brake sensor INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 4311 of 5598

SBC-14

< ECU DIAGNOSIS INFORMATION >

PRE-CRASH SEAT BELT CONTROL UNIT (DRIVER SIDE)

TERMINAL LAYOUT

PHYSICAL VALUES

Fail SafeINFOID:0000000006237884

When a system malfunction is detected, deactivates a part of the system or all functions depending on the

malfunctioning part.

When the malfunction condition recovers to the normal condition, the system returns to the normal opera-

tion.

JMHIA0711ZZ

Te r m i n a l N o .

(Wire color) Description

ConditionVa l u e

(Approx.)

+ – Signal name Input/

Output

1

(Y) Ground Power supply Input — Battery voltage

2

(G) Ground Brake pedal stroke sensor signal 1 Input Brake released

→ depressed 1 V - 4 V

4

(P) Ground CAN-L Input/

Output ——

6

(LG/R) Ground Seat belt buckle switch signal Input Seat belt is fastened 0 V

Seat belt is unfastened 5 V

8

(G) Ground Local Communication Line 2 Output IGN ON 5 V

9

(–) Ground Shield — — —

10

(R) Ground Brake pedal stroke sensor power circuit Output IGN ON 5 V

12

(B) Ground Brake pedal stroke sensor signal 2 Input Brake released

→ depressed 4 V - 1 V

14

(L) Ground CAN-H Input/

Output ——

16

(W) Ground Local Communication Line 1 Input/

Output ——

17

(W) Ground Brake pedal stroke sensor ground circuit — — 0 V

18

(B) Ground Ground — — 0 V

19

(W) Ground Motor drive circuit power supply Input — Battery voltage

20

(B) Ground Motor drive circuit ground — — 0 V

Revision: 2010 May2011 QX56

Page 4313 of 5598

SBC-16

< ECU DIAGNOSIS INFORMATION >

PRE-CRASH SEAT BELT CONTROL UNIT (DRIVER SIDE)

DTC Index

INFOID:0000000006237885

DTC Trouble diagnosis name

(CONSULT-III display) DTC detection condition Reference

U0126 STRG ANG SEN SIG Steering angle sensor malfunction is received SBC-33

U0428 STRG ANGL CAL Steering angle sensor calibration incomplete signal is receivedSBC-34

U1000 CAN COMM CIRCUITPre-crash seat belt control unit cannot transmit and receive CAN

communication signal for 2 seconds or more SBC-35

B2451 SEAT BLT MTR DR CIRC Motor or control unit malfunction

Seat belt motor circuit is open or shorted

SBC-36

B2452 SEAT BLT MTR AS CIRC Motor or control unit malfunction

Seat belt motor circuit is open or shorted SBC-37

B2453 BR_STROKE_SEN_CIRC

Brake pedal stroke sensor malfunction

Brake pedal stroke sensor circuit is open or shorted SBC-38

B2454 SEAT BLT PWR DR CIRC Motor power su

pply circuit is open or shortedSBC-41

B2455 CONTROL UNIT DR Malfunction in pre-crash seat belt control unit SBC-42

B2456 SEAT BLT PWR AS CIRC Motor power supply circuit is open or shortedSBC-43

B2457 CONTROL UNIT AS Malfunction in pre-crash seat belt control unit SBC-44

B2458 LOCAL COMM Local communication line open or shortedSBC-45

B2461 VHCL SPEED SIGNAL Vehicle speed signal malfunction is received SBC-47

B2463 ROLLOVER SIGNAL Rollover signal malfunction is received SBC-48

B2466 DR/AS CONTROL UNIT Control unit is out of the vehicle specificationSBC-49

B2470 SYS HEAT PROTC DRDeactivation for cooling to prevent system heating due to continuous

operation SBC-50

B2471 SYS HEAT PROTC ASDeactivation for cooling to prevent system heating due to continuous

operation

SBC-51

Revision: 2010 May2011 QX56

Page 4335 of 5598

SBC-38

< DTC/CIRCUIT DIAGNOSIS >

B2453 BR STROKE SEN CIRC

B2453 BR STROKE SEN CIRC

DTC LogicINFOID:0000000006237903

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.SELF-DIAGNOSIS WITH PRE-CRASH SEAT BELT CONTROL UNIT

1. Turn ignition switch ON.

2. Check “Self-diagnostic result” with CONSULT-III.

Is DTC detected?

YES >> Refer to SBC-38, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006237904

1.CHECK PRE-CRASH SEAT BELT CONTROL UNIT INPUT SIGNAL

1. Turn ignition switch ON.

2. Select “BRK PEDAL SNSR1” and “BRK PEDAL SNSR2” in “DATA MONITOR” mode with CONSULT-III.

3. Check “BRK PEDAL SNSR1” and “BRK PEDAL SNSR2” indication under the following conditions.

Is the inspection result normal?

YES >> GO TO 6.

NO >> GO TO 2.

2.CHECK BRAKE PEDAL STROKE SENSOR POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect brake pedal stroke sensor harness connector.

3. Check voltage between brake pedal stroke sensor harness connector and ground.

Is the inspection result normal?

YES >> GO TO 4.

NO >> GO TO 3.

3.CHECK BRAKE PEDAL STROKE SENSOR POWER SUPPLY CIRCUIT

1. Disconnect pre-crash seat belt contro l unit (driver side) harness connector.

2. Check continuity between pre-crash seat belt c ontrol unit (driver side) harness connector and brake pedal

stroke sensor harness connector.

DTC No. Self-diagnosis item DTC Detection Condition Possible causes

B2453 BR STROKE SEN CIRC Circuit of brake pedal stroke sensor out-

put is open or shorted Harness or connectors

(The sensor circuit is open or shorted)

Pre-crash seat belt co ntrol unit (driver side)

Brake pedal stroke sensor

Monitor item Condition Voltage (V)

(Approx.)

BRK PEDAL SNSR1 Brake released → depressed 1

→ 4

BRK PEDAL SNSR2 4 → 1

Brake pedal stroke sensor

GroundVoltage (V)

(Approx.)

Connector Terminal

E 111 2 5

Pre-crash seat belt control unit (driver side) Brake pedal stroke sensor Continuity

Connector Terminal Connector Terminal

B9 10 E111 2 Existed

Revision: 2010 May2011 QX56

Page 4336 of 5598

B2453 BR STROKE SEN CIRCSBC-39

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G

I

J

K L

M A

B

SBC

N

O P

3. Check continuity between pre-crash seat belt control unit (driver side) harness connector and ground.

Is the inspection result normal?

YES >> Replace pre-crash seat belt c ontrol unit (driver side). Refer to SB-6, "SEAT BELT RETRACTOR :

Removal and Installation".

NO >> Repair or replace harness or connector.

4.CHECK BRAKE PEDAL STROKE SENSOR CIRCUIT

1. Disconnect pre-crash seat belt control unit (driver side) harness connector.

2. Check continuity between pre-crash seat belt c ontrol unit (driver side) harness connector and brake pedal

stroke sensor harness connector.

3. Check continuity between pre-crash seat belt control unit harness connector (driver side) and ground.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair or replace harness or connector.

5.CHECK BRAKE PEDAL STROKE SENSOR

Refer to SBC-39, "

Component Inspection".

Is the inspection result normal?

YES >> GO TO 6.

NO >> Replace brake pedal stroke sensor. Refer to SBC-63, "

Removal and Installation".

6.CHECK INTERMITTENT INCIDENT

Refer to GI-40, "

Intermittent Incident".

>> INSPECTION END

Component InspectionINFOID:0000000006237905

COMPONENT PARTS INSPECTION

1.CHECK BRAKE PEDAL STROKE SENSOR

1. Turn ignition switch OFF.

2. Disconnect brake pedal stroke sensor connector.

3. Check resistance between brake pedal stroke sensor terminal as per the following.

Pre-crash seat belt control unit (driver side)

GroundContinuity

Connector Terminal

B9 10 Not existed

Pre-crash seat belt control unit (driver side) Brake pedal stroke sensor Continuity

Connector Terminal Connector Terminal

B9 2

E 111 1

Existed

12 3

17 4

Pre-crash seat belt control unit (driver side) GroundContinuity

Connector Terminal

B9 2

Not existed

12

17

Revision: 2010 May2011 QX56

Page 4337 of 5598

SBC-40

< DTC/CIRCUIT DIAGNOSIS >

B2453 BR STROKE SEN CIRC

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace brake pedal stroke sensor. Refer to SBC-63, "

Removal and Installation".

Brake pedal stroke sensor

ConditionResistance (k

Ω)

(Approx.)

Terminal

2 1

Brake released → depressed 1.0

→ 0.2

30.2 → 1.0

Revision: 2010 May2011 QX56

Page 4360 of 5598

BRAKE PEDAL STROKE SENSORSBC-63

< REMOVAL AND INSTALLATION >

C

DE

F

G

I

J

K L

M A

B

SBC

N

O P

REMOVAL AND INSTALLATION

BRAKE PEDAL STROKE SENSOR

Exploded ViewINFOID:0000000006237943

Removal and InstallationINFOID:0000000006237944

REMOVAL

1. Remove the instrument panel lower cover LH. Refer to IP-14, "Removal and Installation".

2. Disconnect the brake pedal stroke sensor connector.

3. Remove the screws (A).

4. Remove the brake pedal stroke sensor (1).

INSTALLATION

Install in the reverse order of removal.

1. Brake pedal stroke sensor

JMHIA0712ZZ

JMHIA0726ZZ

Revision: 2010 May2011 QX56

Page 4408 of 5598

![INFINITI QX56 2011 Factory Service Manual

SCS-48

< PRECAUTION >[AIR LEVELIZER CONTROL SYSTEM]

PRECAUTIONS

5. When the repair work is completed, re-connect bot

h battery cables. With the brake pedal released, turn

the push-button ignition swi INFINITI QX56 2011 Factory Service Manual

SCS-48

< PRECAUTION >[AIR LEVELIZER CONTROL SYSTEM]

PRECAUTIONS

5. When the repair work is completed, re-connect bot

h battery cables. With the brake pedal released, turn

the push-button ignition swi](/img/42/57033/w960_57033-4407.png)

SCS-48

< PRECAUTION >[AIR LEVELIZER CONTROL SYSTEM]

PRECAUTIONS

5. When the repair work is completed, re-connect bot

h battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button igniti on switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Precaution for Procedure without Cowl Top CoverINFOID:0000000006256139

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for Air Levelizer Control SystemINFOID:0000000006256038

Never allow water and dust to enter the inside of air compressor.

Never disassemble the vehicle height sensor.

PIIB3706J

Revision: 2010 May2011 QX56

Page 4631 of 5598

![INFINITI QX56 2011 Factory Service Manual

SEC-24

< SYSTEM DESCRIPTION >[WITH INTELLIGENT KEY SYSTEM]

DIAGNOSIS SYSTEM (BCM)

SELF-DIAG RESULT

Refer to

BCS-57, "DTCIndex".

DATA MONITOR

PW DOWN SET Unlock button pressing time on Intelligent Ke INFINITI QX56 2011 Factory Service Manual

SEC-24

< SYSTEM DESCRIPTION >[WITH INTELLIGENT KEY SYSTEM]

DIAGNOSIS SYSTEM (BCM)

SELF-DIAG RESULT

Refer to

BCS-57, "DTCIndex".

DATA MONITOR

PW DOWN SET Unlock button pressing time on Intelligent Ke](/img/42/57033/w960_57033-4630.png)

SEC-24

< SYSTEM DESCRIPTION >[WITH INTELLIGENT KEY SYSTEM]

DIAGNOSIS SYSTEM (BCM)

SELF-DIAG RESULT

Refer to

BCS-57, "DTCIndex".

DATA MONITOR

PW DOWN SET Unlock button pressing time on Intelligent Key button can be selected from the following with

this mode

MODE 1: 3 sec

MODE 2: Non-operation

MODE 3: 5 sec

WELCOME LIGHT SELECT Welcome light function mode can be selected from the following with this mode

Puddle/Outside Handle

Room lamp

Head & Tail Lamps (this item is displayed, but cannot be used)

Heart Beat

WELCOME LIGHT OP SET Welcome light function mode can be changed to operation with this mode

On: Operate

Off: Non-operation

Monitor item Description

Monitor Item Condition

REQ SW -DR Indicates [On/Off] condition of door request switch (driver side)

REQ SW -AS Indicates [On/Off] condition of door request switch (passenger side)

REQ SW -BD/TR Indicates [On/Off] condition of back door request switch

PUSH SW Indicates [On/Off] condition of push-button ignition switch

CLUTCH SW NOTE:

This item is displayed, but cannot be monitored

BRAKE SW 1 Indicates [On/Off]* condition of stop lamp switch power supply

BRAKE SW 2 Indicates [On/Off] condition of stop lamp switch

DETE/CANCL SW Indicates [On/Off] condition of P position

SFT PN/N SW Indicates [On/Off] condition of P or N position

S/L -LOCK Indicates [On/Off] condition of steering lock unit (LOCK)

S/L -UNLOCK Indicates [On/Off] condition of steering lock unit (UNLOCK)

S/L RELAY -F/B Indicates [On/Off] condition of steering lock relay

UNLK SEN -DR Indicates [On/Off] condition of driver door UNLOCK status

PUSH SW -IPDM Indicates [On/Off] condition of push-button ignition switch

IGN RLY1 -F/B Indicates [On/Off] condition of ignition relay 1

DETE SW -IPDM Indicates [On/Off] condition of P position

SFT PN -IPDM Indicates [On/Off] condition of P or N position

SFT P -MET Indicates [On/Off] condition of P position

SFT N -MET Indicates [On/Off] condition of N position

ENGINE STATE Indicates [Stop/Stall/Crank/Run] condition of engine states

S/L LOCK-IPDM Indicates [On/Off] condition of steering lock unit (LOCK)

S/L UNLK-IPDM Indicates [On/Off] condition of steering lock unit (UNLOCK)

S/L RELAY-REQ Indicates [On/Off] condition of steering lock relay

VEH SPEED 1 Display the vehicle speed signal received from combination meter by numerical value [Km/h]

VEH SPEED 2 Display the vehi cle speed signal received from ABS or VDC or TCM by numerical value [Km/h]

DOOR STAT-DR Indicates [LOCK/READY/UNLK] condition of unlock sensor

DOOR STAT-AS Indicates [LOCK/READY/UNLK] condition of passenger side door status

ID OK FLAG Indicates [Set/Reset] condition of key ID

PRMT ENG STRT Indicates [Set/Reset] condition of engine start possibility

Revision: 2010 May2011 QX56

Page 4766 of 5598

PRECAUTIONSSR-3

< PRECAUTION >

C

DE

F

G

I

J

K L

M A

B

SR

N

O P

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button ignition switch is turned to LOCK position.)

6. Perform self-diagnosis check of a ll control units using CONSULT-III.

Precaution for Battery ServiceINFOID:0000000006113045

Before disconnecting the battery, lower both the driver and passenger windows. This will prevent any interfer-

ence between the window edge and the vehicle when the door is opened/closed. During normal operation, the

window slightly raises and lowers automatically to prev ent any window to vehicle interference. The automatic

window function will not work with the battery disconnected.

Occupant Classification SystemINFOID:0000000006113047

Replace occupant classification system control uni t and passenger front seat cushion as an assembly.

Refer to SE-105, "

Exploded View".

ServiceINFOID:0000000006113046

Never use electrical test equipment to check SRS circuits unless instructed to in this Service Manual.

Before servicing the SRS, turn ignition switch OFF, disconnect battery negative terminal and wait at least 3

minutes.

For approximately 3 minutes after the battery negative termi nal is removed, it is still possible for the air bag

and seat belt pre-tensioner to deploy. Therefore, never work on any SRS connectors or wires until at least 3

minutes have elapsed.

Diagnosis sensor unit must always be installed with their arrow marks “ ⇐” pointing towards the front of the

vehicle for proper operation. Also check diagnosis sensor unit for cracks, deformities, or rust before installa-

tion and replace as required.

The spiral cable must be aligned in the neutral position since its rotations are limited. Never turn steering

wheel and column after removal of steering gear.

Handle air bag module carefully. Always place driver and front passenger air bag modules with the pad side facing upward and seat mounted front side air bag m odule standing with the stud bolt side facing downward.

Perform self-diagnosis to check entire SRS fo r proper function after replacing any components.

After air bag deploys, the front instrument panel assembly should be replaced if damaged.

Always replace instrument panel pad following front passenger air bag deployment.

Revision: 2010 May2011 QX56

Page 5089 of 5598

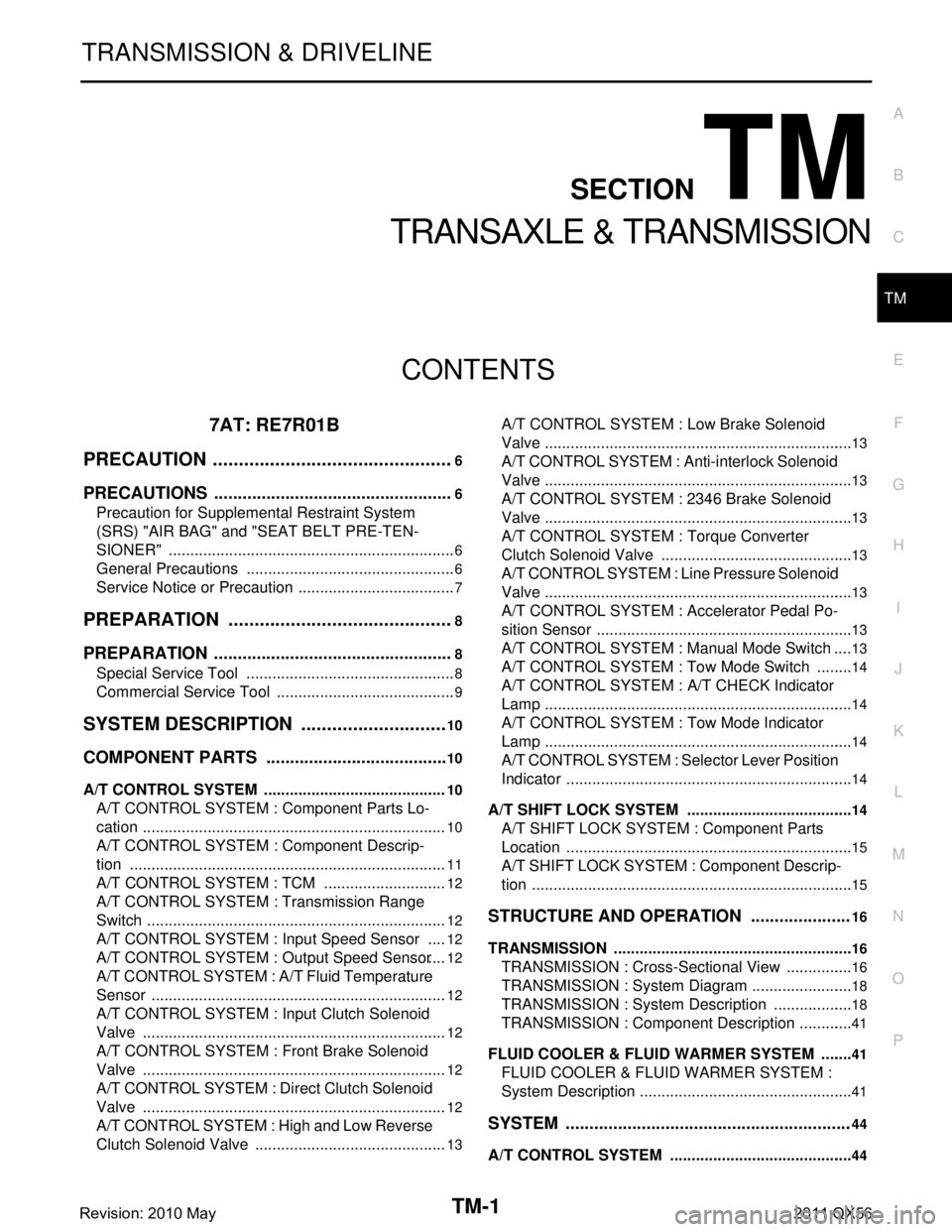

TM-1

TRANSMISSION & DRIVELINE

CEF

G H

I

J

K L

M

SECTION TM

A

B

TM

N

O P

CONTENTS

TRANSAXLE & TRANSMISSION

7AT: RE7R01B

PRECAUTION ................ ...............................

6

PRECAUTIONS .............................................. .....6

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

6

General Precautions .................................................6

Service Notice or Precaution .....................................7

PREPARATION ............................................8

PREPARATION .............................................. .....8

Special Service Tool ........................................... ......8

Commercial Service Tool ..........................................9

SYSTEM DESCRIPTION .............................10

COMPONENT PARTS ................................... ....10

A/T CONTROL SYSTEM ...........................................10

A/T CONTROL SYSTEM : Component Parts Lo-

cation ................................................................... ....

10

A/T CONTROL SYSTEM : Component Descrip-

tion ...................................................................... ....

11

A/T CONTROL SYSTEM : TCM .............................12

A/T CONTROL SYSTEM : Transmission Range

Switch .................................................................. ....

12

A/T CONTROL SYSTEM : Input Speed Sensor .....12

A/T CONTROL SYSTEM : Output Speed Sensor ....12

A/T CONTROL SYSTEM : A/ T Fluid Temperature

Sensor ................................................................. ....

12

A/T CONTROL SYSTEM : Input Clutch Solenoid

Valve ................................................................... ....

12

A/T CONTROL SYSTEM : Front Brake Solenoid

Valve ................................................................... ....

12

A/T CONTROL SYSTEM : Direct Clutch Solenoid

Valve ................................................................... ....

12

A/T CONTROL SYSTEM : High and Low Reverse

Clutch Solenoid Valve ......................................... ....

13

A/T CONTROL SYSTEM : Low Brake Solenoid

Valve .................................................................... ....

13

A/T CONTROL SYSTEM : Anti-interlock Solenoid

Valve ........................................................................

13

A/T CONTROL SYSTEM : 2346 Brake Solenoid

Valve ........................................................................

13

A/T CONTROL SYSTEM : Torque Converter

Clutch Solenoid Valve ......................................... ....

13

A/T CONTROL SYSTEM : Line Pressure Solenoid

Valve .................................................................... ....

13

A/T CONTROL SYSTEM : Accelerator Pedal Po-

sition Sensor ........................................................ ....

13

A/T CONTROL SYSTEM : Manual Mode Switch ....13

A/T CONTROL SYSTEM : To w Mode Switch .........14

A/T CONTROL SYSTEM : A/T CHECK Indicator

Lamp .................................................................... ....

14

A/T CONTROL SYSTEM : Tow Mode Indicator

Lamp .................................................................... ....

14

A/T CONTROL SYSTEM : Selector Lever Position

Indicator ............................................................... ....

14

A/T SHIFT LOCK SYSTEM ................................... ....14

A/T SHIFT LOCK SYSTEM : Component Parts

Location ...................................................................

15

A/T SHIFT LOCK SYSTEM : Component Descrip-

tion ...........................................................................

15

STRUCTURE AND OPERATION .....................16

TRANSMISSION .................................................... ....16

TRANSMISSION : Cross-Sectional View ................16

TRANSMISSION : System Diagram ........................18

TRANSMISSION : System Description ...................18

TRANSMISSION : Component Description .............41

FLUID COOLER & FLUID WARMER SYSTEM .... ....41

FLUID COOLER & FLUID WARMER SYSTEM :

System Description ..................................................

41

SYSTEM ............................................................44

A/T CONTROL SYSTEM ....................................... ....44

Revision: 2010 May2011 QX56