lock INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 1746 of 5598

DLK-210

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-cl utch on M/T models, drive position on A/T models).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

If it is difficult to duplicate the noise, drive the v ehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, chec k ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follo w the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pi npoint the source of the noise, use a listening tool

(Chassis ear: J-39570, Engine ear and mechanics stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

Removing the components in the area that is are suspected to be the cause of the noise.

Do not use too much force when removing clips and fasteners, otherwise clips and fastener can be broken

or lost during the repair, resulting in the creation of new noise.

Tapping or pushing/pulling the component that is are suspected to be the cause of the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only tem-

porarily.

Feeling for a vibration by hand by touching the component (s) that is are suspected to be the cause of the

noise.

Placing a piece of paper between components that are suspected to be the cause of the noise.

Looking for loose components and contact marks. Refer to DLK-211, "

Inspection Procedure".

REPAIR THE CAUSE

If the cause is a loose component, tighten the component securely.

If the cause is insufficient clearance between components:

- Separate components by repositioning or loos ening and retightening the component, if possible.

- Insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or ure-

thane tape. A Nissan Squeak and Rattle Kit (J-43980) is available through the authorized Nissan Parts

Department.

CAUTION:

Never use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

Always check with the Parts Departm ent for the latest parts information.

The following materials are contained in the Nissan Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 ×135 mm (3.94 ×5.31 in)/76884-71L01: 60 ×85 mm (2.36 ×3.35 in)/76884-

71L02:15 ×25 mm (0.59 ×0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50 ×50 mm (1.97 ×1.97 in)/73982-

50Y00: 10 mm (0.39 in) thick, 50 ×50 mm (1.97 ×1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 ×50 mm (1.18 ×1.97in)

FELT CLOTHTAPE

Used to insulate where movement does not occu r. Ideal for instrument panel applications.

68370-4B000: 15 ×25 mm (0.59 ×0.98 in) pad/68239-13E00: 5 mm (0.20 in) wide tape roll

The following materials, not found in the kit, can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Revision: 2010 May2011 QX56

Page 1747 of 5598

SQUEAK AND RATTLE TROUBLE DIAGNOSESDLK-211

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

DLK

N

O P

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that is be visible or does not fit. Will only last a few months.

SILICONE SPRAY

Used when grease cannot be applied.

DUCT TAPE

Used to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Inspection ProcedureINFOID:0000000006226060

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. Cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noi se. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or ra ttle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks to

repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. Trunk lid torsion bars knocking together

4. A loose license plate or bracket

Revision: 2010 May2011 QX56

Page 1748 of 5598

DLK-212

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area c an often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

SEATS

When isolating seat noise it is important to note t he position the seat is in and the load placed on the seat

when the noise is present. These conditions should be duplicated when verifying and isolating the cause of

the noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. Rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the \

vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: 2010 May2011 QX56

Page 1753 of 5598

HOOD

DLK-217

< REMOVAL AND INSTALLATION >

C

D E

F

G H

I

J

L

M A

B

DLK

N

O P

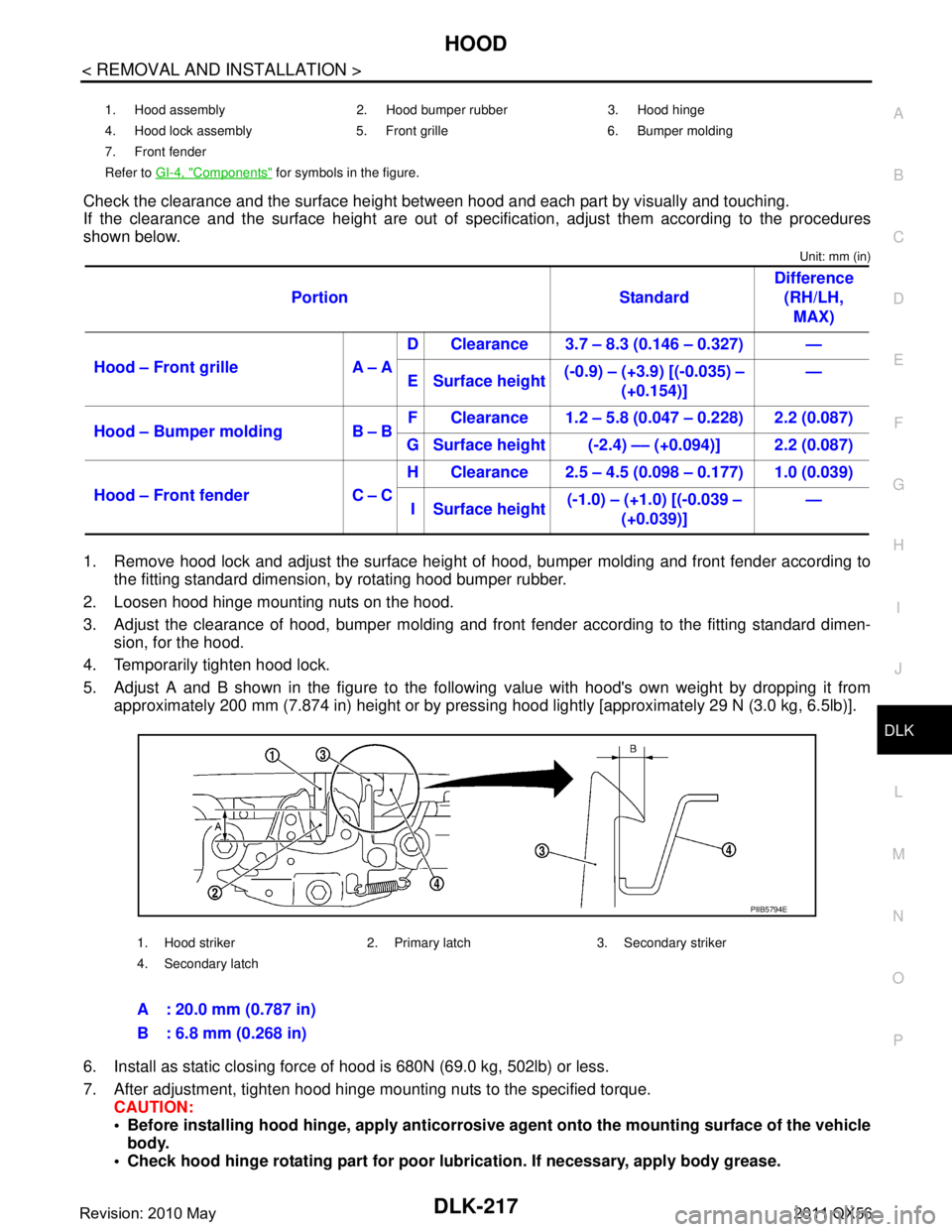

Check the clearance and the surface height betw een hood and each part by visually and touching.

If the clearance and the surface height are out of spec ification, adjust them according to the procedures

shown below.

Unit: mm (in)

1. Remove hood lock and adjust the surface height of hood, bumper molding and front fender according to

the fitting standard dimension, by rotating hood bumper rubber.

2. Loosen hood hinge mounting nuts on the hood.

3. Adjust the clearance of hood, bumper molding and fr ont fender according to the fitting standard dimen-

sion, for the hood.

4. Temporarily tighten hood lock.

5. Adjust A and B shown in the figure to the following value with hood's own weight by dropping it from approximately 200 mm (7.874 in) height or by pressi ng hood lightly [approximately 29 N (3.0 kg, 6.5lb)].

6. Install as static closing force of hood is 680N (69.0 kg, 502lb) or less.

7. After adjustment, tighten hood hinge mounting nuts to the specified torque. CAUTION:

Before installing hood hinge, apply anticorrosive agent onto th e mounting surface of the vehicle

body.

Check hood hinge rotating pa rt for poor lubrication. If necessary, apply body grease.

1. Hood assembly 2. Hood bumper rubber 3. Hood hinge

4. Hood lock assembly 5. Front grille 6. Bumper molding

7. Front fender

Refer to GI-4, "

Components" for symbols in the figure.

Portion Standard Difference

(RH/LH, MAX)

Hood – Front grille A – A D Clearance 3.7 – 8.3 (0.146 – 0.327) —

E Surface height (-0.9) – (+3.9) [(-0.035) –

(+0.154)] —

Hood – Bumper molding B – B F Clearance 1.2 – 5.8 (0.047 – 0.228) 2.2 (0.087)

G Surface height (-2.4) –– (+0.094)] 2.2 (0.087)

Hood – Front fender C – C H Clearance 2.5 – 4.5 (0.098 – 0.177) 1.0 (0.039)

I Surface height (-1.0) – (+1.0) [(-0.039 –

(+0.039)] —

1. Hood striker 2. Primary latch 3. Secondary striker

4. Secondary latch

A : 20.0 mm (0.787 in)

B : 6.8 mm (0.268 in)

PIIB5794E

Revision: 2010 May2011 QX56

Page 1757 of 5598

RADIATOR CORE SUPPORTDLK-221

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

DLK

N

O P

6. Disconnect all harness clips.

7. Remove hood lock assembly. Refer to DLK-238, "

Removal and Installation".

8. Remove fixing clips of air guide seal.

9. Remove mounting bolts, and then remove power steering oil cooler. Refer to ST-54, "

Exploded View".

CAUTION:

Put a wooden block (A) under the oil cooler (1) to prevent

the oil cooler from falling.

10. Remove radiator mounting bolts. Refer to CO-13, "

Removal and Installation".

11. Remove mounting bolts, and then radiator core support upper.

Installation

Note the following items, and then install in the reverse order of removal.

CAUTION:

If aluminum plate remains to the body side when removing radiator core support upper, be sure to

pinch aluminum plate between radiator core support upper and hoodledge upper when installing

radiator core support upper, for preventing electric corrosion.

When installing radiator core support upper, be careful not to damage the painted surface.

RADIATOR CORE SUPPORT LOWER

Removal

1. Remove front bumper fascia, bumper retainer and Bumper retainer bracket CTR. Refer to EXT-13,

"Removal and Installation".

2. Remove fixing clips, and then air guide seal and radiator side seal.

3. Remove ambient sensor. Refer to HAC-147, "

Removal and Installation".

4. Remove crash zone sensor. Refer to SR-22, "

Removal and Installation".

5. Remove all harness clips.

6. Remove mounting bolts, and then remove radiator core support main.

Installation

Install in the reverse order of removal.

JMKIA5480ZZ

Revision: 2010 May2011 QX56

Page 1760 of 5598

DLK-224

< REMOVAL AND INSTALLATION >

FRONT DOOR

FRONT DOOR

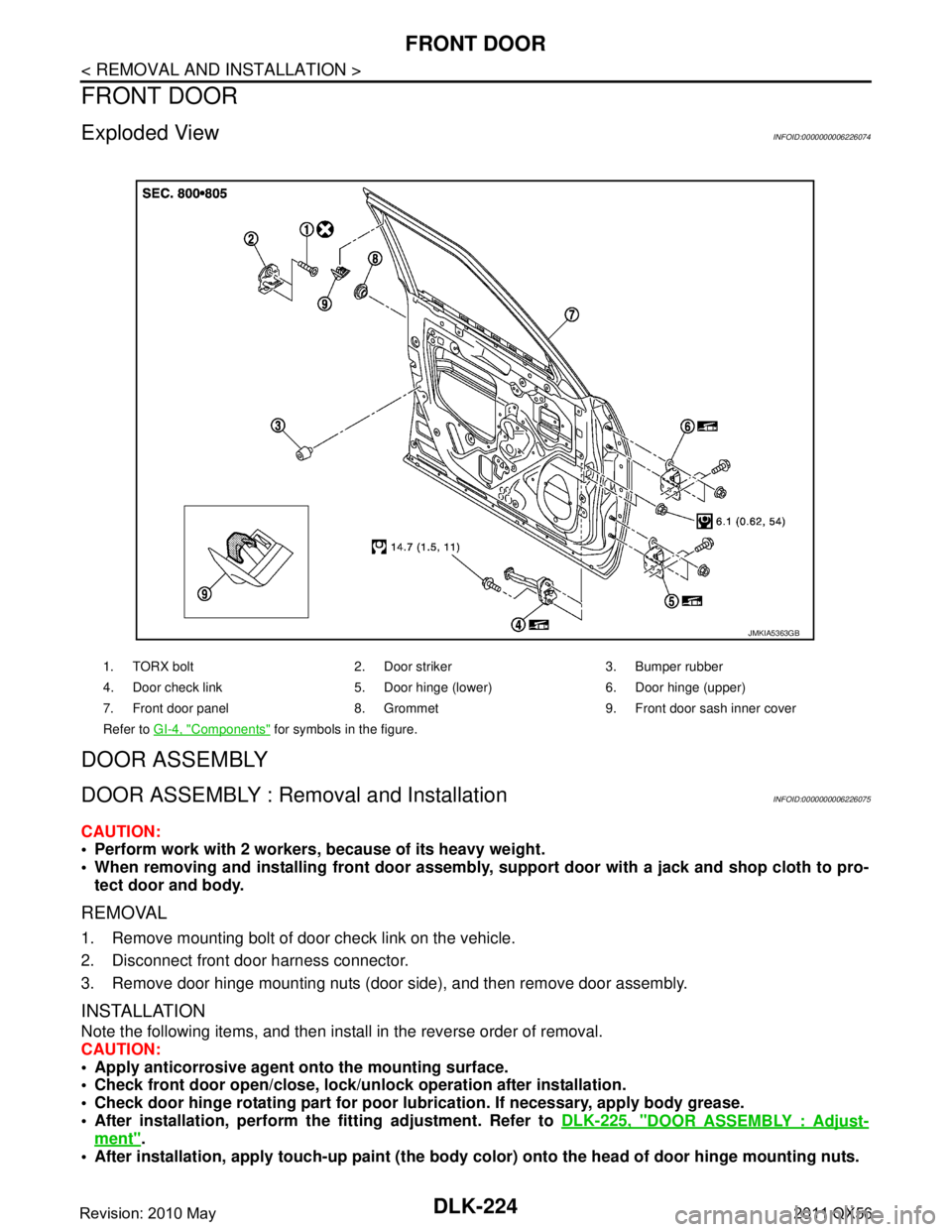

Exploded ViewINFOID:0000000006226074

DOOR ASSEMBLY

DOOR ASSEMBLY : Removal and InstallationINFOID:0000000006226075

CAUTION:

Perform work with 2 workers, because of its heavy weight.

When removing and installing front door assembly, support door with a jack and shop cloth to pro-

tect door and body.

REMOVAL

1. Remove mounting bolt of door check link on the vehicle.

2. Disconnect front door harness connector.

3. Remove door hinge mounting nuts (door side), and then remove door assembly.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

Apply anticorrosive agent onto the mounting surface.

Check front door open/close, lock/un lock operation after installation.

Check door hinge rotating pa rt for poor lubrication. If necessary, apply body grease.

After installation, perform th e fitting adjustment. Refer to DLK-225, "

DOOR ASSEMBLY : Adjust-

ment".

After installation, apply touch-up paint (the body color) onto the head of door hinge mounting nuts.

1. TORX bolt 2. Door striker 3. Bumper rubber

4. Door check link 5. Door hinge (lower) 6. Door hinge (upper)

7. Front door panel 8. Grommet 9. Front door sash inner cover

Refer to GI-4, "

Components" for symbols in the figure.

JMKIA5363GB

Revision: 2010 May2011 QX56

Page 1762 of 5598

DLK-226

< REMOVAL AND INSTALLATION >

FRONT DOOR

4. Temporarily tighten door hinge mounting nuts on door side.

5. Loosen door hinge mounting bolts on body side.

6. Raise front door at rear end to adjust clearance of the front door according to the fitting standard dimen-

sion.

7. After adjustment tighten bolts and nuts to the specified torque. CAUTION:

After installation, apply touch-up paint (the bo dy color) onto the head of hinge mounting bolts

and nuts.

Check door hinge rotating part for poor lubrication. If necessary, apply body grease.

8. Install front fender. Refer to refer to DLK-222, "

FRONT FENDER : Removal and Installation".

DOOR STRIKER ADJUSTMENT

Adjust door striker so that it becomes parallel with door lock insertion direction.

DOOR STRIKER

DOOR STRIKER : Removal and InstallationINFOID:0000000006226077

REMOVAL

Remove TORX bolts, and then remove door striker.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

Check front door open/close, operation after installation.

After installation, be sure to perf orm the fitting adjustment. Refer to DLK-225, "

DOOR ASSEMBLY :

Adjustment".

DOOR HINGE

DOOR HINGE : Removal and InstallationINFOID:0000000006226078

REMOVAL

CAUTION:

Perform work with 2 workers, because of its heavy weight.

When removing and installing front door assembly, support door with a jack and shop cloth to pro-

tect door and body.

1. Remove front fender. Refer to DLK-222, "

FRONT FENDER : Removal and Installation".

2. Remove front door assembly. Refer to DLK-224, "

DOOR ASSEMBLY : Removal and Installation".

3. Remove front door hinge mounting bolts (body side), and then remove front door hinge.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

Apply anticorrosive agent onto the mounting surface.

Check front door open/close, lock/un lock operation after installation.

Check door hinge rotating pa rt for poor lubrication. If necessary, apply body grease.

After installation, perform th e fitting adjustment. Refer to DLK-225, "

DOOR ASSEMBLY : Adjust-

ment".

After installation, apply touch-up paint (the body color) onto the head of door hinge mounting nuts.

DOOR CHECK LINK

DOOR CHECK LINK : Re moval and InstallationINFOID:0000000006226079

REMOVAL

1. Fully close the front door window.

2. Remove front door finisher. Refer to INT-14, "

Removal and Installation".

3. Remove front door speaker mounting bolts.

4. Disconnect connector and remove front door speaker.

Revision: 2010 May2011 QX56

Page 1764 of 5598

DLK-228

< REMOVAL AND INSTALLATION >

REAR DOOR

REAR DOOR

Exploded ViewINFOID:0000000006226080

DOOR ASSEMBLY

DOOR ASSEMBLY : Removal and InstallationINFOID:0000000006226081

CAUTION:

Perform work with 2 workers, because of it’s heavy weight.

When removing and installing rear door assembly, support door with a jack and shop cloth to pro-

tect door and body.

REMOVAL

1. Remove rear door harness grommet, and then pull out door harness from the vehicle.

2. Disconnect rear door harness connector.

3. Remove mounting bolt of door check link on the vehicle.

4. Remove door hinge mounting nuts (door side), and then remove rear door assembly.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

Apply anticorrosive agent onto the mounting surface.

Check rear door open/close, lock/unl ock operation after installation.

Check door hinge rotating pa rt for poor lubrication. If necessary, apply body grease.

1. TORX bolt 2. Door striker 3. Bumper rubber

4. Door check link 5. Door hinge (lower) 6. Door hinge (upper)

7. Rear door panel 8. Rear door sash inner cove r (front) 9. Rear door sash inner cover (rear)

10. Grommet

Refer to GI-4, "

Components" for symbols in the figure.

JMKIA5364GB

Revision: 2010 May2011 QX56

Page 1766 of 5598

DLK-230

< REMOVAL AND INSTALLATION >

REAR DOOR

1. Remove center pillar lower garnish. Refer to INT-22, "CENTER PILLAR LOWER GARNISH : Removal

and Installation".

2. Loosen door hinge mounting nuts on door side.

3. Adjust the surface height of rear door according to the fitting standard dimension.

4. Temporarily tighten door hinge mounting nuts on door side.

5. Loosen door hinge mounting nuts and bolts on body side.

6. Raise rear door at rear end to adjust clearance of rear door according to the fitting standard dimension.

7. After adjustment tighten bolts and nuts to the specified torque. CAUTION:

After installation, apply touch-up paint (the bo dy color) onto the head of hinge mounting bolts

and nuts.

Check door hinge rotating part for poor lubrication. If necessary, apply body grease.

8. Install center pillar lower garnish. Refer to INT-22, "

CENTER PILLAR LOWER GARNISH : Removal and

Installation".

DOOR STRIKER ADJUSTMENT

Adjust door striker so that it becomes parallel with door lock insertion direction.

DOOR STRIKER

DOOR STRIKER : Removal and InstallationINFOID:0000000006226083

REMOVAL

Remove TORX bolts, and then remove door striker.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

Check rear door open/c lose, after installation.

After installation, be sure to perf orm the fitting adjustment. Refer to DLK-229, "

DOOR ASSEMBLY :

Adjustment".

DOOR HINGE

DOOR HINGE : Removal and InstallationINFOID:0000000006226084

CAUTION:

Perform work with 2 workers, because of it’s heavy weight.

When removing and installing r ear door assembly, support door with a jack and shop cloth to pro-

tect door and body.

REMOVAL

1. Remove rear door assembly. Refer to DLK-228, "DOOR ASSEMBLY : Removal and Installation".

2. Remove center pillar lower garnish. Refer to INT-22, "

CENTER PILLAR LOWER GARNISH : Removal

and Installation".

3. Remove rear door hinge mounting bolts and nuts (body side), and then remove door hinge.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

Apply anticorrosive agent onto the mounting surface.

Check rear door open/close op eration after installation.

Check door hinge rotating pa rt for poor lubrication. If necessary, apply body grease.

When removing and inst alling rear door assembly, perform the fitting adjustment. Refer to DLK-229,

"DOOR ASSEMBLY : Adjustment".

After installing, apply the touch-up paint (the body color) onto the head of door hinge mounting nuts.

DOOR CHECK LINK

DOOR CHECK LINK : Removal and InstallationINFOID:0000000006226085

REMOVAL

Revision: 2010 May2011 QX56

Page 1769 of 5598

BACK DOORDLK-233

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

DLK

N

O P

3. Disconnect back door harness connectors (A) and remove back door harness clip (B).

4. Remove back door harness grommet, and then pull harness out of vehicle through roof panel hole.

5. Disconnect washer tube.

6. Remove washer tube grommet, and then pull was her tube out of vehicle through roof panel hole.

7. Support back door lock with the proper material to prevent it from falling. WARNING:

Body injury may occur if no sup porting rod is holding the back door open when removing the

back door stay.

8. Remove back door stay. Refer to DLK-236, "

BACK DOOR STAY : Removal and Installation".

9. Remove back door hinge mounting nuts on back door and remove back door assembly.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

Apply anticorrosive agen t onto the mounting surface.

Check back door open/close, lock/un lock operation after installation.

After installation, perform fitting adjustment. Refer to DLK-234, "

BACK DOOR ASSEMBLY : Adjust-

ment".

JMKIA5262ZZ

Revision: 2010 May2011 QX56