transfer

Water pump malfunction Worn or loose drive belt

—

Thermostat stuck closed —

Damaged fins

Dust contamination or pa-

per clogging

Physical damage

Clogged radiator cooling

tube Excess foreign material

(rust, dirt, sand, etc.)

Reduced air flow Cooling fan does not oper-

ate

Fan assembly —

High resistance to fan rota-

tion

Damaged fan blades

Damaged radiator shroud — — —

Improper engine coolant

mixture ratio ———

Poor engine coolant quality — Engine coolant density —

Insufficient engine coolant Engine coolant leakageCooling hose

Loose clamp

Cracked hose

Water pump Poor sealing

Radiator cap Loose

Poor sealing

Radiator O-ring for da

mage, deterio-

ration or improper fitting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Overflowing reservoir tank Exhaust gas leakage into

cooling system Cylinder head deterioration

Cylinder head gasket deteri-

oration

Revision: 2010 May2011 QX56

Page 949 of 5598

OVERHEATING CAUSE ANALYSISCO-7

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

K L

M A

CO

NP

O

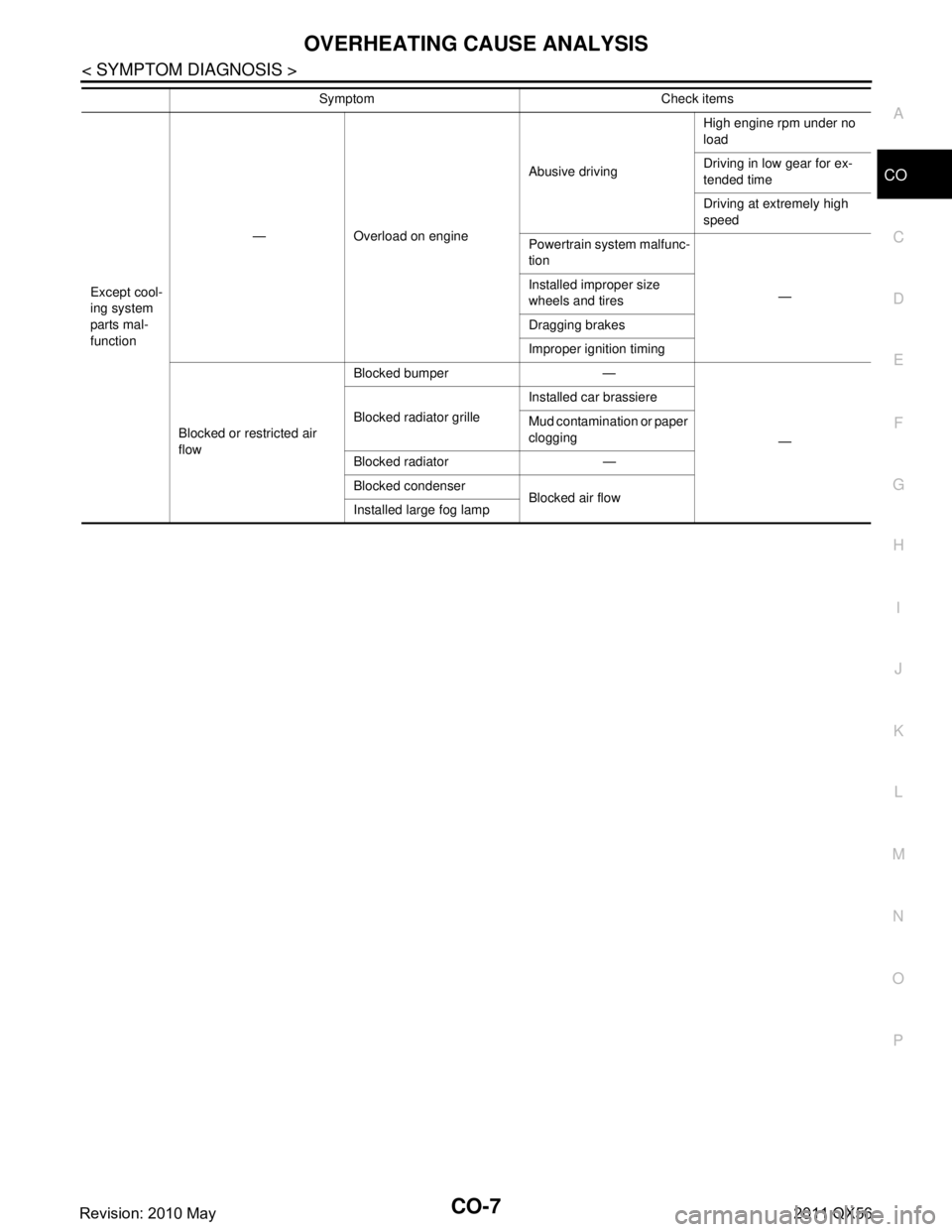

Except cool-

ing system

parts mal-

function — Overload on engine

Abusive driving

High engine rpm under no

load

Driving in low gear for ex-

tended time

Driving at extremely high

speed

Powertrain system malfunc-

tion

—

Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flow Blocked bumper —

—

Blocked radiator grille

Installed car brassiere

Mud contamination or paper

clogging

Blocked radiator —

Blocked condenser Blocked air flow

Installed large fog lamp

Symptom Check items

Revision: 2010 May2011 QX56