service INFINITI QX56 2011 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 732 of 5598

BODY ALIGNMENTBRM-57

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

DE

F

G H

I

J

L

M A

B

BRM

N

O P

Unit: mm (in)

: Vehicle front

Point Material Point Material

A Roof indent of center positioning mark D, d Rear center crossmember joggle

B, b Upper back pillar main joggle E, e Rear end crossmember hole center φ13 (0.51)

C, c Upper back pillar main hole center φ7 (0.28)

JSKIA1903ZZ

Revision: 2010 May2011 QX56

Page 733 of 5598

BRM-58

< SERVICE DATA AND SPECIFICATIONS (SDS)

LOCATION OF PLASTIC PARTS

LOCATION OF PLASTIC PARTS

Precautions for PlasticsINFOID:0000000006248513

CAUTION:

When repairing and painting a portion of the body adjacent to plastic parts, consider their characteristics (influence of heatand solvent) and remove them if necessary or take suitable measures to protect them.

Plastic parts should be repaired and painted using methods suiting the materials

, characteristics.

Abbre-

viation Material name Heat resisting

temperature °C ( °F) Resistance to gasoline and

solvents Other cautions

PE Polyethylene 60 (140) Gasoline and most solvents are

harmless if applied for a very

short time (wipe out quickly).Flammable

ABS Acrylonitrile Butadiene Styrene 80 (176) Avoid gasoline and solvents. —

EPM/

EPDM Ethylene Propylene (Diene) co-

polymer

80 (176)Gasoline and most solvents are

harmless if applied for a very

short time (wipe out quickly). Flammable

PS Polystyrene 80 (176) Avoid solvents. Flammable

PVC Poly Vinyl Chloride 80 (176) Gasoline and most solvents are

harmless if applied for a very

short time (wipe out quickly).Poisonous gas is emitted

when burned.

TPO Thermoplastic Olefine 80 (176) ↑Flammable

AAS Acrylonitrile Acrylic Styrene 85 (185) Avoid gasoline and solvents. —

PMMA Poly Methyl Methacrylate 85 (185) ↑—

EVAC Ethylene Vinyl Acetate 90 (194) ↑—

PP Polypropylene 90 (194) Gasoline and most solvents are

harmless if applied for a very

short time (wipe out quickly).Flammable, avoid bat-

tery acid.

PUR Polyurethane 90 (194) Avoid gasoline and solvents. —

UP Unsaturated Polyester 90 (194) ↑Flammable

ASA Acrylonitrile Styrene Acrylate 100 (212) ↑Flammable

PPE Poly Phenylene Ether 110 (230) ↑—

TPU Thermoplastic Urethane 110 (230) ↑—

PBT+

PC Poly Butylene Terephthalate +

Polycarbonate

120 (248)

↑Flammable

PC Polycarbonate 120 (248) ↑—

POM Poly Oxymethylene 120 (248) ↑Avoid battery acid.

PA Polyamide 140 (284) ↑Avoid immersing in wa-

ter.

PBT Poly Butylene Terephthalate 140 (284) ↑—

PAR Polyarylate 180 (356) ↑—

PET Polyethylene terephthalate 180 (356) ↑—

PEI Polyetherimide 200 (392) ↑—

Revision: 2010 May2011 QX56

Page 734 of 5598

LOCATION OF PLASTIC PARTSBRM-59

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

DE

F

G H

I

J

L

M A

B

BRM

N

O P

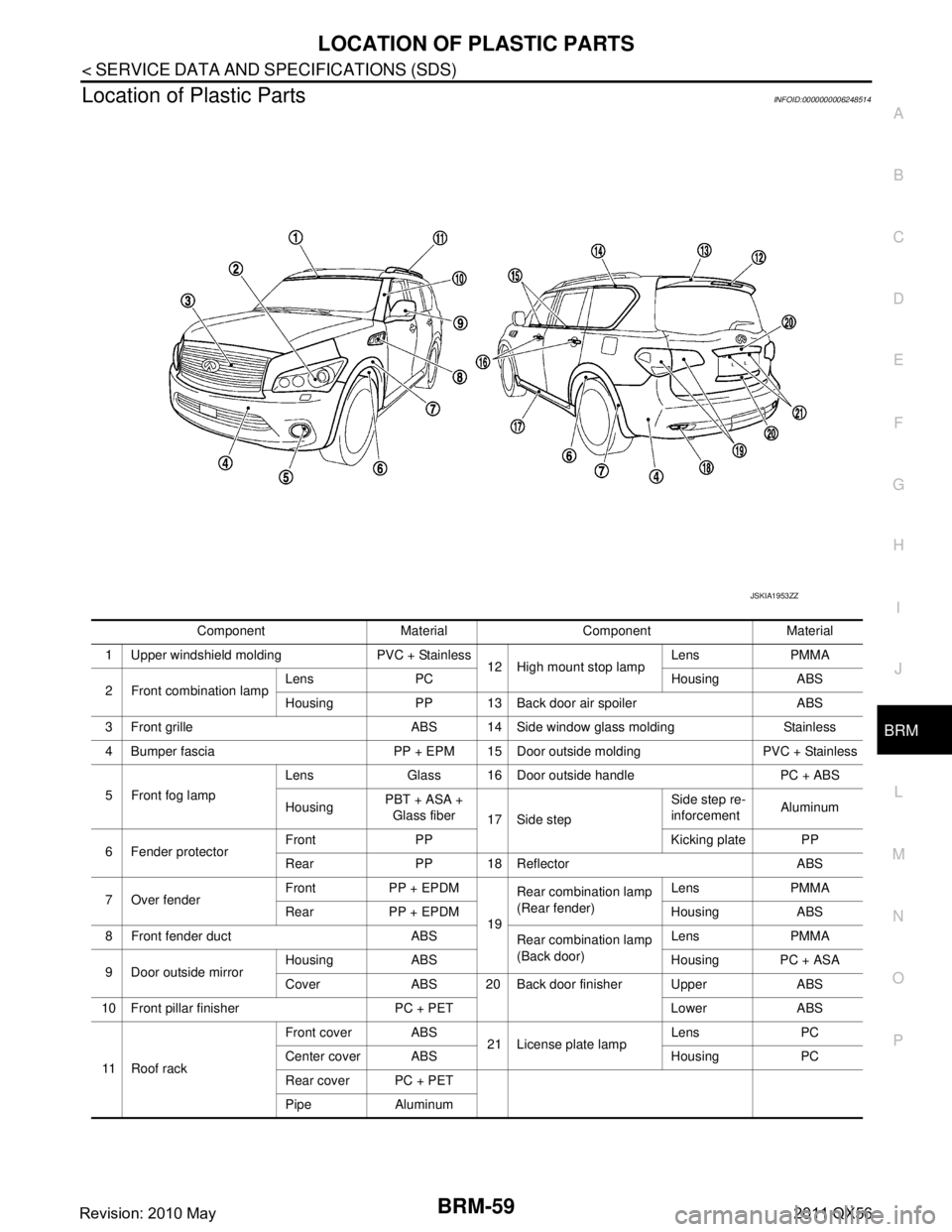

Location of Plastic PartsINFOID:0000000006248514

Component Material Component Material

1 Upper windshield molding PVC + Stainless 12 High mount stop lampLens PMMA

2 Front combination lamp Lens PC Housing ABS

Housing PP 13 Back door air spoiler ABS

3 Front grille ABS 14 Side window glass molding Stainless

4 Bumper fascia PP + EPM 15 Door outside molding PVC + Stainless

5 Front fog lamp Lens Glass 16 Door outside handle PC + ABS

Housing

PBT + ASA +

Glass fiber 17 Side step Side step re-

inforcement

Aluminum

6 Fender protector Front PP Kicking plate PP

Rear PP 18 Reflector ABS

7 Over fender Front PP + EPDM

19Rear combination lamp

(Rear fender)

Lens PMMA

Rear PP + EPDM Housing ABS

8 Front fender duct ABS Rear combination lamp

(Back door)Lens PMMA

9 Door outside mirror Housing ABS Housing PC + ASA

Cover ABS 20 Back door finisher Upper ABS

10 Front pillar finisher PC + PET Lower ABS

11 R o o f r a c k Front cover ABS

21 License plate lampLens PC

Center cover ABS Housing PC

Rear cover PC + PET

Pipe Aluminum

JSKIA1953ZZ

Revision: 2010 May2011 QX56

Page 735 of 5598

BRM-60

< SERVICE DATA AND SPECIFICATIONS (SDS)

LOCATION OF PLASTIC PARTS

Component Material Component Material

1Map lamp Lens PC 7 Center console PP

Housing PP 8 Glove box PP

2 Front pillar garnish PP 9 Instrument panelCore PP

3 Center pillar garnish PP Skin TPU

4Personal lamp Lens PC 10 Cluster lid C PC + ABS

Housing PP 11 Cluster lid D PC + ABS

5 Rear pillar finisher PP 12 Cluster lid A ABS

6 Back pillar garnish PP

JSKIA1905ZZ

Revision: 2010 May2011 QX56

Page 736 of 5598

CCS-1

CRUISE CONTROL & DRIVER ASSISTANCE

C

DE

F

G H

I

J

K L

M B

CCS

SECTION CCS

N

P A

CONTENTS

CRUISE CONTROL SYSTEM

ICC

PRECAUTION ................ ...............................

6

PRECAUTIONS .............................................. .....6

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

6

Precautions For Harness Repair ...............................6

ICC System Service ..................................................7

PREPARATION ............................................8

PREPARATION .............................................. .....8

Special Service Tools .......................................... ......8

SYSTEM DESCRIPTION ..............................9

COMPONENT PARTS ................................... .....9

Component Parts Location .................................. ......9

Component Description ...........................................10

SYSTEM .............................................................12

System Description ............................................. ....12

Fail-safe (ADAS Control Unit) .................................15

Fail-safe (ICC Sensor) ............................................15

VEHICLE-TO-VEHICLE DISTANCE CONTROL

MODE FUNCTION ................................................. ....

15

VEHICLE-TO-VEHICLE DISTANCE CONTROL

MODE FUNCTION : System Description ................

15

CONVENTIONAL (FIXED SPEED) CRUISE CON-

TROL MODE FUNCTION ...................................... ....

18

CONVENTIONAL (FIXED SPEED) CRUISE

CONTROL MODE FUNCTION : System Descrip-

tion ...................................................................... ....

18

OPERATION .......................................................21

VEHICLE-TO-VEHICLE DISTANCE CONTROL

MODE FUNCTION ................................................. ....

21

VEHICLE-TO-VEHICLE DISTANCE CONTROL

MODE FUNCTION : Switch Name and Function ....

21

VEHICLE-TO-VEHICLE DISTANCE CONTROL

MODE FUNCTION : Menu Displayed by Pressing

Each Switch .............................................................

21

CONVENTIONAL (FIXED SPEED) CRUISE CON-

TROL MODE FUNCTION ...................................... ....

25

CONVENTIONAL (FIXED SPEED) CRUISE

CONTROL MODE FUNCTION : Switch Name and

Function ...................................................................

25

CONVENTIONAL (FIXED SPEED) CRUISE

CONTROL MODE FUNCTION : Menu Displayed

by Pressing Each Switch .........................................

25

HANDLING PRECAUTION ...............................27

Precautions for Vehicle- to-Vehicle Distance Con-

trol Mode .............................................................. ....

27

Precautions for Conventional (Fixed Speed)

Cruise Control Mode ................................................

29

DIAGNOSIS SYSTEM (ADAS CONTROL

UNIT) .................................................................

30

On Board Diagnosis Function ..................................30

CONSULT-III Function (ICC/ADAS) ........................31

DIAGNOSIS SYSTEM (ICC SENSOR) .............41

CONSULT-III Function (LASER) .............................41

ECU DIAGNOSIS INFORMATION ..............43

ADAS CONTROL UNIT ....................................43

Reference Value .................................................. ....43

Fail-safe ...................................................................48

DTC Inspection Priority Chart ..................................49

DTC Index ...............................................................50

ICC SENSOR ....................................................54

Reference Value ......................................................54

Fail-safe ...................................................................55

DTC Inspection Priority Chart ..................................55

DTC Index ...............................................................55

Revision: 2010 May2011 QX56

Page 737 of 5598

CCS-2

WIRING DIAGRAM .....................................57

INTELLIGENT CRUISE CONTROL ............... ...57

Wiring Diagram .................................................... ...57

BASIC INSPECTION ...................................69

DIAGNOSIS AND REPAIR WORK FLOW ..... ...69

Work Flow ............................................................ ...69

ADDITIONAL SERVICE WHEN REPLACING

ICC SENSOR .....................................................

71

Description ........................................................... ...71

Work Procedure ......................................................71

LASER BEAM AIMING ADJUSTMENT ............72

Description ........................................................... ...72

Work Procedure (Preparation) ................................72

Work Procedure (Setting The ICC Target Board) ...72

Work Procedure (Laser Beam Aiming Adjustment)

...

75

ACTION TEST ...................................................77

Description ........................................................... ...77

Work Procedure (Vehicle-To-Vehicle Distance

Control Mode) .........................................................

77

Work Procedure [Conventional (Fixed Speed)

Cruise Control Mode] ..............................................

80

DTC/CIRCUIT DIAGNOSIS ...................... ...83

C1A00 CONTROL UNIT ................................. ...83

ADAS CONTROL UNIT ......................................... ...83

ADAS CONTROL UNIT : DTC Logic ......................83

ADAS CONTROL UNIT : Diagnosis Procedure ......83

ICC SENSOR ......................................................... ...83

ICC SENSOR : DTC Logic .....................................83

ICC SENSOR : Diagnosis Procedure .....................83

C1A01 POWER SUPPLY CIRCUIT 1, C1A02

POWER SUPPLY CIRCUIT 2 ............................

85

ADAS CONTROL UNIT ......................................... ...85

ADAS CONTROL UNIT : DTC Logic ......................85

ADAS CONTROL UNIT : Diagnosis Procedure ......85

ICC SENSOR ......................................................... ...85

ICC SENSOR : DTC Logic .....................................85

ICC SENSOR : Diagnosis Procedure .....................86

C1A03 VEHICLE SPEED SENSOR ..................87

DTC Logic ............................................................ ...87

Diagnosis Procedure ..............................................87

C1A04 ABS/TCS/VDC SYSTEM .......................89

DTC Logic ............................................................ ...89

Diagnosis Procedure ..............................................89

C1A05 BRAKE SW/STOP LAMP SW ...............90

DTC Logic ............................................................ ...90

Diagnosis Procedure ..............................................90

Component Inspection (ICC Brake Switch) ......... ...93

Component Inspection (Stop Lamp Switch) ............93

C1A06 OPERATION SW ...................................94

DTC Logic ............................................................ ...94

Diagnosis Procedure ...............................................94

Component Inspection ............................................95

C1A12 LASER BEAM OFF CENTER ...............96

ADAS CONTROL UNIT .......................................... ...96

ADAS CONTROL UNIT : DTC Logic ......................96

ADAS CONTROL UNIT : Diagnosis Procedure ......96

ICC SENSOR .......................................................... ...96

ICC SENSOR : DTC Logic ......................................96

ICC SENSOR : Diagnosis Procedure .....................96

C1A13 STOP LAMP RELAY .............................97

DTC Logic ............................................................ ...97

Diagnosis Procedure ...............................................97

Component Inspection ..........................................102

C1A14 ECM ......................................................103

DTC Logic ............................................................ .103

Diagnosis Procedure .............................................103

C1A15 GEAR POSITION .................................104

Description ........................................................... .104

DTC Logic .............................................................104

Diagnosis Procedure .............................................104

C1A16 RADAR STAIN ................................... ..106

ADAS CONTROL UNIT .......................................... .106

ADAS CONTROL UNIT : DTC Logic ....................106

ADAS CONTROL UNIT : Diagnosis Procedure ....106

ICC SENSOR .......................................................... .106

ICC SENSOR : DTC Logic ....................................106

ICC SENSOR : Diagnosis Procedure ...................107

C1A17 ICC SENSOR ........................................108

DTC Logic ............................................................ .108

Diagnosis Procedure .............................................108

C1A18 LASER AIMING INCMP .......................109

ADAS CONTROL UNIT .......................................... .109

ADAS CONTROL UNIT : DTC Logic ....................109

ADAS CONTROL UNIT : Diagnosis Procedure ....109

ICC SENSOR .......................................................... .109

ICC SENSOR : DTC Logic ....................................109

ICC SENSOR : Diagnosis Procedure ...................110

C1A21 UNIT HIGH TEMP .................................111

ADAS CONTROL UNIT .......................................... .111

ADAS CONTROL UNIT : DTC Logic ....................111

ADAS CONTROL UNIT : Diagnosis Procedure ....111

ICC SENSOR .......................................................... .111

ICC SENSOR : DTC Logic ....................................111

Revision: 2010 May2011 QX56

Page 741 of 5598

![INFINITI QX56 2011 Factory Repair Manual

CCS-6

< PRECAUTION >[ICC]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint S

ystem (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006224261

The Supplemental Rest INFINITI QX56 2011 Factory Repair Manual

CCS-6

< PRECAUTION >[ICC]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint S

ystem (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006224261

The Supplemental Rest](/img/42/57033/w960_57033-740.png)

CCS-6

< PRECAUTION >[ICC]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint S

ystem (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006224261

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision that would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precautions For Harness RepairINFOID:0000000006224262

ITS communication uses a twisted pair line. Be careful when repairing it.

Solder the repaired area and wrap tape around the soldered area.

NOTE:

A fray of twisted lines must be within 110 mm (4.33 in).

SKIB8766E

Revision: 2010 May2011 QX56

Page 742 of 5598

![INFINITI QX56 2011 Factory Repair Manual

CCS

PRECAUTIONSCCS-7

< PRECAUTION > [ICC]

C

D

E

F

G H

I

J

K L

M B

N P A

Bypass connection is never allowed at the repaired area. NOTE:

Bypass connection may cause ITS communication error. The

splic INFINITI QX56 2011 Factory Repair Manual

CCS

PRECAUTIONSCCS-7

< PRECAUTION > [ICC]

C

D

E

F

G H

I

J

K L

M B

N P A

Bypass connection is never allowed at the repaired area. NOTE:

Bypass connection may cause ITS communication error. The

splic](/img/42/57033/w960_57033-741.png)

CCS

PRECAUTIONSCCS-7

< PRECAUTION > [ICC]

C

D

E

F

G H

I

J

K L

M B

N P A

Bypass connection is never allowed at the repaired area. NOTE:

Bypass connection may cause ITS communication error. The

spliced wire becomes separated and t he characteristics of twisted

line are lost.

ICC System ServiceINFOID:0000000006224263

CAUTION:

Never look straight into th e laser beam discharger when adjusting laser beam aiming.

Turn the MAIN switch OFF in conditions similar to driving, such as free rollers or a chassis dyna-

mometer.

Never use the ICC sensor removed from vehicle. Never disassemble or remodel.

Erase DTC when replacing parts of ICC system, then check the operation of ICC system after adjust-

ing laser beam aiming if necessary.

SKIB8767E

Revision: 2010 May2011 QX56

Page 743 of 5598

![INFINITI QX56 2011 Factory Repair Manual

CCS-8

< PREPARATION >[ICC]

PREPARATION

PREPARATION

PREPARATION

Special Service ToolsINFOID:0000000006224264

The actual shapes of Kent-Moore tools may differ fr

om those of special service tools illus INFINITI QX56 2011 Factory Repair Manual

CCS-8

< PREPARATION >[ICC]

PREPARATION

PREPARATION

PREPARATION

Special Service ToolsINFOID:0000000006224264

The actual shapes of Kent-Moore tools may differ fr

om those of special service tools illus](/img/42/57033/w960_57033-742.png)

CCS-8

< PREPARATION >[ICC]

PREPARATION

PREPARATION

PREPARATION

Special Service ToolsINFOID:0000000006224264

The actual shapes of Kent-Moore tools may differ fr

om those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name Description

KV99110100

(J-45718)

ICC target board Uses for laser beam aiming adjustment

PKIA0358J

Revision: 2010 May2011 QX56

Page 806 of 5598

![INFINITI QX56 2011 Factory Repair Manual

CCS

ADDITIONAL SERVICE WHEN REPLACING ICC SENSOR

CCS-71

< BASIC INSPECTION > [ICC]

C

D

E

F

G H

I

J

K L

M B

N P A

ADDITIONAL SERVICE WHEN REPLACING ICC SENSOR

DescriptionINFOID:0000000006224291

Alw INFINITI QX56 2011 Factory Repair Manual

CCS

ADDITIONAL SERVICE WHEN REPLACING ICC SENSOR

CCS-71

< BASIC INSPECTION > [ICC]

C

D

E

F

G H

I

J

K L

M B

N P A

ADDITIONAL SERVICE WHEN REPLACING ICC SENSOR

DescriptionINFOID:0000000006224291

Alw](/img/42/57033/w960_57033-805.png)

CCS

ADDITIONAL SERVICE WHEN REPLACING ICC SENSOR

CCS-71

< BASIC INSPECTION > [ICC]

C

D

E

F

G H

I

J

K L

M B

N P A

ADDITIONAL SERVICE WHEN REPLACING ICC SENSOR

DescriptionINFOID:0000000006224291

Always perform the laser beam aiming adjustment after removing and installing or replacing the ICC sensor.

CAUTION:

The system does not operate normally unless the l aser beam aiming adjustment is performed.

Always perform it.

Perform the ICC system action test to c heck that the ICC system operates normally.

Work ProcedureINFOID:0000000006224292

1.LASER BEAM AIMING ADJUSTMENT

Adjust the laser beam aiming. Refer to CCS-72, "

Description".

>> GO TO 2.

2.ICC SYSTEM ACTION TEST

1. Perform the ICC system action test. Refer to CCS-77, "

Description".

2. Check that the ICC system operates normally.

>> INSPECTION END

Revision: 2010 May2011 QX56