ignition INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 499 of 5598

HYDRAULIC BOOSTER ASSEMBLYBR-29

< REMOVAL AND INSTALLATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

Removal and InstallationINFOID:0000000006222484

REMOVAL

1. Turn the ignition switch OFF. CAUTION:

Never turn the ignition switch ON before th e completion of the installation procedure.

2. Drain brake fluid. Refer to BR-10, "

Draining".

3. Depress the brake pedal 20 times or more to release the pressure from the accumulator. CAUTION:

Always perform this step before re moving the hydraulic booster assembly.

4. Disconnect hydraulic booster assembly harness connector.

5. Separate the brake tube from hydraulic booste r assembly with a flare nut wrench. Refer to BR-22,

"FRONT : Exploded View".

6. Remove brake tube from clip.

1. Reservoir cap 2. Lab el 3. Reservoir tank

4. Pin 5. Motor/accumulator assembly 6. Brake tube

7. Brake hose assembly 8. Grommet 9. Harness band

10. Collar 11. Bushing 12. Pin mount

13. Grommet 14. Bracket 15. Cap

16. Bushing 17. Bracket 18. ABS actuator and electric unit (con- trol unit)

19. Gasket 20. Spacer

: Apply brake fluid.

Refer to GI-4, "

Components" for symbols not described on the above.

JPFIA0748GB

Revision: 2010 May2011 QX56

Page 500 of 5598

BR-30

< REMOVAL AND INSTALLATION >

HYDRAULIC BOOSTER ASSEMBLY

7. Remove snap pin (1) and clevis pin (2) from clevis.

8. Remove nuts on hydraulic booster assembly and brake pedalassembly.

CAUTION:

Hold the hydraulic booster assembly so as to avoid drop-

ping out.

9. Remove hydraulic booster assembly. CAUTION:

Always hold (A) when removi ng the hydraulic booster

assembly.

Never deform or bend the brake tubes when removing the hydraulic booster assembly.

Always use a cushion or an equivalent to place the hydraulic booster assembly. Failure to do this may cause

uneven loads or impact and result in a malfunction.

10. After replacing hydraulic booster assembly, always follow the accumulator disposal procedure to discard the hydraulic booster

assembly. Refer to BR-33, "

Disposal".

INSTALLATION

Note the following, and install in the reverse order of removal.

Perform adjustment before installation. Refer to BR-32, "

Inspection and Adjustment".

Never reuse a hydraulic booster assembly after an e xcessive impact. (Slight impulse caused during installa-

tion work is acceptable.)

Never turn the ignition switch ON before the completion of the installation procedure.

Be careful not to damage hydraulic booster assembly stud bolt threads. If hydraulic booster assembly is

tilted during installation, the dash panel may damage the threads.

Always hold (A) when removing the hydraulic booster assembly.

Never deform or bend the brake tubes when installing the hydraulic booster assembly.

Always use a new gasket between the hydraulic booster assembly, spacer and the dash panel.

Replace the clevis pin if it is damaged. Refer to BR-21, "

Inspection

and Adjustment".

Perform the air bleeding. Refer to BR-11, "

Bleeding Brake Sys-

tem".

Perform the brake pedal adjustment after installing the brake pedal assembly and hydraulic booster assembly. Refer to BR-7, "

Inspec-

tion and Adjustment".

Perform inspection after installation. Refer to BR-32, "

Inspection and Adjustment".

Disassembly and AssemblyINFOID:0000000006222485

DISASSEMBLY

CAUTION:

Disassemble the hydraulic booster assembly when necessary.

1. Remove gaskets and spacer from hydraulic booster assembly.

JPFIA0019ZZ

JPFIA0749ZZ

JPFIA0749ZZ

Revision: 2010 May2011 QX56

Page 502 of 5598

BR-32

< REMOVAL AND INSTALLATION >

HYDRAULIC BOOSTER ASSEMBLY

Apply new brake fluid to grommet of between reservoir tank and grommet and ABS actuator and electric unit

(control unit).

Inspection and AdjustmentINFOID:0000000006222486

ADJUSTMENT BEFORE INSTALLATION

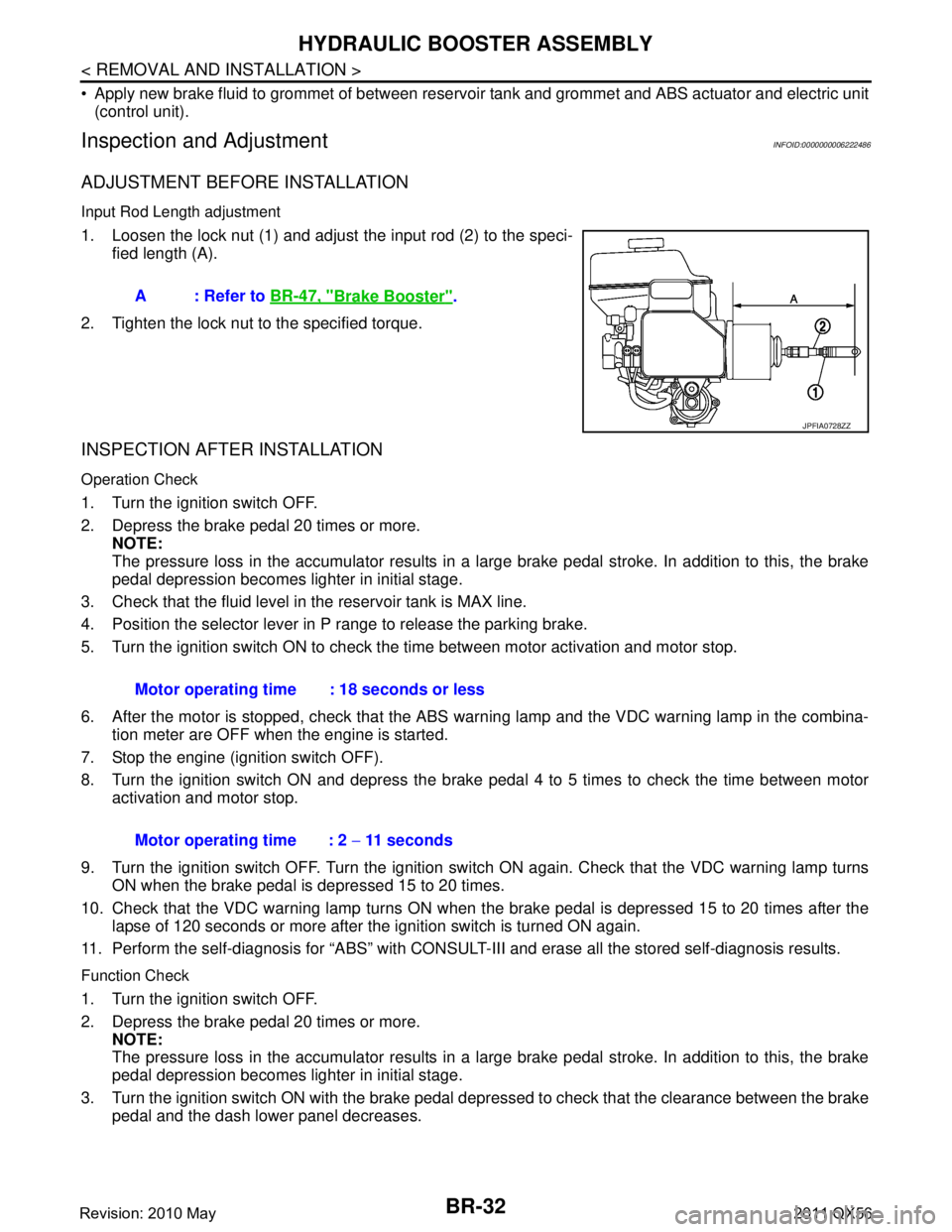

Input Rod Length adjustment

1. Loosen the lock nut (1) and adjust the input rod (2) to the speci-

fied length (A).

2. Tighten the lock nut to the specified torque.

INSPECTION AFTER INSTALLATION

Operation Check

1. Turn the ignition switch OFF.

2. Depress the brake pedal 20 times or more. NOTE:

The pressure loss in the accumulator results in a large brake pedal stroke. In addition to this, the brake

pedal depression becomes lighter in initial stage.

3. Check that the fluid level in the reservoir tank is MAX line.

4. Position the selector lever in P range to release the parking brake.

5. Turn the ignition switch ON to check the time between motor activation and motor stop.

6. After the motor is stopped, check that the ABS warn ing lamp and the VDC warning lamp in the combina-

tion meter are OFF when the engine is started.

7. Stop the engine (ignition switch OFF).

8. Turn the ignition switch ON and depress the brake pedal 4 to 5 times to check the time between motor activation and motor stop.

9. Turn the ignition switch OFF. Turn the ignition swit ch ON again. Check that the VDC warning lamp turns

ON when the brake pedal is depressed 15 to 20 times.

10. Check that the VDC warning lamp turns ON when the brake pedal is depressed 15 to 20 times after the lapse of 120 seconds or more after the ignition switch is turned ON again.

11. Perform the self-diagnosis for “ABS” with CONSULT- III and erase all the stored self-diagnosis results.

Function Check

1. Turn the ignition switch OFF.

2. Depress the brake pedal 20 times or more.

NOTE:

The pressure loss in the accumulator results in a large brake pedal stroke. In addition to this, the brake

pedal depression becomes lighter in initial stage.

3. Turn the ignition switch ON with the brake pedal depr essed to check that the clearance between the brake

pedal and the dash lower panel decreases. A : Refer to

BR-47, "

Brake Booster".

JPFIA0728ZZ

Motor operating time : 18 seconds or less

Motor operating time : 2 − 11 seconds

Revision: 2010 May2011 QX56

Page 522 of 5598

![INFINITI QX56 2011 Factory Service Manual

PRECAUTIONSBRC-5

< PRECAUTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID INFINITI QX56 2011 Factory Service Manual

PRECAUTIONSBRC-5

< PRECAUTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID](/img/42/57033/w960_57033-521.png)

PRECAUTIONSBRC-5

< PRECAUTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006228174

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision that would result in air ba g inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the

ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wh eel Rotation after Battery Disconnect

INFOID:0000000006228175

NOTE:

Before removing and installing any control units, first tu rn the push-button ignition switch to the LOCK posi-

tion, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnos is according to self-diagnosis results.

For vehicle with steering lock unit, if the battery is disconnected or discharged, the steering wheel will lock and

cannot be turned.

If turning the steering wheel is required with the batte ry disconnected or discharged, follow the operation pro-

cedure below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position. (At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock wil l remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

Revision: 2010 May2011 QX56

Page 523 of 5598

![INFINITI QX56 2011 Factory Service Manual

BRC-6

< PRECAUTION >[WITH VDC]

PRECAUTIONS

5. When the repair work is completed, re-connect bot

h battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position INFINITI QX56 2011 Factory Service Manual

BRC-6

< PRECAUTION >[WITH VDC]

PRECAUTIONS

5. When the repair work is completed, re-connect bot

h battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position](/img/42/57033/w960_57033-522.png)

BRC-6

< PRECAUTION >[WITH VDC]

PRECAUTIONS

5. When the repair work is completed, re-connect bot

h battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button igniti on switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Precaution for Procedure without Cowl Top CoverINFOID:0000000006228176

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for Brake SystemINFOID:0000000006222556

WARNING:

Clean any dust from the front brake and rear brake using a vacuum dust collector. Never blow by com-

pressed air.

Brake fluid use refer to MA-10, "

Fluids and Lubricants".

Never reuse drained brake fluid.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off

immediately and wash with water if it gets on a painted surface.

Always confirm the specified tightening torque when installing the brake pipes.

After pressing the brake pedal more deeply or harder t han normal driving, such as air bleeding, check each

item of brake pedal. Adjust brake pedal if it is outside the standard value.

Never use mineral oils such as gasoline or light oil to clean. They may damage rubber parts and cause

improper operation.

Always loosen the brake tube flar e nut with a flare nut wrench.

Tighten the brake tube flare nut to the specified torque with a crow-

foot (A) and torque wrench (B).

Always connect the battery terminal when moving the vehicle.

Turn the ignition switch OFF and disconnect the ABS actuator and

electric unit (control unit) harness connector or the battery negative

terminal before performing the work.

Check that no brake fluid leakage is present after replacing the parts.

Precaution for Brak e Control SystemINFOID:0000000006222557

Slight vibrations are felt on the brake pedal and the operation noises occur, when VDC function, TCS func-

tion, ABS function, EBD function, hill start assist function or brake limited slip differential (BLSD) function

operates. This is not a malfunction because it is caus ed by VDC function, TCS function, ABS function, EBD

function, hill start assist function or brake limited sl ip differential (BLSD) function that is normally operated.

When starting engine or when starting vehicle just after starting engine, brake pedal may vibrate or motor

operating noise may be heard from engine compartment. This is normal condition.

Brake stopping distance may become longer than models without ABS function depending on the road con-

ditions, when ABS function is operated on slippery r oad like rough road, gravel road or snowy road.

When a malfunction is indicated, always collect info rmation from the customer about conditions of occur-

rence, estimate cause and perform operation. Check brake booster operation, brake fluid level and brake

fluid leakage, as well as electrical system.

The optimum performance is achieved by control for V DC function, TCS function, ABS function, EBD func-

tion, hill start assist function or brake limited slip di fferential (BLSD) function when all of brakes, suspensions

PIIB3706J

JPFIA0001ZZ

Revision: 2010 May2011 QX56

Page 541 of 5598

![INFINITI QX56 2011 Factory Service Manual

BRC-24

< SYSTEM DESCRIPTION >[WITH VDC]

SYSTEM

Rear LH caliper Being returned to reservoir tank through ABS OUT valve, fluid pressure of rear LH caliper is decreased.

Component Parts and Function

*: INFINITI QX56 2011 Factory Service Manual

BRC-24

< SYSTEM DESCRIPTION >[WITH VDC]

SYSTEM

Rear LH caliper Being returned to reservoir tank through ABS OUT valve, fluid pressure of rear LH caliper is decreased.

Component Parts and Function

*:](/img/42/57033/w960_57033-540.png)

BRC-24

< SYSTEM DESCRIPTION >[WITH VDC]

SYSTEM

Rear LH caliper Being returned to reservoir tank through ABS OUT valve, fluid pressure of rear LH caliper is decreased.

Component Parts and Function

*: Models with Advanced Driver Assistance System

CONDITION FOR TURN ON THE WARNING LAMP

ABS Warning Lamp

Turns ON at the same time as VDC warning lamp

when either ABS function or EBD function is malfunction-

ing.

Turns ON when ignition switch turns ON and turns OFF when the system is normal, for bulb check purposes.

Brake Warning Lamp

Turns ON at the same time as ABS warning lamp and VDC warning lamp when EBD function, motor/accu- mulator assembly or motor system is malfunctioning.

Turns ON when ignition switch turns ON and turns OFF when the system is normal, for bulb check purposes.

Component Function

Pump Operates the pump drive according

to signals from ABS actuator and electric unit (control unit) by

the motor.

Motor Operates the motor driv e according to signals from ABS actuator and electric unit (control unit).

Accumulator The accumulator accumulates brake fluid conveyed by the motor and pump.

ABS IN valve Increases, holds or decreases the fluid pressure of each caliper according to signals from ABS ac-

tuator and electric unit (control unit).

ABS OUT valve Increases, holds or decreases the fluid pressure of each caliper according to signals from ABS ac-

tuator and electric unit (control unit).

Cut valve 1

Cut valve 2 Shuts off the ordinary brake line fr

om master cylinder to signals from ABS actuator and electric unit

(control unit).

Suction valve 1 Suction Valve 1 switches the brake line to convey accumulator pressure to the front system, accord-

ing to a signal transmitted from the ABS ac

tuator and electric unit (control unit).

Suction valve 2 Suction valve 2 releases

accumulator pressure, acco rding to a signal transmitted from the ABS ac-

tuator and electric unit (control unit).

Control pressure sensor

*Detects the brake fluid pressure of rear brake caliper and transmits a signal to ABS actuator and

electric unit (control unit).

Accumulator pressure sensor The accumulator pressure sensor detects brake fluid pressure accumulated in the accumulator and

conveys the detected result to the ABS actuator and electric unit (control unit).

Master cylinder pressure sensor Detects the brake fluid pressure of master cylinder part and transmits a signal to ABS actuator and

electric unit (control unit).

Condition (status) ABS warning lamp

Ignition switch OFF OFF

For approx. 1 seconds after the ignition switch is turned ON ON

Approx. 1 seconds after ignition switch is turned ON (when the

system is in normal operation) OFF

ABS function is ma lfunctioning ON

EBD function is malfunctioning ON

Condition (status) Brake warning lamp

Ignition switch OFF OFF

For approx. 1 seconds after the ignition switch is turned ON ON

Approx. 1 seconds after ignition switch is turned ON (when the

system is in normal operation) OFF

After engine starts OFF

When parking brake operates (parking brake switch ON) ON

Revision: 2010 May2011 QX56

Page 542 of 5598

![INFINITI QX56 2011 Factory Service Manual

SYSTEMBRC-25

< SYSTEM DESCRIPTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

VDC Warning Lamp

Turns ON when either VDC function,

TCS function, ABS function or EBD function, hill start assist f INFINITI QX56 2011 Factory Service Manual

SYSTEMBRC-25

< SYSTEM DESCRIPTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

VDC Warning Lamp

Turns ON when either VDC function,

TCS function, ABS function or EBD function, hill start assist f](/img/42/57033/w960_57033-541.png)

SYSTEMBRC-25

< SYSTEM DESCRIPTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

VDC Warning Lamp

Turns ON when either VDC function,

TCS function, ABS function or EBD function, hill start assist function or

brake limited slip differential (BLSD) function is malfunctioning.

Turns ON when ignition switch turns ON and turns OFF when the system is normal, for bulb check purposes.

CONDITION FOR TURN ON THE INDICATOR LAMP

VDC OFF Indicator Lamp

Turns ON when VDC function and TCS function are s witched to non-operational status (OFF) by VDC OFF

switch.

Turns ON when ignition switch turns ON and turns OFF when the system is normal, for bulb check purposes.

*: Models with 4WD system

Fail-safeINFOID:0000000006228184

VDC FUNCTION, TCS FUNCTION, hill start assi st FUNCTION AND BRAKE LIMITED SLIP DIFFER-

ENTIAL (BLSD) FUNCTION

VDC warning lamp in combination meter turn ON w hen a malfunction occurs in system [ABS actuator and

electric unit (control unit)]. The control is suspended for VDC function, TCS function, hill start assist function

and brake limited slip differential (BLSD) function. T he Vehicle status becomes the same as models without

VDC function, TCS function, hill star t assist function and brake limited slip differential (BLSD) function. How-

ever, ABS function and EBD f unction are operated normally.

When brake fluid is less than the specified level (brake fluid level

switch ON) ON

ABS function is malfunctioning OFF

EBD function is malfunctioning ON

Accumulator is low pressure ON

Motor system is malfunctioning ON

Ignition power supply system is malfunctioning ON Condition (status) Brake warning lamp

Condition (status) VDC warning lamp

Ignition switch OFF OFF

For approx. 1 seconds after the ignition switch is turned ON ON

Approx. 1 seconds after ignition switch is turned ON (when the

system is in normal operation) OFF

VDC function is malfunctioning ON

TCS function is malfunctioning ON

ABS function is malfunctioning ON

EBD function is malfunctioning ON

hill start assist function is malfunctioning ON

Brake limited slip differential (BLSD) function is malfunctioning ON

VDC function is operating Blinking

TCS function is operating Blinking

Condition (status) VDC OFF indicator lamp

Ignition switch OFF OFF

For approx. 1 seconds after the ignition switch is turned ON ON

Approx. 1 seconds after ignition switch is turned ON (when the

system is in normal operation) OFF

When VDC OFF switch is ON (VDC function and TCS function are

OFF) ON

4WD mode: 4L

*ON

Revision: 2010 May2011 QX56

Page 543 of 5598

![INFINITI QX56 2011 Factory Service Manual

BRC-26

< SYSTEM DESCRIPTION >[WITH VDC]

SYSTEM

ABS FUNCTION

ABS warning lamp and VDC warning lamp in combinati

on meter turn ON when a malfunction occurs in system

[ABS actuator and electric unit (co INFINITI QX56 2011 Factory Service Manual

BRC-26

< SYSTEM DESCRIPTION >[WITH VDC]

SYSTEM

ABS FUNCTION

ABS warning lamp and VDC warning lamp in combinati

on meter turn ON when a malfunction occurs in system

[ABS actuator and electric unit (co](/img/42/57033/w960_57033-542.png)

BRC-26

< SYSTEM DESCRIPTION >[WITH VDC]

SYSTEM

ABS FUNCTION

ABS warning lamp and VDC warning lamp in combinati

on meter turn ON when a malfunction occurs in system

[ABS actuator and electric unit (control unit)]. The c ontrol is suspended for VDC function, TCS function, ABS

function, hill start assist function and brake limited sl ip differential (BLSD) function. The vehicle status

becomes the same as models without VDC function, TCS f unction, ABS function, hill start assist function and

brake limited slip differential (BLSD) function. However, EBD function is operated normally.

NOTE:

ABS self-diagnosis sound may be heard the same as in the normal condition, because self-diagnosis is per-

formed when ignition switch turns ON and when vehicle initially starts.

EBD FUNCTION

ABS warning lamp, brake warning lamp and VDC warning lamp in combination meter turn ON when a mal-

function occurs in system [ABS actuator and electric unit (control unit)]. The control is suspended for VDC

function, TCS function, ABS function, EBD function, hill start assist function and brake limited slip differential

(BLSD) function. The vehicle status becomes the sa me as models without VDC function, TCS function, ABS

function, EBD function, hill star t assist function and brake limited slip differential (BLSD) function.

DTC Malfunction detected condition Fail-safe condition

C1101 When an open circuit is detected in rear RH wheel sensor circuit.

The following functions are sus-

pended.

VDC function

TCS function

ABS function

EBD function (only when both 2 rear wheels are malfunctioning)

hill start assist function

Brake limited slip differential

(BLSD) function

C1102 When an open circuit is detected in rear LH wheel sensor circuit.

C1103 When an open circuit is detected in front RH wheel sensor circuit.

C1104 When an open circuit is detected in front LH wheel sensor circuit.

C1105

When power supply voltage of rear RH wheel sensor is low.

When distance between rear RH wheel sensor and rear RH wheel sensor rotor is

large.

When installation of rear RH wheel sensor or rear RH wheel sensor rotor is not

normal.

C1106 When power supply voltage of rear LH wheel sensor is low.

When distance between rear LH wheel sensor and rear LH wheel sensor rotor is

large.

When installation of rear LH wheel sensor or rear LH wheel sensor rotor is not nor- mal.

C1107 When power supply voltage of front RH wheel sensor is low.

When distance between front RH wheel sensor and front RH wheel sensor rotor

is large.

When installation of front RH wheel sensor or front RH wheel sensor rotor is not normal.

C1108 When power supply voltage of front LH wheel sensor is low.

When distance between front LH wheel sensor and front LH wheel sensor rotor is

large.

When installation of front LH wheel sensor or front LH wheel sensor rotor is not normal.

C1109 When ignition voltage is 10 V or less.

When ignition voltage is 16 V or more. The following functions are sus-

pended.

VDC function

TCS function

ABS function

EBD function

hill start assist function

Brake limited slip differential

(BLSD) function

C 1111

When a malfunction is detected in motor or motor relay.

When a low pressure malfunction is detected in accumulator.

When a malfunction is detected in accumulator pressure sensor.

C 111 5 When difference in wheel speed between any wheel and others is detected during

the vehicle is driven, because of installation of other tires than specified. The following functions are sus-

pended.

VDC function

TCS function

ABS function

hill start assist function

Brake limited slip differential

(BLSD) function

C 111 6

When stop lamp switch signal is not input when brake pedal depress.

When stop lamp switch signal is not input when stop lamp relay operates.

C 111 8

*1When a malfunction is detected in transfer control unit system.

Revision: 2010 May2011 QX56

Page 545 of 5598

![INFINITI QX56 2011 Factory Service Manual

BRC-28

< SYSTEM DESCRIPTION >[WITH VDC]

SYSTEM

*1: Models with 4WD System

*2: Models with Advanced Driver Assistance System

Protection FunctionINFOID:0000000006228185

The VDC warning lamp, ABS warnin INFINITI QX56 2011 Factory Service Manual

BRC-28

< SYSTEM DESCRIPTION >[WITH VDC]

SYSTEM

*1: Models with 4WD System

*2: Models with Advanced Driver Assistance System

Protection FunctionINFOID:0000000006228185

The VDC warning lamp, ABS warnin](/img/42/57033/w960_57033-544.png)

BRC-28

< SYSTEM DESCRIPTION >[WITH VDC]

SYSTEM

*1: Models with 4WD System

*2: Models with Advanced Driver Assistance System

Protection FunctionINFOID:0000000006228185

The VDC warning lamp, ABS warning lamp and brake warning lamp turns ON and DTC “C118E” may be

detected in self-diagnosis result of “ABS” when the br

ake pedal is excessively operated, such as air bleeding.

This is not a system malfunction because this occurs due to the temporary decrease in accumulator fluid pres-

sure. The system returns to normal condition when the accu mulator fluid pressure reaches the specified pres-

sure with the ignition switch ON and the VDC warning lamp, ABS warning lamp, and brake warning lamp turn

OFF. After these steps, erase self-diagnos is results for “ABS” with CONSULT-III.

NOTE:

D T C “ C 1111 ” i s d e t e c t e d i n s e l f - d i agnosis results of “ABS” when the a ccumulator system has a malfunction.

VDC FUNCTION

VDC FUNCTION : System DescriptionINFOID:0000000006222572

Side slip or tail slip may occur while driving on a slippery road or intending an urgent evasive driving. VDC

function detects side slip status using each sensor when side slip or tail slip is about to occur and improves

vehicle stability by brake control and engine output control during driving.

In addition to ABS function, EBD function and TCS functi on, target side slip amount is calculated according

to steering operation amount from steering angle sensor and brake operation amount from pressure sensor.

By comparing this information with vehicle side slip amount that is calculated from information from yaw rate/

C118EWhen performing excessive brake pedal operation with the vehicle stopped. [When

accumulator fluid pressure reaches 11.43 MPa (114 bar, 116.6 kg/cm2, 1657 psi) af-

ter reaching 17.3 MPa (173 bar, 176.5 kg/cm2, 2509 psi.] The following functions are sus-

pended.

VDC function

TCS function

ABS function

EBD function

hill start assist function

Brake limited slip differential

(BLSD) function

U1000 When CAN communication signal is not continuously received for 2 seconds or

more. The following functions are sus-

pended.

VDC function

TCS function

ABS function

hill start assist function

Brake limited slip differential

(BLSD) function

DTC Malfunction detected condition Fail-safe condition

DTC

VDC warning lamp

ABS warning lamp

Brake warning lamp

Condition Description protection function

C118E ON When temporary decrease in accumulator fluid pres-

sure.

NOTE:

System is not malfunction. The following functions are suspended

temporarily

VDC function

TCS function

ABS function

EBD function

hill start assist function

Brake limited slip differential (BLSD)

function

Revision: 2010 May2011 QX56

Page 557 of 5598

![INFINITI QX56 2011 Factory Service Manual

BRC-40

< SYSTEM DESCRIPTION >[WITH VDC]

DIAGNOSIS SYSTEM [

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

DIAGNOSIS SYSTEM [ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

CONSULT-III FunctionINFOID INFINITI QX56 2011 Factory Service Manual

BRC-40

< SYSTEM DESCRIPTION >[WITH VDC]

DIAGNOSIS SYSTEM [

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

DIAGNOSIS SYSTEM [ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

CONSULT-III FunctionINFOID](/img/42/57033/w960_57033-556.png)

BRC-40

< SYSTEM DESCRIPTION >[WITH VDC]

DIAGNOSIS SYSTEM [

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

DIAGNOSIS SYSTEM [ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

CONSULT-III FunctionINFOID:0000000006222578

APPLICATION ITEMS

CONSULT-III can display each diagnostic item using the diagnostic test modes as follows.

*: The following diagnosis information is erased by erasing.

DTC

Freeze frame data (FFD)

ECU IDENTIFICATION

ABS actuator and electric unit (cont rol unit) part number can be read.

SELF DIAGNOSTIC RESULT

Refer to BRC-51, "DTC Index".

When “CRNT” is displayed on self-diagnosis result,

The system is presently malfunctioning.

When “PAST” is displayed on self-diagnosis result, System malfunction in the past is detect ed, but the system is presently normal.

Freeze frame data (FFD)

DATA MONITOR

×: Applicable

Mode Function description

ECU identification Parts number of ABS actuator and electric unit (control unit) can be read.

Self Diagnostic Result Self-diagnostic results and freeze frame data can be read and erased quickly.

*

DATA MONITOR Input/Output data in the ABS actuator and electric unit (control unit) can be read.

ACTIVE TEST Diagnostic Test Mode in

which CONSULT-III drives some act uators apart from the ABS actuator and

electric unit (control unit) and also shifts some parameters in a specified range.

WORK SUPPORT Components can be quickly and accurately adjusted.

Item name Display item

IGN counter

(0 − 39) The number of times that ignition switch is tu

rned ON after the DTC is detected is displayed.

When “0” is displayed: It indicates that the system is presently malfunctioning.

When except “0” is displayed: It indicates that system malfunction in the past is detected, but the system is pres- ently normal.

NOTE:

Each time when ignition switch is turned OFF to ON, numerical number increases in 1 → 2 → 3...38 → 39. When

the operation number of times exceeds 39, the number do not increase and “39” is displayed until self-diagnosis

is erased.

Item (Unit) Monitor item selection

Note

INPUT SIGNALS MAIN ITEMS

FR LH SENSOR

[km/h (MPH)] ××Wheel speed calculated by front LH wheel sensor is dis-

played.

FR RH SENSOR

[km/h (MPH)] ××Wheel speed calculated by front RH wheel sensor is dis-

played.

RR LH SENSOR

[km/h (MPH)] ××

Wheel speed calculated by rear LH wheel sensor is dis-

played.

RR RH SENSOR

[km/h (MPH)] ××Wheel speed calculated by rear RH wheel sensor is dis-

played.

DECEL G-SEN

(G) ××

Decel G detected by decel G sensor is displayed.

Revision: 2010 May2011 QX56