fog light INFINITI QX56 2011 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 1366 of 5598

![INFINITI QX56 2011 Factory Owners Manual

DAS

NORMAL OPERATING CONDITIONDAS-401

< SYMPTOM DIAGNOSIS > [LDW & LDP]

C

D

E

F

G H

I

J

K L

M B

N P A

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000006223842

PRECAUTIONS FOR LANE DEPARTURE WARN INFINITI QX56 2011 Factory Owners Manual

DAS

NORMAL OPERATING CONDITIONDAS-401

< SYMPTOM DIAGNOSIS > [LDW & LDP]

C

D

E

F

G H

I

J

K L

M B

N P A

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000006223842

PRECAUTIONS FOR LANE DEPARTURE WARN](/img/42/57033/w960_57033-1365.png)

DAS

NORMAL OPERATING CONDITIONDAS-401

< SYMPTOM DIAGNOSIS > [LDW & LDP]

C

D

E

F

G H

I

J

K L

M B

N P A

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000006223842

PRECAUTIONS FOR LANE DEPARTURE WARNING (LDW)

LDW system is only a warning devic e to inform the driver of a potential unintended lane departure. It will not

steer the vehicle or prevent loss of c ontrol. It is the driver’s responsibility to stay alert, drive safely, keep the

vehicle in the traveling lane, and be in control of the vehicle at all times.

LDW system will not operate at s peeds below approximately 70 km/h (45 MPH) or if it cannot detect lane

markers.

Excessive noise will interfere with the warning chime sound, and the chime may not be heard.

LDW system may not function properly under the following conditions:

- On roads where there are multiple parallel lane marker s; lane markers that are faded or not painted clearly;

yellow painted lane markers; non-standard lane markers; or lane markers covered with water, dirt or snow,

etc.

- On roads where the discontinued lane markers are still detectable.

- On roads where there are sharp curves.

- On roads where there are sharply contrasting objects, such as shadows, snow, water, wheel ruts, seams or

lines remaining after road repairs. (The LDW syst em could detect these items as lane markers.)

- On roads where the traveling lane merges or separates.

- When the vehicle's traveling direction does not align with the lane marker.

- When traveling close to other vehicle in front of the vehicle, which obstructs the lane camera unit detection

range.

- When rain, snow or dirt adheres to the windshield in front of the lane camera unit.

- When the headlights are not bright due to dirt on the lens or if the aiming is not adjusted properly.

- When strong light enters the lane camera unit. (For example, the light directly shines on the front of the vehi-

cle at sunrise or sunset.)

- When a sudden change in brightness occurs. (For exampl e, when the vehicle enters or exits a tunnel or

under a bridge.)

PRECAUTIONS FOR LANE DEPARTURE PREVENTION (LDP)

LDP system will not steer the vehicle or prevent loss of control. It is the driver’s responsibility to stay alert,

drive safely, keep the vehicle in the traveling lane, and be in control of vehicle at all times.

LDP system is primarily intended for use on well-devel oped freeways or highways. It may not detect the lane

markers in certain roads, weather or driving conditions.

Using the LDP system under some conditions of road, lane marker or weather, or when driver change lanes

without using the turn signal could lead to an unexpect ed system operation. In such conditions, driver needs

to correct the vehicle's direction with dr iver's steering operation to avoid accidents.

When the LDP system is operating, avoid excessive or sudden steering maneuvers. Otherwise, driver could

lose control of the vehicle.

The LDP system will not operate at speeds below approximat ely 70 km/h (45 MPH) or if it cannot detect lane

markers.

The LDP system may not function properly under the following conditions, and do not use the LDP system:

- During bad weather (rain, fog, snow, wind, etc.).

- When driving on slippery roads, such as on ice or snow, etc.

- When driving on winding or uneven roads.

- When there is a lane closure due to road repairs.

- When driving in a makeshift lane.

- When driving on roads where the lane width is too narrow.

- When driving with a tire that is not within normal tire c onditions (for example, tire wear, low tire pressure,

installation of spare tire, tire chains, non-standard wheels).

- When the vehicle is equipped with non-origi nal brake parts or suspension parts.

Excessive noise will interfere with the warning chime sound, and the chime may not be heard.

The functions of the LDP system (warning and brake control assist) may or may not operate properly under

the following conditions:

- On roads where there are multiple parallel lane marker s; lane markers that are faded or not painted clearly;

yellow painted lane markers; non-standard lane markers or lane markers covered with water, dirt or snow,

etc.

- On roads where discontinued lane markers are still detectable.

- On roads where there are sharp curves.

Revision: 2010 May2011 QX56

Page 1504 of 5598

DEF-12

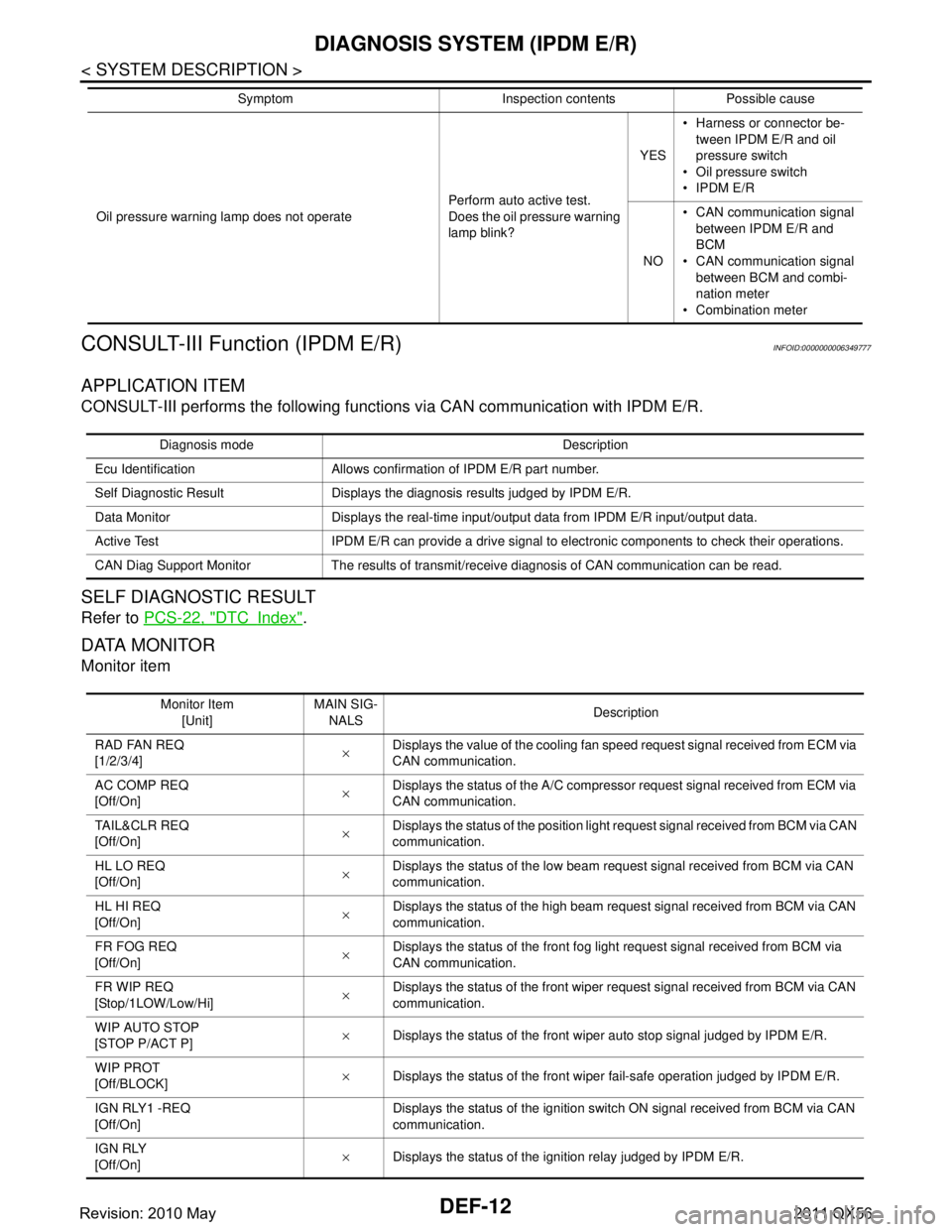

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (IPDM E/R)

CONSULT-III Function (IPDM E/R)

INFOID:0000000006349777

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with IPDM E/R.

SELF DIAGNOSTIC RESULT

Refer to PCS-22, "DTCIndex".

DATA MONITOR

Monitor item

Oil pressure warning lamp does not operate Perform auto active test.

Does the oil pressure warning

lamp blink?YES

Harness or connector be-

tween IPDM E/R and oil

pressure switch

Oil pressure switch

IPDM E/R

NO CAN communication signal

between IPDM E/R and

BCM

CAN communication signal

between BCM and combi-

nation meter

Combination meter

Symptom Inspection contents Possible cause

Diagnosis mode Description

Ecu Identification Allows confirmation of IPDM E/R part number.

Self Diagnostic Result Displays the diagnosis results judged by IPDM E/R.

Data Monitor Displays the real-time input/output data from IPDM E/R input/output data.

Active Test IPDM E/R can provide a drive signal to electronic components to check their operations.

CAN Diag Support Monitor The results of transmit/receive diagnosis of CAN communication can be read.

Monitor Item [Unit] MAIN SIG-

NALS Description

RAD FAN REQ

[1/2/3/4] ×Displays the value of the cooling fan speed request signal received from ECM via

CAN communication.

AC COMP REQ

[Off/On] ×Displays the status of the A/C compressor request signal received from ECM via

CAN communication.

TA I L & C L R R E Q

[Off/On] ×

Displays the status of the position light request signal received from BCM via CAN

communication.

HL LO REQ

[Off/On] ×Displays the status of the low beam request signal received from BCM via CAN

communication.

HL HI REQ

[Off/On] ×Displays the status of the high beam request signal received from BCM via CAN

communication.

FR FOG REQ

[Off/On] ×Displays the status of the front fog light request signal received from BCM via

CAN communication.

FR WIP REQ

[Stop/1LOW/Low/Hi] ×

Displays the status of the front wiper request signal received from BCM via CAN

communication.

WIP AUTO STOP

[STOP P/ACT P] ×

Displays the status of the front wiper auto stop signal judged by IPDM E/R.

WIP PROT

[Off/BLOCK] ×

Displays the status of the front wiper fail-safe operation judged by IPDM E/R.

IGN RLY1 -REQ

[Off/On] Displays the status of the ignition switch ON signal received from BCM via CAN

communication.

IGN RLY

[Off/On] ×

Displays the status of the ignition relay judged by IPDM E/R.

Revision: 2010 May2011 QX56

Page 2091 of 5598

![INFINITI QX56 2011 Factory Owners Manual

DIAGNOSIS SYSTEM (ECM)EC-67

< SYSTEM DESCRIPTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

OLOAD SIGNAL ON/OFF

Indicates [ON/OFF] condition from the electrical

load signal.

ON: Rear window defogger INFINITI QX56 2011 Factory Owners Manual

DIAGNOSIS SYSTEM (ECM)EC-67

< SYSTEM DESCRIPTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

OLOAD SIGNAL ON/OFF

Indicates [ON/OFF] condition from the electrical

load signal.

ON: Rear window defogger](/img/42/57033/w960_57033-2090.png)

DIAGNOSIS SYSTEM (ECM)EC-67

< SYSTEM DESCRIPTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

OLOAD SIGNAL ON/OFF

Indicates [ON/OFF] condition from the electrical

load signal.

ON: Rear window defogger switch is ON and/or

lighting switch is in 2nd position.

OFF: Both rear window defogger switch and light-

ing switch are OFF.

IGNITION SW ON/OFF Indicates [ON/OFF] condition from ignition switch

signal.

HEATER FAN SW ON/OFF Indicates [ON/OFF] condition from the blower fan

ON signal.

BRAKE SW ON/OFF Indicates [ON/OFF] condition from the stop lamp

switch signal.

IGN TIMING BTDC Indicates the ignition timing computed by ECM ac-

cording to the input signals. When the engine is stopped,

a certain value is indicated.

COMBUSTION — These items are displayed but are not applicable to

this model.

CAL/LD VALUE % “Calculated load value” indicates the value of the

current air flow divided by peak air flow.

MASS AIRFLOW g/s Indicates the mass air flow computed by ECM ac-

cording to the signal voltage of the mass air flow

sensor.

PURG VOL C/V % Indicates the EVAP canister purge volume control

solenoid valve control value computed by the ECM

according to the input signals.

The opening becomes larger as the value increas-

es.

INT/V SOL (B1)

% The control value of the intake valve timing control

solenoid valve (determined by ECM according to

the input signals) is indicated.

The advance angle becomes larger as the value increases.

INT/V SOL (B2)

AIR COND RLY ON/OFF

The air conditioner relay control condition (deter-

mined by ECM according to the input signals) is in-

dicated.

VENT CONT/V ON/OFF The control condition of the EVAP canister vent

control valve (determined by ECM according to the

input signals) is indicated.

ON: Closed

OFF: Open

THRTL RELAY ON/OFF Indicates the throttle co

ntrol motor relay control

condition determined by the ECM according to the

input signals.

A/F S1 HTR (B1)

% Air fuel ratio (A/F) sensor 1 heater control value

computed by ECM according to the input signals.

The current flow to the heater becomes larger as the value increases.

A/F S1 HTR (B2)

HO2S2 HTR (B1)

ON/OFF Indicates [ON/OFF] condition of heated oxygen

sensor 2 heater determined by ECM according to

the input signals.

HO2S2 HTR (B2)

ALT DUTY SIG ON/OFF The control condition of the power generation volt-

age variable control (determined by ECM accord-

ing to the input signals) is indicated.

ON: Power generation voltage variable control is

active.

OFF: Power generation voltage variable control is

inactive.

I/P PULLY SPD rpm Indicates the engine speed computed from the in-

put speed sensor signal.

Monitored item Unit Description Remarks

Revision: 2010 May2011 QX56

Page 2097 of 5598

![INFINITI QX56 2011 Factory Owners Manual

ECM

EC-73

< ECU DIAGNOSIS INFORMATION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

TP SEN 1-B1

Ignition switch: ON

(Engine stopped)

Selector lever: D position Accelerator pedal: Fully released More INFINITI QX56 2011 Factory Owners Manual

ECM

EC-73

< ECU DIAGNOSIS INFORMATION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

TP SEN 1-B1

Ignition switch: ON

(Engine stopped)

Selector lever: D position Accelerator pedal: Fully released More](/img/42/57033/w960_57033-2096.png)

ECM

EC-73

< ECU DIAGNOSIS INFORMATION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

TP SEN 1-B1

Ignition switch: ON

(Engine stopped)

Selector lever: D position Accelerator pedal: Fully released More than 0.36 V

Accelerator pedal: Fully depressed Less than 4.75 V

TP SEN 2-B1*

1 Ignition switch: ON (Engine stopped)

Selector lever: D position Accelerator pedal: Fully released More than 0.36 V

Accelerator pedal: Fully depressed Less than 4.75 V

FUEL T/TMP SE Ignition switch: ON Indicates fuel tank tempera-

ture

EVAP SYS PRES Ignition switch: ON Approx. 1.8 - 4.8 V

FUEL LEVEL SE Ignition switch: ON Depending on fuel level of

fuel tank

START SIGNAL Ignition switch: ON → START → ON OFF → ON → OFF

CLSD THL POS Ignition switch: ON

(Engine stopped) Accelerator pedal: Fully released ON

Accelerator pedal: Slightly depressed OFF

AIR COND SIG Engine: After warming up, idle

the engine Air conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)

ON

PW/ST SIGNAL Engine: After warming up, idle

the engine Steering wheel: Not being turned OFF

Steering wheel: Being turned ON

LOAD SIGNAL Ignition switch: ON Rear window defogger switch: ON

and/or

Lighting switch: 2nd position

ON

Rear window defogger switch and lighting

switch: OFF OFF

IGNITION SW Ignition switch: ON → OFF → ON ON → OFF → ON

HEATER FAN SW Engine: After warming up, idle

the engine Heater fan switch: ON ON

Heater fan switch: OFF OFF

BRAKE SW Ignition switch: ON Brake pedal: Fully released OFF

Brake pedal: Slightly depressed ON

IGN TIMING Engine: After warming up

Selector lever: P or N position

A/C switch: OFF

No load Idle 1 - 4

°BTDC

2,000 rpm 25 - 45 °BTDC

COMBUSTION — These items are displayed

but are not applicable to this

model.

CAL/LD VALUE Engine: After warming up

Selector lever: P or N position

A/C switch: OFF

No load Idle 5 - 35%

2,500 rpm 5 - 35%

MASS AIRFLOW Engine: After warming up

Selector lever: P or N position

A/C switch: OFF

No load Idle 2.0 - 6.0 g/s

2,500 rpm 7.0 - 20.0 g/s

PURG VOL C/V Engine: After warming up

Selector lever: P or N position

A/C switch: OFF

No load Idle

(Accelerator pedal: Not depressed even

slightly, after engine starting.)

0%

2,000 rpm 5%

INT/V SOL (B1) Engine: After warming up

Selector lever: P or N position

A/C switch: OFF

No load Idle 0 - 2%

2,000 rpm Approx. 0 - 50%

Monitor Item Condition Values/Status

Revision: 2010 May2011 QX56

Page 2172 of 5598

![INFINITI QX56 2011 Factory Owners Manual

EC-148

< BASIC INSPECTION >[VK56VD]

IDLE AIR VOLUME LEARNING

IDLE AIR VOLUME LEARNING

DescriptionINFOID:0000000006217750

Idle Air Volume Learning is a function of ECM to learn

the idle air volume th INFINITI QX56 2011 Factory Owners Manual

EC-148

< BASIC INSPECTION >[VK56VD]

IDLE AIR VOLUME LEARNING

IDLE AIR VOLUME LEARNING

DescriptionINFOID:0000000006217750

Idle Air Volume Learning is a function of ECM to learn

the idle air volume th](/img/42/57033/w960_57033-2171.png)

EC-148

< BASIC INSPECTION >[VK56VD]

IDLE AIR VOLUME LEARNING

IDLE AIR VOLUME LEARNING

DescriptionINFOID:0000000006217750

Idle Air Volume Learning is a function of ECM to learn

the idle air volume that keeps engine idle speed within

the specific range. It must be perfo rmed under the following conditions:

Each time the electric throttle control actuator or ECM is replaced.

Idle speed or ignition timing is out of the specification.

Work ProcedureINFOID:0000000006217751

1.PRECONDITIONING

Check that all of the following conditions are satisfied.

Learning will be cancelled if any of the follo wing conditions are missed for even a moment.

Battery voltage: More than 12.9 V (At idle)

Engine coolant temperature: 70 - 105 °C (158 - 221 °F)

Selector lever position: P or N

Electric load switch: OFF

(Air conditioner, headlamp, rear window defogger)

On vehicles equipped with daytime light systems, if the parking brake is applied before the engine is

started the headlamp will not illuminate.

Steering wheel: Neutral (Straight-ahead position)

Vehicle speed: Stopped

Transmission: Warmed-up

- With CONSULT-III: Drive vehicle until “ATF TEMP 2” in “DATA MONITOR” mode of “A/T” system indicates

less than 0.9 V.

- Without CONSULT-III: Drive vehicle for 10 minutes.

Will CONSULT-III be used?

YES >> GO TO 2.

NO >> GO TO 3.

2.PERFORM IDLE AIR VOLUME LEARNING

WITH CONSULT-III

1. Perform Accelerator Pedal Released Position Learning. Refer to EC-146, "

Work Procedure".

2. Perform Throttle Valve Closed Position Learning. EC-147, "

Work Procedure".

3. Start engine and warm it up to normal operating temperature.

4. Select “IDLE AIR VOL LEARN” in “WORK SUPPORT” mode.

5. Touch “START” and wait 20 seconds.

Is

“CMPLT” displayed on CONSULT-III screen?

YES >> GO TO 4.

NO >> GO TO 5.

3.PERFORM IDLE AIR VOLUME LEARNING

WITHOUT CONSULT-III

NOTE:

It is better to count the ti me accurately with a clock.

It is impossible to switch the di agnostic mode when an accelerator pedal position sensor circuit has

a malfunction.

1. Perform Accelerator Pedal Released Position Learning. Refer to EC-146, "

Work Procedure".

2. Perform Throttle Valve Closed Position Learning. EC-147, "

Work Procedure".

3. Start engine and warm it up to normal operating temperature.

4. Turn ignition switch OFF and wait at least 10 seconds.

5. Confirm that accelerator pedal is fully releas ed, turn ignition switch ON and wait 3 seconds.

6. Repeat the following procedure quickly 5 times within 5 seconds.

- Fully depress the accelerator pedal.

- Fully release the accelerator pedal.

7. Wait 7 seconds, fully depress the accelerator pedal for approx. 20 seconds until the MIL stops blinking

and turns ON.

8. Fully release the accelerator pedal within 3 seconds after the MIL turns ON.

Revision: 2010 May2011 QX56

Page 2177 of 5598

![INFINITI QX56 2011 Factory Owners Manual

FUEL PRESSUREEC-153

< BASIC INSPECTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

FUEL PRESSURE

Work ProcedureINFOID:0000000006217756

FUEL PRESSURE RELEASE

WITH CONSULT-III

1. Turn ignition switch O INFINITI QX56 2011 Factory Owners Manual

FUEL PRESSUREEC-153

< BASIC INSPECTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

FUEL PRESSURE

Work ProcedureINFOID:0000000006217756

FUEL PRESSURE RELEASE

WITH CONSULT-III

1. Turn ignition switch O](/img/42/57033/w960_57033-2176.png)

FUEL PRESSUREEC-153

< BASIC INSPECTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

FUEL PRESSURE

Work ProcedureINFOID:0000000006217756

FUEL PRESSURE RELEASE

WITH CONSULT-III

1. Turn ignition switch ON.

2. Perform “FUEL PRESSURE RELEASE” in

“WORK SUPPORT” mode with CONSULT-III.

3. Start engine.

4. After engine stalls, crank it two or three times to release all fuel pressure.

5. Turn ignition switch OFF.

WITHOUT CONSULT-III

1. Remove fuel pump fuse in IPDM E/R. NOTE:

For the fuse number, refer to EC-114, "

Wiring Diagram".

For the fuse arrangement, refer to PG-143, "

Fuse, Connector and Terminal Arrangement".

2. Start engine.

3. After engine stalls, crank it two or three times to release all fuel pressure.

4. Turn ignition switch OFF.

5. Reinstall fuel pump fuse after servicing fuel system.

LOW FUEL PRESSURE CHECK

CAUTION:

Before disconnecting fuel line, release fuel pressure from fuel line to eliminate danger.

The fuel hose connection method used when taking fuel pressure check must not be used for other

purposes.

Do not perform fuel pressure check with electrical syst ems operating (i.e. lights, rear defogger, A/C,

etc.) Fuel pressure gauge may indicate false readin gs due to varying engine load and changes in

manifold vacuum.

NOTE:

Prepare pans or saucers under the disconnected fuel line because the fuel may spill out.

1. Release fuel pressure to zero.

2. Prepare fuel hose for fuel pressure check (B) and fuel tube adapter [SST (KV10118400)] (D), then connect fuel pressure

gauge (A).

CAUTION:

Use suitable fuel hose for fuel pressure check (genuine

NISSAN fuel hose without quick connector).

To avoid unnecessary force or tension to hose, use mod-

erately long fuel hose for fuel pressure check.

Do not use the fuel hose for checking fuel pressure with damage or cracks on it.

Use Pressure Gauge to check fuel pressure.

3. Disconnect fuel feed hose from fuel tube. Refer to EM-43, "

Exploded View".

CAUTION:

Do not twist or kink fuel hose because it is plastic hose.

To quick connector

To fuel tube (engine side)

C : Hose clamp

PBIB2982E

Revision: 2010 May2011 QX56

Page 2517 of 5598

![INFINITI QX56 2011 Factory Owners Manual

ELECTRICAL LOAD SIGNALEC-493

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ELECTRICAL LOAD SIGNAL

DescriptionINFOID:0000000006217994

The electrical load signal (Rear window defog INFINITI QX56 2011 Factory Owners Manual

ELECTRICAL LOAD SIGNALEC-493

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ELECTRICAL LOAD SIGNAL

DescriptionINFOID:0000000006217994

The electrical load signal (Rear window defog](/img/42/57033/w960_57033-2516.png)

ELECTRICAL LOAD SIGNALEC-493

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ELECTRICAL LOAD SIGNAL

DescriptionINFOID:0000000006217994

The electrical load signal (Rear window defogger switch

signal, headlamp switch signal, heater fan switch sig-

nal, etc.) is transferred via the CAN communication line.

Component Function CheckINFOID:0000000006217995

1.CHECK REAR WINDOW DEF OGGER SWITCH FUNCTION

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-III.

3. Select “LOAD SIGNAL” and check indication under the following conditions.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Go to EC-493, "

Diagnosis Procedure".

2.CHECK LIGHTING SWITCH FUNCTION

Check “LOAD SIGNAL” indication under the following conditions.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Go to EC-493, "

Diagnosis Procedure".

3.CHECK HEATER FAN CONTROL SWITCH FUNCTION

Select “HEATER FAN SW” and check indication under the following conditions.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Go to EC-493, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000006217996

1.INSPECTION START

Confirm the malfunctioning circuit (rear window defogger, headlamp or heater fan). Refer to EC-493, "

Compo-

nent Function Check".

Which circuit is related to the incident?

Rear window defogger>>GO TO 2.

Headlamp>>GO TO 3.

Heater fan>>GO TO 4.

2.CHECK REAR WINDOW DEFOGGER SYSTEM

Refer to DEF-24, "

Work Flow".

Monitor item Condition Indication

LOAD SIGNAL Rear window defogger switch ON ON

OFF OFF

Monitor item Condition Indication

LOAD SIGNAL Lighting switch ON at 2nd position ON

OFF OFF

Monitor item Condition Indication

HEATER FAN SW Heater fan control switch ON ON

OFF OFF

Revision: 2010 May2011 QX56

Page 2562 of 5598

![INFINITI QX56 2011 Factory Owners Manual

EC-538

< SERVICE DATA AND SPECIFICATIONS (SDS) [VK56VD]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Idle SpeedINFOID:000000000621 INFINITI QX56 2011 Factory Owners Manual

EC-538

< SERVICE DATA AND SPECIFICATIONS (SDS) [VK56VD]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Idle SpeedINFOID:000000000621](/img/42/57033/w960_57033-2561.png)

EC-538

< SERVICE DATA AND SPECIFICATIONS (SDS) [VK56VD]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Idle SpeedINFOID:0000000006218038

*: Under the following conditions

A/C switch: OFF

Electric load: OFF (Lights, heater fan & rear window defogger)

Steering wheel: Kept in straight-ahead position

Ignition TimingINFOID:0000000006218039

*: Under the following conditions

A/C switch: OFF

Electric load: OFF (Lights, heater fan & rear window defogger)

Steering wheel: Kept in straight-ahead position

Calculated Load ValueINFOID:0000000006218040

Mass Air Flow SensorINFOID:0000000006218041

*: Engine is warmed up to normal operating temperature and running under no load.Condition Specification

No load* (in P or N position) 600 ± 50 rpm

Condition Specification

No load* (in P or N position) 12 ± 2 °BTDC

Condition Specification (U sing CONSULT-III or GST)

At idle 5 – 35%

At 2,500 rpm 5 – 35%

Supply voltageBattery voltage (11 – 14 V)

Output voltage at idle 0.9 – 1.1 V*

Mass air flow (Using CONSULT-III or GST) 1.0 – 5.0 g/s at idle*

7.0 – 20.0 g/s at 2,500 rpm*

Revision: 2010 May2011 QX56

Page 2711 of 5598

EXL-1

DRIVER CONTROLS

C

DE

F

G H

I

J

K

M

SECTION EXL

A

B

EXL

N

O P

CONTENTS

EXTERIOR LIGHTING SYSTEM

XENON TYPE

PRECAUTION ................ ...............................

5

PRECAUTIONS .............................................. .....5

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

5

SYSTEM DESCRIPTION ..............................6

COMPONENT PARTS ................................... .....6

EXTERIOR LIGHTING SYSTEM .................................6

EXTERIOR LIGHTING SYSTEM : Component

Parts Location ..................................................... ......

6

EXTERIOR LIGHTING SYSTEM :

Component Description ............................................

7

FRONT COMBINATION LAMP ............................. ......8

FRONT COMBINATION LAMP : Xenon Head-

lamp ..........................................................................

8

FRONT COMBINATION LAMP : HID control unit ......9

FRONT COMBINATION LAMP : High Beam Sole-

noid ...........................................................................

9

FRONT COMBINATION LAMP : Aiming Motor ........9

FRONT COMBINATION LAMP : Swivel Actuator ......9

SYSTEM .............................................................10

HEADLAMP SYSTEM ...............................................10

HEADLAMP SYSTEM : Syst em Diagram ...............10

HEADLAMP SYSTEM : System Description ....... ....10

HEADLAMP SYSTEM : Fail-safe ............................10

AUTO LIGHT SYSTEM ..... ........................................11

AUTO LIGHT SYSTEM : System Diagram ......... ....11

AUTO LIGHT SYSTEM : System Description (For

CANADA) ................................................................

11

AUTO LIGHT SYSTEM : System Description (Ex-

cept for CANADA) ...................................................

12

DAYTIME RUNNING LIGHT SYSTEM ......................14

DAYTIME RUNNING LIGH T SYSTEM : System

Diagram ............................................................... ....

14

DAYTIME RUNNING LIGHT SYSTEM : System

Description ........................................................... ....

14

ACTIVE ADAPTIVE FRONT-LIGHTING SYSTEM ....14

ACTIVE ADAPTIVE FRONT-LIGHTING SYSTEM

: System Diagram ................................................ ....

15

ACTIVE ADAPTIVE FRONT-LIGHTING SYSTEM

: System Description ................................................

15

ACTIVE ADAPTIVE FRONT-LIGHTING SYSTEM

: Fail-Safe ................................................................

17

HEADLAMP AIMING CONTROL (MANUAL) ...........17

HEADLAMP AIMING CO NTROL (MANUAL) :

System Description .............................................. ....

18

TURN SIGNAL AND HAZARD WARNING LAMP

SYSTEM .....................................................................

18

TURN SIGNAL AND HAZARD WARNING LAMP

SYSTEM : System Diagram ................................ ....

18

TURN SIGNAL AND HAZARD WARNING LAMP

SYSTEM : System Description ................................

18

PARKING, LICENSE PLATE, SIDE MARKER AND

TAIL LAMP SYSTEM ............................................. ....

18

PARKING, LICENSE PLATE, SIDE MARKER

AND TAIL LAMP SYSTEM : System Diagram ........

18

PARKING, LICENSE PLATE, SIDE MARKER

AND TAIL LAMP SYSTEM : System Description ....

19

PARKING, LICENSE PLATE, SIDE MARKER

AND TAIL LAMP SYSTEM : Fail-safe .....................

19

FRONT FOG LAMP SYSTEM ............................... ....19

FRONT FOG LAMP SYSTEM : System Diagram ....20

FRONT FOG LAMP SYSTEM : System Descrip-

tion ....................................................................... ....

20

FRONT FOG LAMP SYSTEM : Fail-Safe ...............20

EXTERIOR LAMP BATTERY SAVER SYSTEM ... ....20

EXTERIOR LAMP BATTERY SAVER SYSTEM :

System Diagram ......................................................

20

Revision: 2010 May2011 QX56

Page 2713 of 5598

EXL-3

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

EXTERIOR LAMP FUSE ................................ ....85

Diagnosis Procedure ........................................... ....85

HEADLAMP (HI) CIRCUIT .................................86

Component Function Check ................................ ....86

Diagnosis Procedure ...............................................86

HEADLAMP (LO) CIRCUIT ................................88

Component Function Check ................................ ....88

Diagnosis Procedure ...............................................88

XENON HEADLAMP ..........................................90

Diagnosis Procedure ........................................... ....90

HEADLAMP LEVELIZER CIRCUIT ...................91

Component Function Check ................................ ....91

Diagnosis Procedure ...............................................91

HEADLAMP AIMING SYSTEM (MANUAL) .......93

Component Inspection ........................................ ....93

FRONT FOG LAMP CIRCUIT ............................94

Component Function Check ................................ ....94

Diagnosis Procedure ...............................................94

PARKING LAMP CIRCUIT ............................. ....96

Component Function Check ................................ ....96

Diagnosis Procedure ...............................................96

FRONT SIDE MARKER LAMP CIRCUIT ...........98

Component Function Check ................................ ....98

Diagnosis Procedure ...............................................98

TURN SIGNAL LAMP CIRCUIT .........................99

Component Function Check ................................ ....99

Diagnosis Procedure ...............................................99

OPTICAL SENSOR ..........................................102

Component Function Check ................................ ..102

Diagnosis Procedure .............................................102

HAZARD SWITCH .......................................... ..105

Component Function Check ................................ ..105

Diagnosis Procedure .............................................105

AFS SWITCH ....................................................107

Component Function Check ................................ ..107

Diagnosis Procedure .............................................107

Component Inspection ..........................................108

TAIL LAMP CIRCUIT .......................................109

BODY SIDE ........................................................... ..109

BODY SIDE : Component Function Check ...........109

BODY SIDE : Diagnosis Procedure ......................109

BACK DOOR SIDE ................................................ ..110

BACK DOOR SIDE : Component Function Check ..110

BACK DOOR SIDE : Diagnosis Procedure ...........111

LICENSE PLATE LAMP CIRCUIT ...................112

Component Function Check ................................ ..112

Diagnosis Procedure .............................................112

SYMPTOM DIAGNOSIS ............................113

EXTERIOR LIGHTING SYSTEM SYMPTOMS .113

Symptom Table ................................................... ..113

NORMAL OPERATING CONDITION .............116

Description .............................................................116

BOTH SIDE HEADLAMPS DO NOT SWITCH

TO HIGH BEAM ..............................................

117

Description .............................................................117

Diagnosis Procedure .............................................117

BOTH SIDE HEADLAMPS (LO) ARE NOT

TURNED ON ...................................................

118

Description ........................................................... ..118

Diagnosis Procedure .............................................118

PARKING, LICENSE PLATE, SIDE MARKER

AND TAIL LAMPS ARE NOT TURNED ON ...

119

Description .............................................................119

Diagnosis Procedure .............................................119

BOTH SIDE FRONT FOG LAMPS ARE NOT

TURNED ON ...................................................

120

Description ........................................................... ..120

Diagnosis Procedure .............................................120

PERIODIC MAINTENANCE ......................121

HEADLAMP AIMING ADJUSTMENT .............121

description ........................................................... ..121

Aiming Adjustment Procedure ...............................122

FRONT FOG LAMP AIMING ADJUSTMENT .123

Description .............................................................123

Aiming Adjustment Procedure ...............................123

REMOVAL AND INSTALLATION .............125

FRONT COMBINATION LAMP ......................125

Exploded View ..................................................... ..125

Removal and Installation .......................................125

Replacement .........................................................126

Disassembly and Assembly ...................................127

FRONT FOG LAMP ........................................128

Exploded View .......................................................128

Removal and Installation .......................................128

Replacement .........................................................128

SIDE TURN SIGNAL LAMP ............................130

Exploded View .......................................................130

Removal and Installation .......................................130

OPTICAL SENSOR .........................................131

Exploded View .......................................................131

Removal and Installation .......................................131

LIGHTING & TURN SIGNAL SWITCH ...........132

Exploded View .......................................................132

Revision: 2010 May2011 QX56