service INFINITI QX56 2011 Factory Owner's Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 455 of 5598

BCS

INSPECTION AND ADJUSTMENTBCS-67

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

B A

O P

N

BASIC INSPECTION

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN RE

PLACING CONTROL UNIT (BCM)

ADDITIONAL SERVICE WHEN REPLACIN G CONTROL UNIT (BCM) : Description

INFOID:0000000006324908

BEFORE REPLACEMENT

When replacing BCM, save or print current vehicle specification with CONSULT-III configuration before

replacement.

NOTE:

If “READ CONFIGURATION” can not be used, use the “WRITE CONFIGURATION - Manual selection” after

replacing BCM.

AFTER REPLACEMENT

CAUTION:

When replacing BCM, you must perform “W RITE CONFIGURATION” with CONSULT-III.

- Complete the procedure of “WRITE CONFIGURATION” in order.

- If you set incorrect “WRITE CONF IGURATION”, incidents might occur.

- Configuration is different for each vehicle model. Confirm conf iguration of each vehicle model.

When replacing BCM, perform the system initialization (NATS).

ADDITIONAL SERVICE WHEN REPLACIN G CONTROL UNIT (BCM) : Work Proce-

dure

INFOID:0000000006324909

1.SAVING VEHICLE SPECIFICATION

CONSULT-III Configuration

Perform “READ CONFIGURATION” to save or prin t current vehicle specification. Refer to BCS-67, "

CONFIG-

URATION (BCM) : Description".

NOTE:

If “READ CONFIGURATION” can not be used, use the “WRITE CONFIGURATION - Manual selection” after

replacing BCM.

>> GO TO 2.

2.REPLACE BCM

Replace BCM. Refer to BCS-81, "

Removal and Installation".

>> GO TO 3.

3.WRITING VEHICLE SPECIFICATION

CONSULT-III Configuration

Perform “WRITE CONFIGURATION - Config file” or “W RITE CONFIGURATION - Manual selection” to write

vehicle specification. Refer to BCS-68, "

CONFIGURATION (BCM) : Work Procedure".

>> GO TO 4.

4.INITIALIZE BCM (NATS)

Perform BCM initialization. (NATS)

>> WORK END

CONFIGURATION (BCM)

CONFIGURATION (BCM) : DescriptionINFOID:0000000006324910

Vehicle specification needs to be written with CONSULT- III because it is not written after replacing BCM.

Revision: 2010 May2011 QX56

Page 469 of 5598

BCS

BCM

BCS-81

< REMOVAL AND INSTALLATION >

C

D E

F

G H

I

J

K L

B A

O P

N

REMOVAL AND INSTALLATION

BCM

Removal and InstallationINFOID:0000000006274845

CAUTION:

Before replacing BCM, perform “READ CONFIGURAT

ION” to save or print current vehicle specifica-

tion. Refer to BCS-67, "

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT (BCM) : Descrip-

tion".

REMOVAL

1. Remove combination meter. Refer to MWI-85, "Removal and Installation".

2. Remove bolts.

3. Remove BCM and disconnect the connectors.

INSTALLATION

Install in the reverse order of removal.

CAUTION:

Be sure to perform “WRITE CO NFIGURATION” when replacing BCM.

Be sure to perform the system initializa tion (IVIS) when replacing BCM. Refer to BCS-67, "

ADDI-

TIONAL SERVICE WHEN REPLACING CO NTROL UNIT (BCM) : Work Procedure".

Revision: 2010 May2011 QX56

Page 471 of 5598

BR-1

BRAKES

C

DE

G H

I

J

K L

M

SECTION BR

A

B

BR

N

O P

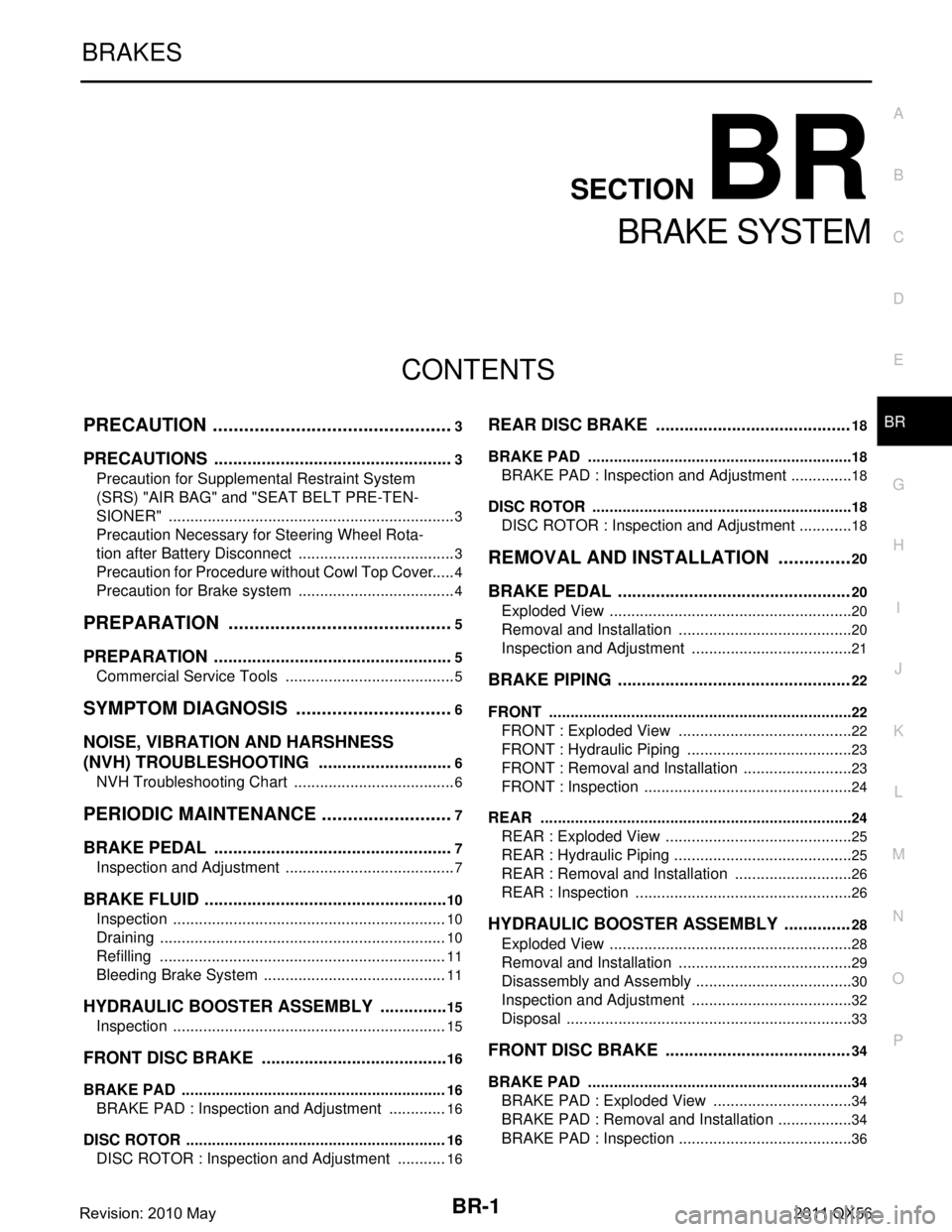

CONTENTS

BRAKE SYSTEM

PRECAUTION ................ ...............................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

3

Precaution for Procedure without Cowl Top Cover ......4

Precaution for Brake system .....................................4

PREPARATION ............................................5

PREPARATION .............................................. .....5

Commercial Service Tools .................................. ......5

SYMPTOM DIAGNOSIS ...............................6

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ .....

6

NVH Troubleshooting Chart ................................ ......6

PERIODIC MAINTENANCE ..........................7

BRAKE PEDAL .............................................. .....7

Inspection and Adjustment .................................. ......7

BRAKE FLUID ....................................................10

Inspection ............................................................ ....10

Draining ...................................................................10

Refilling ...................................................................11

Bleeding Brake System ...........................................11

HYDRAULIC BOOSTER ASSEMBLY ...............15

Inspection ............................................................ ....15

FRONT DISC BRAKE .................................... ....16

BRAKE PAD .......................................................... ....16

BRAKE PAD : Inspection and Adjustment ..............16

DISC ROTOR ......................................................... ....16

DISC ROTOR : Inspection and Adjustment ............16

REAR DISC BRAKE .........................................18

BRAKE PAD .......................................................... ....18

BRAKE PAD : Inspection and Adjustment ...............18

DISC ROTOR ......................................................... ....18

DISC ROTOR : Inspection and Adjustment .............18

REMOVAL AND INSTALLATION ...............20

BRAKE PEDAL ................................ .................20

Exploded View ..................................................... ....20

Removal and Installation .........................................20

Inspection and Adjustment ......................................21

BRAKE PIPING ................................ .................22

FRONT ................................................................... ....22

FRONT : Exploded View .........................................22

FRONT : Hydraulic Piping .......................................23

FRONT : Removal and Installation ..........................23

FRONT : Inspection .................................................24

REAR ..................................................................... ....24

REAR : Exploded View ............................................25

REAR : Hydraulic Piping ..........................................25

REAR : Removal and Installation ............................26

REAR : Inspection ...................................................26

HYDRAULIC BOOSTER ASSEMBLY ..............28

Exploded View .........................................................28

Removal and Installation .........................................29

Disassembly and Assembly .....................................30

Inspection and Adjustment ......................................32

Disposal ...................................................................33

FRONT DISC BRAKE .......................................34

BRAKE PAD .......................................................... ....34

BRAKE PAD : Exploded View .................................34

BRAKE PAD : Removal and Installation ..................34

BRAKE PAD : Inspection . ........................................36

Revision: 2010 May2011 QX56

Page 472 of 5598

BR-2

BRAKE CALIPER ASSEMBLY ................................36

BRAKE CALIPER ASSEMBLY : Exploded View ....36

BRAKE CALIPER ASSEMBLY : Removal and In-

stallation .................................................................

37

BRAKE CALIPER ASSEMBLY : Disassembly and

Assembly ................................................................

38

BRAKE CALIPER ASSEMBLY : Inspection ...........39

REAR DISC BRAKE ..........................................41

BRAKE PAD .......................................................... ...41

BRAKE PAD : Exploded View ................................41

BRAKE PAD : Removal and Installation .................41

BRAKE PAD : Inspection ........................................42

BRAKE CALIPER ASSEMBLY ............................. ...42

BRAKE CALIPER ASSEMBLY : Exploded View ....42

BRAKE CALIPER ASSEMBLY : Removal and In-

stallation ............................................................... ...

43

BRAKE CALIPER ASSEMBLY : Disassembly and

Assembly ................................................................

44

BRAKE CALIPER ASSEMBLY : Inspection ............45

SERVICE DATA AND SPECIFICATIONS

(SDS) .......... ................................................

47

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ...

47

General Specification ........................................... ...47

Brake Pedal ............................................................47

Brake Booster .........................................................47

Front Disc Brake .....................................................47

Rear Disc Brake ......................................................47

Revision: 2010 May2011 QX56

Page 473 of 5598

PRECAUTIONSBR-3

< PRECAUTION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006228171

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision that would result in air ba g inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the

ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wh eel Rotation after Battery Disconnect

INFOID:0000000006228172

NOTE:

Before removing and installing any control units, first tu rn the push-button ignition switch to the LOCK posi-

tion, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnos is according to self-diagnosis results.

For vehicle with steering lock unit, if the battery is disconnected or discharged, the steering wheel will lock and

cannot be turned.

If turning the steering wheel is required with the batte ry disconnected or discharged, follow the operation pro-

cedure below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position. (At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock wil l remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

Revision: 2010 May2011 QX56

Page 475 of 5598

PREPARATIONBR-5

< PREPARATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

PREPARATION

PREPARATION

Commercial Service ToolsINFOID:0000000006222460

Tool name Description

Power tool Loosening bolts and nuts

Pin punch

a: 4 mm (0.16 in) Removing and installing reservoir tank

Brake caliper wrench Return the piston

PBIC0190E

NT410

NNFIA0040ZZ

Revision: 2010 May2011 QX56

Page 501 of 5598

HYDRAULIC BOOSTER ASSEMBLYBR-31

< REMOVAL AND INSTALLATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

2. Remove the reservoir tank mounting pin with a pin punch (com- mercial service tool).

3. Remove bolt and remove the reservoir tank and grommets from the ABS actuator and electric unit (control unit).

CAUTION:

Never drop the removed parts. The parts must not be

reused if they are dropped.

4. Slide the clamp and remove brake hose assembly.

5. Remove the brake tube with a flare nut wrench. CAUTION:

Never scratch the flare nut and the brake tube.

6. Remove the cap with a suitable tool (A).

7. Remove grommets and screws ( ) and remove motor/accumu- lator assembly harness.

8. Cut harness band. CAUTION:

Never damage the harness.

9. Remove motor/accumulator assembly from ABS actuator and electric unit (control unit).

10. Remove bushings and collars from motor/accumulator assem- bly.

11. Remove brackets and bushing fr om ABS actuator and electric

unit (control unit).

12. Remove pin mount.

13. After replacing motor/accumulator assembly, always follow the accumulator disposal procedure to discard the motor/accumulator assembly. Refer to BR-33, "

Disposal".

ASSEMBLY

Note the following, and assembly in the reverse order of disassembly.

Never use mineral oils such as kerosene or gasoline and rubber grease during the cleaning and assembly

process.

Never drop the removed parts when installing. The parts must not be reused if they are dropped.

Never allow foreign matter (e.g. dust) and oils ot her than brake fluid to enter the reservoir tank.

For non reusable parts, refer to BR-28, "

Exploded View".

When connecting motor/accumulator assembly harness, check the order of harness colors.

Temporarily tighten the brake tube flare nut to the motor/accumula- tor assembly and ABS actuator and electric unit (control unit) by

hand. Then tighten it to the specified torque with a crowfoot and

torque wrench.

CAUTION:

Never scratch the flare nut and the brake tube.

JPFIA0750ZZ

JPFIA0752ZZ

JPFIA0751ZZ

A: Black

B: Red

JPFIA0753ZZ

Revision: 2010 May2011 QX56

Page 517 of 5598

SERVICE DATA AND SPECIFICATIONS (SDS)

BR-47

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D E

G H

I

J

K L

M A

B

BR

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000006222502

Unit: mm (in)

Brake PedalINFOID:0000000006222503

Unit: mm (in)

Brake BoosterINFOID:0000000006222504

Unit: mm (in)

Front Disc BrakeINFOID:0000000006222505

Unit: mm (in)

Rear Disc BrakeINFOID:0000000006222506

Unit: mm (in)

Front brake Cylinder bore diameter 50.8 (2.000)

× 2

Pad length × width × thickness 151.6 (5.97) × 56.5 (2.224) × 12.0 (0.472)

Rotor outer diameter × thickness 350 (13.78) × 30.0 (1.181)

Rear brake Cylinder bore diameter 48.1 (10894)

Pad length

× width × thickness 110.0 (4.43) × 41.0 (1.614) × 9.0 (0.354)

Rotor outer diameter × thickness 350 (13.78) × 20.0 (0.787)

Control valve Valve type Electric brake force distribution

Recommended brake fluid Refer to MA-10, "

Fluids and Lubricants".

Item Standard

Brake pedal height 168.5 (6.63) – 178.5 (7.03)

Depressed brake pedal height

[Depressing 490 N (50 kg, 110 lb) while turning the engine ON] 100 (3.94) or more

Clearance between stop lamp switch and brake switch threaded end and the

brake pedal bracket 0.2 (0.008) – 1.96 (0.0772)

Brake pedal play 3 (0.12) – 11 (0.43)

Item Standard

Input rod length 202.2 (7.96)

Item Limit

Brake pad Wear thickness 1.5 (0.059)

Disc rotor Wear thickness 28.5 (1.122)

Thickness variation (measured at 8 positions) 0.015 (0.0006)

Runout (with it attached to the vehicle) 0.053 (0.0021)

Item Limit

Brake pad Wear thickness 2.0 (0.079)

Disc rotor Wear thickness 18.0 (0.709)

Thickness variation (measured at 8 positions) 0.015 (0.0006)

Runout (with it attached to the vehicle) 0.05 (0.0020)

Revision: 2010 May2011 QX56

Page 518 of 5598

BRC-1

BRAKES

C

DE

G H

I

J

K L

M

SECTION BRC

A

B

BRC

N

O P

CONTENTS

BRAKE CONTROL SYSTEM

WITH VDC

PRECAUTION ................ ...............................

5

PRECAUTIONS .............................................. .....5

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

5

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

5

Precaution for Procedure without Cowl Top Cover ......6

Precaution for Brake System ....................................6

Precaution for Brake Control System ........................6

Precaution for Harness Repair ..................................7

PREPARATION ............................................9

PREPARATION .............................................. .....9

Commercial Service Tools .................................. ......9

SYSTEM DESCRIPTION .............................10

COMPONENT PARTS ................................... ....10

Component Parts Location .................................. ....10

Component Description ...........................................13

ABS Actuator and Electric Unit (Control Unit) .........14

Wheel Sensor and Sensor Rotor ............................14

Stop Lamp Switch ...................................................15

Steering Angle Sensor ............................................15

Yaw Rate/Side/Decel G sensor ...............................15

Brake Fluid Level Switch .........................................15

Parking Brake Switch ..............................................15

VDC OFF Switch .....................................................15

SYSTEM .............................................................16

System Description ............................................. ....16

Fail-safe ..................................................................25

Protection Function .................................................28

VDC FUNCTION .................................................... ....28

VDC FUNCTION : System Description ...................28

TCS FUNCTION ..................................................... ....31

TCS FUNCTION : System Description ....................31

ABS FUNCTION .................................................... ....32

ABS FUNCTION : System Description ....................33

EBD FUNCTION .................................................... ....34

EBD FUNCTION : System Description ....................34

HILL START ASSIST FUNCTION ......................... ....36

hill start assist FUNCTION : System Description ....36

BRAKE LIMITED SLIP DIFFERENTIAL (BLSD)

FUNCTION ............................................................. ....

37

BRAKE LIMITED SLIP DIFFERENTIAL (BLSD)

FUNCTION : System Description ............................

37

DIAGNOSIS SYSTEM [ABS ACTUATOR

AND ELECTRIC UNIT (CONTROL UNIT)] .......

40

CONSULT-III Function ............................................40

ECU DIAGNOSIS INFORMATION ..............45

ABS ACTUATOR AND ELECTRIC UNIT

(CONTROL UNIT) .............................................

45

Reference Value .................................................. ....45

Fail-safe ...................................................................47

Protection Function ..................................................50

DTC Inspection Priority Chart ..................................50

DTC Index ...............................................................51

WIRING DIAGRAM ......................................53

BRAKE CONTROL SYSTEM ...........................53

Wiring Diagram .................................................... ....53

BASIC INSPECTION ...................................60

DIAGNOSIS AND REPAIR WORK FLOW .......60

Work Flow ............................................................ ....60

Diagnostic Work Sheet ............................................61

Revision: 2010 May2011 QX56

Page 519 of 5598

BRC-2

ADDITIONAL SERVICE WHEN REPLACING

ABS ACTUATOR AND ELECTRIC UNIT

(CONTROL UNIT) ..............................................

63

Description ........................................................... ...63

ADJUSTMENT OF STEERING ANGLE SEN-

SOR NEUTRAL POSITION ...............................

64

Description ........................................................... ...64

Work Procedure ......................................................64

CALIBRATION OF DECEL G SENSOR ...........66

Description ........................................................... ...66

Work Procedure ......................................................66

DTC/CIRCUIT DIAGNOSIS ...................... ...68

C1101, C1102, C1103, C1104 WHEEL SEN-

SOR ................................................................. ...

68

DTC Logic ............................................................ ...68

Diagnosis Procedure ..............................................68

C1105, C1106, C1107, C1108 WHEEL SEN-

SOR ....................................................................

70

DTC Logic ............................................................ ...70

Diagnosis Procedure ..............................................70

C1109 POWER AND GROUND SYSTEM .........72

Description ........................................................... ...72

DTC Logic ...............................................................72

Diagnosis Procedure ..............................................72

C1111 PUMP MOTOR .......................................75

DTC Logic ............................................................ ...75

Diagnosis Procedure ..............................................75

C1115 WHEEL SENSOR ...................................77

DTC Logic ............................................................ ...77

Diagnosis Procedure ..............................................77

C1116 STOP LAMP SWITCH ............................79

DTC Logic ............................................................ ...79

Diagnosis Procedure ..............................................79

Component Inspection (Stop lamp Switch) ............85

Component Inspection (Stop Lamp Relay) .............86

C1118 TRANSFER CONTROL UNIT ................87

DTC Logic ............................................................ ...87

Diagnosis Procedure ..............................................87

C1120, C1122, C1124, C1126 ABS IN VALVE

SYSTEM .......................................................... ...

88

DTC Logic ............................................................ ...88

Diagnosis Procedure ..............................................88

C1121, C1123, C1125, C1127 ABS OUT

VALVE SYSTEM ................................................

90

DTC Logic ............................................................ ...90

Diagnosis Procedure ..............................................90

C1130 ENGINE SIGNAL ...................................92

DTC Logic ............................................................ ...92

Diagnosis Procedure ............................................ ...92

C1140 ACTUATOR RELAY SYSTEM ..............93

DTC Logic ............................................................ ...93

Diagnosis Procedure ...............................................93

C1142 PRESS SENSOR ...................................95

DTC Logic ............................................................ ...95

Diagnosis Procedure ...............................................95

C1143 STEERING ANGLE SENSOR ...............97

DTC Logic ............................................................ ...97

Diagnosis Procedure ...............................................97

C1144 INCOMPLETE STEERING ANGLE

SENSOR ADJUSTMENT ..................................

99

DTC Logic ............................................................ ...99

Diagnosis Procedure ...............................................99

C1145, C1146 YAW RATE/SIDE/DECEL G

SENSOR ...........................................................

100

DTC Logic ............................................................ .100

Diagnosis Procedure .............................................100

C1155 BRAKE FLUID LEVEL SWITCH ..........103

DTC Logic ............................................................ .103

Diagnosis Procedure .............................................103

Component Inspection ..........................................104

C1160 DECEL G SEN SET ..............................105

DTC Logic ............................................................ .105

Diagnosis Procedure .............................................105

C1164, C1165 CV SYSTEM .............................106

DTC Logic ............................................................ .106

Diagnosis Procedure .............................................106

C1166, C1167 SV SYSTEM .............................108

DTC Logic ............................................................ .108

Diagnosis Procedure .............................................108

C1170 VARIANT CODING ...............................110

DTC Logic ............................................................ .110

Diagnosis Procedure .............................................110

C118E ACCUMULATOR ..................................111

DTC Logic ............................................................ .111

Diagnosis Procedure .............................................111

U1000 CAN COMM CIRCUIT ...........................112

Description ........................................................... .112

DTC Logic .............................................................112

Diagnosis Procedure .............................................112

POWER SUPPLY AND GROUND CIRCUIT ....113

Description ........................................................... .113

Diagnosis Procedure .............................................113

PARKING BRAKE SWITCH .............................117

Component Function Check ................................ .117

Diagnosis Procedure .............................................117

Component Inspection ..........................................118

Revision: 2010 May2011 QX56