ignition INFINITI QX56 2011 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 61 of 5598

ADP-52

< BASIC INSPECTION >

INSPECTION AND ADJUSTMENT

*1: Default value is 40 mm.

NOTE:

Notice that disconnecting the battery when detected DTC are present will erase the DTC memory.

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Special Repair Re-

quirement

INFOID:0000000006248327

1.SYSTEM INITIALIZATION

Perform system initialization. Refer to ADP-52, "

SYSTEM INITIALIZATION : Special Repair Requirement".

>> GO TO 2.

2.MEMORY STORAGE

Perform memory storage. Refer to ADP-53, "

MEMORY STORING : Special Repair Requirement".

>> GO TO 3.

3.INTELLIGENT KEY INTERLOCK STORAGE

Perform Intelligent Key interlock storage. Refer to ADP-54, "

INTELLIGENT KEY INTERLOCK STORING :

Special Repair Requirement".

>> GO TO 4.

4.SYSTEM SETTING

Perform system setting. Refer to ADP-55, "

SYSTEM SETTING : Special Repair Requirement".

>> END

SYSTEM INITIALIZATION

SYSTEM INITIALIZATION : DescriptionINFOID:0000000006248328

Always perform the initialization when the battery termi nal is disconnected or the driver seat control unit is

replaced.

The entry/exit assist function will not operate normally if no initialization is performed.

SYSTEM INITIALIZATION : Special Repair RequirementINFOID:0000000006248329

INITIALIZATION PROCEDURE

1. CHOOSE METHOD

There are two initialization methods.

Which method do you use?

With door switch>>GO TO 2.

With vehicle speed>>GO TO 4.

2. STEP A-1

Turn ignition switch from ACC to OFF position.

>> GO TO 3.

3. STEP A-2

Driver door switch is ON (open) → OFF (close) → ON (open).

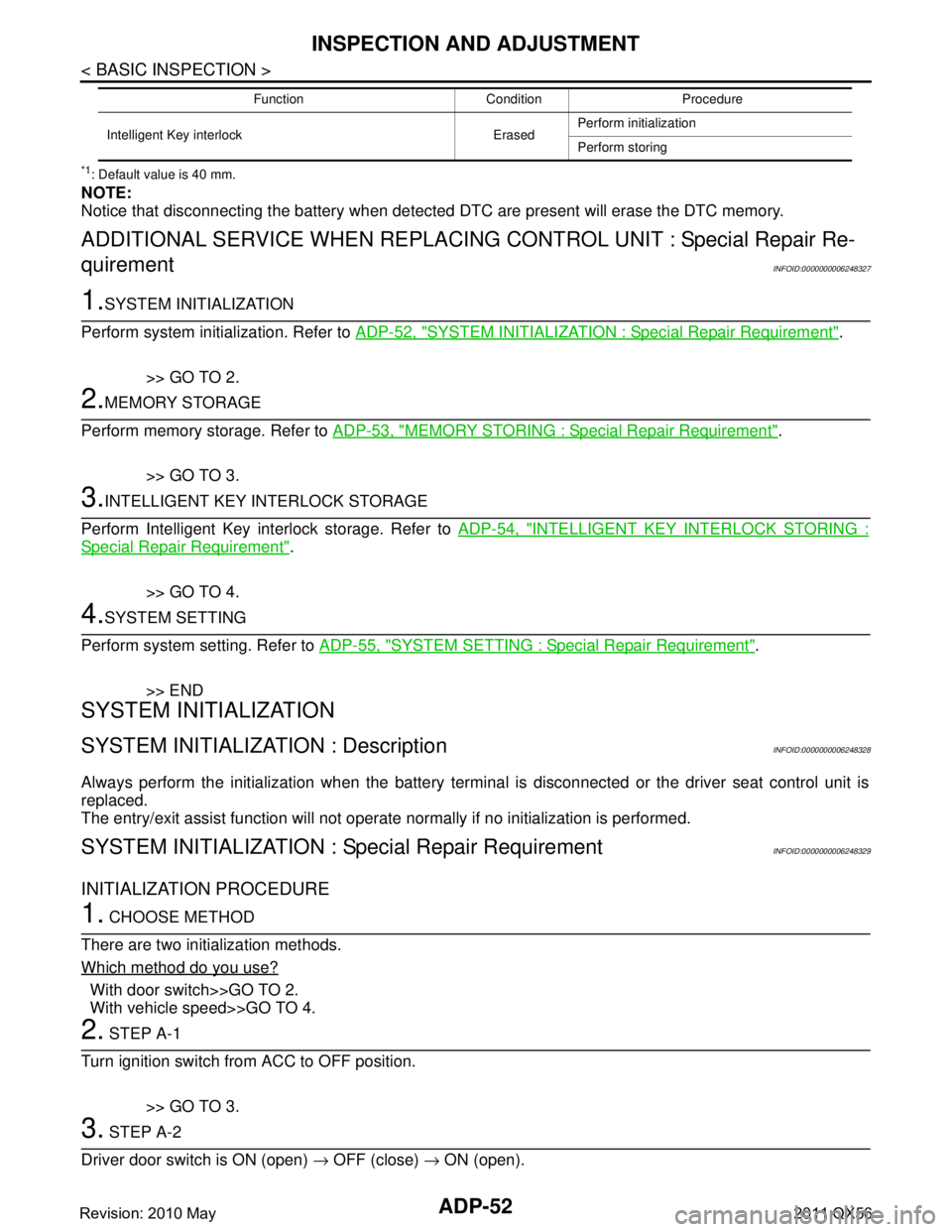

Intelligent Key interlock Erased Perform initialization

Perform storing

Function Condition Procedure

Revision: 2010 May2011 QX56

Page 63 of 5598

ADP-54

< BASIC INSPECTION >

INSPECTION AND ADJUSTMENT

INTELLIGENT KEY INTERLOCK STORING : Description

INFOID:0000000006248332

Always perform the Intelligent Key interlock function st orage when the battery terminal is disconnected or the

driver seat control unit is replaced. The Intelligent Key interlock function will not operate normally if no memory

storage is performed.

INTELLIGENT KEY INTERLOCK STORIN G : Special Repair RequirementINFOID:0000000006248333

Intelligent Key Interlock Storage Procedure

Performing the following operation associates the regist ered driving position with Intelligent Key. When driver

door unlock operation is performed by Intelligent Key or driver door request switch, display of the registered

driving position and turnout operation can be performed.

1.STEP 1

Check the following conditions.

Ignition switch: OFF

Initialization: done

Driving position: registered

>> GO TO 2.

2.STEP 2

1. Push set switch. NOTE:

Memory indicator for which driver seat position is already retained in memory is illuminated for 5 seconds.

2. Push the Intelligent Key unlock button within 5 seconds after pushing memory switch (while the memory indicator is turned ON).

NOTE:

From the time registration is performed, the app licable memory indicator blinks for 5 seconds.

>> GO TO 3.

3.STEP 3

Confirm the operation of each part with memory operation and Intelligent Key interlock operation.

>> END

SYSTEM SETTING

SYSTEM SETTING : DescriptionINFOID:0000000006248334

The settings of the automatic driv ing positioner system can be changed, us ing CONSULT-III, the display unit

in the center of the instrument panel and the set s witch. Always check the settings before and after discon-

necting the battery terminal or replacing driver seat control unit.

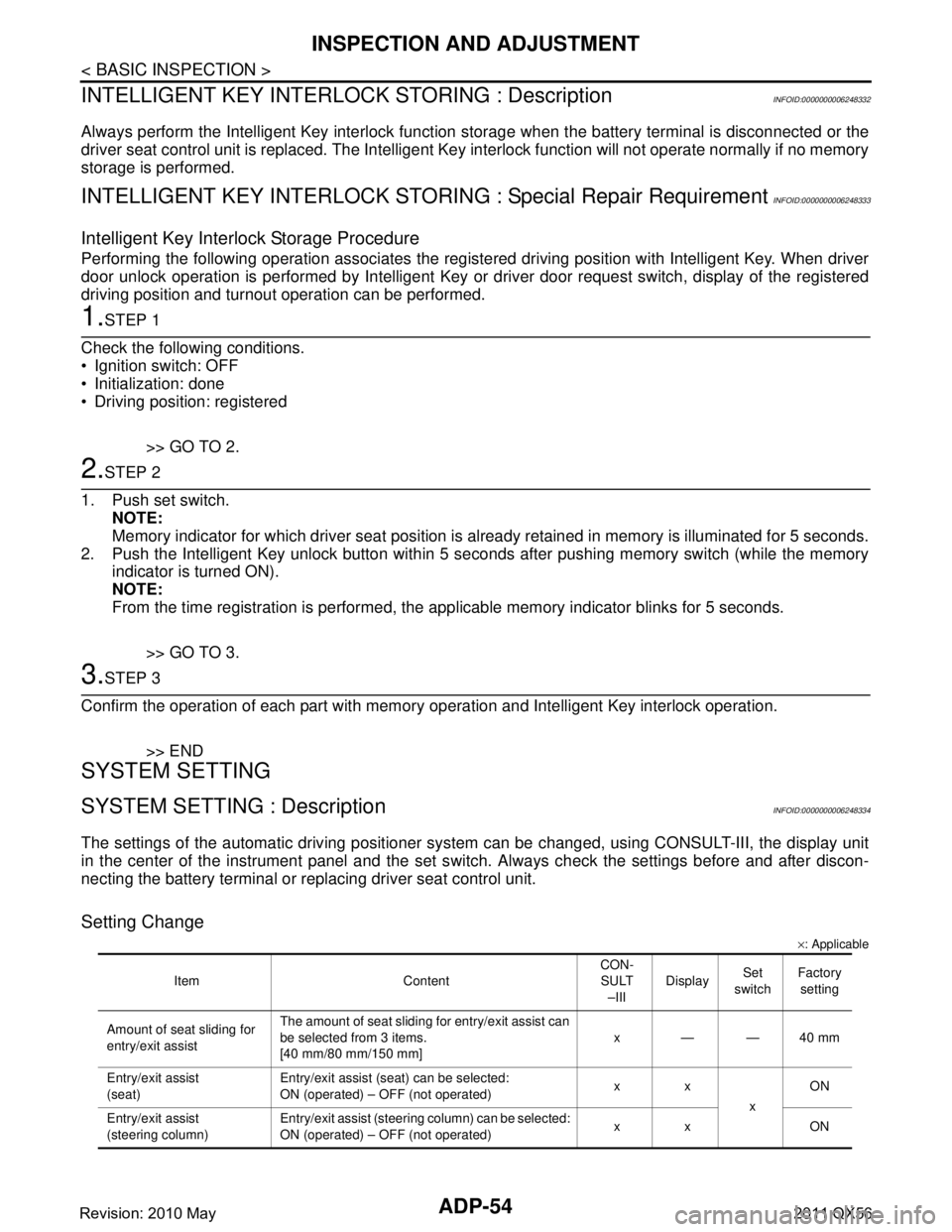

Setting Change

× : Applicable

Item Content CON-

SULT

–III Display

Set

switch Factory

setting

Amount of seat sliding for

entry/exit assist The amount of seat sliding for entry/exit assist can

be selected from 3 items.

[40 mm/80 mm/150 mm]

x——40 mm

Entry/exit assist

(seat) Entry/exit assist (seat) can be selected:

ON (operated) – OFF (not operated)

xx

xON

Entry/exit assist

(steering column) Entry/exit assist (steering column) can be selected:

ON (operated) – OFF (not operated)

xx ON

Revision: 2010 May2011 QX56

Page 64 of 5598

INSPECTION AND ADJUSTMENTADP-55

< BASIC INSPECTION >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

SYSTEM SETTING : Special Repair RequirementINFOID:0000000006248335

1. CHOOSE METHOD

There are three way of setting method.

Which method do you choose?

With CONSULT-III>>GO TO 2.

With set switch>>GO TO 4.

2. WITH CONSULT-III - STEP 1

Select “Work support”.

>> GO TO 3.

3. WITH CONSULT-III - STEP 2

1. Select “EXIT SEAT SLIDE SETTING”, or “EXIT TI LT SETTING” then touch display to change between ON

and OFF.

- EXIT SEAT SLIDE SETTING: Entry/exit assist (seat)

- EXIT TILT SETTING: Entry/exit assist (steering column)

2. Select “SEAT SLIDE VOLUME SET” and touch either of “40 mm”, “80 mm”, or “150 mm”.

3. Then touch “OK”.

>> END

4. WITH SET SWITCH - STEP 1

Turn ignition switch OFF.

>> GO TO 5.

5. WITH SET SWITCH - STEP 2

Push set switch and hold for more than 10 seconds, then confirm blinking of the memory switch indicator.

Entry/exit assist (seat/steering column) are ON : Memory switch indicator blink two times.

Entry/exit assist (seat/steering column) ar e OFF: Memory switch indicator blink once.

>> END

Revision: 2010 May2011 QX56

Page 65 of 5598

ADP-56

< DTC/CIRCUIT DIAGNOSIS >

U1000 CAN COMM CIRCUIT

DTC/CIRCUIT DIAGNOSIS

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000006248336

CAN (Controller Area Network) is a serial communication line for real time applications. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Modern

vehicle is equipped with many electronic control unit, and each control unit shares information and links with

other control units during operation (not independent). In CAN communication, control units are connected

with 2 communication lines (CAN H-line, CAN L-line) al lowing a high rate of information transmission with less

wiring. Each control unit transmits/receives data but selectively reads required data only.

DTC LogicINFOID:0000000006248337

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.STEP 1

Turn ignition switch ON and wait at least 3 seconds.

>> GO TO 2.

2.STEP 2

Check “Self diagnostic result” with CONSULT-III.

Is the DTC detected?

YES >> Perform diagnosis procedure. Refer to ADP-56, "DiagnosisProcedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006248338

Refer to LAN-18, "Trouble Diagnosis Flow Chart".

Special Repair RequirementINFOID:0000000006248339

Refer to ADP-52, "SYSTEM INITIALIZATION : Description".

DTC No. CONSULT-III display

description DTC detecting condition Possible cause

U1000 CAN COMM CIR-

CUIT Driver seat control unit cannot communicate to other

control units.

When driver seat control unit cannot communicate CAN communication signal continuously for 2 seconds or

more. CAN communication system

Revision: 2010 May2011 QX56

Page 67 of 5598

ADP-58

< DTC/CIRCUIT DIAGNOSIS >

B2112 SLIDING MOTOR

B2112 SLIDING MOTOR

DTC LogicINFOID:0000000006248342

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.STEP 1

Turn ignition switch ON.

>> GO TO 2.

2.STEP 2

Check “Self diagnostic result” with CONSULT-III.

Is the DTC detected?

YES >> Perform diagnosis procedure. Refer to ADP-58, "DiagnosisProcedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006248343

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Check “Self diagnostic result” with CONSULT-III.

3. Erase the DTC.

4. Perform DTC confirmation procedure. Refer to ADP-58, "

DTC Logic".

Is the DTC displayed again?

YES >> GO TO 2.

NO >> Check intermittent incident. Refer to GI-40, "

Intermittent Incident".

2.CHECK SLIDING MOTOR CIRCUIT (POWER SHORT)

1. Turn ignition switch OFF.

2. Disconnect sliding motor and driver seat control unit connector.

3. Check voltage between sliding motor harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace harness or connector.

3.CHECK DRIVER SEAT CONTROL UNIT OUTPUT SIGNAL

1. Connect driver seat control unit connector.

2. Check voltage between driver seat control unit harness connector and ground.

DTC No. Trouble diagnosis

name DTC detecting condition Possible cause

B2112 SEAT SLIDE The driver seat control unit detects the output of slid-

ing motor output terminal for 0.1 second or more

even if the sliding switch is not input. Driver seat control unit

Slide motor harness is shorted

(+)

(-)Voltage (V)

(Approx.)

Sliding motor

Connector Terminals

B461 34

Ground 0

38

Revision: 2010 May2011 QX56

Page 69 of 5598

ADP-60

< DTC/CIRCUIT DIAGNOSIS >

B2113 RECLINING MOTOR

B2113 RECLINING MOTOR

DTC LogicINFOID:0000000006248344

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.STEP 1

Turn ignition switch ON.

>> GO TO 2.

2.STEP 2

Check “Self diagnostic result” with CONSULT-III.

Is the DTC detected?

YES >> Perform diagnosis procedure. Refer to ADP-60, "DiagnosisProcedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006248345

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Check “Self diagnostic result” with CONSULT-III.

3. Erase the DTC.

4. Perform DTC confirmation procedure. Refer to ADP-60, "

DTC Logic".

Is the DTC displayed again?

YES >> GO TO 2.

NO >> Check intermittent incident. Refer to GI-40, "

Intermittent Incident".

2.CHECK RECLINING MOTOR CIRCUIT (POWER SHORT)

1. Turn ignition switch OFF.

2. Disconnect reclining motor and driver seat control unit connector.

3. Check voltage between reclining motor harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace harness or connector.

3.CHECK DRIVER SEAT CONTROL UNIT OUTPUT SIGNAL

1. Connect driver seat control unit connector.

2. Check voltage between driver seat control unit harness connector and ground.

DTC No. Trouble diagnosis

name DTC detecting condition Possible cause

B2113 SEAT RECLINING The driver seat control unit detects the output of re-

clining motor output terminal for 0.1 second or more

even if the reclining switch is not input. Driver seat control unit

Reclining motor harness is short-

ed

(+)

(-)Voltage (V)

(Approx.)

Reclining motor

Connector Terminals

B454 35

Ground 0

39

Revision: 2010 May2011 QX56

Page 71 of 5598

ADP-62

< DTC/CIRCUIT DIAGNOSIS >

B2116 TILT MOTOR

B2116 TILT MOTOR

DTC LogicINFOID:0000000006248346

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.STEP 1

Turn ignition switch ON.

>> GO TO 2.

2.STEP 2

Check “Self diagnostic result” with CONSULT-III.

Is the DTC detected?

YES >> Perform diagnosis procedure. Refer to ADP-62, "DiagnosisProcedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006248347

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Check “Self diagnostic result” with CONSULT-III.

3. Erase the DTC.

4. Perform DTC confirmation procedure. Refer to ADP-62, "

DTC Logic".

Is the DTC displayed again?

YES >> GO TO 2.

NO >> Check intermittent incident. Refer to GI-40, "

Intermittent Incident".

2.CHECK TILT MOTOR CIRCUIT (POWER SHORT)

1. Turn ignition switch OFF.

2. Disconnect automatic drive positioner control unit and tilt motor connector.

3. Check voltage between tilt motor harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace harness or connector.

3.CHECK AUTOMATIC DRIVER POSITION ER CONROL UNIT OUTPUT SIGNAL

1. Connect automatic drive positioner control unit connector.

2. Check voltage between automatic drive posit ioner control unit harness connector and ground.

DTC No.Trouble diagnosis

name DTC detecting condition Possible cause

B2116 STEERING TILT The automatic drive positioner control unit detects

the output of tilt motor output terminal for 0.1 second

or more even if the tilt switch is not input. Automatic drive positioner con-

trol unit

Tilt motor harn ess is shorted

(+)

(-)Voltage (V)

(Approx.)

Tilt motor

Connector Terminals

M116 1

Ground 0

2

Revision: 2010 May2011 QX56

Page 73 of 5598

ADP-64

< DTC/CIRCUIT DIAGNOSIS >

B2128 UART COMMUNICATION LINE

B2128 UART COMMUNICATION LINE

DescriptionINFOID:0000000006248348

Driver seat control unit performs UART communication with the automatic drive positioner control unit using 1

communication lines. Driver seat control unit receives t he operation signals of tilt & telescopic switch, door mir-

ror remote control switch, and the position signals of door mirror sensor from the automatic drive positioner

control unit and transmits the operation request signal.

DTC LogicINFOID:0000000006248349

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.STEP 1

Turn ignition switch ON.

>> GO TO 2.

2.PROCEDURE

Check “Self diagnostic result” with CONSULT-III.

Is the DTC detected?

YES >> Perform diagnosis procedure. Refer to ADP-64, "DiagnosisProcedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006248350

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Check “Self diagnostic result” with CONSULT-III.

3. Erase the DTC.

4. Perform DTC confirmation procedure. Refer to ADP-62, "

DTC Logic".

Is the DTC displayed again?

YES >> GO TO 2.

NO >> Check intermittent incident. Refer to GI-40, "

Intermittent Incident".

2.CHECK UART COMMUNICATION LINE CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect driver seat control unit and autom atic drive positioner control unit connector.

3. Check continuity between driver seat control uni t harness connector and automatic drive positioner con-

trol unit harness connector.

4. Check continuity between driver seat control unit harness connector and ground.

DTC No. Trouble diagnosis name DTC detecting condition Possible cause B2128 UART COMM The communication between driver seat control unit

and auto drive positioner control unit is interrupted for

a period of time. UART communication line

(UART communication line is

open or shorted)

Driver seat control unit

Automatic drive positioner

control unit

Driver seat control unit Automatic drive positioner control unit Continuity

Connector Terminal Connector Terminal

B452 2 M75 8 Existed

Revision: 2010 May2011 QX56

Page 75 of 5598

ADP-66

< DTC/CIRCUIT DIAGNOSIS >

B2130 EEPROM

B2130 EEPROM

DTC LogicINFOID:0000000006248351

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.STEP 1

Turn ignition switch ON.

>> GO TO 2.

2.STEP 2

Check “Self diagnostic result” with CONSULT-III.

Is the DTC detected?

YES >> Perform diagnosis procedure. Refer to ADP-66, "DiagnosisProcedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006248352

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Check “Self diagnostic result” with CONSULT-III.

3. Erase the DTC.

4. Perform DTC confirmation procedure. Refer to ADP-66, "

DTC Logic".

Is the DTC displayed again?

YES >> GO TO 2.

NO >> Check intermittent incident. Refer to GI-40, "

Intermittent Incident".

2.REPLACE DRIVER SEAT CONTROL UNIT

Replace driver seat control unit.

>> INSPECTION END

DTC No. Trouble diagnosis

name DTC detecting condition Possible cause

B2130 EEPROM Driver seat contro l unit detected CPU malfunction. Driver seat control unit

Revision: 2010 May2011 QX56

Page 76 of 5598

POWER SUPPLY AND GROUND CIRCUITADP-67

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

POWER SUPPLY AND GROUND CIRCUIT

DRIVER SEAT CONTROL UNIT

DRIVER SEAT CONTROL UNIT : Diagnosis ProcedureINFOID:0000000006248353

1.CHECK FUSE

Check that the following fuse and fusible link are not fusing.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace the blown fuse after repairing the affected circuit.

2.CHECK DRIVER SEAT CONTROL UNIT POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect driver seat control unit connector.

3. Check voltage between driver seat control unit harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace harness.

3.CHECK DRIVER SEAT CONTROL UNIT GROUND CIRCUIT

Check continuity between the driver s eat control unit harness connector and ground.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Repair or replace harness.

DRIVER SEAT CONTROL UNIT : Special Repair RequirementINFOID:0000000006248354

1.PERFORM ADDITIONAL SERVICE

Perform additional service when removing battery negative terminal.

>> Refer to ADP-51, "

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMI-

NAL : Description".

AUTOMATIC DRIVE POSITIONER CONTROL UNIT

AUTOMATIC DRIVE POSITIONER CO NTROL UNIT : Diagnosis Procedure

INFOID:0000000006248355

NOTE:

Do not disconnect the battery negative terminal and the dr iver seat control unit connector until DTC is con-

firmed with CONSULT-III.

1.CHECK FUSE

Check that the following fuse and fusible link are not fusing.

Signal name Fuse No.

Battery power supply K (50 A)

(+) (-)Voltage (V)

(Approx.)

Driver seat control unit

Connector Terminals B451 33 Ground Battery voltage

Driver seat control unit GroundContinuity

Connector Terminal

B451 43 Existed

Revision: 2010 May2011 QX56