wheel INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 3672 of 5598

MA-2

FRONT DIFFERENTIAL GEAR OIL: R180A :

Draining ..................................................................

24

FRONT DIFFERENTIAL GEAR OIL: R180A : Re-

filling .......................................................................

25

REAR DIFFERENTIAL GEAR OIL: R230 ............. ...25

REAR DIFFERENTIAL GEAR OIL: R230 : Inspec-

tion ..........................................................................

25

REAR DIFFERENTIAL GEAR OIL: R230 : Drain-

ing ...........................................................................

25

REAR DIFFERENTIAL GEAR OIL: R230 : Refill-

ing ...........................................................................

26

WHEELS (BONDING WEIGHT TYPE) .....................26

WHEELS (BONDING WEIGHT TYPE) : Adjust-

ment ..................................................................... ...

26

BRAKE FLUID LEVEL AND LEAKS ........................27

BRAKE FLUID LEVEL AND LEAKS : Inspection ...28

BRAKE LINES AND CABLES ............................... ...28

BRAKE LINES AND CABLES : Inspection .............28

BRAKE FLUID ....................................................... ...28

BRAKE FLUID : Bleeding Brake System ................28

DISC BRAKE ......................................................... ...30

DISC BRAKE : Inspection ......................................30

DISC BRAKE : Front Disc Brake ............................31

DISC BRAKE : Rear Disc Brake .............................31

STEERING GEAR AND LINKAGE ........................ ...31

STEERING GEAR AND LINKAGE : Inspection ......31

POWER STEERING FLUID AND LINES ............... ...32

POWER STEERING FLUID AND LINES : Inspec-

tion ..........................................................................

32

AXLE AND SUSPENSION PARTS ...........................32

AXLE AND SUSPENSION PARTS : Inspection .. ...32

DRIVE SHAFT ........................................................ ...33

DRIVE SHAFT : Inspection .....................................33

BODY MAINTENANCE .....................................34

LOCKS, HINGES AND HOOD LATCH .................. ...34

LOCKS, HINGES AND HOOD LATCH : Lubricat-

ing ...........................................................................

34

SEAT BELT, BUCKLES, RETRACTORS, AN-

CHORS AND ADJUSTERS ................................... ...

34

SEAT BELT, BUCKLES, RETRACTORS, AN-

CHORS AND ADJUSTERS : Inspection .................

34

SERVICE DATA AND SPECIFICATIONS

(SDS) .......... ................................................

35

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ...

35

DRIVE BELTS ........................................................ ...35

DRIVE BELTS : Drive Belts ....................................35

ENGINE COOLANT ............................................... ...35

ENGINE COOLANT :

Periodical Maintenance Specification ....................

35

ENGINE OIL ........................................................... ...35

ENGINE OIL : Periodical Maintenance Specifica-

tion ..........................................................................

35

SPARK PLUG ........................................................ ...35

SPARK PLUG : Spark Plug ....................................35

ROAD WHEEL ....................................................... ...35

ROAD WHEEL : Road Wheel .................................35

Revision: 2010 May2011 QX56

Page 3674 of 5598

MA-4

< PERIODIC MAINTENANCE >

GENERAL MAINTENANCE

PERIODIC MAINTENANCE

GENERAL MAINTENANCE

Explanation of General MaintenanceINFOID:0000000006287728

General maintenance includes those items which shoul d be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform

checks and inspections themselves or have their INFINITI dealers do them.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed fr om time to time, unless otherwise specified.

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the vehicle,

etc.

Item Reference page

Tires Check the pressure with a gauge often and always prior to long distance trips.

Adjust the pressure in all tires, including the spare, to the pressure specified.

Check carefully for damage, cuts or excessive wear. WT-69

Wheel nuts

When checking the tires, make sure no nuts are missing, and check for any

loose nuts. Tighten if necessary. —

Tire rotation Tires should be rotated every 12,000km (7,500 miles). If the vehicle is equipped

with different sized tires in the front and rear, tires cannot be rotated. WT-63

Tire Pressure Moni-

toring System (TPMS)

transmitter compo-

nentsReplace the TPMS transmitter grommet seal, valve core and cap when the tires

are replaced due to wear or age.

WT-66

Wheel alignment and

balanceIf the vehicle should pull to either side while driving on a straight and level road,

or if you detect uneven or abnormal tire wear, there may be a need for wheel

alignment. If the steering wheel or seat vibrates at normal highway speeds,

wheel balancing may be needed. FSU-7

RSU-6

Windshield

Clean the windshield on a regular basis. Check the windshield at least every six

months for cracks or other damage. Repair as necessary. —

Windshield wiper

blades Check for cracks or wear if they do not wipe properly. —

Doors and engine

hood Check that all doors and the engine hood operate smoothly as well as the back

door. Also make sure that all latches lock securely. Lubricate if necessary. Make

sure that the secondary latch keeps the hood from opening when the primary

latch is released.

When driving in areas using road salt or other corrosive materials, check lubri-

cation frequently. MA-34

Lamps

Make sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and

other lamps are all operating properly and installed securely. Also check head-

lamp aim. Clean the headlamps on a regular basis. —

Item

Reference page

Warning lamps and

chimes Make sure that all warning lamps and chimes are operating properly. —

Windshield wiper and

washer Check that the wipers and washer operate properly and that the wipers do not

streak.

—

Windshield defroster Check that the air comes out of the defroster outlets properly and in sufficient

quantity when operating the heater or air conditioner. —

Steering wheel Check that it has the specified play. Check for changes in the steering condi-

tion, such as excessive play, hard steering or strange noises.

Free play: Less than 35 mm (1.38 in) —

Revision: 2010 May2011 QX56

Page 3696 of 5598

MA-26

< PERIODIC MAINTENANCE >

CHASSIS MAINTENANCE

2. Remove drain plug (1) and drain gear oil.

3. Set a gasket on drain plug (1) and install it to final drive assem-bly and tighten to the specified torque. Refer to DLN-203,

"Exploded View".

CAUTION:

Never reuse gasket.

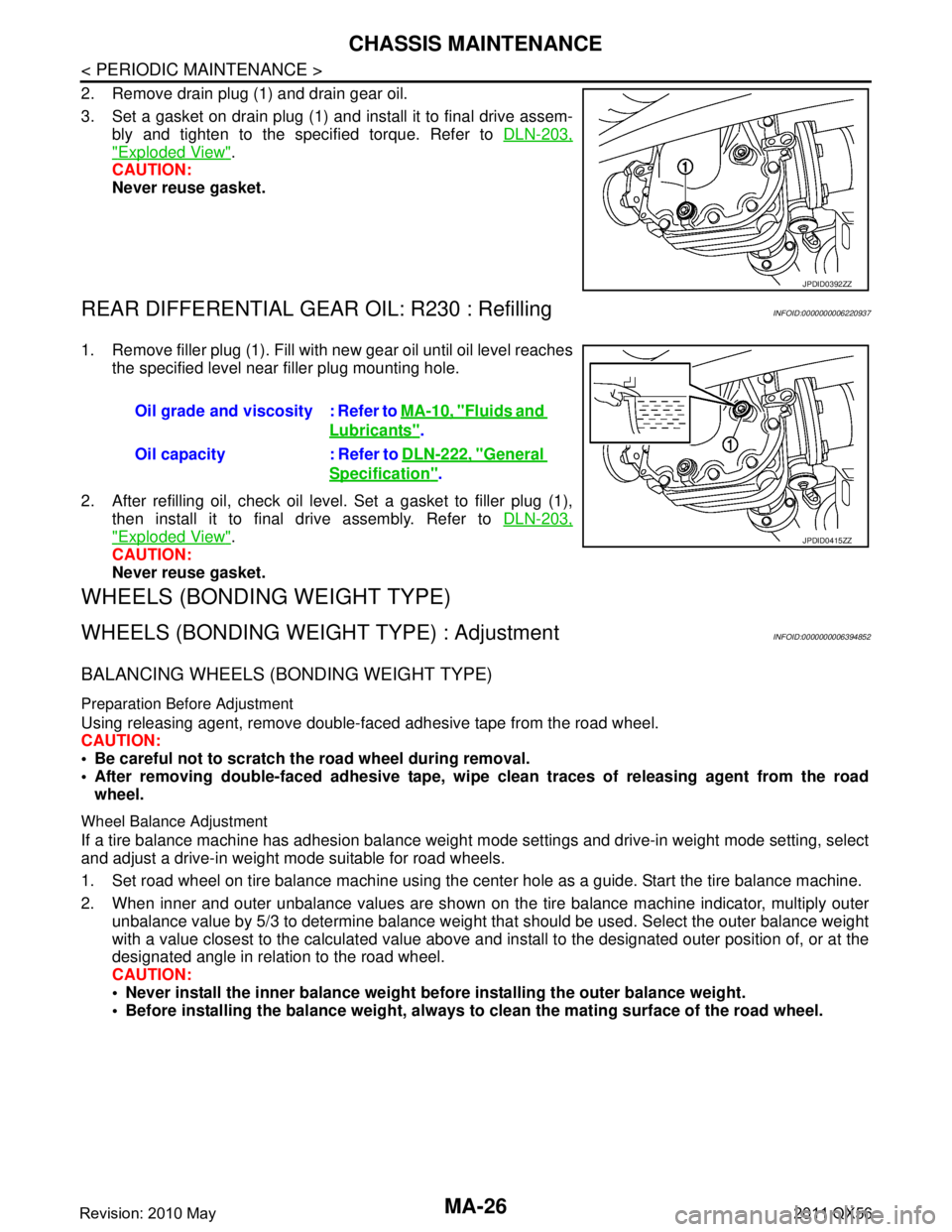

REAR DIFFERENTIAL GEAR OIL: R230 : RefillingINFOID:0000000006220937

1. Remove filler plug (1). Fill with new gear oil until oil level reaches

the specified level near filler plug mounting hole.

2. After refilling oil, check oil level. Set a gasket to filler plug (1), then install it to final drive assembly. Refer to DLN-203,

"Exploded View".

CAUTION:

Never reuse gasket.

WHEELS (BONDING WEIGHT TYPE)

WHEELS (BONDING WEIG HT TYPE) : AdjustmentINFOID:0000000006394852

BALANCING WHEELS (BONDING WEIGHT TYPE)

Preparation Before Adjustment

Using releasing agent, remove double-faced adhesive tape from the road wheel.

CAUTION:

Be careful not to scratch th e road wheel during removal.

After removing double-faced adhesive tape, wi pe clean traces of releasing agent from the road

wheel.

Wheel Balance Adjustment

If a tire balance machine has adhesion balance weight m ode settings and drive-in weight mode setting, select

and adjust a drive-in weight mode suitable for road wheels.

1. Set road wheel on tire balance machine using the center hole as a guide. Start the tire balance machine.

2. When inner and outer unbalance values are shown on the tire balance machine indicator, multiply outer unbalance value by 5/3 to determine balance weight t hat should be used. Select the outer balance weight

with a value closest to the calculated value above and in stall to the designated outer position of, or at the

designated angle in relation to the road wheel.

CAUTION:

Never install the inner balance weight be fore installing the outer balance weight.

Before installing the balance weight, always to clean the mating surface of the road wheel.

JPDID0392ZZ

Oil grade and viscosity : Refer to MA-10, "Fluids and

Lubricants".

Oil capacity : Refer to DLN-222, "

General

Specification".

JPDID0415ZZ

Revision: 2010 May2011 QX56

Page 3697 of 5598

CHASSIS MAINTENANCEMA-27

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

a. Indicated unbalance value

× 5/3 = balance weight to be installed

Calculation example:

23 g (0.81 oz) × 5/3 = 38.33 g (1.35 oz) ⇒ 37.5 g (1.32 oz) bal-

ance weight (closer to calculated balance weight value)

NOTE:

Note that balance weight value must be closer to the calculated

balance weight value.

Example:

36.2 ⇒ 35 g (1.23 oz)

36.3 ⇒ 37.5 g (1.32 oz)

b. Installed balance weight in the position. When installing balance weight (1) to road wheels, set it into

the grooved area (A) on the inner wall of the road wheel as

shown in the figure so that the balance weight center (B) is

aligned with the tire balance machine indication position

(angle) (C).

CAUTION:

Always use genuine NISSAN ad hesion balance weights.

Balance weights are non-re usable; always replace with

new ones.

Never install more than four sheets of balance weight.

c. If calculated balance weight value exceeds 50 g (1.76 oz), install two balance weight sheets in line with each other as shown in

the figure.

CAUTION:

Never install one balance weight sheet on top of another.

3. Start the tire balance machine again.

4. Install drive-in balance weight on inner side of road wheel in the tire balance machine indication position (angle).

CAUTION:

Never install more than two balance weight.

5. Start the tire balance machine. Check that the inner and outer residual unbalance value is within the allowable unbalance

value.

CAUTION:

If either residual unbalan ce value exceeds limit, repeat installation procedures.

BRAKE FLUID LEVEL AND LEAKS

SMA054D

JPEIC0040ZZ

Allowable unbalance value

Dynamic (At flange) : Refer to WT-69, "

Road Wheel".

Static (At flange) : Refer to WT-69, "

Road Wheel".

PEIA0033E

Revision: 2010 May2011 QX56

Page 3702 of 5598

MA-32

< PERIODIC MAINTENANCE >

CHASSIS MAINTENANCE

Check gear housing and boots for looseness, damage and greaseleakage.

Check connection with steering column for looseness.

STEERING LINKAGE

Check ball joint, dust cover and other component parts for looseness, wear, damage and grease leakage.

POWER STEERING FLUID AND LINES

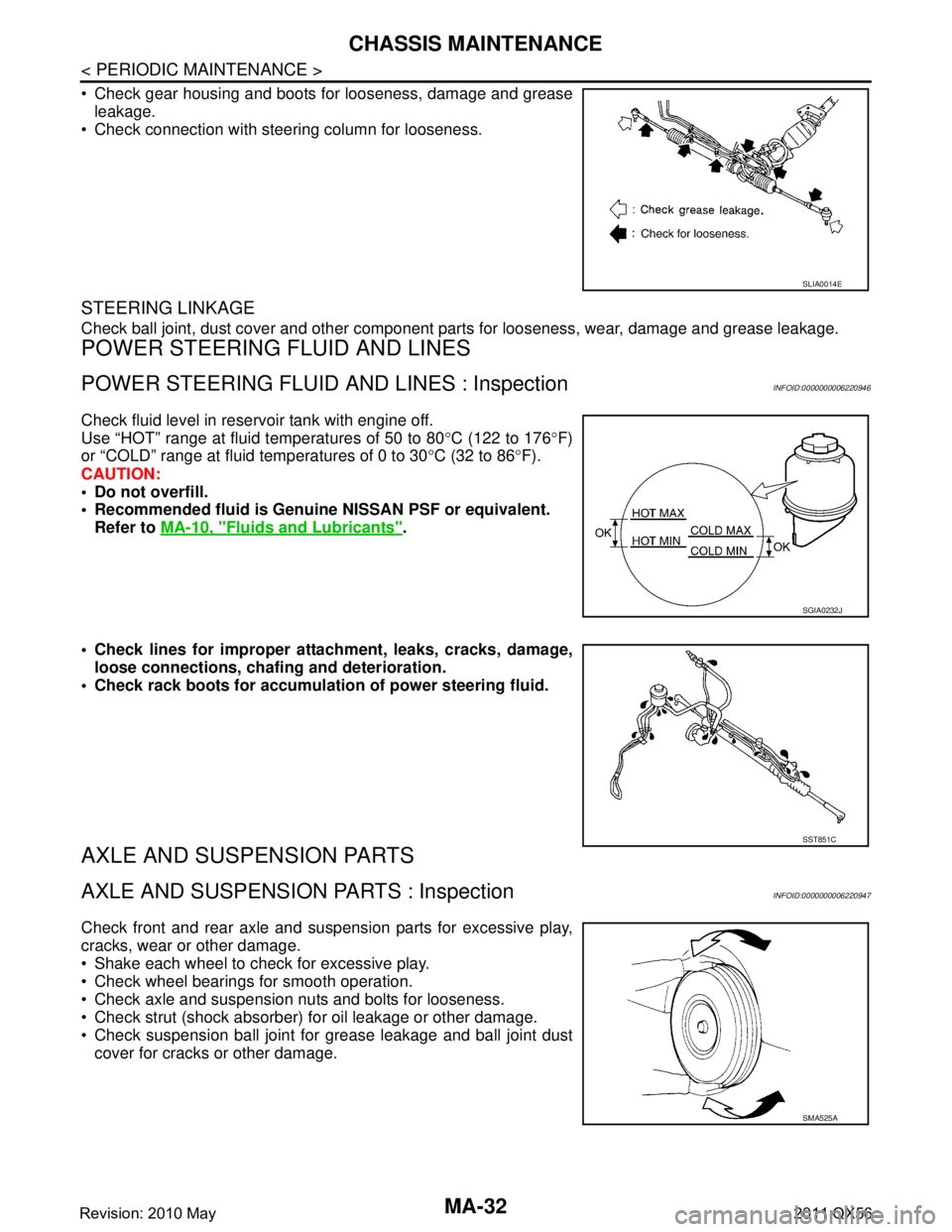

POWER STEERING FLUID AND LINES : InspectionINFOID:0000000006220946

Check fluid level in reservoir tank with engine off.

Use “HOT” range at fluid temperatures of 50 to 80 °C (122 to 176 °F)

or “COLD” range at fluid temperatures of 0 to 30 °C (32 to 86 °F).

CAUTION:

Do not overfill.

Recommended fluid is Genuine NISSAN PSF or equivalent.

Refer to MA-10, "

Fluids and Lubricants".

Check lines for improper attachment, leaks, cracks, damage, loose connections, chaf ing and deterioration.

Check rack boots for accumulati on of power steering fluid.

AXLE AND SUSPENSION PARTS

AXLE AND SUSPENSION PARTS : InspectionINFOID:0000000006220947

Check front and rear axle and suspension parts for excessive play,

cracks, wear or other damage.

Shake each wheel to check for excessive play.

Check wheel bearings for smooth operation.

Check axle and suspension nuts and bolts for looseness.

Check strut (shock absorber) for oil leakage or other damage.

Check suspension ball joint for grease leakage and ball joint dust

cover for cracks or other damage.

SLIA0014E

SGIA0232J

SST851C

SMA525A

Revision: 2010 May2011 QX56

Page 3705 of 5598

SERVICE DATA AND SPECIFICATIONS (SDS)

MA-35

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D E

F

G H

I

J

K L

M B

MA

N

O A

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

DRIVE BELTS

DRIVE BELTS : Drive BeltsINFOID:0000000006394853

DRIVE BELT

ENGINE COOLANT

ENGINE COOLANT : Periodical Maintenance SpecificationINFOID:0000000006394856

ENGINE COOLANT CAPACITY (APPROXIMATELY)

Unit: (US qt, Imp qt)

ENGINE OIL

ENGINE OIL : Periodical Maintenance SpecificationINFOID:0000000006394855

ENGINE OIL CAPACITY (APPROXIMATE)

Unit: (US qt, Imp qt)

SPARK PLUG

SPARK PLUG : Spark PlugINFOID:0000000006394854

SPARK PLUG

Unit: mm (in)

ROAD WHEEL

ROAD WHEEL : Road WheelINFOID:0000000006349771

ALUMINUM WHEEL

Tension of drive belts Belt tension is not necessary, as it is automatically adjusted by drive belt auto-tensioner.

Engine coolant capacity [With reservoir tank (“MAX” level)] 14.9 (15-6/8, 13-1/8)

Reservoir tank engine coolant capacity (At “MAX” level) 1.0 (1, 7/8)

Drain and refill

With oil filter change 6.5 (6-7/8, 5-3/4)

Without oil filter change 6.2 (6-4/8, 5-1/2)

Dry engine (engine overhaul) 7.6 (8, 6-3/4)

Make NGK

Standard type DILKAR7B11

Gap Standard 1.1 (0.043)

Limit 1.25 (0.049)

Item Limit

Radial runout Lateral deflection

Less than 0.3 mm (0.012 in)

Vertical deflection

Allowable unbalance Dynamic (At flange) Less than 7 g (0.25 oz) (one side)

Static (At flange) Less than 14 g (0.49 oz)

Revision: 2010 May2011 QX56

Page 3706 of 5598

MIR-1

DRIVER CONTROLS

C

DE

F

G H

I

J

K

M

SECTION MIR

A

B

MIR

N

O P

CONTENTS

MIRRORS

PRECAUTION ................ ...............................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

3

PREPARATION ............................................5

PREPARATION .............................................. .....5

Commercial Service Tools ................................. ......5

SYSTEM DESCRIPTION ..............................6

COMPONENT PARTS ................................... .....6

DOOR MIRROR ..................................................... ......6

DOOR MIRROR : Component Parts Location ..........6

DOOR MIRROR : Component Description ...............6

INSIDE MIRROR .................................................... ......7

INSIDE MIRROR : Component Description ..............7

SYSTEM ..............................................................8

DOOR MIRROR SYSTEM ..................................... ......8

DOOR MIRROR SYSTEM : System Diagram ..........8

DOOR MIRROR SYSTEM : System Description ......8

AUTO ANTI-DAZZLING INSIDE MIRROR SYS-

TEM ........................................................................ ......

9

AUTO ANTI-DAZZLING INSIDE MIRROR SYS-

TEM : System Description .........................................

9

ECU DIAGNOSIS INFORMATION ..............10

DRIVER SEAT CONTROL UNIT, AUTOMAT-

IC DRIVE POSITIONER CONTROL UNIT ..... ....

10

List of ECU Reference ........................................ ....10

WIRING DIAGRAM ......................................11

DOOR MIRROR SYSTEM .................................11

Wiring Diagram .................................................... ....11

AUTO ANTI-DAZZLING INSIDE MIRROR

SYSTEM ............................................................

19

Wiring Diagram - INSIDE MIRROR SYSTEM - ... ....19

BASIC INSPECTION ....... ............................21

DIAGNOSIS AND REPAIR WORKFLOW ........21

Work Flow ............................................................ ....21

DTC/CIRCUIT DIAGNOSIS .........................22

DOOR MIRROR REMOTE CONTROL

SWITCH .............................................................

22

OPEN/CLOSE SWITCH ......................................... ....22

OPEN/CLOSE SWITCH : Component Inspection ....22

SYMPTOM DIAGNOSIS ..............................23

REVERSE INTERLOCK DOOR MIRROR

DOES NOT OPERATE ......................................

23

Diagnosis Procedure ........................................... ....23

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ..............................................................

24

Work Flow ................................................................24

Inspection Procedure ...............................................26

Diagnostic Worksheet ..............................................28

REMOVAL AND INSTALLATION ...............30

INSIDE MIRROR ...............................................30

Exploded View ..................................................... ....30

Removal and Installation .........................................30

OUTSIDE MIRROR ...........................................32

Exploded View .........................................................32

DOOR MIRROR ASSEMBLY ....................................32

Revision: 2010 May2011 QX56

Page 3708 of 5598

PRECAUTIONSMIR-3

< PRECAUTION >

C

DE

F

G H

I

J

K

M A

B

MIR

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006257245

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision that would result in air ba g inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the

ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wh eel Rotation after Battery Disconnect

INFOID:0000000006257246

NOTE:

Before removing and installing any control units, first tu rn the push-button ignition switch to the LOCK posi-

tion, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnos is according to self-diagnosis results.

For vehicle with steering lock unit, if the battery is disconnected or discharged, the steering wheel will lock and

cannot be turned.

If turning the steering wheel is required with the batte ry disconnected or discharged, follow the operation pro-

cedure below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position. (At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock wil l remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

Revision: 2010 May2011 QX56

Page 3709 of 5598

MIR-4

< PRECAUTION >

PRECAUTIONS

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button igniti on switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Revision: 2010 May2011 QX56

Page 3756 of 5598

MWI

SYSTEMMWI-13

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K L

M B A

O P

SPEEDOMETER

SPEEDOMETER : System DiagramINFOID:0000000006221696

SPEEDOMETER : System DescriptionINFOID:0000000006221697

The ABS actuator and electric unit (control unit) conv erts the rectangular wave signal provided by the wheel

sensor to a vehicle speed signal and transmits it to the combination meter via CAN communication.

The combination meter indicates the vehicle speed to the speedometer according to the vehicle speed sig-

nal received via CAN communication.

TACHOMETER

Warning lamp/indicator lamp ABS warning lamp

The lamp turns ON by suspending communication.

VDC warning lamp

Brake warning lamp

IBA OFF indicator lamp

4WD warning lamp

Malfunction indicator lamp

VDC OFF indicator lamp

CRUISE warning lamp

Low tire pressure warning lamp The lamp blinking caused by suspending communication.

High beam indicator lamp

The lamp turns OFF by suspending communication.

Turn signal indicator lamp

Tail lamp indicator lamp

A/T CHECK indicator lamp

Key warning lamp

AT P w a r n i n g l a m p

Lane departure warning lamp

LDP ON indicator lamp

CRUISE indicator lamp

Oil pressure warning lamp

SNOW mode indicator lamp

TOW mode indicator lamp

CK SUSP indicator lamp

BSW indicator lamp

Function Specifications

JSNIA2382GB

Revision: 2010 May2011 QX56