alternator INFINITI QX56 2011 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2094 of 5598

![INFINITI QX56 2011 Factory Owners Manual

EC-70

< SYSTEM DESCRIPTION >[VK56VD]

DIAGNOSIS SYSTEM (ECM)

*: The item is indicated, but not used.

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the displa INFINITI QX56 2011 Factory Owners Manual

EC-70

< SYSTEM DESCRIPTION >[VK56VD]

DIAGNOSIS SYSTEM (ECM)

*: The item is indicated, but not used.

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the displa](/img/42/57033/w960_57033-2093.png)

EC-70

< SYSTEM DESCRIPTION >[VK56VD]

DIAGNOSIS SYSTEM (ECM)

*: The item is indicated, but not used.

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

ACTIVE TEST MODE

Test Item

ECM TEMP 1

°C or °F Displays a temperature calculated from a signal of

ECM temperature sensor 1.

ECM TEMP 2 °C or °F Displays a temperature calculated from a signal of

ECM temperature sensor 2.

FUEL PUMP DUTY % The control condition of the fuel pump control mod-

ule (FPCM) (determined by ECM according to the

input signals) is indicated.

Monitored item Unit Description Remarks

TEST ITEM CONDITION JUDGMENT CHECK ITEM (REMEDY)

VENT CON-

TROL/V Ignition switch: ON (Engine

stopped)

Turn solenoid valve ON and OFF with the CONSULT-III and listen

to operating sound. Solenoid valve makes an operating

sound.

Harness and connectors

Solenoid valve

ENG COOLANT

TEMP Engine: Return to the original

non-standard condition

Change the engine coolant tem- perature using CONSULT-III. If malfunctioning symptom disap-

pears, see CHECK ITEM. Harness and connectors

Engine coolant temperature sen-

sor

Fuel injector

FUEL INJEC-

TION Engine: Return to the original

non-standard condition

Change the amount of fuel injec- tion using CONSULT-III. If malfunctioning symptom disap-

pears, see CHECK ITEM.

Harness and connectors

Fuel injector

Air fuel ratio (A/F) sensor 1

FUEL/T TEMP

SEN Change the fuel tank temperature using CONSULT-III.

PURG VOL

CONT/V Engine: After warming up, run en-

gine at 1,500 rpm.

Change the EVAP canister purge

volume control solenoid valve

opening percent using CON-

SULT-III. Engine speed changes according to

the opening percent.

Harness and connectors

Solenoid valve

FAN DUTY CON-

TROL* Ignition switch: ON

Change duty ratio using CON-

SULT-III. Cooling fan speed changes. Harness and connectors

Cooling fan motor

Cooling fan relay

Cooling fan control module

IPDM E/R

ALTERNATOR

DUTY Engine: Idle

Change duty ratio using CON-

SULT-III. Battery voltage changes. Harness and connectors

IPDM E/R

Alternator

POWER BAL-

ANCE Engine: After warming up, idle the

engine.

A/C switch OFF

Selector lever: P or N

Cut off each injector signal one at a time using CONSULT-III. Engine runs rough or stops.

Harness and connectors

Compression

Fuel injector

Power transistor

Spark plug

Ignition coil

IGNITION TIM-

ING Engine: Return to the original

non-standard condition

Timing light: Set

Retard the ignition timing using

CONSULT-III. If malfunctioning symptom disap-

pears, see CHECK ITEM.

Perform Idle Air Volume Learning.

Revision: 2010 May2011 QX56

Page 2582 of 5598

EM-20

< PERIODIC MAINTENANCE >

DRIVE BELTS

PERIODIC MAINTENANCE

DRIVE BELTS

Exploded ViewINFOID:0000000006289524

CheckingINFOID:0000000006289525

WARNING:

Be sure to perform the these steps when engine is stopped.

Check that the indicator (C) (notch on fixed side) of each auto-tensioner is within the possible use range (A).

NOTE:

Check the each auto-tensioners indication when the engine is cold.

When new drive belts is installed, the indicator (notch on fixed side) should be within the range (B) in the\

figure.

Visually check all drive belts for wear, damage or cracks.

If the indicator (notch on fixed side) is out of the possible use range or drive belts are damaged, replace drive

belts.

Tension AdjustmentINFOID:0000000006289526

Refer to EM-132, "Drive Belts".

Removal and InstallationINFOID:0000000006289527

REMOVAL

1. Move reservoir tank to the position without the hindrance for work. Refer to CO-13, "Exploded View".

1. Drive belt 2. Power steering oil pump pulley 3. Alternator pulley

4. Crankshaft pulley 5. A/C compressor 6. Idler pulley

7. Cooling fan pulley 8. Water pump pulley 9. Drive belt auto-tensioner

A. Possible use range B. Range when new drive belt is in-

stalledC. Indicator

D. View D

JPBIA3264ZZ

Revision: 2010 May2011 QX56

Page 2602 of 5598

EM-40

< REMOVAL AND INSTALLATION >

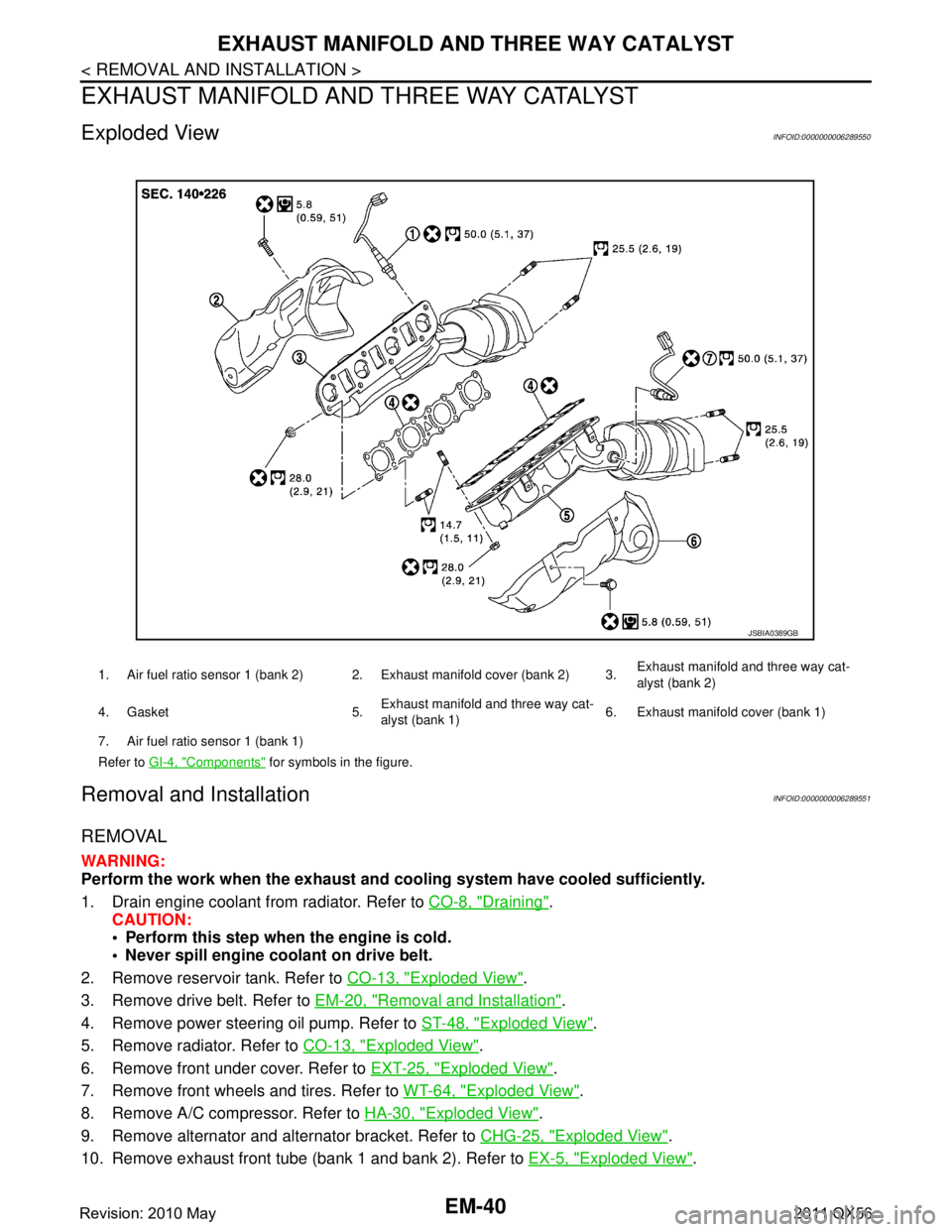

EXHAUST MANIFOLD AND THREE WAY CATALYST

EXHAUST MANIFOLD AND THREE WAY CATALYST

Exploded ViewINFOID:0000000006289550

Removal and InstallationINFOID:0000000006289551

REMOVAL

WARNING:

Perform the work when the exhaust and cooling system have cooled sufficiently.

1. Drain engine coolant from radiator. Refer to CO-8, "

Draining".

CAUTION:

Perform this step when the engine is cold.

Never spill engine coolant on drive belt.

2. Remove reservoir tank. Refer to CO-13, "

Exploded View".

3. Remove drive belt. Refer to EM-20, "

Removal and Installation".

4. Remove power steering oil pump. Refer to ST-48, "

Exploded View".

5. Remove radiator. Refer to CO-13, "

Exploded View".

6. Remove front under cover. Refer to EXT-25, "

Exploded View".

7. Remove front wheels and tires. Refer to WT-64, "

Exploded View".

8. Remove A/C compressor. Refer to HA-30, "

Exploded View".

9. Remove alternator and alternator bracket. Refer to CHG-25, "

Exploded View".

10. Remove exhaust front tube (bank 1 and bank 2). Refer to EX-5, "

Exploded View".

1. Air fuel ratio sensor 1 (bank 2) 2. Exhaust manifold cover (bank 2) 3. Exhaust manifold and three way cat-

alyst (bank 2)

4. Gasket 5. Exhaust manifold and three way cat-

alyst (bank 1)6. Exhaust manifold cover (bank 1)

7. Air fuel ratio sensor 1 (bank 1)

Refer to GI-4, "

Components" for symbols in the figure.

JSBIA0389GB

Revision: 2010 May2011 QX56

Page 2624 of 5598

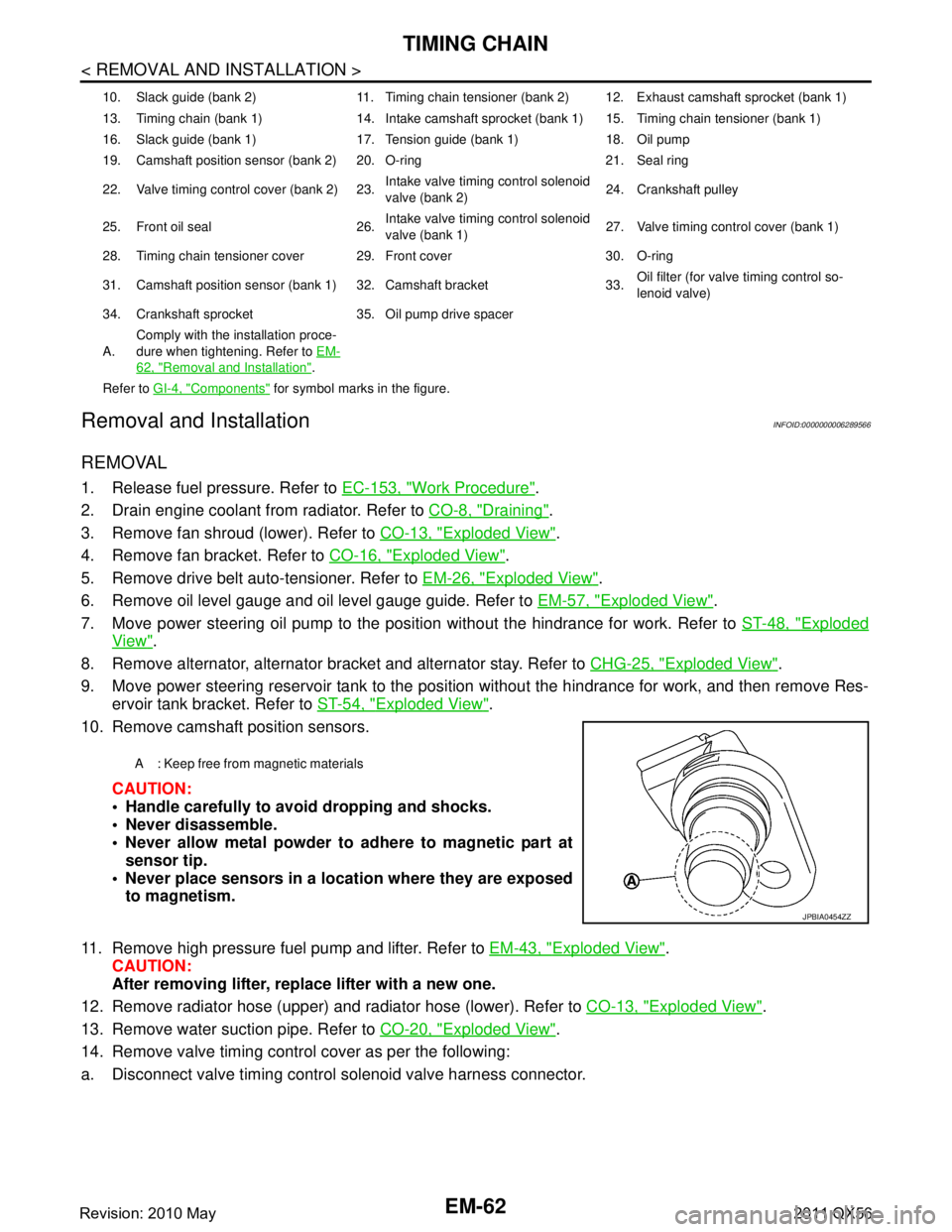

EM-62

< REMOVAL AND INSTALLATION >

TIMING CHAIN

Removal and Installation

INFOID:0000000006289566

REMOVAL

1. Release fuel pressure. Refer to EC-153, "Work Procedure".

2. Drain engine coolant from radiator. Refer to CO-8, "

Draining".

3. Remove fan shroud (lower). Refer to CO-13, "

Exploded View".

4. Remove fan bracket. Refer to CO-16, "

Exploded View".

5. Remove drive belt auto-tensioner. Refer to EM-26, "

Exploded View".

6. Remove oil level gauge and oil level gauge guide. Refer to EM-57, "

Exploded View".

7. Move power steering oil pump to the posit ion without the hindrance for work. Refer to ST-48, "

Exploded

View".

8. Remove alternator, alternator bracket and alternator stay. Refer to CHG-25, "

Exploded View".

9. Move power steering reservoir tank to the position without the hindrance for work, and then remove Res- ervoir tank bracket. Refer to ST-54, "

Exploded View".

10. Remove camshaft position sensors.

CAUTION:

Handle carefully to avoid dropping and shocks.

Never disassemble.

Never allow metal powder to adhere to magnetic part atsensor tip.

Never place sensors in a lo cation where they are exposed

to magnetism.

11. Remove high pressure fuel pump and lifter. Refer to EM-43, "

Exploded View".

CAUTION:

After removing lifter, replace lifter with a new one.

12. Remove radiator hose (upper) and radiator hose (lower). Refer to CO-13, "

Exploded View".

13. Remove water suction pipe. Refer to CO-20, "

Exploded View".

14. Remove valve timing control cover as per the following:

a. Disconnect valve timing control solenoid valve harness connector.

10. Slack guide (bank 2) 11. Timing chain tensioner (bank 2) 12. Exhaust camshaft sprocket (bank 1)

13. Timing chain (bank 1) 14. Intake camshaft sprocket (bank 1) 15. Timing chain tensioner (bank 1)

16. Slack guide (bank 1) 17. Tension guide (bank 1) 18. Oil pump

19. Camshaft position sensor (bank 2) 20. O-ring 21. Seal ring

22. Valve timing control cover (bank 2) 23. Intake valve timing control solenoid

valve (bank 2)24. Crankshaft pulley

25. Front oil seal 26. Intake valve timing control solenoid

valve (bank 1)27. Valve timing control cover (bank 1)

28. Timing chain tensioner cover 29. Front cover 30. O-ring

31. Camshaft position sensor (bank 1) 32. Camshaft bracket 33. Oil filter (for valve timing control so-

lenoid valve)

34. Crankshaft sprocket 35. Oil pump drive spacer

A. Comply with the installation proce-

dure when tightening. Refer to

EM-

62, "Removal and Installation".

Refer to GI-4, "

Components" for symbol marks in the figure.

A : Keep free from magnetic materials

JPBIA0454ZZ

Revision: 2010 May2011 QX56

Page 2663 of 5598

ENGINE ASSEMBLYEM-101

< UNIT REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

5. Remove A/T assembly. Refer to

TM-205, "2WD : Exploded View" (2WD models) or TM-208, "4WD :

Exploded View" (4WD models).

6. Remove steering gear assembly. Refer to ST-41, "

Exploded View".

7. Remove front final drive assembly. Refer to DLN-162, "

Exploded View".

8. Remove exhaust manifold. Refer to EM-40, "

Exploded View".

9. Remove alternator. Refer to CHG-25, "

Exploded View".

Engine Room LH

1. Remove air cleaner and air duct. Refer to EM-27, "Exploded View".

2. Remove A/C compressor. Refer to HA-30, "

Exploded View".

3. Disconnect fuel feed hose and EVAP hose. Refer to EM-43, "

Exploded View".

CAUTION:

Fit plugs onto disconnected hoses to prevent fuel leakage.

Engine Room RH

1. Remove power steering oil pump and reservoir tank. Refer to ST-48, "Exploded View".

2. Disconnect heater hose at heater core side, and fit a plug onto hose end to prevent engine coolant leak-

age.

3. Disconnect ground cable.

4. Disconnect all clips and connectors of the engine harness from vehicle side.

Removal Work

1. Install alternator bracket. Refer to CHG-25, "Exploded View".

Temporarily tighten mounting bolts.

2. Remove intake manifold. Refer to EM-30, "

Exploded View".

3. Remove starter motor. Refer to STR-17, "

Exploded View".

4. Install engine slingers.

5. Lift using a hoist and secure the engine in position.

6. Remove engine mounting bracket (LH, RH) and engine mounting insulator (LH, RH). Refer to EM-98,

"Exploded View".

7. Remove the engine from the vehi cle, avoid interference with the

vehicle body.

CAUTION:

Before and during lifting, always check that any har-

nesses are left connected.

Never damage engine mounti ng insulator and avoid oil/

grease smearing or spills onto engine mounting insulator.

A Engine front slinger (bank 2) B Engine rear slinger C Engine front slinger (bank 1)

Slinger bolts:

: 45.0 N·m (4.6 kg-m, 33 ft-lb)

JPBIA3970ZZ

JPBIA3497ZZ

Revision: 2010 May2011 QX56

Page 3666 of 5598

OIL PUMPLU-13

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

LU

NP

O

OIL PUMP

Exploded ViewINFOID:0000000006289624

Removal and InstallationINFOID:0000000006289625

REMOVAL

NOTE:

Do not remove the engine assembly to perform this procedure.

1. Disconnect battery cable from

negative terminal. Refer to PG-165, "

Exploded View".

2. Drain engine oil. Refer to LU-8, "

Draining".

3. Drain engine coolant from radiator. Refer to CO-8, "

Draining".

CAUTION:

Perform this step when engine is cold.

Never spill engine coolant on drive belts.

4. Remove the following components and related parts: Air cleaner case assembly and air duct. Refer to EM-27, "

Exploded View".

Drive belt auto tensioner and idler pulley. Refer to EM-26, "

Exploded View".

Fan shroud. Refer to CO-13, "

Exploded View".

Cooling fan, fan coupling and fan bracket. Refer to CO-16, "

Exploded View".

Front under cover. Refer to EXT-25, "

Exploded View".

Protector A and B. Refer to SCS-32, "

FRONT TUBE ASSEMBLY : Exploded View".

Front suspension rear cross member. Refer to TM-205, "

2WD : Exploded View" (2WD models) or TM-

208, "4WD : Exploded View" (4WD models).

Steering gear assembly. Refer to ST-41, "

Exploded View".

Front final drive assembly. Refer to DLN-162, "

Exploded View".

Power steering oil pump. Refer to ST-48, "

Exploded View".

Alternator, alternator bracket and alternator stay. Refer to CHG-25, "

Exploded View".

Oil pan (lower) and oil strainer. Refer to EM-54, "

Exploded View".

Oil pan (upper). Refer to EM-57, "

Exploded View".

Electric throttle control actuator. Refer to EM-30, "

Exploded View".

Radiator hoses. Refer to CO-13, "

Exploded View".

Water suction hose and water suction pipe. Refer to CO-20, "

Exploded View".

Water pump pulley. Refer to CO-18, "

Exploded View".

Rocker cover. Refer to EM-33, "

Exploded View".

WBIA0415E

1. Oil pump body 2. Outer rotor 3. Inner rotor

4. Oil pump cover 5. Oil pump drive spacer 6. Regulator valve

7. Regulator spring 8. Regulator plug

Revision: 2010 May2011 QX56

Page 3682 of 5598

MA-12

< PERIODIC MAINTENANCE >

ENGINE MAINTENANCE

ENGINE MAINTENANCE

DRIVE BELTS

DRIVE BELTS : Exploded ViewINFOID:0000000006394835

DRIVE BELTS : CheckingINFOID:0000000006394836

WARNING:

Be sure to perform the these steps when engine is stopped.

Check that the indicator (C) (notch on fixed side) of each auto-tensioner is within the possible use range (A).

NOTE:

Check the each auto-tensioners indication when the engine is cold.

When new drive belts is installed, the indicator (notch on fixed side) should be within the range (B) in the\

figure.

Visually check all drive belts for wear, damage or cracks.

If the indicator (notch on fixed side) is out of the possible use range or drive belts are damaged, replace drive

belts.

DRIVE BELTS : Tension AdjustmentINFOID:0000000006394837

Refer to EM-132, "Drive Belts".

ENGINE COOLANT

ENGINE COOLANT : InspectionINFOID:0000000006394844

LEVEL

1. Drive belt 2. Power steering oil pump pulley 3. Alternator pulley

4. Crankshaft pulley 5. A/C compressor 6. Idler pulley

7. Cooling fan pulley 8. Water pump pulley 9. Drive belt auto-tensioner

A. Possible use range B. Range when new drive belt is in-

stalledC. Indicator

D. View D

JPBIA3264ZZ

Revision: 2010 May2011 QX56

Page 3783 of 5598

MWI-40

< ECU DIAGNOSIS INFORMATION >

COMBINATION METER

11

(G) Ground Enter switch signal Input Ignition

switch

ONWhen switch (enter

switch) is pressed

0 V

Other than the above 5 V

12

(O) Ground Select switch signal Input Ignition

switch

ONWhen switch (select

switch) is pressed

0 V

Other than the above 5 V

13

(W/R) Ground

Illumination control switch

signal (+) InputIgnition

switch

ON When switch [illumi-

nation control sw

itch (+)] is

pressed 0 V

Other than the above 5 V

14

(R) Ground Illumination control switch

signal (

−) InputIgnition

switch

ON When switch [illumi-

nation control switch (

−)] is

pressed 0 V

Other than the above 5 V

15

(R/W) Ground Air bag signal Input Ignition

switch

ONAir bag warning lamp

ON

4 V

Air bag warning lamp

OFF 0 V

18

(W/R) Ground Ambient sensor signal Input — —

19

(V/W) Ground A/C auto amp. connection

recognition signal Input —When A/C auto amp. is

connected

5 V

Other than the above 0 V

20

(B) Ground Ambient sensor ground — Ignition

switch

ON—0 V

21

(L) —CAN-H — — — —

22

(P) —CAN-L — — — —

23

(B) Ground Ground — Ignition

switch

ON

—0 V

24

(V) Ground Fuel level sensor ground — Ignition

switch

ON—0 V

25

(O/L) Ground Alternator signal Input Ignition

switch

ONCharge warning lamp ON 2 V

Charge warning lamp OFF Battery voltage

26

(W) Ground Parking brake switch signal Input Ignition

switch

ONParking brake applied 0 V

Parking brake released 12 V

Te r m i n a l N o .

(Wire color) Description

ConditionVa l u e

(Approx.)

+ – Signal name Input/

Output

JSNIA0014GB

Revision: 2010 May2011 QX56

Page 3847 of 5598

![INFINITI QX56 2011 Factory Owners Manual

PCS-6

< SYSTEM DESCRIPTION >[IPDM E/R]

SYSTEM

NOTE:

BCM controls the starter relay.

RELAY CONTROL SYSTEM : Fail-SafeINFOID:0000000006220163

CAN COMMUNICATION CONTROL

When CAN communication with ECM a INFINITI QX56 2011 Factory Owners Manual

PCS-6

< SYSTEM DESCRIPTION >[IPDM E/R]

SYSTEM

NOTE:

BCM controls the starter relay.

RELAY CONTROL SYSTEM : Fail-SafeINFOID:0000000006220163

CAN COMMUNICATION CONTROL

When CAN communication with ECM a](/img/42/57033/w960_57033-3846.png)

PCS-6

< SYSTEM DESCRIPTION >[IPDM E/R]

SYSTEM

NOTE:

BCM controls the starter relay.

RELAY CONTROL SYSTEM : Fail-SafeINFOID:0000000006220163

CAN COMMUNICATION CONTROL

When CAN communication with ECM and BCM is impossible,

IPDM E/R performs fail-safe control. After CAN

communication recovers normally, it also returns to normal control.

If No CAN Communication Is Available With ECM

If No CAN Communication Is Available With BCM

Control relay Input/output Transmi t unit Control part Reference page

Headlamp low relay

Headlamp high relay Low beam request signal

High beam request signal

BCM (CAN)

Headlamp (LO)

Headlamp (HI) EXL-10

Front fog lamp relay Front fog light request signal BCM (CAN) Front fog lamp

EXL-20

Tail lamp relay Position light request signal BCM (CAN) Parking lamp

License plate

lamp

Tail lamp

Side marker lamp EXL-18

Illuminations

INL-6

Front wiper relay

Front wiper high relayFront wiper request signal BCM (CAN)

Front wiper motorWW-7Front wiper stop position sig-

nal Front wiper motor

Rear window defogger

relay Rear window defogger control

signal

BCM (CAN)

Rear window defog-

ger

DEF-6

Horn relay

Theft warning horn

relay Theft warning horn request

signal

Horn reminder signal BCM (CAN)

Horn (high)

Horn (low) SEC-17

Starter relayNOTE

Starter control relayStarter control rela

y signal BCM (CAN)

Starter motorSEC-10

,

SEC-10Steering lock unit condition

signal Steering lock unit

Starter relay control signal TCM

Steering lock relay Steering lock relay signal BCM (CAN)

Steering lock unitSEC-10

Steering lock unit condition

signal Steering lock unit

A/T shift selector (detention

switch) signal A/T shift selector

(detention switch)

A/C relay A/C compressor request sig-

nal ECM (CAN)

A/C compressor

(Magnet clutch) HAC-17

Headlamp washer relay

Headlamp washer request

signal BCM (CAN)Headlamp washer

pump WW-13

Ignition relay

Ignition relay-2

Ignition relay-3Ignition switch ON signal BCM (CAN)

Each control unit,

sensor, actuator and

relay (ignition power

supply)PCS-29Vehicle speed signal

Combination meter

(CAN)

Push-button ignition switch

signal Push-button ignition

switch

Control part Fail-safe operation

Cooling fan Transmits the pulse duty signal (PWM signal) 100% when the ignition switch is turned ON.

Transmits the pulse duty signal (PWM signal) 0% when the ignition switch is turned OFF.

A/C compressor A/C relay OFF

Alternator Transmits the power generation command signal (PWM signal) 0%

Revision: 2010 May2011 QX56

Page 3849 of 5598

![INFINITI QX56 2011 Factory Owners Manual

PCS-8

< SYSTEM DESCRIPTION >[IPDM E/R]

SYSTEM

POWER CONTROL SYSTEM : System Diagram

INFOID:0000000006220164

POWER CONTROL SYSTEM : System DescriptionINFOID:0000000006220165

COOLING FAN CONTROL

IPDM INFINITI QX56 2011 Factory Owners Manual

PCS-8

< SYSTEM DESCRIPTION >[IPDM E/R]

SYSTEM

POWER CONTROL SYSTEM : System Diagram

INFOID:0000000006220164

POWER CONTROL SYSTEM : System DescriptionINFOID:0000000006220165

COOLING FAN CONTROL

IPDM](/img/42/57033/w960_57033-3848.png)

PCS-8

< SYSTEM DESCRIPTION >[IPDM E/R]

SYSTEM

POWER CONTROL SYSTEM : System Diagram

INFOID:0000000006220164

POWER CONTROL SYSTEM : System DescriptionINFOID:0000000006220165

COOLING FAN CONTROL

IPDM E/R outputs cooling fan control signal (PWM signal ) to the electrically-controlled cooling fan coupling

according to the status of the cooling fan speed request signal received from ECM via CAN communication.

Refer to EC-41, "

COOLING FAN CONTROL : System Diagram".

ALTERNATOR CONTROL

IPDM E/R outputs power generation command signal (PWM signal ) to the alternator according to the status of

the power generation command value signal received from ECM via CAN communication. Refer to CHG-7,

"POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM : System Diagram".

SIGNAL BUFFER SYSTEM

SIGNAL BUFFER SYSTEM : System DiagramINFOID:0000000006220166

SIGNAL BUFFER SYSTEM : System DescriptionINFOID:0000000006220167

IPDM E/R reads the status of the oil pressure switch and transmits the oil pressure switch signal to BCM via

CAN communication. Refer to MWI-15, "

OIL PRESSURE WARNING LAMP : System Diagram".

IPDM E/R reads the status of the hood switch and tr ansmits the hood switch signal to BCM via CAN commu-

nication. Refer to SEC-17, "

VEHICLE SECURITY SYSTEM : System Diagram".

IPDM E/R receives the rear window defogger control signal from BCM via CAN communication and trans- mits it to ECM and AV control unit via CAN communication. Refer to DEF-6, "

System Diagram".

POWER CONSUMPTION CONTROL SYSTEM

JMMIA0491GB

JPMIA0952GB

Revision: 2010 May2011 QX56