service INFINITI QX56 2011 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 520 of 5598

BRC-3

C

DE

G H

I

J

K L

M A

B

BRC

N

O P

VDC OFF SWITCH ......................................... ..119

Component Function Check ................................ ..119

Diagnosis Procedure .............................................119

Component Inspection ..........................................120

ABS WARNING LAMP ................................... ..122

Component Function Check ................................ ..122

Diagnosis Procedure .............................................122

BRAKE WARNING LAMP ...............................123

Component Function Check ................................ ..123

Diagnosis Procedure .............................................123

VDC WARNING LAMP .....................................125

Component Function Check ................................ ..125

Diagnosis Procedure .............................................125

VDC OFF INDICATOR LAMP ..........................126

Component Function Check ................................ ..126

Diagnosis Procedure .............................................126

SYMPTOM DIAGNOSIS ............................127

EXCESSIVE OPERATION FREQUENCY ...... ..127

Description .......................................................... ..127

Diagnosis Procedure .............................................127

UNEXPECTED BRAKE PEDAL REACTION ...128

Description .......................................................... ..128

Diagnosis Procedure .............................................128

THE BRAKING DISTANCE IS LONG ..............129

Description .......................................................... ..129

Diagnosis Procedure .............................................129

DOES NOT OPERATE .....................................130

Description .......................................................... ..130

Diagnosis Procedure .............................................130

BRAKE PEDAL VIBRATION OR OPERA-

TION SOUND OCCURS ...................................

131

Description .......................................................... ..131

Diagnosis Procedure .............................................131

VEHICLE JERKS DURING ..............................132

Description .......................................................... ..132

Diagnosis Procedure .............................................132

NORMAL OPERATING CONDITION ...............133

Description .......................................................... ..133

REMOVAL AND INSTALLATION .............134

WHEEL SENSOR ........................................... ..134

FRONT WHEEL SENSOR ..................................... ..134

FRONT WHEEL SENSOR : Exploded View .........134

FRONT WHEEL SENSOR : Removal and Instal-

lation ......................................................................

134

REAR WHEEL SENSOR ....................................... ..135

REAR WHEEL SENSOR : Exploded View ...........135

REAR WHEEL SENSOR : Removal and Installa-

tion ....................................................................... ..

135

SENSOR ROTOR ............................................136

FRONT SENSOR ROTOR ..................................... ..136

FRONT SENSOR ROTOR : Removal and Instal-

lation ......................................................................

136

REAR SENSOR ROTOR ....................................... ..136

REAR SENSOR ROTOR : Removal and Installa-

tion .........................................................................

136

ABS ACTUATOR AND ELECTRIC UNIT

(CONTROL UNIT) ...........................................

137

Removal and Installation .......................................137

YAW RATE/SIDE/DECEL G SENSOR ...........138

Exploded View .......................................................138

Removal and Installation .......................................138

STEERING ANGLE SENSOR .........................139

Removal and Installation .......................................139

VDC OFF SWITCH ..........................................140

Removal and Installation .......................................140

BRAKE ASSIST (WITH PREVIEW FUNC-

TION)

PRECAUTION ............... .............................

141

PRECAUTIONS ...............................................141

Precautions for Preview Function Service ........... ..141

SYSTEM DESCRIPTION ...........................142

COMPONENT PARTS ....................................142

Component Parts Location .................................. ..142

Component Description .........................................143

SYSTEM ..........................................................145

BRAKE ASSIST (WITH PREVIEW FUNCTION) ... ..145

BRAKE ASSIST (WITH PREVIEW FUNCTION) :

System Description ................................................

145

DTC/CIRCUIT DIAGNOSIS .......................146

BRAKE ASSIST (WITH PREVIEW FUNC-

TION) ...............................................................

146

Diagnosis Procedure ........................................... ..146

SYMPTOM DIAGNOSIS ............................147

NORMAL OPERATING CONDITION .............147

Description ........................................................... ..147

INTELLIGENT BRAKE ASSIST

PRECAUTION ............... .............................

148

PRECAUTIONS ...............................................148

Precautions for IBA System Service .................... ..148

Revision: 2010 May2011 QX56

Page 522 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

PRECAUTIONSBRC-5

< PRECAUTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID INFINITI QX56 2011 Factory Workshop Manual

PRECAUTIONSBRC-5

< PRECAUTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID](/img/42/57033/w960_57033-521.png)

PRECAUTIONSBRC-5

< PRECAUTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006228174

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision that would result in air ba g inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the

ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wh eel Rotation after Battery Disconnect

INFOID:0000000006228175

NOTE:

Before removing and installing any control units, first tu rn the push-button ignition switch to the LOCK posi-

tion, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnos is according to self-diagnosis results.

For vehicle with steering lock unit, if the battery is disconnected or discharged, the steering wheel will lock and

cannot be turned.

If turning the steering wheel is required with the batte ry disconnected or discharged, follow the operation pro-

cedure below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position. (At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock wil l remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

Revision: 2010 May2011 QX56

Page 526 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

PREPARATIONBRC-9

< PREPARATION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PREPARATION

PREPARATION

Commercial Service ToolsINFOID:0000000006222681

Tool name Description

Power tool Loosening bolts INFINITI QX56 2011 Factory Workshop Manual

PREPARATIONBRC-9

< PREPARATION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PREPARATION

PREPARATION

Commercial Service ToolsINFOID:0000000006222681

Tool name Description

Power tool Loosening bolts](/img/42/57033/w960_57033-525.png)

PREPARATIONBRC-9

< PREPARATION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PREPARATION

PREPARATION

Commercial Service ToolsINFOID:0000000006222681

Tool name Description

Power tool Loosening bolts and nuts

PBIC0190E

Revision: 2010 May2011 QX56

Page 580 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

ADDITIONAL SERVICE WHEN REPLACING ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

BRC-63

< BASIC INSPECTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

ADDITIONAL SERVICE WHEN REPL ACING ABS ACTUATO INFINITI QX56 2011 Factory Workshop Manual

ADDITIONAL SERVICE WHEN REPLACING ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

BRC-63

< BASIC INSPECTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

ADDITIONAL SERVICE WHEN REPL ACING ABS ACTUATO](/img/42/57033/w960_57033-579.png)

ADDITIONAL SERVICE WHEN REPLACING ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

BRC-63

< BASIC INSPECTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

ADDITIONAL SERVICE WHEN REPL ACING ABS ACTUATOR AND ELEC-

TRIC UNIT (CONTROL UNIT)

DescriptionINFOID:0000000006222587

When replaced the ABS actuator and electric unit (contro l unit), perform decel G sensor calibration. Refer to

BRC-66, "

Work Procedure".

Revision: 2010 May2011 QX56

Page 658 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

PRECAUTIONSBRC-141

< PRECAUTION > [BRAKE ASSIST (WITH PREVIEW FUNCTION)]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PRECAUTION

PRECAUTIONS

Precautions for Preview Function ServiceINFOID:0000000006228290

CAUTI INFINITI QX56 2011 Factory Workshop Manual

PRECAUTIONSBRC-141

< PRECAUTION > [BRAKE ASSIST (WITH PREVIEW FUNCTION)]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PRECAUTION

PRECAUTIONS

Precautions for Preview Function ServiceINFOID:0000000006228290

CAUTI](/img/42/57033/w960_57033-657.png)

PRECAUTIONSBRC-141

< PRECAUTION > [BRAKE ASSIST (WITH PREVIEW FUNCTION)]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PRECAUTION

PRECAUTIONS

Precautions for Preview Function ServiceINFOID:0000000006228290

CAUTION:

Never look straight into th e laser beam discharger when adjusting laser beam aiming.

Never use the ICC sensor removed from vehicle. Never disassemble or remodel.

Erase DTC when replacing parts of ICC system. The n check the operation of ICC system after adjust-

ing laser beam aiming if necessary.

Revision: 2010 May2011 QX56

Page 665 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

BRC-148

< PRECAUTION >[INTELLIGENT BRAKE ASSIST]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precautions for IBA System ServiceINFOID:0000000006228296

CAUTION:

Never look straight into the laser beam

disch INFINITI QX56 2011 Factory Workshop Manual

BRC-148

< PRECAUTION >[INTELLIGENT BRAKE ASSIST]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precautions for IBA System ServiceINFOID:0000000006228296

CAUTION:

Never look straight into the laser beam

disch](/img/42/57033/w960_57033-664.png)

BRC-148

< PRECAUTION >[INTELLIGENT BRAKE ASSIST]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precautions for IBA System ServiceINFOID:0000000006228296

CAUTION:

Never look straight into the laser beam

discharger when adjusting laser beam aiming.

Never use the ICC sensor removed from vehicle. Never disassemble or remodel.

Erase DTC when replacing parts of ICC system. Then check the operation of ICC system after adjust-

ing laser beam aiming if necessary.

Never change IBA system state ON/OFF without the consent of the customer.

NOTE:

IBA system automatically returns to ON, when erasing self-diagnosis result of “ICC/ADAS” with CONSULT-III.

Revision: 2010 May2011 QX56

Page 676 of 5598

BRM-1

BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITY

C

D

E

F

G H

I

J

L

M

SECTION BRM

A

B

BRM

N

O P

CONTENTS

BODY REPAIR

VEHICLE INFORMATION ... ..........................2

BODY EXTERIOR PAINT COLOR ................ .....2

Body Exterior Paint Color ................................. ......2

PRECAUTION ...............................................4

REPAIRING HIGH STRENGTH STEEL ......... .....4

High Strength Steel (HSS) ................................ ......4

Handling of Ultra High Strength Steel Plate Parts ......6

PREPARATION ............................................7

REPAIRING MATERIAL ................................ .....7

Foam Repair ....................................................... ......7

BODY COMPONENT PARTS .............................9

Underbody Component Parts ............................ ......9

Body Component Parts ...........................................11

Frame Component Parts .........................................13

REMOVAL AND INSTALLATION ...............15

CORROSION PROTECTION ......................... ....15

Description .......................................................... ....15

Anti-corrosive Wax ..................................................15

Undercoating ...........................................................16

Stone Guard Coat ...................................................17

Body Sealing ...........................................................18

BODY CONSTRUCTION ....................................22

Body Construction ............................................... ....22

REPLACEMENT OPERATIONS .......................24

Description ...............................................................24

Radiator Core Support .............................................26

Hoodledge ...............................................................26

Hoodledge (Partial Replacement) ...........................27

Front Pillar ...............................................................29

Center Pillar .............................................................32

Outer Sill .................................................................35

Rear Fender ............................................................39

Rear Fender Extension ............................................42

Rear Panel and Rear End Crossmember ................42

Rear Floor Rear .....................................................45

Crush Horn ..............................................................46

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .............................................

48

BODY ALIGNMENT ..........................................48

Body Center Marks ............................................ ....48

Description ...............................................................48

Engine Compartment ..............................................49

Underbody ...............................................................52

Passenger Compartment .........................................54

Rear Body ...............................................................56

LOCATION OF PLASTIC PARTS ....................58

Precautions for Plastics ...........................................58

Location of Plastic Parts ..........................................59

Revision: 2010 May2011 QX56

Page 682 of 5598

REPAIRING MATERIALBRM-7

< PREPARATION >

C

DE

F

G H

I

J

L

M A

B

BRM

N

O P

PREPARATION

REPAIRING MATERIAL

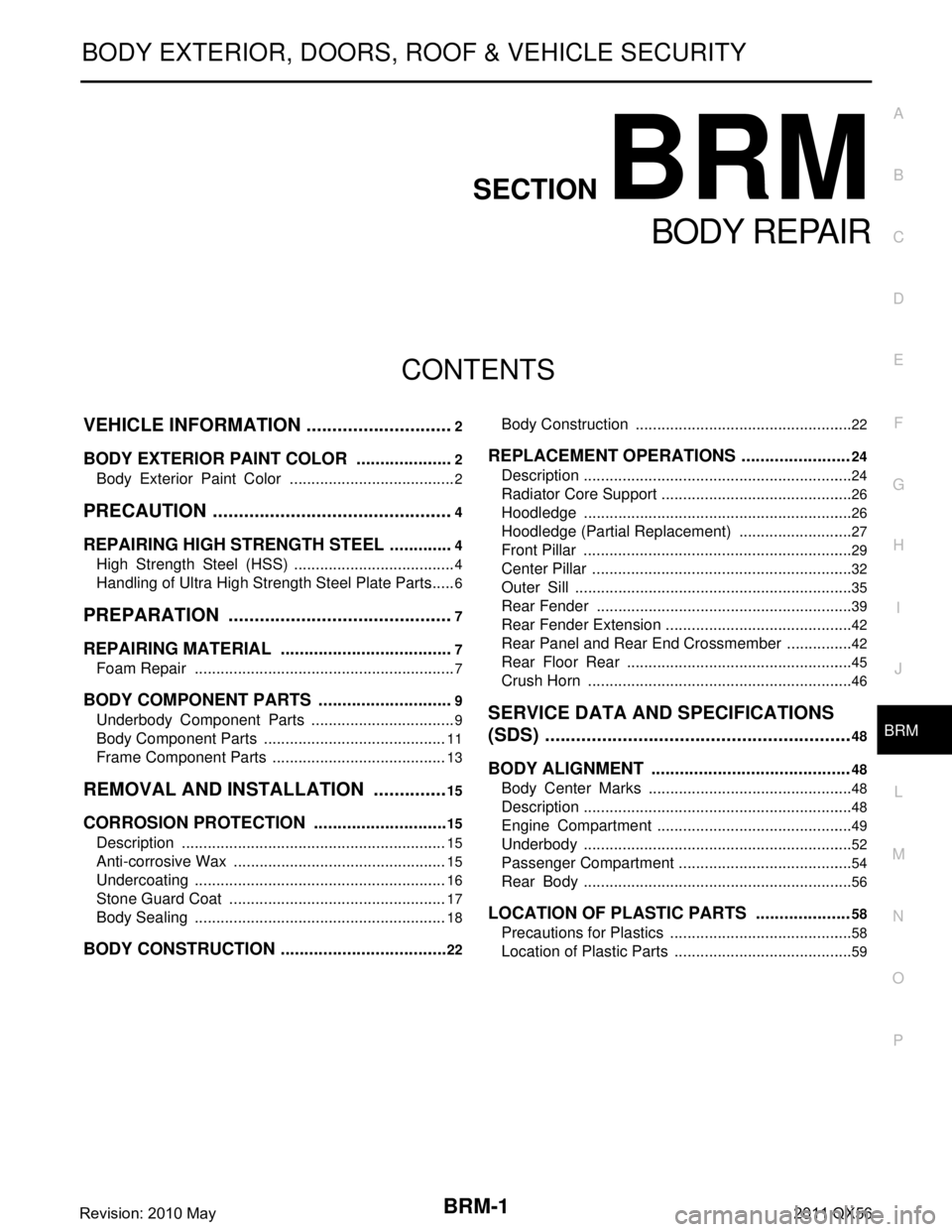

Foam RepairINFOID:0000000006248486

During factory body assembly, foam insulators are installed in certain body panels and locations around the

vehicle. Use the following procedure(s) to r eplace any factory-installed foam insulators.

URETHANE FOAM APPLICATIONS

Use commercially available Urethane foam for sealant (foam material) repair of material used on vehicle.

Read instructions on product for fill procedures.

Example of foaming agent filling operation procedure

1. Fill procedures after installation of service part.

a. Eliminate foam material remaining on vehicle side.

b. Clean area after eliminating form insulator and foam material.

c. Install service part.

d. Insert nozzle into hole near fill area and fill foam ma terial or fill enough to close gap with the service part.

2. Fill procedures before installation of service part.

a. Eliminate foam material remaining on vehicle side.

b. Clean area after eliminating foam insulator and foam material.

c. Fill foam material on wheelhouse outer side.

Automix™ Flexible Foam 08463 or equiva-

lent

1. Urethane foam

A. Nozzle insert hole

: Vehicle front

JSKIA0129GB

Revision: 2010 May2011 QX56

Page 683 of 5598

BRM-8

< PREPARATION >

REPAIRING MATERIAL

NOTE:

Fill enough to close gap with service part while avoiding flange

area.

d. Install service part. NOTE:

Refer to label for information on working times.

1. Urethane foam

A. Fill while avoiding flange area

: Vehicle front

JSKIA0130GB

Revision: 2010 May2011 QX56

Page 700 of 5598

REPLACEMENT OPERATIONSBRM-25

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

BRM

N

O P

Front pillar butt joint can be determined anywhere within shaded area as shown in the figure. The best location for the butt joint is at

position A due to the construction of the vehicle.

Determine cutting position and record distance from the locating indent. Use this distance when cutting the service part. Cut outer

front pillar over 60 mm (2.36 in) above the inner front pillar cut

position.

Prepare a cutting jig to make outer pillar easier to cut. Also, this will permit the service part to be accurately cut at the joint position.

An example of cutting operation using a cutting jig is as per the fol- lowing.

1. Mark cutting lines.

A: Cut position of outer pillar

B: Cut position of inner pillar

2. Align cutting line with notch on jig. Clamp jig to pillar.

3. Cut outer pillar along groove of jig (at position A).

4. Remove jig and cut remaining portions.

5. Cut inner pillar at position B in same manner.

PIIA0150E

JSKIA0104GB

JSKIA0105GB

PIIA0153E

Revision: 2010 May2011 QX56