door INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2892 of 5598

DOOR SASH COVEREXT-37

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

EXT

N

O P

DOOR SASH COVER

Exploded ViewINFOID:0000000006367623

Removal and InstallationINFOID:0000000006367624

FRONT DOOR SASH COVER

Removal

1. Remove front door sash cover fixing clips.

1. Front door sash cover 2. Rear door sash cover 3. Double sided tape [1.2 mm (0.047) in]

4. Double sided tape [2.0 mm (0.079) in] 5. Double sided tape

[1.6 mm (0.063) in] 6. EPT seal

[1.6 mm (0.063) in]

: Clip

: Vehicle front

Refer to GI-4, "

Components" for symbols in the figure.

JMKIA5312ZZ

Revision: 2010 May2011 QX56

Page 2893 of 5598

EXT-38

< REMOVAL AND INSTALLATION >

DOOR SASH COVER

2. Insert a remover tool (A) between front door sash cover (1) anddoor panel, cut double-sided tape using a cutter (B) while lifting

front door sash cover, and remove front door sash cover.

CAUTION:

Use a remover tool which is made of a material that doesnot damage door panel.

Never lift front door sash cover with excessive force.

Installation

Note the following items, and then install in the reverse order of removal.

CAUTION:

When installing, slid e and install front door sash cover (2)

from door rear side, so that front door outside molding (1) is

not deformed.

Replace double-sided tape on back of front door sash cover with a new double-sided adhesive tape

if front door sash cover is reused.

Replace EPT sealer of front door sash cover with a new EPT sealer if front door sash cover is

reused.

Remove double-sided adhesive ta pe remaining on body and back of front door sash cover using

double-sided adhesive tape remover wh en removing front door sash molding.

Install after cleaning adhesive parts of doo r side and back of front door sash cover.

To secure contact, do not wash vehicle within 24 hours after installation.

REAR DOOR SASH COVER

Removal

1. Remove rear door sash cover fixing clips.

2. Insert a remover tool (A) between rear door sash cover (1) and

door panel, cut double-sided tape using a cutter (B) while lifting

rear door sash cover, and remove rear door sash cover.

CAUTION:

Never use an item as a remover tool that could damagedoor panel.

Never lift rear door sash cover with excessive force.

Installation

Note the following items, and install in the reverse order of removal.

CAUTION:

JMKIA2034ZZ

JMKIA5005ZZ

JMKIA2034ZZ

Revision: 2010 May2011 QX56

Page 2894 of 5598

DOOR SASH COVEREXT-39

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

EXT

N

O P

When installing, slide and inst all rear door sash cover (2) from

door front, so that rear door outside molding (1) is not

deformed.

Replace double-sided adhesive tape on back of r ear door sash cover with a new double-sided adhe-

sive tape if rear door sash cover is reused.

Replace EPT sealer of rear door sash cover with a new EPT sealer if rear door sash cover is reused.

Remove double-sided adhesive tape remaining on bo dy and back of rear door sash cover using dou-

ble-sided adhesive tape remover when removing rear door sash cover.

Install after cleaning adhesive parts of d oor side and back of rear door sash cover.

To secure contact, do not wash vehicle within 24 hours after installation.

JMKIA5007ZZ

Revision: 2010 May2011 QX56

Page 2896 of 5598

REAR SPOILEREXT-41

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

EXT

N

O P

REAR SPOILER

Exploded ViewINFOID:0000000006367627

Removal and InstallationINFOID:0000000006367628

REMOVAL

1. Remove back door trim. Refer to INT-39, "Removal and Installation".

2. Remove rear spoiler mounting nuts.

3. Cut rear spoiler fixing double-sided tape with cutter knife.

4. Disengage rear spoiler fixing clips with remover tool (A), and then remove rear spoiler.

CAUTION:

Apply a protective tape (B) on body panel and rear spoiler

to protect the painted surface from damage.

1. Rear spoiler assembly 2. Grommet 3. High-mounted stop lamp

4. High-mounted stop lamp cover 5. Washer nozzle 6. EPT sealer [t: 5.0 mm (0.197 in)]

7. Double-sided tape

[t: 1.6 mm (0.063 in)] 8. EPT sealer [t: 4.0 mm (0.157 in)]

: Clip

: Vehicle front

Refer to GI-4, "

Components" for symbols in the figure.

JMKIA5322ZZ

: Clip

JMKIA5383ZZ

Revision: 2010 May2011 QX56

Page 2897 of 5598

EXT-42

< REMOVAL AND INSTALLATION >

REAR SPOILER

5. Remove following parts after removing rear spoiler. High-mounted stop lamp

Grommets

Washer nozzle

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

Be careful no to damage the back door.

Always replace double-sided tape with a new one, if rear spoiler is reused.

Remove double-sided tape remain ing on back door panel and back of rear spoiler with a double-

sided tape remover, after removing rear spoiler.

When installing, visually check the rear spoiler and the clips, then replace them with new parts if

they are damaged.

When installing rear spoiler, check that clips an d bolts are securely fitted in back door panel holes,

and then press them in.

Never wash the vehicle within 24 hours af ter installing so as to keep adhesive.

Revision: 2010 May2011 QX56

Page 2899 of 5598

EXT-44

< REMOVAL AND INSTALLATION >

BACK DOOR FINISHER

BACK DOOR FINISHER

Exploded ViewINFOID:0000000006367631

Removal and InstallationINFOID:0000000006367632

REMOVAL

Back Door Finisher Center Upper

1. Remove back door trim. Refer to INT-39, "Removal and Installation".

2. Disconnect rear view camera and back door opener switch harness connectors.

3. Remove back door finisher center upper mounting nuts.

4. Disengage fixing clips, and then remove back door finisher center upper.

5. Remove following parts after removing back door finisher center upper mounting nuts. Rear view camera

Back door opener switch

License lamp

Back Door Finisher Center Lower

1. Remove back door trim. Refer to INT-39, "Removal and Installation".

2. Remove back door finisher center lower mounting nuts.

3. Disengage fixing clips, and then remove back door finisher center lower.

INSTALLATION

Install in the reverse order of removal.

1. Grommet 2. Back door finisher center lower 3. Rear view camera

4. Back door opener request switch 5. Back door finisher center upper

JMKIA5466ZZ

Revision: 2010 May2011 QX56

Page 2975 of 5598

HOW TO READ WIRING DIAGRAMSGI-11

< HOW TO USE THIS MANUAL >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

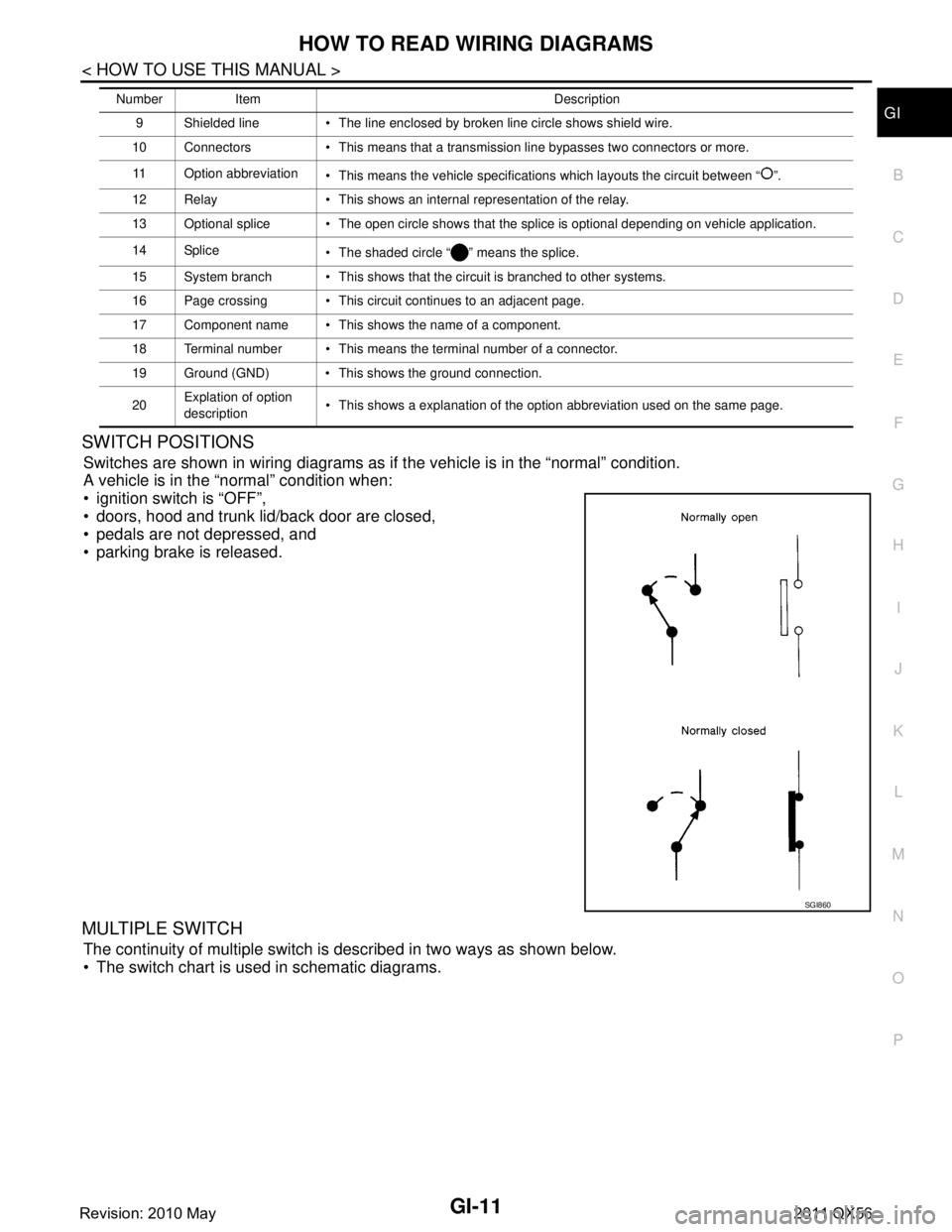

SWITCH POSITIONS

Switches are shown in wiring diagrams as if the vehicle is in the “normal” condition.

A vehicle is in the “normal” condition when:

ignition switch is “OFF”,

doors, hood and trunk lid/back door are closed,

pedals are not depressed, and

parking brake is released.

MULTIPLE SWITCH

The continuity of multiple switch is described in two ways as shown below.

The switch chart is used in schematic diagrams.

9 Shielded line The line enclosed by broken line circle shows shield wire.

10 Connectors This means that a transmission line bypasses two connectors or more.

11 Option abbreviation This means the vehicle specifications which layouts the circuit between “ ”.

12 Relay This shows an internal representation of the relay.

13 Optional splice The open circle shows that the splice is optional depending on vehicle application.

14 Splice The shaded circle “ ” means the splice.

15 System branch This shows that the circuit is branched to other systems.

16 Page crossing This circuit continues to an adjacent page.

17 Component name This shows the name of a component.

18 Terminal number This means the terminal number of a connector.

19 Ground (GND) This shows the ground connection.

20 Explation of option

description This shows a explanation of the option abbreviation used on the same page.

Number Item Description

SGI860

Revision: 2010 May2011 QX56

Page 3012 of 5598

GI-48

< BASIC INSPECTION >

CONSULT-III/GST CHECKING SYSTEM

CONSULT-III/GST CHECKING SYSTEM

DescriptionINFOID:0000000006280856

When CONSULT-III/GST is connected with a data link connector

(A) equipped on the vehicle side, it will communicate with the con-

trol unit equipped in the vehicle and then enable various kinds of

diagnostic tests.

Refer to “CONSULT-III Software Operation Manual” for more infor- mation.

CONSULT-III Function a nd System Application*1INFOID:0000000006280857

1 : Instrument lower panel LH

JPAIA0769ZZ

Diagnostic test

mode Function

ENGINE

TRANSMISSION AIR BAG

METER/M&A

AUTO BACK DOOR BCM

AUTO DRIVE POS. ABS

IPDM E/R

ALL MODE AWD/4WD MULTI AV

ICC/ADAS SONAR

AIR PRESSURE MONITOR AFS (ADAPTIVE LIGHT)

PRECRASH SEAT BELT HVAC

LASER

LANE CAMERA

ACCELE PEDAL ACT

E–SUS

SIDE RADAR LEFT

SIDE RADAR RIGHT CAN GATEWAY

Work Support This mode

enables a

technician to

adjust some

devices fast-

er and more

accurately.xx - - - xxx - xxxxxx - xxx - xxx -

Self Diagnostic

Results Retrieve DTC

from ECU

and display

diagnostic

items.

xxxxxxxxxxxxxxxxxxxxxxxx

Data Monitor Monitor the

input/output

signal of the

control unit in

real time.xx - xxxxxxxxxxxxxxxxxxxx -

CAN Diagnosis This mode

displays a

network diag-

nosis result

about CAN

by a diagram.xxxxxxxxxxxx -xxxxxxxxxxx

CAN Diagnosis

Support Moni-

tor It monitors

the status of

CAN commu-

nication.

xx - xxxxxxxxx -xxxxxxxxxxx

Revision: 2010 May2011 QX56

Page 3013 of 5598

CONSULT-III/GST CHECKING SYSTEMGI-49

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

x: Applicable

*1: If GST application is equipped , functions in accordance with SAE J1 979 and ISO 15031-5 can be used.

Active Test

Send the

drive signal

from CON-

SULT-III to

the actuator.

The opera-

tion check

can be per-

formed.x - - - - xxxx - - xxxx - x - - xxxx -

DTC & SRT

confirmation The status of

system moni-

toring tests

and the self-

diagnosis

status/result

can be con-

firmed.

xx----------------------

ECU Identifica-

tion Display the

ECU identifi-

cation num-

ber (part

number etc.)

of the select-

ed system.

xxx - xxxxxxxxxxxxxxxxxxxx

Function Test This mode

can show re-

sults of self-

diagnosis of

ECU with ei-

ther “OK” or

“NG”. For en-

gine, more

practical

tests regard-

ing sensors/

switches and/

or actuators

are available.xxx----x----------------

Configuration Function to

READ/

WRITE vehi-

cle configura-

tion.-----x----x------------x

Special

Function Other results

or histories,

etc. that are

recorded in

ECU are dis-

played.

-xxx--------------------

Diagnostic test

mode Function

ENGINE

TRANSMISSION AIR BAG

METER/M&A

AUTO BACK DOOR

BCM

AUTO DRIVE POS. ABS

IPDM E/R

ALL MODE AWD/4WD

MULTI AV

ICC/ADAS SONAR

AIR PRESSURE MONITOR AFS (ADAPTIVE LIGHT)

PRECRASH SEAT BELT HVAC

LASER

LANE CAMERA

ACCELE PEDAL ACT E–SUS

SIDE RADAR LEFT

SIDE RADAR RIGHT CAN GATEWAY

Revision: 2010 May2011 QX56

Page 3029 of 5598

INSPECTION AND ADJUSTMENTGI-65

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

M B

GI

N

O PINSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL : Re-

quired Procedure After Battery Disconnection

INFOID:0000000006344676

*: Not equipped. SYSTEM ITEM REFERENCE

Front automatic air

conditioning system Temperature setting trimmer (Front)

HAC-68, "

FRONT AUTOMATIC

AIR CONDITIONING SYSTEM :

Temperature Setting Trimmer

(Front)"

Foot position setting trimmer

HAC-68, "

FRONT AUTOMATIC

AIR CONDITIONING SYSTEM :

Foot Position Setting Trimmer"

Inlet port memory function* —

Inlet port memory function (FRE)

HAC-69, "

FRONT AUTOMATIC

AIR CONDITIONING SYSTEM :

Inlet Port Memory

Function (FRE)"

Inlet port memory function (REC) HAC-69, "

FRONT AUTOMATIC

AIR CONDITIONING SYSTEM :

Inlet Port Memory Function (REC)"

ACCS (Advanced Cli-

mate Control System)Exhaust gas / outside odor detecting sensor sensitivity adjustment func-

tion

HAC-70, "

ACCS (ADVANCED

CLIMATE CONTROL SYSTEM) :

Exhaust Gas / Outside Odor De-

tecting Sensor Sensitivity Adjust-

ment Function"

Auto intake switch interlocking movement change function

HAC-70, "

ACCS (ADVANCED

CLIMATE CONTROL SYSTEM) :

Auto Intake Switch Interlocking

Movement Change Function"

Clean switch interlocking movement change function* —

Rear automatic air

conditioning system Temperature setting trimmer (Rear) HAC-69, "

REAR AUTOMATIC AIR

CONDITIONING SYSTEM : Tem-

perature Setting

Trimmer (Rear)"

Automatic drive posi-

tioner Automatic drive positioner system ADP-51, "

ADDITIONAL SERVICE

WHEN REMOVING BATTERY

NEGATIVE TERMINAL : Descrip-

tion"

Power window control Power window control system

PWC-31, "Description"

Sunroof system* Sunroof system —

Sunshade system* Sunshade system —

Rear view monitor* Rear view monitor predictive course line center position adjustment —

Around view monitor Predictive course line center position adjustment AV- 111 , "

Description"

Automatic back door

systemAutomatic back door system DLK-80, "

ADDITIONAL SERVICE

WHEN REMOVING BATTERY

NEGATIVE TERMINAL : Descrip-

tion"

Engine oil level read* Engine oil level read —

Revision: 2010 May2011 QX56